Publisher’s version / Version de l'éditeur:

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site

7th International Conference on Short and Medium Span Bridges [Proceedings],

pp. 1-10, 2006-08-23

READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE.

https://nrc-publications.canada.ca/eng/copyright

NRC Publications Archive Record / Notice des Archives des publications du CNRC :

https://nrc-publications.canada.ca/eng/view/object/?id=aaf1bcff-3fd0-4e2c-9682-1f8d632d4e03 https://publications-cnrc.canada.ca/fra/voir/objet/?id=aaf1bcff-3fd0-4e2c-9682-1f8d632d4e03

NRC Publications Archive

Archives des publications du CNRC

This publication could be one of several versions: author’s original, accepted manuscript or the publisher’s version. / La version de cette publication peut être l’une des suivantes : la version prépublication de l’auteur, la version acceptée du manuscrit ou la version de l’éditeur.

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at

Field performance of prestressed concrete bridge girders protected by

cathodic protection and concrete surface treatment

http://irc.nrc-cnrc.gc.ca

F i e l d p e r f o r m a n c e o f p r e s t r e s s e d c o n c r e t e

b r i d g e g i r d e r s p r o t e c t e d b y c a t h o d i c

p r o t e c t i o n a n d c o n c r e t e s u r f a c e t r e a t m e n t

N R C C - 4 8 6 1 8

C h a g n o n , N .

A version of this document is published in / Une version de ce document se trouve dans: 7th International Conference on Short and Medium Span Bridges, Montreal, August 23-25, 2006, pp. 1-10

FIELD PERFORMANCE OF PRESTRESSED CONCRETE

BRIDGE GIRDERS PROTECTED BY CATHODIC

PROTECTION AND CONCRETE SURFACE TREATMENT

Nathalie Chagnon and Zoubir LounisNational Research Council Canada, Canada

Abstract

This paper presents the results of a five years study on the field performance of prestressed concrete girders of two highway bridges in Québec, which were protected by two different techniques namely a galvanic cathodic protection (GCP) system and a concrete surface treatment. The anode materials of the GCP systems consisted of zinc (Zn), zinc-magnesium (Zn-Mg) and aluminum-zinc-indium (Al-Zn-In) and the concrete surface treatment was a combination of silane primer and acrylic top coating. The five years monitoring of the protected girders showed that the three anodes and the concrete surface treatment were effective in reducing the rate of delamination of concrete cover. A comparison of the three anodes used in GCP systems indicated that the Al-Zn-In anode was more effective than the Zn and Zn-Mg anodes in reducing the corrosion rate of reinforcing steel, especially during summer months. On the concrete surface treatment section, the positive shift observed in the half-cell potential data indicated a significant decrease in the risk of corrosion of the reinforcing steel, following the application of the products.

1. Introduction

Prestressed concrete (PC) bridges are the most widely used type of bridges in North America, primarily for reasons of reduced construction time, savings in life-cycle cost

and excellent performance1. The failures of prestressing concrete structures reported to

date are rather few and have been attributed to poor design, bad workmanship or faulty

prestressing steel, and not to deterioration of well designed concrete structures2.

However, given the aging of these bridge superstructures and their exposure to chlorides from deicing salts, corrosion of prestressing steel and deterioration of concrete have increased over the last two decades. Because prestressed concrete elements are under significant mechanical stress, the consequences of corrosion can be quite serious in

terms of reduced safety and serviceability, as well as increased maintenance and users costs. A relatively small reduction in the cross-sectional area of the prestressing steel, due to general or pitting corrosion, can lead to a significant increase of the net stress in the prestressing, possibly leading to premature yielding and ultimately result in a brittle fracture. Therefore, to extend the service life of PC bridge girders, corrosion problems need to be identified and protection measures applied on existing structures. However, limited research has been conducted to evaluate the long-term performance of protection techniques in reducing or delaying the corrosion of prestressing steel.

