Publisher’s version / Version de l'éditeur:

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

Fire Study (National Research Council of Canada. Division of Building Research),

1969-06-01

READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE. https://nrc-publications.canada.ca/eng/copyright

NRC Publications Archive Record / Notice des Archives des publications du CNRC : https://nrc-publications.canada.ca/eng/view/object/?id=11a74f9f-4faf-4e68-8bfe-3a170e859dcb https://publications-cnrc.canada.ca/fra/voir/objet/?id=11a74f9f-4faf-4e68-8bfe-3a170e859dcb

NRC Publications Archive

Archives des publications du CNRC

For the publisher’s version, please access the DOI link below./ Pour consulter la version de l’éditeur, utilisez le lien DOI ci-dessous.

https://doi.org/10.4224/40001361

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at

Comparison of flame-spread ratings by radiant panel tunnel furnace

and Pittsburgh Corning apparatus

NATIONAL RESEARCH COUNCIL OF CANADA DIVISION OF BUILDING RESEARCH

COMPARISON OF FLAME -SPREAD RATINGS BY RADIANT PANEL, TUNNEL FURNACE,

AND PITTSBURGH CORNING APPARATUS

by A. R o s e F i r e Study No. 22 of the D i v i s i o n of Building R e s e a r c h Ottawa June 1969

COMPARISON O F FLAME -SPREAD RATINGS B Y RADIANT PANEL, TUNNEL FURNACE,

AND PITTSBURGH CORNING APPARATUS

A. Rose

T h e s t a n d a r d North A m e r i c a n f l a m e - s p r e a d t e s t s of building m a t e r i a l s a r e those s e t f o r t h in ASTM Methods E 84 ( I ) , the s t a n d a r d tunnel t e s t ; E 162 ( 2 ) , the radiant panel t e s t ; and E 286 ( 3 ) , the

8-foot tunnel t e s t . T h e s e t e s t s r e q u i r e expensive and complex

equipment and techniques of calibration, and through the y e a r s e f f o r t s have been m a d e t o devise s i m p l e , inexpensive equipment that would give r e s u l t s c o m p a r a b l e t o those obtained with the t h r e e m a j o r methods.

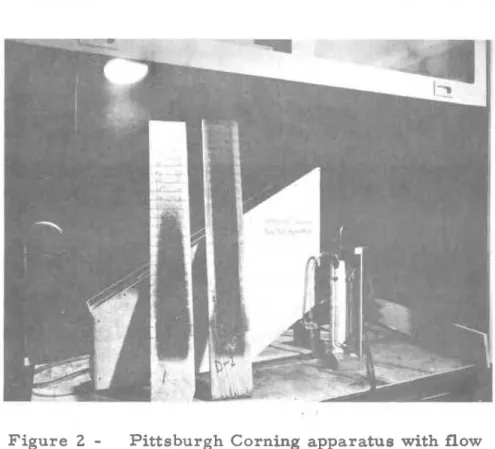

Among the m o r e r e c e n t developments, the a p p a r a t u s that s e e m e d t o have the g r e a t e s t potential w a s t h a t introduced i n 1966 by M. M. Levy of P i t t s b u r g h Corning (4). T h i s simple f l a m e

-

s p r e a d testing device, called the "30/30 apparatus" because of the s i z e of s a m p l e and the slope of i t s supports ( F i g u r e s 1 , 2 , 3 ) , evolved during development w o r k on foamed p l a s t i c s f o r the Company, but w a s thought t o have wider application i n the field of building m a t e r i a l s .In the f i r s t phase of t h i s work, i t was possible only t o c o m p a r e f l a m e - s p r e a d r a t i n g s obtained with the 30/30 a p p a r a t u s with those f r o m the r a d i a n t panel method a s t h e s e w e r e the two m e a n s available a t t h e

DBR/NRC. R e s u l t s of t e s t s on a few m a t e r i a l s that had been t e s t e d in

E 8 4 tunnel f u r n a c e s a t U n d e r w r i t e r s ' L a b o r a t o r i e s of Canada

(Scarborough) a s well a s on s o m e that had been r u n in the 8-foot tunnel f u r n a c e (3) at the F o r e s t P r o d u c t s L a b o r a t o r y (Ottawa), became available during t h i s stage of the work. T h e s e a r e included, with p e r m i s s i o n , in the r e s u l t s given i n Table I.

