Publisher’s version / Version de l'éditeur:

Proceedings of an International Joint Workshop on Recycling and Sustainable Development Montreal, Canada April 23-26, 2001, pp. 137-161, 2001-07-01

READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE. https://nrc-publications.canada.ca/eng/copyright

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

NRC Publications Archive

Archives des publications du CNRC

This publication could be one of several versions: author’s original, accepted manuscript or the publisher’s version. / La version de cette publication peut être l’une des suivantes : la version prépublication de l’auteur, la version acceptée du manuscrit ou la version de l’éditeur.

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at

Synergistic effects of chemical admixtures in concretes containing

supplementary cementing materials

Mailvaganam, N. P.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

NRC Publications Record / Notice d'Archives des publications de CNRC: https://nrc-publications.canada.ca/eng/view/object/?id=a19a44e2-e29c-40e0-a0bb-fd9325d6b9fe https://publications-cnrc.canada.ca/fra/voir/objet/?id=a19a44e2-e29c-40e0-a0bb-fd9325d6b9fe

ュHIセHjセ@

セ@

Z3-Z6, ZOO!

III

Europran CommissionDirecLOrale Ceneral XII

Science, Research and Del'eioprncnl

Canadian ,\ssocialion of Rcnding Induslrics

CANMET -CARl-EC INTERNATIONAL JOINT WORKSHOP 137

SYNERGISTIC EFFECTS OF CHEMICAL ADMIXTURES IN

CONCRETES CONTAINING SUPPLEMENTARY

CEMENTING MATERIALS

N.P. Mailvaganam

Institute for Research in Construction National Research Council of Canada

to

CANMET -CARI-EC INTERNATIONAL JOINT WORKSHOP l39

ABSTRACT

Concrete today is recycled, placed faster, transported to higher locations and used under cold and hot arid conditions because of the continued evolution of chemical admixtures. The new generation of admixtures affords designers and contractors more control over the properties they want in a concrete mix. Current concern over salt damage to concrete, the alkali-aggregate reaction, the need to produce more durable structures, make some admixtures more topical than others. For these reasons, chemical admixtures such as superplasticizers and supplementary cementing materials such as silica fume and fly ash is the subject of increased interest. The combined use of these materials produces synergistic effects, which result in a range of modifications enabling highly durable concretes to be placed under a variety of conditions.

1. INTRODUCTION

Pozzolanic and other hydraulic cementitious materials are added as partial replacement of cement not only to achieve economy but also to obtain specific engineering properties in the finished product. A well-proportioned mixture generally shows improved mobility, cohesiveness, ultimate strength and durability (1-6).

It is possible to achieve the required workability without strength reduction at early ages with replacement levels of 15-20% or 6-8% by weight fly ash or silica fume, respectively (7). Higher substitutions lead to pronounced thixotropic effects, lower strengths and higher drying shrinkage. The use of increased levels of fly ash therefore, will require some method of offsetting such constraints. Previous work (8-11) shows that the use of admixtures in mixes containing fly ash and silica fume affords a method of overcoming the slow rate of strength gain at early ages, improving rheology and durability. It is now possible to produce high strength concrete at early ages using large percentages of fly ash and superplasticizers (12). Ultra high strength concretes with strengths in excess of 100 MPa at 28 days (12) have been developed using silica fume and superplasticizers. (Fig.!)

·

,140 RECYCLING AND SUSTAINABLE DEVELOPMENT

16000 14000 705 Ib cemenUyd3 102 Ib silica fume/yd3 12000

-N C <;::: 10000 .0 ::::::-.c ... C> C Q) セ@ 8000 ... (/) Q) > Reference: 705 Ib'w

(/) CemenUyd2 Q) セ@ a. 6000E

0 0 4000 2000o

20Age (Days)'

Fig I, High-strength concrete through the use of silica fume and a high range water reducing admixture (Dobson [15])

CANMET-CARI-EC INTERNATIONAL JOINT WORKSHOP 141

The role that admixtures play in augmenting the desired features in fly ash or silica fume / portland cement mixes is described; specific applications are cited to illustrate the manner in which admixtures offset limitations and increase the effectiveness of the two supplementary cementing materials.