This paper presents the results of a five years study on the field performance of PC girders of a highway bridge in Québec, which were protected by two different techniques namely: (i) a galvanic cathodic protection system; and (ii) a concrete surface treatment. The main objectives of this investigation were: (i) to evaluate the in-service performance of protected PC girders subjected to the simultaneous effects of de-icing salt contamination, freeze-thaw cycles and wet-dry cycles; and (ii) to understand the factors governing the performance of galvanic cathodic protection systems and concrete surface treatment in the field.

2. Protection techniques for PC structures

Protection techniques that can be applied to corrosion-damaged PC structures can be classified as mechanical or electrochemical. Mechanical techniques are physical barriers that prevent or delay the ingress of chlorides, oxygen, and moisture in the concrete cover to the reinforcing steel. They include concrete surface treatment such as admixtures, sealers, membranes and surface coating. Electrochemical techniques involve controlling the electron flow within the reinforced concrete environment to halt metal loss. Cathodic protection (CP) either by impressed-current (ICP) or galvanic mode (GCP), function by this second approach. Although ICP and GCP can be used to protect reinforced concrete structures, the galvanic system is usually selected for prestressed concrete structures. The preference of using GCP system for PC structure stems from the fact that this system is considered intrinsically safe for prestresssing steel due to the low driving voltage provided by the sacrificial anodes instead of power supply.

2.1 Performance of concrete surface treatments

Concrete surface sealers and coatings have been used for several years to provide protection and extend the service life of concrete structures exposed to aggressive environments. However, while most studies on concrete surface treatments have focused on their ability to control chloride and water penetration in concrete, a relatively limited research work has been carried out to evaluate the effectiveness of surface treatments in controlling on-going corrosion of reinforced concrete structures.

A wide variety of products is available to bridge owners for concrete surface treatments. However, depending on their chemical compositions, their field performance and

Amongst the more promising treatments, materials with silane and acrylic have

demonstrated better performances 4,5.

2.2 Performance of galvanic cathodic protection system

The concept behind galvanic cathodic protection (GCP) is to control corrosion by making the embedded reinforcing steel cathodic, as opposed to anodic where corrosion occurs. This process is made by electrically connecting the reinforcing steel to a more electrically active metal, which serves as the anode. Thus, the reinforcing steel potential moved towards an artificially cathodic condition and the corrosion rate of the reinforcing steel is reduced.

Cathodic protection has been recognized for more than 20 years as a technology that is both sufficiently mature and proven in practice for reducing or stopping ongoing

corrosion of embedded steel in concrete6. However, because high strength steel is

susceptible to hydrogen embrittlement, practice of using cathodic protection to mitigate corrosion in prestressed concrete bridge components has often raised concern. It is only recently that cathodic protection has been recognized as a technique that can be used safely and reliably to protect PC structures by limiting the polarization potential of

non-microalloyed prestressing tendon to a value of –974 mV vs. Cu/CuSO47, 8.

One of the most important parameters to consider when installing a GCP system is the anode selection. In the last decade, the most widely used anode has been zinc (Zn). Since the first trial of sprayed zinc anode in 1991 in Florida, many research projects have

contributed to improve its application procedure and performance9,10,11. However, due to

a decrease in current delivery of the Zn anode in the absence of direct wetting, a limited success has often been reported with this anode.

To increase the application of GCP, a new galvanic anode composed of aluminum-zinc-indium (Al-Zn-In) was developed as part of a research and development program funded

by the Federal Highway Administration12. Short term testing indicated that compared to

Zn anode, Al-Zn-In anode is capable of providing a better degree of cathodic protection

to the embedded steel13. However, long-term evaluations are necessary to assess the

performance of that anode and identify its ability to reduce the corrosion of embedded steel in concrete.

3. Experimental investigation of protected PC bridge girders

3.1 Test structures

Two bridges located North of Montreal have been selected for this study (Figure 1). These highway bridges built in the early 1970’s were identified as good candidates for both GCP system and surface coating application, based on a preliminary evaluation of their conditions. Indeed, during an evaluation performed in 1998, visual inspection, delamination survey and half-cell potential measurements indicated that corrosion was initiated at few locations were the steel reinforcements were close to the concrete

surface. However, corrosion-induced damage was limited and localized on the inclined portion of the bottom flange of the external girders.