In spite of s o m e s e r i o u s d i s p a r i t i e s between r a d i a n t panel and 30/30 r e s u l t s , the usefulness of the l a t t e r a p p a r a t u s w a s sufficiently d e m o n s t r a t e d t o justify f u r t h e r work when the 25-foot tunnel f u r n a c e w a s i n s t a l l e d a t the NRC F i r e R e s e a r c h Section in November 1967. As m a n y a s possible of the original o r closely s i m i l a r m a t e r i a l s w e r e rechecked by a l l t h r e e m e t h o d s in the second phase of the study.

OTHER OBJECTIVES

Although the p r i m a r y purpose of this study w a s a c o m p a r i s o n of f l a m e - s p r e a d r a t i n g s by the t h r e e m e t h o d s in question, i t was a l s o c a r r i e d out t o build up a backlog of information using the 25-foot

tunnel f u r n a c e method on Canadian building m a t e r i a l s with f l a m e - s p r e a d r a t i n g s i n the 35 t o 200 range. Only a few lining m a t e r i a l s i n this r a n g e a r e l i s t e d i n the "Building Construction" section of the "List of M a t e r i a l s and Equipment" published by U n d e r w r i t e r s ' L a b o r a t o r i e s of Canada. The f l a m e

-

s p r e a d classification l i m i t s e s t a b l i s h e d f o r v a r i o u s occupancies in the National Building Code (1 965) a r e 25, 75 and 150 (5). An upper l i m i t of 1 50 f o r lining m a t e r i a l s in single -family dwellings i s being c o n s i d e r e d by r e g u l a t o r y bodies and thus the r e s u l t s i n T a b l e s Il and IU f o r wood- f i b r e ceiling t i l e s , h a r d b o a r d s and p a r t i c l e b o a r d s a r e of i n t e r e s t .Information was a l s o r e q u i r e d a s a b a s i s f o r informed selection of m a t e r i a l s f o r the f u l l - s c a l e c o r r i d o r t e s t s being c a r r i e d out by the DBR F i r e R e s e a r c h Section (6). In m a n y of the e a r l i e r c o r r i d o r t e s t s f l a m e - s p r e a d r a t i n g s of b o a r d s t r e a t e d with f i r e - r e t a r d a n t s a l t s o r coatings w e r e r a d i a n t panel v a l u e s and not always i n good a g r e e m e n t with E 84 r a t i n g s established l a t e r .

THE PITTSBURGH CORNING APPARATUS

A s i n the l a r g e - s c a l e tunnel f u r n a c e methods, Levy used suitably conditioned r e d oak a s the "100 standard" and a s b e s t o s - c e m e n t board a s the "zero standardIt i n the 4-minute t e s t . He did not specify any p a r t i c u l a r humidity o r t e m p e r a t u r e range, but i t was a s s u m e d t h a t the conditions w e r e 48 t o 52 p e r cent R.H. and 68 t o 72 deg F. (Typical calculations of f l a m e - s p r e a d r a t i n g s and a r e d oak c a l i b r a t i o n r u n a r e given i n Appendix A.

1

The p r a c t i c a l upper limit of the t e s t i s a f l a m e - s p r e a d rating (FSR) of about 135; although Levy includes r a t i n g s a s high a s 150.

Typical h a r d b o a r d s and p a r t i c l e b o a r d s with r a t i n g s i n t h i s r a n g e produce f l i c k e r i n g f l a m e f r o n t s which a r e difficult to r e a d a s they a p p r o a c h the end of the box. E s t i m a t i o n of the t i m e r e q u i r e d t o r e a c h the 22- o r 23-in. m a r k w a s not found s a t i s f a c t o r y a s a method of establishing r e l a t i v e r a t i n g s

above 140.

