Publisher’s version / Version de l'éditeur:

Construction Specifier, 46, 12, pp. 110-119, 1993-12

READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE. https://nrc-publications.canada.ca/eng/copyright

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

NRC Publications Archive

Archives des publications du CNRC

This publication could be one of several versions: author’s original, accepted manuscript or the publisher’s version. / La version de cette publication peut être l’une des suivantes : la version prépublication de l’auteur, la version acceptée du manuscrit ou la version de l’éditeur.

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at

Cementitious bonding agents

Mailvaganam, N. P.; Nunes, S. C.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site

LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

NRC Publications Record / Notice d'Archives des publications de CNRC:

https://nrc-publications.canada.ca/eng/view/object/?id=f190a607-6968-472f-b833-b35a7ce4737e

https://publications-cnrc.canada.ca/fra/voir/objet/?id=f190a607-6968-472f-b833-b35a7ce4737e

Ce m e nt it ious bonding a ge nt s

N R C C - 3 7 0 3 2

M a i l v a g a n a m , N . P . ; N u n e s , S . C .

D e c e m b e r 1 9 9 3

A version of this document is published in / Une version de ce document se trouve dans:

Construction Specifier, 46, (12), pp. 110-119, December-93

http://www.nrc-cnrc.gc.ca/irc

The material in this document is covered by the provisions of the Copyright Act, by Canadian laws, policies, regulations and international agreements. Such provisions serve to identify the information source and, in specific instances, to prohibit reproduction of materials without written permission. For more information visit http://laws.justice.gc.ca/en/showtdm/cs/C-42

Les renseignements dans ce document sont protégés par la Loi sur le droit d'auteur, par les lois, les politiques et les règlements du Canada et des accords internationaux. Ces dispositions permettent d'identifier la source de l'information et, dans certains cas, d'interdire la copie de documents sans permission écrite. Pour obtenir de plus amples renseignements : http://lois.justice.gc.ca/fr/showtdm/cs/C-42

CEMENTITIOUS

I

Zサ・}セAij@

ャセ{ゥIa@

gents

by

Noel

P.

Mailvaganam and Stacey Nunes

Adhesion of new concrete to old depends on a number of factors, including ウオイセ@ face preparation, mechanical

compat-ibility

of the two concretes, tempera-ture of the concrete substrate, and ambient temperature conditions at the time the new concrete is placed.Success-ful

bonding also depends on the care exer-cised in placing the fresh concrete. Somepractitio-Do bonding agents

improve adhesion,

or are they merely

substitutes for

good concrete

practice?

ners and building product manufacturers promote the use of bonding agents to augment the bond at the interface. These products reportedly increase adhesion by enhancing wetting and sealing of the concrete substrate, thereby minimizing water loss from the fresh concrete to the substrate.

Whether bonding agents effectively improve adhesion bas been debated. Some practitioners contend that they are too often used as substitutes for good con·

',•,

Above, dry repair material is applied on top of the bonding agent. The dry material is then tamped and smaothed with a trowel.

Mix Proportions

Product# Material Latex Cement Concrete Water

(g)

(g)

Sand(g)

(ml) (1) Latex 506 908 908 --(2) Latex 185 680 680 185 (3) Neat Cement--

1000--

400 (4) Latex 227 1135 567 227(5) ConcJConc. See Table 2 for concrete mix proportions.

Table 1. Mix proportions of bonding agents

Proportions For 30 kg Bag of Prepackaged Concrete Type 10 Coarse Fine

Mix Cement Aggr:,rte Aggregate (kg) (kg (kg)

1 {Initial) 4.8 14.4 10.8

2 (at45 min) 4.8 14.4 10.8

3 (Initial) 4.9 14.4 10.9 • Air entraining agent

Table 2. Control concrete mix proportions crete practiCe. Others cite several situa-tions where bonding agents help

aug-ment bonding

characteristics-particu-larly with friable substrates that reqoire fortification before toppings and over-lays are applied.