Fig. 1. View of the investigated bridges

The two 76.8-m long bridges consisted of three single spans of prestressed concrete girders supporting a reinforced concrete slab. On the external girders of the bridges, a group of twelve 2-m long sections was selected for the study: nine sections for cathodic protection systems, one section for concrete surface treatment and two sections as control.

3.2 Installation of the protective systems

Two protective systems were selected for this study: galvanic cathodic protection and concrete surface treatment. For the GCP systems three different anodes were evaluated: zinc (Zn), aluminum-zinc-indium (Al-Zn-In) and zinc-magnesium (Zn-Mg). The concrete surface treatment selected was a combination of silane primer and acrylic top coating.

The application of protective systems on the girder was preceded by first removing the delaminated concrete and cleaning the concrete surface and exposed reinforcing steel by sandblasting. The three anodes where applied by flame spray, as shown in Figure 2, and the concrete treatment was applied with a paint roller as shown in Figure 3.

Fig. 2. Application of zinc anode Fig. 3. Application of concrete surface

3.3 Evaluation of the performance of the protective systems

Three types of techniques were used to evaluate the protective systems namely: (i) electrochemical measurements were performed monthly from November 1998 to April 2004 to follow the performance of the systems with environmental conditions; (ii) non-destructive testing was performed at the beginning and at the end of the project for condition assessment of the girders; (iii) scanning electron microscopy (SEM) images were obtained at the end of the project to evaluate the extend of deterioration of the applied protective systems.

Half-cell potential measurements were performed monthly on the protected and control

sections. The measurements were taken using embedded manganese dioxide (MnO2)

reference electrodes. On girder sections with GCP system, the potential measurements were taken at different time intervals to allow the calculation of the polarization decay

without IR drop, as describe in the RP0290 standard14. A first potential reading was

taken before opening the electrical circuit, a second reading immediately after the opening of the circuit and a last reading four hours later.

Delamination survey was used to compare the initial and final conditions of the protected and control sections of the girders. Delamination survey was performed with a hammer by tapping concrete and listening for a hollow sound. The hollow sounding areas were marked and measured to evaluate the increase of delamination of concrete between 1998 and 2004.

Long-term deterioration of the protective systems was evaluated using SEM images. SEM images were obtained from cores having a diameter of 3 cm and a length of 2.5 cm taken from the girder 5½ years after the application of the products. Few images were taken on each sample to observe the microstructure of the protective systems. Chemical analyses of the cross-sections were performed using X-ray analyzer at different locations, to determine the local composition of the anodes and surface concrete coating.

4. Analysis of field results

4.1 Polarization decay monitoring on sections with GCP systems

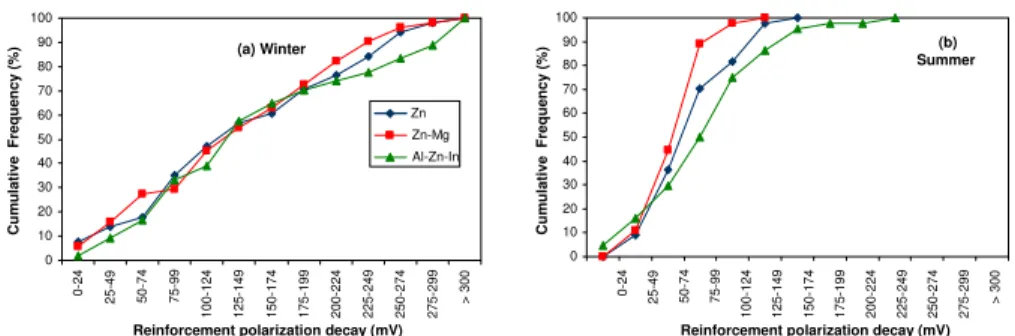

The cumulative frequency distributions of the polarization decay calculated for each sacrificial anode are plotted in Figure 4. It is shown clearly that the performance of the three galvanic systems varied with environmental conditions. The three sacrificial anodes provided similar polarization decay of the reinforcing steel during winter months. However, in summer when wet condition were limited, Al-Zn-In provided polarization to reinforcing steel that was higher than the two other anodes. This is consistent with

what others researchers found when comparing Zn and Al-Zn-In anodes12. Based on

those data, Al-Zn-In might be considered more efficient than Zn and Zn-Mg anode in reducing corrosion rate of reinforcing steel especially in period of absence of direct salt wetting.