B e c a u s e p r o g r e s s of the f l a m e f r o n t i s o b s e r v e d through the

opening i n the u p p e r end of t h e box ( F i g u r e 3), obscuration o r obliteration of t h e 1 -inch-interval m a r k i n g s by heavy smoke o r smoke d e p o s i t s m a y l i m i t the u s e f u l n e s s of the a p p a r a t u s , a s i s often the c a s e when testing p l a s t i c s and painted products. Expedients f o r overcoming t h i s difficulty will be d i s c u s s e d l a t e r .

Although Levy c l a i m e d s a t i s f a c t o r y c o r r e l a t i o n between the values obtained using the 30/30 a p p a r a t u s and those with the E 84 tunnel f u r n a c e , m o s t of h i s E 84 values f o r wood-based m a t e r i a l s w e r e b a s e d on published r a t i n g s r a t h e r than on the r e s u l t s of p a r a l l e l r u n s on m a t c h e d s a m p l e s , and unfortunately s o m e of t h e s e published values a r e open t o question. F o r t h i s r e a s o n the p r e s e n t study w a s designed t o c o v e r a s broad a range of m a t e r i a l s a s possible.

T H E D B R T U N N E L F U R N A C E

The DBR tunnel f u r n a c e ( F i g u r e s 4, 5) w a s patterned a f t e r t h a t i n s t a l l e d a t the r e s e a r c h c e n t r e of the National Gypsum Company at Buffalo, N. Y. Some modifications we r e unavoidable because of s p a t i a l l i m i t a t i o n s and the n e c e s s i t y of connecting the f u r n a c e t o an existing 6000-cfm exhaust fan.

The o r i g i n a l exhaust s y s t e m m a d e m a n u a l control of the d r a f t a t the specified l e v e l v e r y difficult o v e r the 10-minute c o u r s e of the t e s t when the m a t e r i a l s being t e s t e d w e r e of high fuel value, such a s

h a r d b o a r d s and p a r t i c l e b o a r d s . T h i s difficulty, although i t unquestionably reduced the r e l i a b i l i t y of t h e "smoke density" (SD) values i n Table 11-B, is probably not a s g r e a t a s o u r c e of e r r o r in the r e s u l t s l i s t e d under "flame s p r e a d classification1' (FSC) o r "fuel contributed" ( F C ) . Red oak flooring is the "100 standardtt f o r a l l t h r e e values, hence any i n c r e a s e i n the absolute value of the smoke d e n s i t y due to a reduction in tunnel d r a f t and a i r velocity during the c o u r s e of a c a l i b r a t i o n t e s t on oak would be m a t c h e d by a proportionate i n c r e a s e f o r o t h e r m a t e r i a l s .

T h i s difficulty w a s o v e r c o m e by the installation of a 16-inch- d i a m e t e r b a r o m e t r i c d a m p e r between the manually -operated control d a m p e r and the exhaust fan. Control of the d r a f t w a s f u r t h e r improved

by the addition of a pneumatically -controlled d a m p e r between the b a r o m e t r i c d a m p e r and the f a n . T h e s e modifications w e r e m a d e before the t e s t s

r e p o r t e d in Table 111-B w e r e begun. The a v e r a g e absolute value f o r the smoke d e n s i t y f o r r e d oak flooring w a s reduced about 50 p e r c e n t , but the c o m p a r a b l e SD values f o r such m a t e r i a l s a s unfinished $-in. Douglas fir plywood and p a r t i c l e b o a r d R i n T a b l e s 11-B ( s a m p l e s 46 and 47) and 111-B ( s a m p l e 85) a r e i n r e a s o n a b l e a g r e e m e n t .