2. Role of Admixtures

2.1 Rheological Properties:

Admixtures modify rheological behavior and improve the quality of plastic concrete. e.g. increased workability, or water reduction at given consistencies, improved finishing qualities, controlled bleeding and segregation

(aJ Effects on Plastic Properties:

Replacement of small amounts of cement by fly ash generally improves the workability of concrete and reduces water demand. The improvement is postulated to result from better packing and the "ball bearing" effect produced by the spherical fly ash particles. Addition of these materials to the mix reportedly reduces the mean free space for water by increasing the total surface area and reducing sedimentation (10). Consequently, internal friction due to particle-particle contact in the aggregate is decreased without increasing viscosity. High carbon fly ashes and some Type C fly ashes however, may cause workability problems even at low (5-10%) replacement levels (14). A higher water demand than that required by a 100% Type 1 cement mix may be observed at a given slump value (Fig. 2). This has been attributed to the increased levels of ettringite fonned in Fly Ash / Portland cement mixes. Ettringite crystals have a higher affinity for water and, therefore, increase the water demand (16). At higher cement replacement levels, however, the effect is generally masked by the lubricating effect produced by the increased number of spherical particles. Much improved water reduction and workability in blended mixes can be provided through the use of a superplasticizer. The admixture reduces the rate of fonnation of ettringite (16) and the inherent high cohesion by greater dispersion of the fine particles.

-

..

142

75

I

50

RECYCLING AND SUSTAINABLE DEVELOPMENT

350 KG

CEMENT CONTENT M 14

-x-x-

100% OPC• • 5% FLY ASH/ 95% OPC

... ---0IIII- 20% CEMENT REPLACEMENT

WATER CONTENT (Kg)

Figure 2. Effect of cement replacement levels on the water demand and slump of fly ash Portland cement concrete

CANMET -CARl-EC INTERNATIONAL JOINT WORKSHOP 143

Medium cement content mixes produce highly cohesive concrete at cement replacement levels exceeding 10% fly ash and 4% silica fume, by weight of cement. As a result, the incidence of "bug hole" formation in precast products, and finishing problems such as "stickiness" due to frictional drag on finishing tools is increased. Admixtures can alleviate such problems by increasing the dispersion of the particles. The effect of the dispersing action is seen in the change in viscosity observed in cement / fly ash and cement / silica fume paste (Figs. 3 and 4). The reduction in yield value and plastic viscosity makes the mix more responsive to vibratory compaction causing entrapped water to be driven to the surface or the periphery of the concrete effectively reducing "bug holing". Frictional drag on the finishing tools is reduced due to the presence of some free water in the mix providing a "slickness" on the trowel. Superplasticized flowing concrete are often prone to segregation. The use of silica fume in such mixes however, enables the production of cohesive. concretes of very high mobility. Thus, the synergistic effects produced by the interaction of silica fume with the superplasticizer afford flowing mixes, which remain cohesive without segregation. This is rarely possible when the materials are used individually.

(b) Pumping of Fly Ash or Silica Fume / Portland Cement Mixes

Successful pumping of concrete requires two basic mix properties: (a) sufficient paste content to form an annular grout fihn against the pipe wall to act as a slip surface (b) suitable grout consistency and interstitial void structure to offer good resistance to the forced bleeding of water from the cement paste and prevention of dewatering under pressure. Silica fume increases the viscosity of the cement paste and also influences the void structure by acting as pore filler. Conventional water reducing admixtures or superplasticizers augment the "pumping aid" action of silica fume by increasing thixotropy but allowing ready mobility due to shear thinning effects. Such benefit is best realized in lean or harsh mixes where low paste content or poor shape, texture and gradation of the available aggregate makes it difficult to pump concrete.

2.2 Improvements to the Quality of Hardened Concrete:

Improvements to the quality of hardened fly ash and silica fume concrete such as increased long-term strength, uniformity, decreased permeability and absorption, and increased abrasion resistance is realized when admixtures are used.

