Publisher’s version / Version de l'éditeur:

Concrete International: Design and Construction, 15, 10, pp. 38-43, 1993-10

READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE. https://nrc-publications.canada.ca/eng/copyright

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

NRC Publications Archive

Archives des publications du CNRC

This publication could be one of several versions: author’s original, accepted manuscript or the publisher’s version. / La version de cette publication peut être l’une des suivantes : la version prépublication de l’auteur, la version acceptée du manuscrit ou la version de l’éditeur.

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at

Expansive admixtures in structural grout

Mailvaganam, N. P.; Nunes, S. C.; Bhagrath, R. S.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site

LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

NRC Publications Record / Notice d'Archives des publications de CNRC:

https://nrc-publications.canada.ca/eng/view/object/?id=6928abd6-a399-4af8-9bf1-096aa8f1c299 https://publications-cnrc.canada.ca/fra/voir/objet/?id=6928abd6-a399-4af8-9bf1-096aa8f1c299

Ex pa nsive a dm ix ture s in st ruc t ura l grout

N R C C - 3 6 9 7 9

M a i l v a g a n a m , N . P . ; N u n e s , S . C . ; B h a g r a t h ,

R . S .

O c t o b e r 1 9 9 3

A version of this document is published in / Une version de ce document se trouve dans:

Concrete International: Design and Construction,

15, (10), pp. 38-43,

October-93

http://www.nrc-cnrc.gc.ca/irc

The material in this document is covered by the provisions of the Copyright Act, by Canadian laws, policies, regulations and international agreements. Such provisions serve to identify the information source and, in specific instances, to prohibit reproduction of materials without written permission. For more information visit http://laws.justice.gc.ca/en/showtdm/cs/C-42

Les renseignements dans ce document sont protégés par la Loi sur le droit d'auteur, par les lois, les politiques et les règlements du Canada et des accords internationaux. Ces dispositions permettent d'identifier la source de l'information et, dans certains cas, d'interdire la copie de documents sans permission écrite. Pour obtenir de plus amples renseignements : http://lois.justice.gc.ca/fr/showtdm/cs/C-42

Expansive

Admixtures in

Structural Grout

by Noel Mailvaganam, Stacey Nunes, and Raj Bhagrath

S

hrinkage compensatingments (SCC) are used in ce-ment-based grouts to offset volume changes from shrinkage and settlement in the bedding of ma-chinery and in structural underpinning applications. However, these cements in many instances do not produce the ex-pansion necessary to maintain the strin-gent requirements for dimensional sta-bility. They are also prone to aeration deterioration during storage, which re-duces their expansiveness.' Also, under drastic field conditions, such as in hot and arid climates, higher expansion levels than that provided by sees may be required to offset the adverse effects of rapid drying. Therefore, to overcome these constraints, some grout manufac-turers have resorted to the use of ex-pansive admixtures, which permit greater flexibility in formulation.

Commercially available, non-gas producing expansive admixtures are ei-ther lime or calcium sulfoaluminate (CSA) based.' They are used with port-land cements to produce expansion sim-ilar to that obtained in SCCs. The amount of expansion can be varied to suit the needs of the intended applica-tion. For example, lower dosages could be employed for shrinkage compensa-tion under normal curing condicompensa-tions, while higher dosages could be used to offset the reduced expansion that occurs under rapid drying conditions. The ad-mixtures can be used as an addition or as a replacement to cement. When used as an addition, mix proportions are ad-justed by reducing the sand an amount

38

corresponding to that of the admixture. 1 Expansion of the grout is produced by crystal growth. CSA type admixtures form ettringite while the calcium oxide (CaO) particles in the lime-based system hydrate to form calcium hy-droxide (Ca(OH)z). Under restrained conditions the deformation that accom-panies expansion as strength increases introduces compressive stresses into the concrete. Consequently, the contraction that occurs on drying is reduced.' The

reaction mechanism for the conversion

of CSA to ettringite is uncertain, and several hypotheses have been advanced. A mechanism advanced and supported by a number of workers is schematically represented in Fig. I. • Particle type and size, range of particle size, thickness of protective coating, and presence of moisture determine the rate and dura-tion of expansion in both these

admix-tures.2,S

Although the mechanism of expan-sion in grout compositions is initiated by the expansive admixture, the rate and extent of expansion is also determined by the resulting modification produced by other components in the formula-tion.' For example, the inclusion of silica fume in the grout composition may reduce expansion of products made with Type K cement. • Silica fume, a pozzolan used to decrease permeability and bleeding, decreases formation of et-tringite by reducing the concentration of cations and anions like Ca2+ and OH- in-volved in the formation of ettringite.7•8

Superplasticizers used to provide flow-able consistencies and accelerators

em-ployed for rapid strength development have also been shown to reduce expan-sion significantly.'