A Comparison Study

Bonding agents are broken down into two categories: systems based on port-land cement!latex and those based on synthetic resins such as epoxies. Cement-based materials are cheaper, and most site operatives are more familiar with them than with resins. Proprietary ce-ment-based products usually consist of a liquid latex emulsion (e.g., acrylics, sty-rene-butadiene) or a mix of cement/sand! powder latex that requires the addition of water on site. The liquid latex emul-sion is used as gauging water (the mea-sured amount of water used in the mix) wfth cement/sand mixtures to produce a

mヲNセ@ Water mセィャケ@ 150 Slump Unit %Air

(ml) (kg) supar (mm) Mall Grosa Supefnastlcizer (kglm')

ml)

2.0 2.75

-

150 2!08 5.42.0 2.76

-

75 2329 4.72.0 2.75 10.0 240 2319 4.8

thick slurry. The slurry is then applied to the concrete's prepared surface just be-fore new concrete is placed to prevent the bonding agent from drying out.

A two-part laboratory study was con-ducted to determine the effectiveness of both cement-based and epoxy-based bonding agents. Part one, which evalu-ated cement-based materials, is the sub-ject of this article.

The performance of the three propri-etary products consisting of cement/sand! latex mixtures was compared to that ob-tained in specimens where a neat ce-ment sluriy and normal concrete-to-con-crete bonding was used. Factors that influence and determine bond strength and other important properties were

in-カ・ウエゥァセエ・、N@ Hardened properties such as

compressive strength, modulus of rup-ture, the'nnal coefficient of expansion, bond, and shear strength were deter-. mined at various ages, under different

112 The Construction Specifier I December 1993

curing conditions and varying fresh con-crete slumps.

Preparation

Table 1 lists mix proportions of the pro-prietary materials (products 1-4), and Table 2 shows mix proportions for the control concrete (product 5) cast for com-parative purposes.

Control specimens were cast from a 25 MPa ( 3625 psi) class concrete made with Type 1 cement and 16 mm (%in.) maximum size aggregate. The same mix was used for the half sections of the composite specimens.

Two types of test specimens were pre-pared: bonding and composite. Mixing time for

all

materials was three to four miimtes.Bonding specimens--cubes

50

mm3 and prisms 25 X 25 X 125 mm-were cast solely from the bonding agent to test its physical characteristics and mechanical properties. Specimens for testing ther-mal coefficient of expansion and modu-lus of rupture were prepared at 23oc

(73 'F) and 50 percent relative humidity (RH) and wet-cured at 23 'C.Compressive strength test specimens were made and stored at 23 'C and 100 percent RH.

Composite specimens, in which the product was used to bond concrete to concrete to simulate repair, were tested at various ages. Cylinders measuring 150 mm (6 in.) with 75 mm (3 in.) diam-eters were used for the bond strength tests, and concrete slabs 406 X 406 X

150 mm (16 X 16 X 6 in.) were tested for shear strength. Workability of the fresh concrete was varied to assess the effect of mix consistency (wetness) on the bond strength. Composite specimen configu-ration is shown in Figures A and B .

To prepare the composite specimens,

l

1.1 I: Fresh concrete Bonding agent applied to hardened concrete p p

Figure A. Composite specimens for bond strength test(ASTM 8821

the surface of the concrete substrate was sand-blasted to remove laitance and roughen it. It was then saturated with

water, coated with the bonding agent,

and immediately covered with fresh crete. On some specimens, new con-crete placing was delayed for 45 minutes

after the bonding agent was applied. Five types of specimens were

pre-pared and cured under different condi-tions as described below.

• Type

1. The bonding agent was ap-plied to dampened, saturated surface dry (SSD) concrete. SSD describes the moisture condition of the slab-it is firstsoaked with water, and when the surface

dries the agent is applied. Fresh

con-crete was then placed and the composite

specimen cured at 23 'C and 50 RH.

Specimens were prepared for one, seven, and 28 days. Fresh concrete slumps for these specimens varied from

75

mm to240 mm (3 in. to 9 in.).

• Type 2.

Specimens were cured at23 'C and 100 percent RH for l l months.

Fresh concrete slumps ranged from

75 mm to 100 mm.

• Type 3.

Specimens were cured at32

·c

(90 'F) and 50 percent RH for one,seven, and 28 days prior to testing. Fresh concrete slumps varied from 75 mm to

!OOmm.