T h e effect of v a r i a t i o n s in tunnel d r a f t and a i r velocity on SD values h a s been thoroughly covered i n the c o u r s e of smoke obscuration

Standardization with Red Oak and Influence of F u e l Rate

In t h e calibration of the tunnel f u r n a c e with 13/ 16-in. r e d oak flooring, the t i m e in which the f l a m e f r o n t i s r e q u i r e d t o r e a c h the end ( a net advance of 19. 5 f e e t ) i s 5. 5 f 0.25 m i n u t e s . The

t i m e i s d e t e r m i n e d by the attainment of a t e m p e r a t u r e of 980 deg F a t the vent-end thermocouple, which i s located 1 foot f r o m the end of and 1 in. below the sample. With due allowance f o r the variability of the oak and the inevitable e r r o r s in m e a s u r e m e n t , the t i m e s

obtained in the m o s t r e l i a b l e r u n s w e r e found t o be strongly dependent on the g a s feed-rate t o the T e e - b u r n e r . T o k e e p the "red oak time" within the p e r m i s s i b l e r a n g e it i s n e c e s s a r y t o c o n t r o l the fuel input (including t h a t of t h e pilot b u r n e r ) within the l i m i t s 4385 f 35 ~ t u / m i n .

o r 4.362 *O. 035 s t a n d a r d cubic f e e t of n a t u r a l g a s p e r minute a t 1005 Btu p e r s t a n d a r d cubic foot. It w a s n e c e s s a r y to r e p l a c e the o r i g i n a l p r e s s u r e r e g u l a t o r i n the g a s t r a i n with a m o r e p r e c i s e device, and t o u s e a 314-in. needle valve f o r fine adjustment of the g a s r a t e t o compensate f o r changes in b a r o m e t r i c p r e s s u r e .

When the a v e r a g e fuel r a t e during a 1 0-minute t e s t r u n deviated significantly f r o m 438 5 ~ t u / m i n . within the s e l i m i t s , a n "equivalent r e d oak time" w a s used i n calculating f l a m e s p r e a d c l a s s i f i c a t i o n s over 100, t h a t is, w h e r e the f l a m e front r e a c h e d the end of the tunnel i n l e s s than 5.5 m i n u t e s (Appendix B).

In the c a s e of m a t e r i a l s o t h e r than r e d oak, the t i m e t o r e a c h the 25-foot m a r k i s d e t e r m i n e d visually. The difficulty of deciding on the t i m e f o r the f l a m e f r o n t t o r e a c h t h i s point i s i n c r e a s e d by fouling of the windows by smoke in m a n y c a s e s . The r e s e a r c h staff a t the National Gypsum Company suggested the addition of a s m a l l window in the f l o o r of the f u r n a c e just beyond the 25-foot m a r k . In the DBR/NRC f u r n a c e the s e a l e d window w a s inclined s o a s t o sight on the 25-foot m a r k , the s a m p l e s used being actually 2 5 f t 3 in. i n length.

T h i s a r r a n g e m e n t h a s given visual "red oak t i m e s " in excellent a g r e e m e n t with the 980-deg point, and the a g r e e m e n t i s usually good f o r o t h e r unpainted wood-based m a t e r i a l s . Nine of the twenty m a t e r i a l s in Table 11-B with FSC1s of 100 o r higher w e r e run a f t e r the installation of t h i s window.

Ignition T i m e

The ignition t i m e , I T , ( T a b l e s 11-B and III-B) i s not a r e q u i r e d observation in E 84 t e s t s . B e c a u s e of the p a r t i c u l a r window construction

employed in the DBR tunnel f u r n a c e i t i s s o m e t i m e s difficult to d e t e r m i n e . Other tunnel f u r n a c e o p e r a t o r s r e c o r d i t a s an index of e a s e of ignition, and t h i s was done whenever possible in this study.

The ignition t i m e f o r r e d oak flooring in the DBR tunnel f u r n a c e i s 4 5 t o 60 seconds.

THE RADIANT PANEL APPARATUS

The DBR r a d i a n t panel a p p a r a t u s ( F i g u r e s 6,7) h a s been used o v e r the p a s t seven y e a r s i n the evaluation of a wide v a r i e t y of m a t e r i a l s . It h a s been used i n acceptance testing of m a r i n e deck and bulkhead

m a t e r i a l s , a d h e s i v e s and coatings, a s well a s in investigational work f o r f i r e a u t h o r i t i e s w h e r e the s i z e of s a m p l e available was limited. In the c a s e of s o m e p l a s t i c s and synthetic c a r p e t s i t h a s given f l a m e - s p r e a d indexes differing widely f r o m the corresponding E 84 ratings.