The suitability of expansive admix-tures as alternatives to shrinkage com-pensating cements was investigated in the study described below. The objec-tive of the study was to determine: • whether increased dosages of the ex-pansive admixtures would provide the desired level of expansion, enabling greater flexibility in formulation, and • whether the performance of these compositions in increased dosages would be similar to that obtained with Type

K

expansive cements.Experimental consideration

Grout compositions containing two lime-based materials, two calcium sul-foaluminate-based materials, and Type K SCC were formulated and tested in the study. Two levels of addition of each of the expansive admixtures were used. All test methods, including ASTM C 827 and CRD C 621, were applied pri-marily to provide a comparative evalu-ation of the efficiencies of the various expansive admixtures and to determine their effect on strengths and other prop-erties rather than their compliance to the standards.

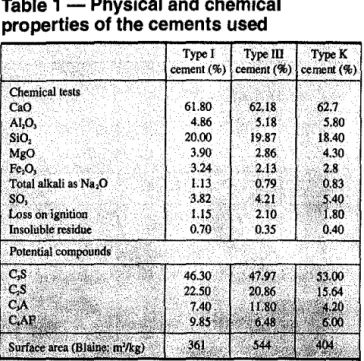

Materials investigated

ASTM Type I, Type ill, and Type K ce-ments were used in the study. Table I gives the chemical and physical proper-ties of the cements. Four expansive ad-mixtures- two CSA based, CSA-1 and CSA-2, and two lime based, L-1

andL-Concrete International

f

I

f

Calcium Sulfoalumlnate

1

WeierEttrlnglte Precursor

セ@

Ettrlnglte Acicular Crystals

E•p•nr•

Mm'""'"

Free Umeセw。エ・イ@

Calcium セケ、イックャ、・@ Free Anhydrous Calcium Sulphate Water (Topochemlcal Reaction)Fig. 1 - Proposed mechanism for the hydration of a cal-cium sulfoaluminate type admixture to form ettringite.

Table 1 - Physical and chemical

properties of the cements used

Setting time

2 - were used at two dosage levels

("a" and "b"). The most widely used calcium sulfoaluminate admixtureto is composed of 30 percent C..A,S, 50 per-cent Caso. and 20 perper-cent CaO with small amounts of glassy phase. Chem-ical and physChem-ical properties of the product are given in Table 2.• Products with a range of CaO contents (80-90 percent), and particle sizes and particle size distributions are used as lime-based admixtures.2.11 Typical physical and chemical properties of the material used is given in Table 3.11

a melamine formaldehyde sulphonate-based superplasticizer to provide there-quired flow characteristics. They con-tain, as well, other admixtures that in-clude pozzolans for low permeability and accelerators for rapid strength de-velopment.

Final set time of each grout was deter-mined according to ASTM C 807-75.

Grout compositions

Structural grout compositions combine two or more admixtures to furnish de-sired properties such as flowability, volume stability, rapid strength devel-opment and low permeability.' The grout compositions designed for this study are given in Table 4, and include

Table 3 - Chemical and

physical properties*

October 1993

Test procedure

All grout compositions were precondi-tioned to the laboratory temperature of 22

±

2 C (72±

4 F), and relative hu-midity of 50 percent for at least 24 hours prior to testing. A mixer of lO l (2.6 gal) capacity was used to blend each 5 kg (11 1b) grout composition for4 minutes. The following properties were determined using standard test methods:Flow characteristics

The consistency of each grout was de-termined by measuring the time of ef-flux through a flow cone according to the CRD-C6ll-80 specification.