50r

セ@

4°1

-

w

30--セ@

I

0:: 0::20

«

w

I CJ) 10--YIELD VALUEI

t

I

T

セ@ -)(-X-- 100% OPCtl

MMM・セM 20% FLY ASH - NO ADMIXTURE--001IIII---'- 20% FLY ASH + SUPERPLASTICIZER

,

W/C

=

0.4600

900

1200

Figure 3. Shear stress/shear rate relationship for cement/fly ash paste with and without admixtures

...

t

セ@

() ><: () t'"""Z

o

セ@

tilc:::

til セ@セ@

セ@

o

tI1セ@

t'"""o

'"d セ@セ@

. Iセ@ :;; E セ@ w

セ@

0::i1i

J: CI)50

40

30

20

10

YIELD VALUE)( )( 100

%OPC

- e - e -

80/0 SILICA FUME - NO ADMIXTURE

セセM

8% SILICA FUME

+

SUPERPLASTICIZER

WIC = 0.4

600

900

1200

Figure 4. Shear stress/shear rate relationship for cement/silica fume paste with and without admixtures

セ@

tTl....,

In

セ@

tTln

セ@

セ@

-セ@

t"'" ...o

2

....,

セ@セ@

::r:

o

'"d...

.f::>. VI..

146 RECYCLING AND SUSTAINABLE DEVELOPMENT

(a) Maintenance o/Uniformity in Fly Ash/Portland Cement Mixtures:

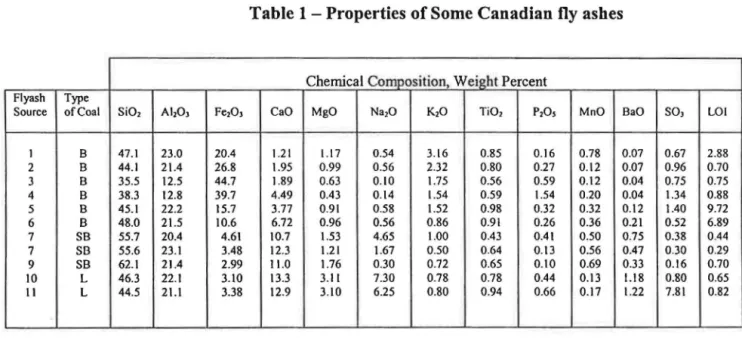

The variability of fly ashes (both types C and F) is well-documented (14). There is often a wide range in chemical composition between fly ashes from different sources (Tab. 1 ). The range of chemical composition within a given fly ash source although fairly small, may still cause variations in performance. Admixtures play a significant role in maintaining the consistency of the specified concrete mix properties by ensuring a reduced standard deviation in compressive strength values through the reduction of water content at the desired slump. (Fig. 5).

(b) Durability: One of the most dramatic improvements that result from the use of silica fume and fly ash is the durability of the hardened concrete. When used in conjunction with admixtures, both silica fume and fly ash significantly improve properties such as permeability, abrasion, sulfate resistance, freeze thaw resistance and reduced alkali / aggregate reaction.

A number of workers (18-22) have shown that the pore size range of hardened silica fume or fly ash concrete is significantly shifted to the smaller sizes. Permeability is further reduced when these materials are used with superplasticizers (22) and dense concrete bodies are produced. Consequently, permeability to water and injurious chemicals is drastically reduced and its susceptibility to freeze / thaw damage and scaling diminished (Fig.6). Advantages obtained from the increased density are reflected in improved resistance to abrasion and shock impact stresses in warehouse floors and roll-on and roll-off docks, respectively.

Dense superplasticized fly-ash or silica fume concrete is well suited for use in structures such as water retaining towers and in breakwater applications where both sulfate attack and abrasion and erosion is experienced at the tidal zones. Sulfate resisting cement is typically used in marine environments where the concrete is required to withstand sulfate and chloride attack. However, it is possible to obtain sulfate resisting properties with fly ash / Portland cement mixes when a 30% cement replacement is used in conjunction with a superplasticizer (22).