• Type

4. Specimens were cured at10 'C (50 'F) and 50 percent RH for one,

seven, and 28 days prior to testing. Fresh concrete slumps varied from

75

mm toIOOmm.

• Type

5. Specimens for freeze/thaw'"testing were prepared and cured at 23

·c

and 50 percent RH for 14 days prior to testing.Workability

The tests measured workabillty and work llfe according to the material's ability to form a brnshable or sprayable slurry and

in the time it remained usable as a slurry. Latex-cement slurries were fOund to be more workable at lower water-ce-ment ratios than neat cewater-ce-ment slurries. At

32

·c

the "working time" of both ()pes ofslurries was reduced, and to avoid loss of

bond the fresh concrete had to be placed

soon after the slurry coat was brushed

114 The Construction Specifier I dセ」・ュ「・イ@ 1993

Bonding agent applied to sandblasted surface of hardened concrete

Figure B. Composite specimens for shear strength test(CRDC C·89-64 modified) onto the surface of the concrete sub-strate. Thus, under severe drying condi-tions, the "Working time" for these mate-rials can be too short to ensure a good

bond between the repair material and

the concrete substrate.

Coefficient of Thermal Expansion

Two modifications were made to the

ASTM C531 test: a different specimen size-25 X 25 X 150 mm (I X I X 6

in.)-and a given test temperature were used. Tests were carried out at two different

temperature ranges: -25

·c

to 23·c

(-13'F to 73'F) and 23'C to IOO'C (73 'F to 212 'F). The change in lengthat various temperatures was used to cal-culate the coefficient of thermal expan-sion.

Values obtained at the two tempera-ture cycles are shown in Figure C. In the

first cycle, the results yielded by

speci-mens containing the cement-latex bond-ing agent were similar to those for speci-mens using a neat cement slurry.

Results from the second cycle showed

each material and a significant differ-ence in the values obtained for the latex materials and neat cement slurry.

How-ever, since the coefficient of thermal

expansion values of the bonding agents are similar to these of the base concrete, these materials are compatible with the substrate and will not cause shearing stresses at the bond interface at normal seiVice temperatures. Compressive Strength

.§

50 0lilSS

Cycle 23 ' to ·25 •c[-x"'

40[;Zi

Cycle 23 • to t 00 'Cw;:

ox

ゥセ@ 30·u-u

20 OEls.

10 セ@ F-0 2 3 4Figure C. Thennal coefficient of expansion of proprietary bonding agents

COMPRESSIVE STRENGTH (MPa)

Compressive strengths (ASTM C109) were determined at the ages of one

day,

seven days, 28 days, and 11 months at 23 'Cat 50 percent and 100 percent RH.Cured @ 23'C and 100% rh Cured@ 23'C and 50% rh

Table 3 summarizes the test results. At 24 hours, the proprietary bonding agents yielded strength values below those of control concrete or neat cement. At seven days, however, two of the proprietary products yielded values higher than those of control concrete but lower than those of neat cement. One product gave

con-11 I (2) (3) (4) (5) Material Latex Latex Neat Cement Latex Control Concrete 1 5.9 16.4 19.4 16.3 18,7

Age (Days) Age (Days)

7 28 1 7 24.1 32.8 7.0 27.7 45.0 54.9 12.9 35.0 48.4 60.5 19.7 47.0 45.8 51.2 18,0 49.7 24.7 32.5 18.2 22.9

sistently lower results (at all ages) than Table 3. Compressive strength values (ASTM C1091 for bonding specimens the control concrete. Curing under 100

percent RH improved the strength val-ues of two of the bonding agents by 17 percent to 35 percent, compared to those cured under 50 percent RH.

Modulus of Rupture

The modulus of rupture was determined according to ASTM C7S at 14 days. The flexural strength results are presented in

Figure D. Proprietary bonding agents developed strengths ofless than 20 MPa (2,900 psi)-similar to the control con-crete-but all values were higher than those of neat cement.

Bond Strength (In Compression)

Tests for bond strength (ASTM C882) were conducted at different

tempera-..

0. セ@ !8.

"

a:

0 0 セ@'ll

:; 30 20 10 0 9 Producttures-10

·c.