Table 2 - Chemical and

physical properties•

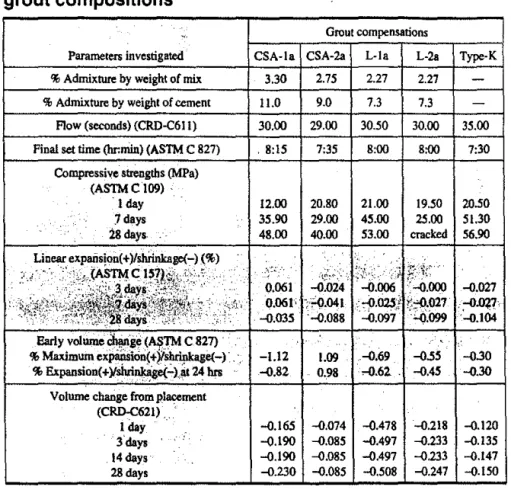

Table 4 - Mix proportions for grout compositions by

weight of mix

Table 5 -

Fresh and hardened properties of low dosage

grout compositions

Parameters investigated

% Admixture by weight of mix % Admixture by weight of cement

Flow (seconds} (CRD-C611}

Final set time (hr:min) (ASTM C 827}

Compressive strengths (MPa) (ASTM C 109} ·

·1 day }days

28 days

Linear expansion( +)/shrinkage(-}(%}

I

Z[ゥ[HGBセG[ヲセセセ。セ[セセセAセGZNAセ@

...

A •.Early volume セァ・@ Hセtm@

c

827) · .··%Maximum ・クー。ゥゥウゥッョHKェゥセ。ァ・HMス@ ·. ·

% Expansion(+)lsluink8ge(-}.11124 brs

Volume change from ーャセュ・ョエ@

(CRD-C621} .. ' I

day

.

3'days 14 days 28 days CSA-la 3.30 11.0 30.00 . 8:15 12.00 35.90 48.00 ';-'. 0.061 0.06F -0.035 -1.12 -0.82 -0.165 -0.190 -0.190 -0.2.30 Grout compensationsCSA-2a L-Ia L-2a Type-K

2.75 2.27 2.27 9.0 7.3 7.3 29.00 30.50 30.00 35.00 7:35 8:00 8:00 7:30 20.80 21.00 19.50 20.50 29.00 45.00 25.00 51.30 40.00 53.00 cracked 56.90 ·'t:;':•·:· ·, セMNゥNGMZGMZᄋN@ :-:} fNZᄋᄋセエセᄋᄋᄋ@ -0.024 -0.006

:..o.ooo

-0.027 ·;·:'0.041.,_ ,-p.025}

セZGHINPRW@ -O,Op '-0,088 -0.097 '-0.099 '-0.104 1.09 .-0.69 .-0.55. . -0.30 0.98 ,..0.62. . -0.45 -0.30 . -0.074 -0.478 -0.218 -0.120 -0.085 -0.497 -0.233 -0.135 -0.085 -0.497 -0.2.33 -0.147 -0.085 -0.508 -0.247 -0.150Table 6 -

Fresh and hardened properties of high dosage

grout compositions

Grout compensations

Parameters investigated CSA-lb CSA-2b L-Ib L-2b Type-K

% Admixture by weight of mix 3.83 3.67 2.75 2.75

-% Admixture by weight of cement 13.0 12.4 9.4 9.4

-Flow (seconds} (CRD-C611} 28.00 28.00 26.50 31.00 35.00

Final set time (hr:min} (ASTM C 827} 8:00 8:00 8:00 8:00 7:30

Compressive strengths (MPa)

(ASTMC 109)

I day 13.00 22.00 18.00 22.00 20.50

7days 40.00 41.00 42.00 cracked 51.30

28 days 50.00 43.00 53.00 cracked 56.90

Linear expansion(+ }!shrinkage(-) (%) (ASTMC 157)

. 3 day• 0.097 -o.019 -0.012 -0.019 -o.027

7days 0.086 -0.030 -o.ooi -o.002 -o.027

28 days -0.051 -0.068 -0.024 -0.006 -0.104

Early volume change (ASTM C 827)

%Maximum expansion(+}lsbrinkage(-} -0.67 1.11 -o.91 -o.87 -0.30

% Expansion(+ )/shrinkage(-} at 24 hrs -0.38 0.87 -0.80 -o.69 -0.30

Volume change from placement (CRD-C621) I day -o.082 -0.037 -0.007 -0.512 -0.120 3 days -o.075 -0.059 -0.010 -0.520 -0.135 14 days -0.120 -0.061 -0.015 -0.521 -0.147 28 days :.0.125

-o.on

-0.023 -0537 -0.150 40 Compressive strengthCompressive strength was determined at 1, 7. and 28 days using 2 in. cubes ac-cording to ASTM C 109-80. Four spec-imens were cast for each age. The cubes were de molded after 24 hours and moist cured at 22 C (72 F) and 100 percent rel-ative humidity until they reached there-quired age for testing.