(b) Summer C u mu la ti ve F req u e n cy (% ) 0 10 20 30 40 50 60 70 80 90 100

Reinforcement polarization decay (mV)

0-2 4 25 -49 50 -74 75 -99 100-124 125-149 150-174 175-199 200-224 225-249 250-274 275-299 > 300 (a) Winter

Reinforcement polarization decay (mV)

C u mu la ti ve F req u e n cy (% ) 0 10 20 30 40 50 60 70 80 90 100 Zn Zn-Mg Al-Zn-In 0-2 4 25 -49 50 -74 75 -99 100-124 125-149 150-174 175-199 200-224 225-249 250-274 275-299 > 300 (a) Winter Potential (mV) C u m u la ti ve F req u en cy ( % ) 0 10 20 30 40 50 60 70 80 90 100 > -299 -300 to -349 -350 to -399 -400 to -449 -450 to -499 -500 to -549 -550 to -599 -600 to -649 -650 to -699 -700 to -749 -750 to -799 -800 to -849 -850 to -899 -900 to -949 -950 to -999 -1 000 to -1049 -1 050 to -1099 -1 100 to -1149 Zn Zn-Mg Al-Zn-In (b) Summer Potential (mV) C u m u la ti ve F req u en cy ( % ) 0 10 20 30 40 50 60 70 80 90 100 > -299 -300 to -349 -350 to -399 -400 to -449 -450 to -499 -500 to -549 -550 to -599 -600 to -649 -650 to -699 -700 to -749 -750 to -799 -800 to -849 -850 to -899 -900 to -949 -950 to -999 -10 00 to -1049 -10 50 to -1099 -11 00 to -1149

Fig.4. Cumulative frequency distribution of reinforcement polarization decay potential

To evaluate risk of hydrogen embrittlement, the potentials of the prestressing tendons under cathodic protection were also recorded on a monthly basis. The data showed that even in winter, when the polarisation of the tendons was the most significant, the tendon

did not reach values more negative than –800 mV vs. Cu/CuSO4, which is below the

cathodic protection limit of –974 mV vs. Cu/CuSO47,8. Thus, the galvanic cathodic

protection systems can be considered safe for the application on prestressed concrete girders.

The potentials of the anodes after 4 hours of polarization decay are presented in Figure 5. For all anodes, a shift in the potential towards more negative values can be observed during the winter months. This trend can explain the increase recorded in the reinforcing steel polarization during that same period of the year (Figure 4). During winter, the presence of salt contaminated water has certainly improved the dissolution activity of the anodes and the contact surface between the anodes and the concrete. Those two factors are believed to have contributed to shift the potential of the anodes towards more negative values, improving the polarization of the reinforcing steel. Amongst the three anodes evaluated, Al-Zn-In anode showed the most negative potential independent of the environmental conditions, which was expected from the steel polarization data.

Fig. 5. Cumulative frequency distribution of potential of the anodes after 4 hours of polarization decay

Date

Control Concrete surface treatment

Pot e n tia l ( m V v s C u /C u S O4 ) Oc t-98 J an-99 Apr-99 Ju l-9 9 Oc t-99 J an-00 Apr-00 Ju l-0 0 Oc t-00 J an-01 Apr-01 Ju l-0 1 Oc t-01 J an-02 Apr-02 Ju l-0 2 Oc t-02 J an-03 Apr-03 Ju l-0 3 Oc t-03 J an-04 Apr-04 -400 -350 -300 -250 -200 -150 -100 -50 0

4.2 Half-cell potential monitoring on control and concrete surface treatment sections

Half-cell potential readings recorded from the embedded reference electrodes between November 1998 and April 2004 are presented in Figure 6. It can be observed on the control section that the potential of prestressing tendons had seasonal variations and an overall trend towards more negative readings over the years. However, on the treated surface, the potential generally moved towards more positive readings between November 1998 and October 2003. While potentials around –230 mV were recorded three months after the application of the concrete surface treatment, a value of –42 mV was measured 5 years later, which indicates a significant reduction in risk of corrosion of reinforcing steel due to concrete surface treatment.