23·c,

and 30·c

(50 'F, f"ogure D. Modulus of rupture lASTM C78J. Age: 14 days28 41.6 35.6 49.8 59.7 31.0

1 0°C Failure Load 23°C Failure Load 30°C Failure Load

(MPa) (MPa) (MPa)

Material

3day 7day 28day 3day 7day 28day 3day 7 day 28 day (t) Latex 7.9 10.6 13.5 13.3 14.5 15.8 14.4 15.7 17.2 (2) Latex 6.3 9.3 10.7 12.8 14.5 16.9 14.1 14.5 16.4 (3) Neat Cement 8.4 11.6 14.1 13.6 16.6 17.5 15.3 17.2 17.3 (4) Latex 7.1 7.8 10.0 14.5 16.3 18.1 14.2 15.5 16.7 (5) Conc./Conc. 5.3 6.1 8.3 10.4 12.9 13.9 11.1 11.2 12.1

Note:(1) Fresh concrete slumps 75-100 mm.

(2) Fresh concrete placed immediately after bonding agent applied. (3) Concrete design strength 25 MPa.

Table 4. Effect of variation in curing temperature on bond strengths

Slump 75-100 mm Slump 150 mm Slump240mm

(MPa) (MPa) (MPa)

Material

3day 7day 28day 3 day 7day 28day 3 day 7day 28day (1) Latex 13.3 14.5 15.8 13.4 13.4 14.5 14.2 14.2 16.5 (2) Latex 12.8 14.5 16.9 12.6 14.0 14.8 11.4 15.3 16.3 (3) Neat Cement 13.6 16.6 17.5 13.0 14.4 15.5 10.6 15.4 16.2 (4) Latex 14.5 16.3 18.1 13.0 13.1 14.7 11.9 15.0 17.1 (5) ConcJConc. 10.4 12.9 13.9 8.6 12.7 13.7 8.3 16.2 17.0

Note: (1) Curing temperature 23'C.

(2) Fresh concrete placed immediately after bonding agent applied. (3) Concrete design strength 25 MPa.

Table 5. Effect of variation in fresh concrete slump on bond strengths

23'C, 75-100 mm Slump Concrete

Bonding Agent Applied and Fresh Bonding Agent Applied and Fresh Concrete Placed 45 Minutes Later Concrete Immediately Placed Material Bond Strength (MPa) Bond Strength (M Pa)

Age (Days) Age (Days)

3 7 28 7 28

(1) Latex 8.6 9.6 10.4 13.4 14.5

(2) Latex 8.9 10.4 12.2 14.0 14.8

(3) Neat Cement 10.7 11.8 10.4 14.4

.•

15.5(4) Latex 9.0 9.7 9.9 13.1 14.7

Table 6. Bond strength (ASlM C882)

Effect of time delay between applying bonding agent and placement of fresh concrete

116 The Construction Specifier I Dec:ember 1993

73 'F, and 86 'F) on composite speci-mens made with fresh concrete with various slumps (75 mm to 240 mm). Test results are summarized in Tables 4 through 6.

All bonding agents showed improved bond strengths compared to the

con-」イ・エ・セエッM」ッョ」イ・エ・@ specimens where no bond-promoting materials were used. The proprietary materials gave similar results, but neat cement gave a consistently higher result at all temperatures and ages. Low temperature affected bond strength sig-nificantly, while the higher temperature (32 'C) produced mixed results-increas-ing some values and decreasresults-increas-ing others in comparison to those obtained at 23 °C.

Variation of fresh concrete slumps in the 75 mm to 100 mm range produced no adverse ・セ・」エウ@ in specimens using pro-prietary materials. Though higher than the concrete-to-concrete specimens, bond strengths were similar to specimens where neat cement was used (see Table 5). When slumps exceeding 100 mm were placed, some products showed a slight decrease in strength at 3 days. Concrete-to-con-crete specimens showed improvement in 28-day bond strengths when fresh con-crete slumps were increased.

Bond strengths of the commercial products exceeded those of the concrete-to-concrete specimens when the fresh concrete was placed immediately after the bonding agent was applied to the concrete substrate. However, when there was a delay between bonding agent ap-plication and placement of fresh con-crete, bond strengths decreased 17 per-cent to 33 perper-cent (see Table 6). All three proprietary bonding agents per-formed similarly.