Length and volume changes Expansion and shrinkage characteristics were determined using three different test methods:

• Linear expansion of hardened mortar ASTM C 157 (modified): mortar bars

of dimensions 25 x 25 x 250 mm (I x 1

x 10 in.) were cured in !heir molds for 24 hours at 22 C (72 F) and I 00 percent relative humidity, then demolded, mea-sured and coated with a curing mem-brane Io simulate field conditions. The

specimens were cured at 22 C (72 F) and

50 percent relative humidity for the re-maining time. This method correlates more closely with grout curing in the field than does Ihe unmodified method, where the specimens are cured in lime water for 28 days. Length change mea-surements were taken at 3, 7. and 28 days, and percent expansion/shrinkage values were based on the values recorded at 24 hours.

• Early volume change. Light Projec-tion Method (ASTM C 827): Initial volume change measurements were made within 3 minutes after completion of the mix cycle. The changes (expan-sion or shrinkage) were recorded for 24 hours, while curing at 22 C (72 F) and 50 percent relative humidity, and

ex-pressed as a percentage of the initial reading. This test method is particularly applicable to grouting, where the ob-jective is to completely fill a cavity or

other defined space with a plastic mix-ture that will continue to fill the same space after hardening.

• Volume Change of Hardened Grout (CRD C 621 ): The various grout com-positions were placed in special cylin-drical75 x 150 mm (3 x 6 in.) molds and cured at 22-23 C (72-73 F) and 50 per-cent relative humidity. The initial reading was taken under restrained con-ditions 4 hours after final set. Measure-ments were !hen taken at 1, 3, 14, and 28 days after final set, according Io the above specifications, and expressed as a percentage of the initial reading. Since

.t ;< 'i' Comprenlve Strength (MPa) 60.00

CSA·1 CSA·2 l·1 l·2 TYPE·K

"

E X p A N s I 0 NAdmixture CSA·I CSA-2 l·l l·2 TYPE· K

Admixture

Fig. 2 - Comparison of 28 day compressive strength for mortar containing low and high dosages of expansive ad· mixtures vs. Type K cement.

Fig. 4 - Comparison of 28 day linear expansion produced by low and high dosages of expansive admixtures vs. Type K cement. 0.1 - C S A · t 0.08 0.06

"

0Jl4 E"

'

X O.Q2 X p 0 A N ·0.02 p A 30 N s s I ·0Jl4 0 ·0.06 N I 0 N....

...

,

(a) 0.1 0.08 0.06 OD4 0.02 0 ·0.02 ·0.04 -0.06 -0.08...

,

$ 1;- .... LセMAゥMNLQU@ 30 • • I TIME (DAYS) - "-

... .

...

:..:

:

... .

...

'·,

(b)Fig. 3 - Linear expansion vs. time for (a) low dosage and (b) high dosage of ex· pansive admixtures vs. Type K cement.

the grout is contained inside a steel cylinder and covered by a glass plate, which prevents evaporation of any water from the grout, this procedure does not simulate field curing of grouts. With regard to accelerated curing, 2 in. (50 mm) cubes were subjected to a high-temperature-water bath (33 C [92 F]) accelerated curing 24 hours after casting to detennine potential expansive cracking at later ages.

Results and discussion

The average values obtained from the various tests are presented in Tables 5 and 6. An analysis of the results ob-tained during the investigation are as follows:

Flow characteristics

Efflux time measured for the different grout compositions ranged from 28 to 35 seconds. No bleeding was observed in any of the compositions tested. The longest flow time was that of the

com-October 1993

position containing Type K cement, and from an ease-of-placement perspective the compositions containing expansive admixtures were more effective at main-taining flow characteristics than those containing Type K cement.

Final set time

Set time values for the two types of ad-mixtures and the Type K cement ranged from 71

/, to 9 hours. While the

differ-ences in the set times are not significant with respect to the performance of the grout, it is evident that all admixtures, with the exception of CSA-2 at the lower dosage, were retarding in com-parison to Type K cement.