Flyash Type

Source orCoal Si02 AhO) Fe2O)

1 B 47.1 23.0 20.4 2 B 44.1 21.4 26.8 3 B 35.5 12.5 44.7 4 B 38.3 12.8 39.7 5 B 45.1 22 .2 15.7 6 B 48.0 21.5 10.6 7 SB 55.7 20.4 4.61 7 SB 55.6 23.1 3.48 9 SB 62.1 21.4 2.99 10 L 46.3 22 .1 3.\0 11 L 44.5 21.\ 3.38

'----Table 1 - Properties of Some Canadian fly ashes

Chemical Composition, Weight Percent

CaO MgO Na20 K20 Ti02 P20S MnO BaO

1.21 1.17 0.54 3.16 0.85 0.16 0.78 0.07 1.95 0.99 0.56 2.32 0.80 0.27 0.12 0.07 1.89 0.63 0.10 1.75 0.56 0.59 0 .12 0.04 4.49 0.43 0.14 1.54 0.59 1.54 0.20 0.Q4 3.77 0.91 0.58 1.52 0.98 0.32 0.32 0.12 6.72 0.96 0.56 0.86 0.91 0.26 0.36 0.21 10.7 \.53 4.65 \.00 0.43 0.41 0.50 0.75 12.3 1.21 \.67 0.50 0.64 0.\3 0.56 0.47 11.0 1.76 0.30 0.72 0.65 0.10 0.69 0.33 13.3 3.11 7.30 0.78 0.78 0.44 0.\3 1.\8 12.9 3.10 6.25 0 .80 0.94 0.66 0.17 1.22 I I SO) LOI 0.67 2.88 0.96 0.70 0.75 0.75 1.34 0.88 1.40 9 .72 0.52 6.89 0.38 0.44 0.30 0.29 0.16 0.70 0.80 0.65 7.81 0.82

i

tI1 セ@In

セ@

I tI1n

セ@

tI1セ@

-セ@

>

l ''-o

セ@

セ@セ@

:r::

セ@

-

セ@ -...J..

14835

--

co

a.

セ@28

--..c

...

0> C <D セ@21

...

en

>-co

"0 Ico

14

N200

--

E 150

E

a.

E

::J100

en

50

Water contentWIC

ratioRECYCLING AND SUSTAINABLE DEVELOPMENT

154

0.54

166

0.58

178

0.62

Cement E, Type 1286.7 kg

m·3o

-With water-reducing admixture • -Without admixture190

0.66

202

0.70

214

Kg0.75

Figure 5. Influence of water-reducing admixture on water content, slump and water-cement ratio (Howard et al. [14])

50

160

140

-

ro a. セ@ -en セ@40

120

E -..c セ@ セ@....

0> I C100

セ@

(]) セ@ セ@....

en (]) :0 >30

80

ro·w

(]) en E (]) ' -' - (]) a. a.E

60

0+-0 0 u....

>- c (])co

20

40

·0 "C1E

<X) C\I (]) 020

010

0

0.40

0.50

0.60

0.70

Water-cement ratio

Figure 6. Impact of water-cement ratio on both compressive strength and permeability based on data from ACt 211.1 (Acl 221, 1991, and Powers et aI., 1954b)

()

セ@

tI1 セ@I ()セ@

I tI1 ()Z

セ@ tI1セ@

セ@...

セ@

セ@ セ@ 0Z

....:j セ@ 0セ@

U)::r:

0 '"0 ... セ@ \0I

• I

150 RECYCLING AND SUSTAINABLE DEVELOPMENT

The effect of fly ash and silica fume on the alkali-aggregate reaction has been well reported (1,21,23). Greater stability of the concrete can be ensured by the use ofa water-reducing admixture, that affords the benefits of the use of silica fume - but at much reduced water contents than concretes that contain no admixtures. The greater water demand of silica fume is therefore offset allowing for reduced moisture levels in the hardened concrete.

2.3. Special Concretes

Various classes of admixtures facilitate design and construction techniques not readily practicable without such materials. The following examples illustrate the important function admixtures play in modifying fly ash and silica fume concrete to meet the specific requirements of special applications.