Based on the significant potential shift in the positive direction observed in the treated section, it is believed that the application of the sealer and coating have contributed to reduce the penetration of aggressive agents in concrete and at the same time allowed concrete to dry out. Indeed, with the dryness of the concrete at the rebar level, the electrical concrete resistance increases, which contributes to reduce the corrosion rate of the reinforcement and then shifts the potential towards more positives values.

Fig.6. Time variations of the potential values on control and concrete surface treatment sections

4.3 Delamination survey

The percentages of delaminated concrete area to non-delaminated concrete area measured in 1998 and 2004 for all protected and control sections are summarized in Table 1. It can be seen from those data that protective systems provided either by GCP or concrete surface treatment were beneficial to reduce progression of concrete delamination. Indeed, while delaminated areas between 1998 and 2004 increased by 11% in the control sections, less than 2.5 % increase was recorded in protected sections.

Zinc Concrete Epoxy Al-Zn-In A Zinc Magnesium Zinc Coating Concrete Epoxy (a) (b) (c) (d) Table 1. Results of concrete delamination surveys in 1998 and 2004

Ratio of delaminated to non-delaminated concrete area

Section 1998 2004 Increase

CP / Zn 11.5% 12.3% 0.8%

CP / Zn-Mg 22.1% 22.1% 0.0%

CP / Al-Zn-In 21.2% 23.8% 2.5%

Concrete surface treatment 33.0% 33.4% 0.4%

Control 9.2% 20.2% 11.0%

4.5 Scanning electron microscopy images

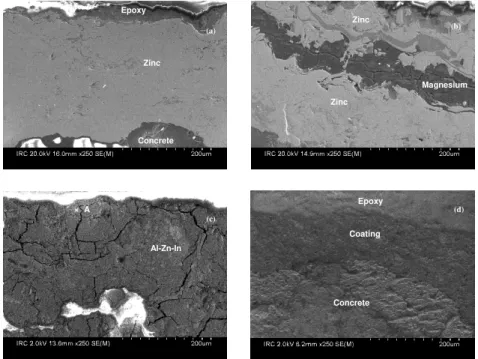

Figure 7(a) is a scanning electron microscopy image of the Zn anode. The image shows that Zn anode has maintained a good condition with very few cracks and imperfections throughout the duration of the study. Figure 7(b) shows the Zn-Mg anode. While fine cracks and imperfections are present in the layers of zinc, many relatively large cracks can be observed in the layer of magnesium. The cracks in the magnesium layer were explained by the significant oxidation of that metal. Based on X-ray analysis, oxygen comprised more than half of the atomic weight in the magnesium layer, which could have reduced the performance of this anode.

Fig. 7. Scanning electron microscopy images: (a) Zn anode; (b) Zn-Mg anode; (c) Al-Zn-In anode; (d) concrete surface treatment

Al-Zn-In anode SEM image presented in Figure 7(c) shows many cracks distributed throughout its thickness. Since cracks increased the apparent surface area of the anode, it is possible that this phenomenon has contributed to maintain a higher level of dissolution activity of the anode compared to Zn and Zn-Mg anodes, which was beneficial to increase the polarization of the reinforcing steel. However, it is likely that the cracks observed in the Al-Zn-In anode result in a loss of adhesion between the anode and the concrete and contribute to reduce its service life.

SEM image of the concrete surface coating is presented in Figure 7(d). The image shows that the coating has kept a good appearance despite its exposition to aggressive environment. Beside air bubbles, very few imperfections are visible.

5. Conclusions

The field performance of galvanic cathodic protection systems and concrete surface treatment was evaluated over five years (from November 1998 to April 2004). From the results of this investigation the following conclusions can be drawn:

• Protective systems provided either by GCP or concrete surface treatment were effective in reducing the rate of delamination of concrete cover. It was observed that the delaminated area increased by 11% over the five years on the control section compared to only 2.5% on the protected sections.