A s the construction and operation of the radiant panel a r e d e s c r i b e d i n ASTM E 162, only a d i s c u s s i o n of the method of calculating the t h r e e f l a m e - s p r e a d indexes used in the DBR study will be included in t h i s r e p o r t .

T h e calculation of the s i m p l e a r i t h m e t i c index Isl f o r a s p e c i m e n of fir plywood i s d e m o n s t r a t e d in Appendix C. T h i s index i s the product of a f l a m e - s p r e a d f a c t o r Fs and a heat evolution f a c t o r , Q. Q i s a function of T , the m a x i m u m t e m p e r a t u r e r i s e during the 15-minute t e s t period above t h e b a s e t e m p e r a t u r e r e c o r d e d with a n a s b e s t o s - c e m e n t board in the s a m p l e holder. The t e m p e r a t u r e r i s e i s r e a d by m e a n s of seven thermocouples in p a r a l l e l in the s t a c k above the panel.

The second index, Is,, i s a computer -calculated value based on the s e m i - l o g a r i t h m i c c o r r e c t i o n plot suggested i n Section 8 ( e ) of ASTM E 1 62

-

67. It is designed t o give m o r e reasonable approximations when ignition of thes a m p l e by the acetylene pilot f l a m e i s a b n o r m a l l y rapid o r slow, i. e . , when tg (the t i m e , in m i n u t e s , t o r e a c h the 3-in. m a r k ) i s a b n o r m a l l y high o r low in r e l a t i o n t o t 6 , tg, e t c . , in a plot of d, (the d i s t a n c e t r a v e l e d , in i n c h e s ) a g a i n s t log t. Is, a l s o n o r m a l i z e s the relationship where e r r a t i c

propagation of the f l a m e f r o n t o c c u r s , e. g . , in c a s e s w h e r e rapid flashing p a s t the 3 - , 6 - , o r 9-in. m a r k s i s followed by a m o r e r e g u l a r advance to the 1 2 - and 15-in. m a r k s .

When r a p i d flashing p a s t the 3- o r 6-in. m a r k i s followed by

r e t r o g r e s s i o n and then development of a sustained and n o r m a l l y p r o g r e s s

-

ing f l a m e f r o n t , two independent s e t s of calculations a r e usually m a d e ( s e e s a m p l e s Nos, 48 and 58, Table11-B).

The t h i r d index Is3 w a s designed by G. Williams-Leir of the DBR F i r e R e s e a r c h Section t o put into effect the principle t h a t 'no s p e c i m e n should be given a higher f l a m e - s p r e a d index than it would have had if the f l a m e front had p a s s e d any m a r k e a r l i e r than it actually did. It follows that index 3 cannot be g r e a t e r than index 1; the difference m a y be z e r o and i s usually small. The t h i r d index g i v e s b e t t e r a g r e e m e n t with the E 84 r a t i n g s in the c a s e s of s o m e unfinished cellulosic m a t e r i a l s but among the m a t e r i a l s considered h e r e i t only b e c o m e s significantly lower than the f i r s t index i n the c a s e of s o m e of the m o r e f l a m m a b l e c a r p e t s and p l a s t i c s .

PREPARATION O F MATERIALS AND SAMPLING PLAN

Whenever factory-finished lining m a t e r i a l s could be conveniently obtained f r o m l o c a l s o u r c e s they w e r e included in the p r o g r a m . B o a r d s not f a c t o r y -finished w e r e r o l l e r -coated with c o m m e r c i a l flat, s e m i - g l o s s o r g l o s s alkyd paints a s r e q u i r e d , except in the c a s e of the ceiling t i l e s l i s t e d in Table

III,

w h e r e a light r o l l e r coat of an intumescent l a t e x paint w a s applied.Since two 4 - by 8 - f t panels w e r e r e q u i r e d f o r e a c h tunnel f u r n a c e t e s t , the sampling plan used ( F i g u r e 8) p e r m i t t e d the averaging of the r e s u l t s f o r eight r a d i a n t panel and s i x P i t t s b u r g h Corning s p e c i m e n s of e a c h m a t e r i a l . T h i s s c h e m e could not be followed in the c a s e of c a r p e t s , foamed vinyl wall c w e r i n g ( s a m p l e No. 63), prefinished hardboard siding ( s a m p l e No. 56), and ceiling t i l e s ( s a m p l e s Nos, 8 8 t o 95).