Compressive strength

The 28 day strength values obtained from specimens of all compositions tested are compared in Fig. 2. Grouts formulated with Type K cement had the highest 28-day strengths of all those tested. Although the increase in admix-ture dosage had little effect on the

28-day strengths of the grout samples, a comparison of the 7 day strength values of CSA-1/a and CSA-2/a samples with those ofCSA-1/b and CSA-2/b (Tables 5 and 6) suggests that the increased ad-mixture dosage had an accelerating ef-fect on the rate of strength development. A similar comparison of the L-Ila and L-1/b samples indicates that the in-creased dosage of L-1 retarded the ini-tial strength development. Samples con-taining the L-2 admixture, in both low and high dosages, displayed cracks be-fore completion ofthe 28-day moist cure, demonstrating that they are prone to cracking when moist curing is ex-tended beyond a 7-day period.

Length and volume change

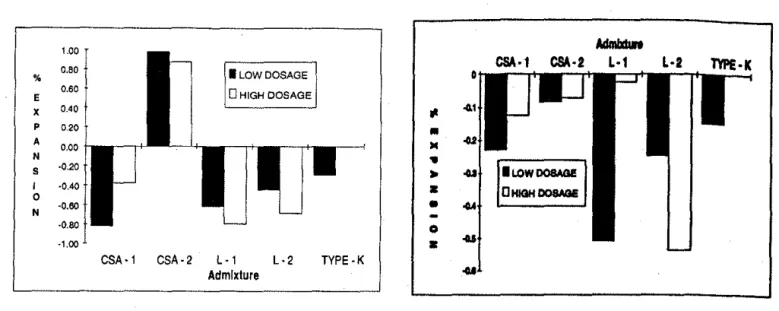

• Length change of hardened cement mortar and concrete (ASTM C 157, modified): The results, plotted in Fig. 3, represent linear length changes in the hardened state for unrestrained bars. Most of the expansion appeared to have been produced at early ages. Subse-quently, on exposure to lower relative humidity levels, as in air curing, a gradual decrease in the amount of ex-pansion occurred with time. The degree of final shrinkage compensation de-pended on the extent of expansion achieved in the initial moist curing pe-riod and on the rate of shrinkage soon after demolding. Therefore, extended moist curing of the grouts containing these admixtures is important to achieve desired expansion. However, as was seen with the L-2 compressive strength samples, prolonged moist curing of grouts employing lime based expansive admixtures can cause degradative ex-pansion.Compositions containing expansive admixtures reduced linear shrinkage 41

1"-·· 1.0 l ... . 'lloo.a: セ@

:

セ[@

O.olセ@

" p A 02 N°

'1 2 3 4 li 6 '1 8 h"lme,h s ..0.2 '-... I ..0.4 セ@ ' " - • · · - - - · · · - - · · 0 .0.8 ... _ _ _ N セ@.•

'\. •1.0-" -(a)'·'

セOᄋᄋᄋᄋᄋ@

... .

"" o.s ; e o.a X 0.4 p0.2!

セ@ 0 '" 1 2 3 4 5 6 7 8 241lrne,h -(1.2 ... セ@ s ... ___ ,. _____ ,. ... .. I -().4セ@ セZZセMO@

·1.0 (b)Fig. 5 - Early volume change vs. time for (a) low dosage and (b) high dosage of expansive admixtures vs. Type K cement.

more than compositions incorporating Type K cement, with the CSA-1 ad-mixture being the most effective at both dosage levels. All compositions using. the lower dosage of admixture exhibited overall shrinkage after 28 days. At the higher dosage, however, both CSA-1 and L-2 produced overall expansion after 28 days. A comparison of the 28 day linear expansion/shrinkage of the low and high admixture dosage mixes is provided in Fig. 4. Increasing the dosage reduced the 28 day shrinkage for all the expansive admixtures, although the reduction observed in CSA-2 was not as dramatic as the others.

A comparison of the slopes of the curves in Fig.s 3(a) and 3(b) shows that the slopes of the curves in Fig. 3(b) are much less than those in Fig. 3(a), yet, the initial readings at the 3 day point are not very different. This suggests that the increased dosage was more effective at reducing the rate of shrinkage following the 3 day point than at reducing the early (up to 3 days) shrinkage. The rate of shrinkage following the third day of curing was reduced from an average of 0.035 percent per day ("a", lower dosage) to an average of 0.006 percent per day ("b", higher dosage) for all the

expansive admixtures.