(a) Shotcrete:

Shotcrete is a process by which concrete is sprayed on to a surface under pressure. The sprayed material is expected to stay in place on vertical and overhead surfaces, and this is usually effected by acceleration of the set-time to within 5 to 10 minutes. This results in a 20-30% strength loss. Admixtures used in Shotcrete usually fall into four categories: (a) air entraining agents; (b) accelerators; (c) retarders; and (d) finely divided inert or hydraulic reactive solids. Silica fume which falls under category (d), has afforded this application, a method of providing the required mix characteristics (of high cohesion and rapid setting to prevent sloughing off from vertical surfaces) without the attendant 20-30% strength loss that occurs with traditional accelerators (24). It is now possible to use additions of silica fume in conjunction with superplasticizers in shotcrete mixes that give reduced rebound levels, good dense layers with only a marginal strength reduction in comparison with nonnal concrete mlxes.

(b) Mass Concrete:

Perhaps the most widely known application of fly ash has been in mass concrete - where it is used to reduce the heat evolved in huge placements. Even with replacements in the range of 50%, damaging peak temperatures often result. One method of reducing the heat evolved is by the use of admixtures. Although water-reducing retarders do not reduce the total amount of heat evolved, they delay and spread the heat generated over an extended period (6). They also facilitate higher cement replacement levels (60-75%) by ensuring that

CANMET -CARI-EC INTERNATIONAL JOINT WORKSHOP 151

specified strengths are achieved (1,12). Thus, further reduction in the total amount of heat generated can be achieved.

(c) Underwater Concrete:

Fly ash has been used in undeIWater concrete to increase the cohesiveness of the mix and prevent cement "wash-out". More recently, the "structured" consistency afforded by silica fume incorporation has given mixes that are quite suited for tremie concrete (6,25). When used in conjunction with superplasticizers and antiwashout admixtures, the "gel like" consistency of the mix shows little tendency for cement "wash out" and spreads in a wider circumference than that given by fly ash / cement mixes when it drops from the pipe. Consequently, tremie pipe spacing and pour time is reduced.

(d) High Strength Concrete:

Aggregate-cement bond and matrix strength plays a significant role in determining the strength of high strength concrete. The high cement contents that are generally required for such mixes are often counter-productive since the resultant high shrinkage stresses cause loss of aggregate-cement bond or cracking of the cement paste. Matrix strength is primarily dependent on matrix porosity, which is governed by the w / c ratio and efficacy of packing. Admixtures can be used to effect cement and water content reductions (without decreasing strength) and improve packing (Table.2). The importance of compaction produced with the help of admixtures, fly ash and silica fume is well documented (12, 23, 26). The work of Birchall and MukheIjee et al (26 and 12) showed that remarkably high flexural strengths can be obtained by the blending of cementitious materials and control of rheological properties of pastes with low w / c ratios. Very high strengths have also been reported when silica fume is blended with cement in the presence of a superplasticizer (13).

2.4. Economic Considerations:

The chief use of admixtures in most ready-mix and precast operations is to reduce the cost of concreting operations by effecting a reduction of the overall cost of concrete ingredients, permitting rapid mould tum over and ease of placing and finishing. The following applications show how they function in fly ash or silica fume concrete to obtain these objectives.

152 RECYCLING AND SUSTAINABLE DEVELOPMENT

Table 2. Cement reduction and change to type I with superplasticizers

Cement Water! Admixture Compressive strength (Mpa) Remarks cement 18 hour 28 day

ratio

Type Content Type Dosage Slump Vefle 21°C 60°C 21°C

(kgrn·3) (mm) (s) cure cure cure

III 415 0.37 Zeecon 228ml 57 38 24.24 40.34 7550 Control

III 386 0.36 Mighty 1.2% 51 3.8 29.23 44.75 77 16 150 II 386 0.33 Sikament 2.5 38 5.8 29.10 49.71 8246 I 386 0.34 Mighty 1.2% 57 3.8 17.72 39.65 72 33 150 I 386 0.31 Sikament 2.5% 114 2.1 22.62 22.62 8102

Zeecon in milliliters per 50 kg cement

Superplasticizers in percent of liquid by weight of cement

(aJ Improved Early Strength Development:

The strength development of concrete containing fly ash depends on the mix proportioning and on the type of ash used in the mix. When it is used in concrete in the classical manner, i.e. as direct replacement for cement, the strength gain at early ages is slower than that for control concretes. This retarding effect is accentuated at lower temperatures. However, fly ash concrete whose strength at early ages is comparable with that of control concrete (100% Portland) can be made using admixtures (Fig. 7 and Table 3).