A m i n i m u m of four s p e c i m e n s i s r e q u i r e d f o r the r a d i a n t panel and t h r e e f o r the P i t t s b u r g h Corning t e s t , but w h e r e 4 - by 8-ft panels w e r e used, the n u m b e r was i n c r e a s e d to eight and s i x s p e c i m e n s , respectively. T h i s w a s justified by the variability and e r r a t i c f l a m e f r o n t propagation encountered in the c a s e of m a n y painted b o a r d s in both t e s t s .

All l a b o r a t o r y -painted s a m p l e s w e r e d r i e d thoroughly i n f r e e l y circulating a i r , then conditioned f o r a t l e a s t 30 d a y s , again with good ventilation, before testing. Samples f o r the tunnel f u r n a c e w e r e

conditioned a t 35 t o 40 p e r cent R. H., 73 to 75 deg F, and f o r the o t h e r t e s t s a t 48 t o 52 p e r cent R.H., 68 t o 70 deg F.

DISCUSSION O F RESULTS

The d i v e r s i t y of m a t e r i a l s covered in t h i s study p r e c l u d e s any s i m p l e a n a l y s i s of the r e s u l t s . No t e s t i s capable of producing meaningful

Galues f o r a l l types of m a t e r i a l s , p a r t i c u l a r l y i f carpeting, plastic f o a m s and composite products a r e included.

Because r e d oak l u m b e r o r flooring i s the "1 00 standard" i n a l l t h r e e t e s t methods, i t is t o be expected that a g r e e m e n t among t h e m will be good f o r m o s t unfinished cellulosic products. (In the c a s e of the radiant panel t e s t , r e d oak was used t o e s t a b l i s h the original

p a r a m e t e r s i n the development of the equipment by the National B u r e a u of Standards. It is not a s a t i s f a c t o r y m a t e r i a l for r e c a l i b r a t i o n purposes. An o i l - t e m p e r e d $-in. hardboard with Is = 150 was distributed by NBS a s a secondary standard. When the supply of t h i s board w a s exhausted, a new m a t e r i a l with Is = 20 5 was m a d e available. )

(1 ) Wood-based P r o d u c t s

, F o r unfinished cellulosic products containing inorganic f i r e r e t a r d a n t s ( s a m p l e s Nos. 17, 18, 52, 53) the radiant panel t e s t gives inordinately low r a t i n g s i n relation t o E 84 classifications, while the 30/30 t e s t is the r e v e r s e . The intense radiation a t the top of the sample i n the E 162 t e s t often produces pronounced c h a r r i n g without any m e a s u r a b l e f l a m e s p r e a d i n such c a s e s . The high values obtained in the 30/30 t e s t a r e due i n p a r t t o coloration of the flame by the s a l t s p r e s e n t . This opinion is supported by another Canadian u s e r of the device.

In the c a s e of p a r t i c l e b o a r d sample No. 53, a f u l l - s c a l e c o r r i d o r t e s t

( 6 )

strongly supported the 30/30 and E 84 values.( 2 ) Effects of Coatings

Where conventional low

-

o r s e m i -glos s oil -base paints a r e applied t o wood-based products, the radiant panel indexes a r e alwayssubstantially lower than the r a t i n g s found by the other t e s t s ( s a m p l e s Nos. 44, 49, 51, 65 t o