• Early volume change (ASTM-C827): The results obtained for plastic expan-sion/shrinkage are plotted in Fig. 5. The greatest volume change occurred within the first 2 hours when the mixes were most plastic. Grouts containing CSA-2 adntixture showed a large early volume expansion at both dosages, while all the other compositions revealed early volume shrinkage. Grouts using all other expansive admixtures, at both dosage levels, exhibited a higher early volume shrinkage than Type K cement. However, at the higher 、ッセ。ァ・L@ the 24

42

hour early volume change for CSA-1 was close to that of Type K.

Increasing the dosage of the lime-based admixtures had an unfavorable ef-fect on early volume shrinkage, as can be seen from Fig. 6, in which the shrinkage increased from 0.62 percent to 0.80 percent and from 0.45 to 0.7 per-cent for grouts containing L-1 and L-2 admixtures, respectively. A slight re-duction (0.11 percent) of the expansion was also noted for grouts having a high dosage of CSA-2 admixture.

• Volume change of hardened grout (CRD-C621 ): The results for restrained expansion/shrinkage after final set are plotted in Fig. 7, with time equal to 0 representing fmal set. All samples ex-hibited shrinkage under this test method, with most of the shrinkage oc-curring in the first 24 hours followed by a very gradual, almost linear, volume re-duction for the remainder of the curing period. At the lower dosage, only CSA-2 samples exhibited less shrinkage than those containing Type K cement, and was the most effective. At the higher dosage, all the grouts using admixtures, except for those using L-2, showed less shrinkage than grouts using Type K ce-ment. Fig. 8 reveals that the increased dosage of L-2 caused an increase in the amount of shrinkage after 28 days, how-ever, the L-1 admixture showed a sub-stantial decrease in shrinkage with in-creased dosage, and was the most ef-fective at reducing restrained hardened shrinkage at the higher dosage.

With regard to accelerated curing: While no cracking was observed in the compositions containing calcium sul-foaluminate admixtures or Type K ce-ment, high temperature, moist curing produced visible cracks in both lime-based compositions at both dosages (Fig. 9). L-1 developed cracks 8 weeks earlier than L-2 under accelerated moist

curing, while as mentioned previously, L-2 compressive strength samples demonstrated visible cracking after 28 days of normal moist curing. Thus, none of the lime-based admixtures was stable during accelerated curing.

Conclusions

• It is possible to achieve similar shrinkage compensation, without ad-verse effects on strength and other prop-erties, by substituting portland cement

containing expansive admixtures in

place of Type K cement.

• Increased dosages of both types of ex-pansive admixtures provided greater shrinkage compensation than Type K cement. Hence, higher dosages of these admixtures can be used in grouts to offset the reduced expansion that results when these grouts are employed in drastic environmental conditions. • The calcium sulfoaluminate-based ad-mixtures performed better than the lime-based admixtures in reducing shrinkage of the grouts in both fresh and hardened states at low and high dosages. • Results from accelerated curing indi-cate that CSA admixtures are stable under accelerated moist curing, but the potential for cracking exists when using lime-based admixtures under hot, humid weather conditions.

• Based on the volumetric change re-sults of the grouts (both in the plastic and hardened states) incorporating dif-ferent expansive admixtures, the accel-erated curing results, and the effect the admixtures had on other grout proper-ties, CSA-2 was found to be the most effective expansive admixture tested. • The overall order of expansive ad-mixture effectiveness, based on the re-sults obtained in this study, was CSA-2 better than CSA-1 better than Type K better than L-1 better than L-2.

References

1. Hoff, G. "Practical Applications of eクー。ョセ@

sive Cements,'' CTIAC Report 8, U.S. Anny eョセ@

gineer Waterways Experiment Station, Vicksburg, Mississippi, 1972.