5

4.5

4

3.5

-

...

.s::::3

-

tn:::::

セ@2.5

-

-

co

Q)::r:

1.5

1

0.5

0

0

10

20

30

Time (hour)

セopc@ 070/30 .70/30 + FAA40

50

60Figure 7. Conduction calorimetry curve showing accelaration of hydration in the presence of an accelerating admixture (FAA)

i

tTl セ@ I (Jセ@

I tTl (Jセ@

tTlセ@

:jセ@

t""' '-4o

セ@

セ@セ@

Vl::c

セ@

...

VI VJTable 3

MORTAR 1-day Compressive Strength

Mix OPC lold"FA Point Tupper Sand Acc(no SF) Acc(SF} Water

FA 1 350 150 0 1375 0 2 350 0 150 1375 0 3 350 150 0 1375 16 4 350 0 150 1375 16 5 350 150 0 1375 0 6 350 0 150 1375 0 -Note: Water/Cementitious

=

0.45 Sand/Cementitious=

2.75Mix 3 and 4 contained accelerator without silica fume Mix 5 and 6 contained accelerator with silica fume All units are in gram unless specified

0 225 0 225 0 213.19 0 213.19 16 213.99 16 213.99

Load(lb) Strength(MPa)

I

Avg strength(MPa) 6340 11.167 6100 10.744 10.8 6030 10.621 5130 9.036 5530 9.740 9.5 5440 9.582 7930 13.968 7550 13.298 13.6 7600 13.386 6990 12.312 7390 13.017 12.6 7030 12.382 7950 14.003 8120 14.302 14.1 7960 14.020 6940 12.224 7910 13.932 12.8 6870 12.101

...

VI .j::o.セ@

(J >-<: (J r-<*

セ@

C/)c:::

C/)セ@

to&;

o

セ@

tTl r-<o

"'tj セ@セ@

CANMET-CARJ-EC INTERNATIONAL JOINT WORKSHOP 155

The reduced rate of hydration of Portland cement / fly ash mixes has been attributed to the retarding effect of fly ash on the hydration of C3S (15), C3A and C4AF phases of Portland cement (27 and 28). Other work (29) has shown that the retardation may also be related to the condition of the fly ash surfaces. This is demonstrated in the heat evolution curves obtained by the investigators for samples of fly ash as received and on materials previously leached prior to blending with cement (Figs. 8 and 9). The rate of heat evolution of pure cement and and fly ash mixtures hydrated in de-ionized water at 38°C is shown in Fig.8 The data shows that both Class C and class F fly ash retard cement hydration. The major peak is delayed and the amount of heat evolved (peak size) in the fly ash containing mixtures is diminished relative to that of the pure cement paste. In Fig 9 the rates of heat evolution of mixtures of leached fly ashes under the same conditions as above is compared. The data indicate that the class C and class F leachates still retard hydration of cement but that leaching has influenced the rate of the reaction of the fly ashes (29).

The role of an admixture in improving rate of strength gain of fly ash/cement concretes at very early ages may also be that of improving the surface condition of the fly ash particle enhancing its ability to react with the surrounding liquor. Other strength accelerating effects produced by admixtures include the following:

(i) An increased rate of hydration due to the high degree of defloculation of the cementing particles, resulting in more rapid Ca (OH)2 production and promotion of the pozzolanic reaction.

(ii) An autocatalytic effect due to higher peak temperatures generated during hydration at low w / c ratios. The low w / c ratio influences the hydration kinetics by causing a greater adsorption of the admixture by the cement grains.

(iii) A reduction in the amount of freezable water during hydration at lower temperatures. (iv) Improved compaction due to the improved particle packing.

-VI

8 0\

...-..c. I TYPE 1 CEMENT + 01 WATER

C)

:::::= 0% FLY ASH

CO

(J

- - - -

40 % CLASS C FLY ASHセ@

---Z

6_.