• A comparison of the three anodes used in GCP systems indicated that the Al-Zn-In anode was more effective than the Zn and Zn-Mg anodes in reducing the corrosion rate of reinforcing steel, especially during the summer months. The high polarization decay of the reinforcing steel observed with Al-Zn-In anode was attributed to the ability of this anode to maintain high negative potential independent of the environmental conditions.

• A significant reduction in half-cell potential was recorded on the concrete surface treatment section following the application of the silane primer and acrylic top coating. As a result, the risk of corrosion of the reinforcing steel decreased in this section.

• Scanning electron microscopy images indicated that both the Zn anode and the concrete surface coating had a good condition after more than five years of service. However, the magnesium layer in the Zn-Mg anode and the Al-Zn-In anode showed many cracks, which may have resulted in a loss of their adhesions to the concrete and thus reduce their service lives.

6. Acknowledgements

The financial and technical contributions of Ministère des Transports du Québec are gratefully acknowledged. The authors would also like to thank Dr. Shiyuan Qian, Dr. Gerry Pernica, Mr. Bruce Baldock, Mr. Rock Glazer, Mr. Jim Margeson and Mr. Ken Trischuk from NRC/IRC for their valuable technical assistance.

7. References

1. Dunker, K. F. and Rabbar, B. G., “Performance of Prestressed Concrete Highway Bridges in the United States – The First 40 years”, PCI Journal, 37 (3) (1992) 47-64. 2. Novokshchenov, V., “Salt penetration and corrosion in prestressed concrete

members”, Report No. FHWA-RD-88-269, FHWA, 1989, 212 pp.

3. Mallett, G.P., “State of the art review: repair of concrete bridges”, Thomas Telford, London, 1994, 194 pp.

4. Basheer, P. A. M., Basheer, L., Cleland, D. J. et Long, A. E., “Surface treatments for concrete: assessment methods and reported performance”, Construction and Building Materials 11(7-8) (1997) 413-429.

5. Ibrahim, M., Al-Gahtani, A. S., Maslehuddin, M. and Dakhil, F. H., “Use of surface treatment materials to improve concrete durability”, Journal of materials in civil engineering February (1999) 36-40.

6. Teng, T.P., “Long-term effectiveness of cathodic protection systems on highway structures”, Publication No. FHWA-RD-01-096, FHWA, 2001, 96 pp.

7. Bennett, J.E. and Shue, T.J.,“Cathodic protection field trials on prestressed concrete components”, Publication No. FHWA-RD-97-153, FHWA, 1997, 74 pp.

8. Hartt, W.H., Joubert, E. and Kliszowski, S., “Long term effects of cathodic protection on prestressed bridge components”, Publication No. FHWA-RD-96-029, FHWA, 1996, 120 pp.

9. Sagüés, A.A. et Powers, R.G., “Sprayed Zinc Galvanic Anodes for Concrete Marine Bridge Substructures”, SHRP-S-405, Strategic Highway Research Program, 1994, 85 pp.

10. Bullard, S.J., Covino, B.S., Cramer, S.D., Holcomb, G.R., Russel J. H., Cryer, C.B.

and Laylor, H. M., “Anodes for cathodic protection of reinforced concrete”, in

Corrosion 2000 Proceeding, Paper 00810 (2000) 12 pp.

11. Covino, B. S., Cramer, S. D., Bullard, S. J., Holcomb, G. R., Russell, J. H. and Collins W. K., “Performance of zinc anodes for cathodic protection of reinforced concrete bridges”, Final report SPR 364, Oregon Department of Transportation and Federal Highway Administration, (2002), 136 pp.

12. Funahashi, M. and Young, W.T.. “Development of a new sacrificial cathodic protection system for steel embedded in concrete,” Report No. FHWA-RD-96-171, FHWA, 1997, 160 pp.

13. Funahashi, M. and Young, W.T., “Field evaluation of a new aluminium alloy as a sacrificial anode for steel embedded in concrete”, Report No. FHWA-RD-98-058, FHWA, 1998, 65 pp.

14. NACE, “Cathodic protection of reinforcing steel in atmospherically exposed