Shear Strength

compos-Product 1 XセセセセセセMMMML@ 3 days at 23"C and 50% m 7 'j 6 セ@

I:

j

3 "' 2 0 7 • • • • 26 " • • " • 11 months at23•C and tOO% rhProduct 4 Product2 Vertical Slab ProductS Horizontal Slab XセセMMセセセMMMML@ • 3 days at 23"C and 50% rh 7

:Ia : · " · "

0c 11 months at23°C and t 00%

Vertical Slab

Horizontal Slab

Figure E (Products 1 througb S, above!. Shear strength of vertical and horizontal slabs in three, seven, and 28 days

at

23·c

and SO percent RHite slab specimens were tested for shear

strength at three, seven, and 28 days according to a modified CRCD C-89-64 method. Specimens were stored at 23

·c

and RH of 50 percent and 100percent.

Figures E

andF

show the values ob-tained. With the exception of product 4and the neat cement, values for horizon-tally cast slabs exceeded those of verti-cally cast slabs. Only product 4 gave a higher value than neat cement in verti-cally cast specimens. The product's

bet-ter performance can be attributed to its non-sag characteristics that prevent

ma-terial from sloughing off in the vertical position. Results also showed that:

• Product 1 produced slow strength development at early ages. Neat cement slurries gave Consistently higher values

.in compalison to the slabs where 」ッョセ@ crete-to-concrete bonding was done キゥエィセ@

out the use of such materials.

• When proprietary products were used, higher shear strengths were ッ「セ@ tained at early ages (three and seven days) compared to 」ッョ」イ・エ・セエッセ」ッョ」イ・エ・@

bonding. However, at 28 days all strengths, including those for

concrete-エッセ」ッョ」イ・エ・@ bonding were similar both in

horiwntal and vertical applications. • Failure modes showed that speci-mens using proprietary bonding agents and neat cement had a higher failure percentage in the concrete substrate than at the bond interface-particularly at early ages. At 28 days, however, all fail-ure was in the concrete substrate.

• All specimens stored at 23

·c

and 100 percent RH and tested at 11 months7 6 5 4 3 2 0 Vertical Slab 2 Product 3 3 Horizontal Slab 4 5

Figure F. Shear strength of vertical and horizontal slabs in 11 months at 23 "C

and 100 percent RH

developed similar shear strength values (see

Figure F).