68,

70, 74, 76, 77, 86). With high-gloss alkyd e n a m e l s , the values a g r e e m u c h b e t t e r f o r b o a r d s over $ in. in thickness ( s a m p l e s Nos. 45, 55, 71). T h i s behaviour d e s e r v e s f u r t h e r comment.It should be emphasized that in the 4-minute 30/30 t e s t , in which 1

a z-in. a s b e s t o s - c e m e n t board i s placed on top of the sample, cellulosic m a t e r i a l s , even those a s thin a s 1/8 in., a r e seldom penetrated by the impingeing b u r n e r flame. In t h e radiant panel t e s t , which continues f o r

1 5 m i n u t e s if not t e r m i n a t e d sooner because the descending f l a m e f r o n t h a s r e a c h e d the 15-in. m a r k , unfinished $-in. b o a r d s a r e usually pene- t r a t e d by the pilot f l a m e well before the end of the t e s t . The upper t h i r d of t h e s a m p l e m a y , i n the c a s e of h a r d b o a r d s and p a r t i c l e b o a r d s , be

a l m o s t totally consumed. The application of a finish, even a coat of g l o s s alkyd enamel, p r e v e n t s t h i s penetration in m a n y c a s e s ( s a m p l e s No. 22, 40, 42).

In the 10-minute tunnel furnace t e s t ,

5-

and 3/8-in. Douglas f i r plywood and hardboards a r e penetrated by the burner flame. Gloss o r semi-gloss alkyd enamels on +-in. plywood lead to a high FSC because the back of the sample becomes involved for some distance along i t s length (samples Nos. 40 t o 42).1

Douglas fir plywood, z-in. o r m o r e in thickness, i s usually not penetrated by the flame and is preferable t o thinner panels a s a substrate f o r evaluating the effects of conventional coatings.

The agreement among the three methods in the case of gloss alkyd enamels on $-in. plywood and particleboard in a few c a s e s (samples Nos. 45, 55) m a y be due to the countervailing effects in the radiant panel t e s t of reflectivity and a b a r r i e r action on the one hand and the easy ignitability and high fuel value of the coating on the other.

G r o s s and Loftus of the National Bureau of Standards prefer $-in. oil-tempered hardboard f o r comparisons of the effects of conventional and f i r e -retardant paints in the radiant panel method (8). Their values f o r

Is,

,

in the case of conventional coatings on )-in. hardboard andplywood, a r e generally in agreement with those obtained in this study

(9).

The m o s t satisfactory agreement among the three methods i s found with factory-finished low-density fibreboard panels and ceiling t i l e s (samples Nos. 57, 58, 87, 88, 92).

(3) Floor Coverings and Foamed P l a s t i c s

The problem of selecting a r e a l i s t i c flame-spread t e s t for floor coverings has become urgent with the introduction in recent y e a r s of highly flammable synthetic carpet m a t e r i a l s . The r e s u l t s in Tables I and 11 emphasize the complexity of the problem.

The r e s u l t s f o r closed-cell polyvinyl chloride foam wall coverings (samples Nos. 28, 63) can be taken a s an example of the disparities to be expected in the plastics field, as emphasized recently by Collishaw (1 0). Results of a full-scale c o r r i d o r t e s t

and a "corner-wall" t e s t c a r r i e d out by J. H. McGuire of the DBR/NRC F i r e Research Section supported the 30/30 and E 84 t e s t s a s being the m o r e realistic for the

P V C

foam m a t e r i a l .It should be pointed out in f a i r n e s s to the E 162 and 30/30 t e s t s , particularly in the case of PVC foam m a t e r i a l and of some c a r p e t s , that the r a t e of advance of the flame front in the tunnel furnace m a y be very high f o r brief intervals even though the flame fails t o r e a c h the 25-foot mark. This r a t e i s not taken into consideration, except a s p a r t of the

r e c o r d of t e s t , in ratings below 100, but m a y be a useful m e a s u r e of flash hazard.