_.-

40 % CLASS F FLY ASH (")0

セ@(")J-

t"""4:::>

Z

-.J C')0

;l>>

4セ@

W CIlセ@

/...

.

C CIl...,

W.

'"

;l>I

I

"'

.

...-

...

Z

LLI

/"".

"

,

セ@

.\

0

2 / セ@...

セ@

WI

/,

...

0セ@

/"

...

.

tI1<:

I

/-...

-

-.

-.

tl'10::

/...

-

-

.::::-..:..,--.

t"""4-

0"

セ@ セ@o

I

セN@I

I

I tTlZ

0 8 16 24...,

TIME (h)

CANMET-CARJ-EC INTERNATIONAL JOINT WORKSHOP 157

- - - Type 1 Cement

- - - Leached C Fly Ash/Cement Blend (40% FA)

8 Leached Fly Ash/Cement Blend (40% FA)

6 4 2

o

o

8 1624

lime (hrs)

Figure 9. Rate of heat evolution of 100% cement and previously leached fly ash/cement blends (Ref 30)

158 RECYCLING AND SUSTAINABLE DEVELOPMENT

(b) Increased Use of Type F Fly Ashes:

Due to the higher carbon content and lower pozzolanic activity of type F fly ashes, their use in normal concrete is more limited than the higher CaO containing type C fly ashes. Often the percentage replacement is kept to levels below 10% due to the slow strength development and higher water demand. The use of a superplasticizer will significantly reduce the water demand and promote early strength gain. The improved defloculation of cement agglomerates produces an increased rate of Ca (OH)2 generation, which stimulates pozzolanic activity in the fly ash. The superplasticizer, therefore facilitates a greater use of Type F particularly in areas where bituminous coal is used.

Concluding Remarks

The above examples clearly demonstrate that modifications to the interparticle forces in the cementitious paste by admixtures influences both the hydration and packing efficiency in fly ash or silica fume· concrete. This produces significant improvements in rheological, structural and durability characteristics of the concrete, which are not readily realized when the materials are used individually. They enable concrete containing fly ash or silica fume to be transported farther, placed faster and increase its ability to remain functional in the intended service environment.

REFERENCES

1. Berry, E.E. and Malhotra, V.M., "Fly Ash for Use in Concrete Part II - A Critical review of the Effects of Fly Ash on the Properties of Concrete". Report 78-16 CANMET. Energy, Mines and Resources Canada. p 43, 1978,

2. Kalousek, G.L., Porter, L.C., Benton, E.J., "Concrete for Long Time Service in Sulfate Environment:", C & C.R., Vol. 2, pp.78-89.1972,

3. Pepper, L. and Mather, B., "Effectiveness of Mineral Admixtures in Preventing Excessive Expansion of Concrete Due to Alkali Aggregate Reaction", Proceeding. ASTM, 1178-1202, 1959.

CANMET-CARJ-EC INTERNATIONAL JOINT WORKSHOP 159

4. Phileo, RE., "Fly Ash in Mass Concrete", Proceeding, First Symposium of Fly Ash Utilization, Pittsburgh,. U.S. Bureau of Mines: Information Circular I.C. 8348, pp. 69-79. March 1967

5. Traetteberg, A., "Frost Action in Mortar of Blended Cement with Silica Dust", ASTM STP-691, pp 536-548,1980.

6. Rixom, M. R and Mailvaganam, N. P. Chemical Admixtures for Concrete 2nd ed.,

E, & P.N. Spon London 1986.

7. Bhardewat, M.C., Batra, V.S. and Sastry, V.V., "Effects of Admixtures on Pozzolanic Concrete", Indian Concrete Journal (Bombay) V-54, NO.5, pp. 134-138. May 1980,

8. Lovewell, C.E. and Hyland, E.J., "Effects of Combination of Two or More Admixtures in Concrete", Highway res. Record No. 370, pp. 90-98. 1971,

9. Yamamoto, Y., Kobyashi, A., "Use of Mineral Fines in High Strength Concrete -Water Requirement and Strength Gain", Concrete International, Vol. 4, No.7, pp. 33-40. July 1982,

9. Diamond, Sidney, "Effects of Fly Ash in Cement and Concrete", Proceedings, M.RS., Symposium, Boston, No. 16-18, p. 331 (1981).