2. ''Expansive Admixtures For Use in Concrete Mortar and Grout,'' SAA Mp 20-3, Standards aウセ@

sociation of Australia, 1977,

3. Moyer, W., Jr., and Johanson, S. R., U.S. patent assigned to Raychem Corp., 1980.

4. Matusumoto, S., ''Expansive Additive For Cement,'' CEER, May 1970.

usly, pies

er

28none

able dar ad- ·op-1ent; in

ex-tter eK tese ; to ·Jlts in ad- ne-1ge 1ed 1 di-ble the ing ot, セᄋ・ᆳ セゥ」@ if-el-he

.!f->St d- e-·2 Kn-,_

g, te ;, 1.00 0.80 I LOW DOSAGE % 0.60 0 HIGH DOSAGE E X 0.40 セ@ p 0.20..

A 0.00..

N..

s ·0.20,.

I -0.40•

0•

N ·0.60 ·0.80 0 -1.00•

CSA·1 CSA·2 L·1 L·2 TYPE ·K

Admixture

Fig. 6 -Comparison of 24-hour early volume change using low and high dosages of expansive admixtures vs. Type K cement.

Fig. 8 - Comparison of 28 day hardened volume change using low and high dosages of expansive admixtures vs. Type K cement. timセ@ (DAY$) % ッイMMKMMセセセセセセセ@ s

...

5 1 0 1 ! ! 2 0 2 5-

... .

H ·0.1 30 TIME (OAYS) 0 -セ@ ·- .. 5 •••• QNP⦅ZZMNセ@..

ZZセMセMセZZ@ 30 R'·-·---·-·-·

-csA-1 H -0.1 ... _. · - · - · - · - · セ@ .0.2 N セ@ .(),21 K ·0 I ----csA-2 - - L·1 A • I - - L·2 K ·0.3 A a .04 I -·-TYPE·K G ·0.4 E . I'

NHIセ@ セMMMMMMMMMMMMM E <.5 ' -(a) ·0.6 (b)Fig. 7 - Hardened volume change vs. time for (a) low dosages and (b) high dosages of expansive admixtures vs. Type K cement.

5. Mailvaganam, N. P., "Miscellaneous Ad-mixtures,'' Concrete Admixtures Handbook, V.

S. Ramachandran, Editor, Noyes Data

Publica-tions, pp 500-505, 1985.

I Research for Con-struction Products Research, Inc., in the United States,

Noel P. Mailva· ganam was

previ-ously Head of the Polymer Products

Group with the Materials Laboratory at the Canadian National Research Council's Institute for Research in Con-struction. He is also former Chairman of the GSA Committee on Admixtures and a member, as well, of other GSA, ACI, and RILEM committees. He has co-au-thored two books on admixtures and edited a book on repair and protection of concrete structures.

October 1993

6. Bayasi, Ziad, and Abifaher, Rabih, ''Prop-erties of Shrinkage Compensating-Silica Fume Concrete Made With Type K Cement" Concrete

International, V. 14, No.4, Aprill992, pp 35-37.

7. Cohen, M.D., Olek, J., Mather, B., "Silica Fume Improves Expansive-Cement Concretes,''

Concrete International, V. 13, No.3, March 1991,

pp 31-37.

8. Xie, P., and Beaudoin, J.J., "Sulphate

Ex-pansion, II Validation of Thermodynamic

from York Univer-sity, Stacey Nunes

is currently em-ployed as a Tech· nical Officer with the Materials Labo-ratory of the Cana-dian National

Re-search Council's Institute for RA!'A"rr.h in Construction. His work centers on the investigation of creep, shrinkage and fa-tigue behavior of structural grout and patching materials.

Fig. 9 - Visible cracking in lime based admixture samples exposed to accelerated curing conditions.

Theory,'' Cement and Concrete Research, V. 22,

!992, pp 845-854.

9. Sheik, S. A.; Fu, Yan; and O'Neill, W. M.,

"Expansive Cement Concrete For Drilled Shafts,'' Submitted to ACI Materials Journal.

10. Denka CSA, Manual, Data Edition.,

D.K.K.K.K. Company, Tokyo, Japan, 1982.

11. ''Onoda Expansive Additive for Prevention of Shrinkage Cracks," Technical Literature,

Onoda Cement Company, Tokyo, Japan, 1972. Received and reviewed under Institute publica-tion policies.

Raj Bhagrath is the

Group Leader of the Cement Prod-ucts Division of Stern son Ltd., Rn,ntfnnci. Ontario. p I

from the Universitv of Liverpool,

currently involved in the de•vei<Jorner1t structural grout and repair products.