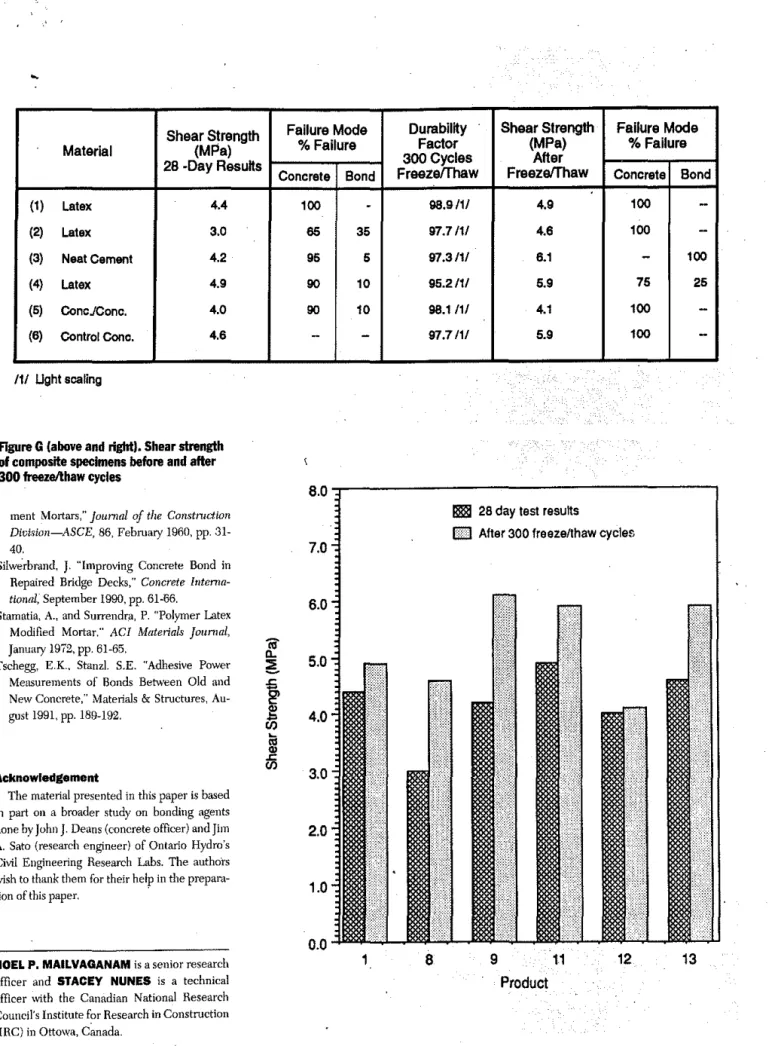

Freeze/Thaw Resistance

Specimens were first tested for freeze/ thaw (F (f) resistance according to ASTM C666 procedure A and then tested in shear. Pulse velocity measurements were made after300

Frr

cycles using an ultra-sonic pulse velocity device "soniscope" with built-in oscilloscope. The test pro-cedure, equipment, and basic require-ments were done according to ASTM C597.The effects ofFff action were deter-mined by changes in weight, dynamic modulus of elasticity, and pulse veloc-ity measurements. Table 7 and Figure

G summarize the test results. Use of

proprietary bonding agents or neat

Number of Dynamic Pulse Velocity

Durability Material Cycles at end of Modulus %Eo Length Across Bond Change Weight Factor

Freezellhaw Eo Ef Vo VI Vo VI % 300 Cycles (1)

Latex

300 36.71 36.28 98.9 4640 4450 4820 4820 .0.02 98.9/1/ (2)Latex

300 35.77 34.93 97.7 4620 4490 4820 4550 .0.26 97.7/1/ (3) Neat Cement 300 40.07 39.02 97.3 4640 4470 4820 4420 .0.16 97.3/1/ (4)Latex

300 39.96 36.02 95.2 4620 4450 4420 4420 .0.30 95.2/1/ (5) Conc./Conc 300 36.55 37.81 98.1 4640 4450 4820 4490 .0.09 98.1/1/ (6) Control Concrete 300 36.68 35.81 97.7 4570 4520 4360 4360 .0.41 97.7/1/..

/1/ lセァィエ@ scaling of concrete.

Note:

Eo • Ongmal dynamic modulusEf • Final dynamic modulus

Vo • oョァセョ。ャ@ pulse velocity

VI • Final pulse velocity

Table 7. Weight, dynamic modulus of elasticity, pulse velocity measurements after 300 freeze/thaw cycles IASTM C666 Procedure AI

ment slurry did not appear to adversely affect the FIT resistance compared to

the traditional concrete-to-concrete

bonding. The values obtained for the specimens containing the bonding agents exceeded the minimum dura-bility factor value of 80 percent and in ali instances were quite similar to those given by the concrete-to-concrete bonded specimens. No clear difference in FIT performan.ce was noted between the three bonding agents.

Observations

The following observations can be made based on the results of the evaluation.

• In general, bonding agents

per-formed better in horizontal versus verti-cal applications. The neat cement slurry performed better than the proprietary products.

• Variation in the slumps of the fresh concrete produced a marginal effect on the bonding agent specimens, but higher slumps improved the normal concrete-to-concrete bond. The better '\vetting" of the concrete substrate surface by wet-ter mixes is probably the reason for im-proved bonding.

• Neat cement slurries performed consistently, giving similar or higher val-ues than the proprietary materials. Al-though the proprietary products and

neat cement improved shear and bond strengths at early ages (three and seven days), the 28-day strengths were simi-lar, regardless of whether they were cast horizontally or vertically. The useful-ness of these materials in routine appli-cations is therefore questionable, and their application should probably be lim-ited to specific instances.