11 . Ola-Hogstand, "Experiences from Ready Mixed Production of Silica Concrete: BML Report 82610, Division of building Materials, The Norwegian Institute of Technology, University of Trondheim, Norway, pp. 287-293 (1982).

12. Mukherjee, P.K., Loughborough, M.T. and Malhotra, V.M., "Development of High Strength Concrete Incorporating a Large Percentage of Fly Ash and Superplasticizers", Division Report MRPIMSL 81-124 (OP&J). Mineral Science Laboratories CANMET, Ottawa. 1979.

160 . - RECYCLING AND SUSTAINABLE DEVELOPMENT

14. Malhotra, V.M., "The Use of Fly Ash, Silica Fume and Slag and Other Mineral By-Products in Concrete", International Jou for Development Technology, VoL 1, 307-315 (1983).

15. McKesall, W.C. and Ledbetter, W.C., "Variability and Control of Class C Fly Ash", Cement Concrete and Aggregates CCAGDP, Vol. 4, No.2, pp.87-93.

16. Howard, E.L., Griffiths, K.K. and Moulton, W.E. Journal of Materials 14, pp. 220-230, 1959.Winter 1982,

17. Uckikawa, H., Ogawa, K. and Uchida, S., "Influence of Organic Additives on the Rheological Properties of Fly Ash Cement Paste", Concrete Rheology. Proc. M.R.S. Meeting, Boston, MA, pp. 192-202. Aug 1986.

18. Jawed, I. and Skalny, J., Proceedings, M.R.S. Meeting; Boston, M.A. p.60 (1981).

19. Metha, P.K, "Durability of Concrete in Marine Environment - A Review", ACI Publication SP-65, pp. 1-20. Aug 1980.

20. Haynes, H.H., "Penneability of Concrete in Sea Water", ACI Publication SP-65, pp. 21-38. Aug 1980.

21. Malhotra, V.M., Carette, G.G., Bremner, "Durability of Concrete in Marine Environment Containing Granulated Slag, Fly Ash, or both", ACI Publication SP-65, pp. 157-168. Aug, 1980.

22. Bache, H.H., Second International Conference on Superplasticizers in Concrete, Ottawa, Jun 1981.

23. Mailvaganam, N.P., Bhagrath, R.S. and Shaw, K.L., "Sulfate Resistance of Mortars Containing Superplasticizers with Fly Ash or Blast Furnace Slag", ACI Publication SP-68-30, pp. 535-555. 1981.

24. Malhotra, V.M. and Carette, G.G., "Silica Fume Concrete Properties Applications and Limitations", 10th, Annual Meeting of the Institute of Concrete Technology, Fulmer Grange Slough, England, June 1982.

CANMET-CARJ-EC INTERNATIONAL JOINT WORKSHOP 161

25. Morgan, D.R., McAskill, N., Richardson, B.W., and Zellers, R.C. " A Comparative Evaluation of Plain, Polypropylene Fibre and Wire Mesh Reinforced Shotcrete". T.R.B., Annual Meeting Washington, D.C. Jan 1989.

26. Mailvaganam, N.P., ed, Repair and Protection of Concrete Structures., C.R.C., Press, Boca Raton, U.S.A., Jan.,1992. p 470

27. Birchall, J., Howard, A.J. and Kendall, K., "Nature", 289, 388 (1981).

28. Cabrera, J.G. and Plowman,

c.,

Proceedings, 7th Int. Cong.on Cement Chemistry 3, N -85, Paris (1980).29. Plowman, C. and Cabrera, J.G., Cement and Conc. Res - 14,238 (1984).

30. Fajuin, W., Grutzek, M., Roy, M.D., "The Retarding Effects of Fly Ash Upon the Hydration of Cement Pastes: The First 24 Hours", Cement and Concrete Res, Vol. 15,pp. 174-184. 1983.