• Bonding agents are useful when con-creting is done in low temperatures (10 'C). Although the early strength gain was not high, offsetting low temperature set retardation, as afforded by the pro-prietary products, could be advantageous in situations where rapid turnaround is required, e.g., warehouse and factory floors. Using latex-modified materials may well mitigate adverse effects resulting from poor substrate preparation, such as porous and friable concrete slabs.

• The bond and shear strength results obtained for the three proprietary mate-rials showed a wide scatter. This obser-vation is in agreement with the work of other investigators. Some workers have questioned the validity of such tests on this basis, arguing that results cannot be compared well among each other and do not simulate failure typically found in service. Despite the subjective nature of the assessment, some distinctive trends emerge, however.

118 The Construction Specifier I Dect>mbt>r 199."3

...

-·-----Recommendations

Many proprietary bonding agents are latex emulsions. Lattices are susceptible to freeze damage, which causes the emul-sion to coagulate. Therefore, these ma-terials must be stored above freezing temperatures prior to their use. Using frozen materials after thawing should be discouraged.

When using cement-based bonding agents, the bonding agent must be ap-plied just prior to placing the fresh con-crete; otherwise, the bonding agent will dry out, possibly leading to significant reduction in bond strength. Further, the concrete surface should be saturated with water and allowed to dry before place-ment of fresh concrete.

+

References

"Acrylic Modifiers for Cement," Concrete

Con-struction, Febmary 1982, pp. 107-108.

Review of Available Infornuztlon on Polyvinyl

Acetate as an Admb.ture for Concrete, U.S.

Army Corps of Engineers Technical Hepoit No. 6-486, July 1958.

Bentur, A. "Properties of Latex Cement

Com-posites," International journal of Cement &

Composites, 4 (1), Febmary 1982, pp. 57-65.

Dixon, J.F. and Sun ley, V.K. "Use of Bond Coats in Concrete Repair," Concrete 27 (8), 1983,

pp. 34-35.

Higgins, D. "Hepairs to Reinforced Concrete,"

Concrete, 16 (12), December 1982, pp. 36-40.

Ce-Shear Strength Material (MPa) 28 -Day ResuHs (1) Latex 4.4 (2) Latex 3.0 (3) Neat Cement 4.2 (4) Latex 4.9 (5) ConcJConc. 4.0 (6) Control Cone. 4.6 111 Ught sceling

Figure G (above and right). Shear strength

of composite specimens before and after 300 freeze/thaw cycles

ment Mortars," journal of the Constrndion

dゥカゥセゥッョMasceL@ 86, February 1960, pp.

31-40.

sゥャキセイ「イ。ョ、L@

J.

"Improving Concrete Bond inRepaired Bridge Decks," Concrete

Interna-tional,' September 1990, pp. 61-66.

Stamatia, A., and Surrendra, P. "Polymer Latex

Modified Mortar." ACI MateriaLs ]our11al, January 1972, pp. 61-65.

Tschegg, E.K., Stanzl. S.E. "Adhesive Power Measurements of Bonds Between Old and New Concrete," Materials & Structures,

Au-gust 1991, pp. 189-192.

Acknowledgement

The material presented in this paper is based in part on a broader study on bonding agents

done by John J. Deans (concrete officer) and Jim

A. Sato (research engineer) of Ontario Hydro's Civil Engineering Research Labs. The authors wish to thank them for their help in the

prepara-tion of this paper. .

NOEL P. MAILVAGANAM is a senior research

officer and STACEY NUNES is a technical officer with the Canadian National Research Council's Institute for Research in Construction (IRC) in Ottowa, Canada.

Failure Mode %Failure Concrete Bond 100

-65 35 95 5 90 10 90 10-

-8.0 7.0 6.0 5.0 4.0 3.0 2.0 1.0 0.0 1dオイ。「ゥャセケ@ Shear Strength Failure Mode

Factor (MPa) %Failure

300 Cycles After

Freezeffhaw Freeze/Thaw Concrete Bond

98.9/1/ 4.9 100

-97.7/1/ 4.6 100 -97.3/1/ 6.1-

100 95.2/1/ 5.9 75 25 98.1/1/ 4.1 100 -97.7/1/ 5.9 100-ll!!l!l

28 day test resuttsEEl

After 300 freezenhaw eyelet8

9 11 1213

Product