CONCLUSIONS AND RECOMMENDATIONS (1) The P i t t s b u r g h Corning Apparatus

In a g r e a t m a n y c a s e s involving unfinished l u m b e r and plywood, other wood products coated with conventional paints, factory -finished f i b r e b o a r d ceiling t i l e s , and s o m e carpeting, t h i s device gives r a t i n g s which f a l l between those obtained in the other two t e s t s . In the c a s e of wood products in g e n e r a l , t e s t s using t h i s apparatus tend to n a r r o w the

range of f l a m e - s p r e a d ratings vis-2-vis the tunnel furnace and t o group the FSR values around the 100 m a r k .

Some of t h e difficulties encountered with m a t e r i a l s emitting heavy smoke have a l r e a d y been suggested. A number of expedients w e r e used t o m i n i m i z e t h i s problem, e. g., the i n s e r t i o n of s t a p l e s o r metal-headed m a p pins a t the 1-in. m a r k s f o r c a r p e t s and p l a s t i c s , heavy incising of the l i n e s on painted hardboards, o r punching of an identifying a r r a y of points along t h e s e lines.

The estimation of f l a m e f r o n t advance in the c a s e of v e r y glossy s u r f a c e s o r those of low FSR was improved by the mounting of a 6-watt l a m p and a s m a l l m i r r o r i n the t r i a n g u l a r vent a t the exhaust end of the box ( F i g u r e 1).

The m o s t logical solution t o the p r o b l e m of smoky m a t e r i a l s , g l o s s y o r textured s u r f a c e s , o r low f l a m e - s p r e a d s followed by rapid r e t r o g r e s s i o n , is the installation of a suitably m a r k e d h e a t - r e s i s t a n t window below the s a m p l e support. T h i s is the principal f e a t u r e of the m o r e sophisticated and expensive Monsanto 2-ft tunnel (1 1). To

facilitate reading of f l a m e t r a v e l a n d t o i n c r e a s e p r e c i s i o n i n the range of 2 5 t o 75, t h i s a p p a r a t u s h a s been extensively modified by the Abitibi R e s e a r c h C e n t r e and t h e Ontario R e s e a r c h Foundation, both a t Sheridan P a r k , Ontario.

Lengthening of the P i t t s b u r g h Corning a p p a r a t u s t o p e r m i t e s t i m a t i o n of FSR1s o v e r 1 50 might l e a d t o difficulties with m a t e r i a l s of low f l a m e - s p r e a d , but adding a suitable window might solve t h i s and other p r o b l e m s , and will be t r i e d l a t e r .

( 2 ) The E 84 Tunnel F u r n a c e

Although modifications and improvements i n the design and operation have been c a r r i e d out during the c o u r s e of the p r e s e n t study, t h e r e have been no r e a l opportunities t o c o m p a r e r e s u l t s f r o m the DBR f u r n a c e with those f r o m other installations with the exception of t h r e e types of carpeting and two o t h e r m a t e r i a l s . No c l a i m s f o r the validity of the r e s u l t s of t h i s study (Table

U)

will be m a d e until t h e proposedround-robin t e s t p r o g r a m involving eight other tunnels has been completed and analysed.

It

is hoped t h a t t h i s can be done by l a t e October 1969.In anticipation of t h i s p r o g r a m s o m e m i n o r modifications, p a r t i c u l a r l y i n the smoke m e a s u r i n g installation, a r e to be m a d e a s well a s changes i n the T e e - b u r n e r a s s e m b l y t o produce m o r e s y m m e t r i c a l f l a m e

impingement on the s a m p l e and allow e a s i e r determination of the ignition time.

(3)

The Radiant P a n e l ApparatusAlthough the d i s p a r i t i e s between the r e s u l t s f r o m t e s t s using the r a d i a n t panel and tunnel f u r n a c e on s u c h common m a t e r i a l s a s painted plywood and h a r d b o a r d m a y a p p e a r t o be c a u s e f o r s e r i o u s concern, i t should be emphasized that t h e s e d i s p a r i t i e s a r e not e n t i r e l y due to d i f f e r e n c e s i n the design of the r e s p e c t i v e a p p a r a t u s e s . The calculation of the f l a m e - s p r e a d classification in tunnel f u r n a c e t e s t s where the f l a m e f r o n t d o e s not r e a c h the 25-ft m a r k , o r r e a c h e s i t i n m o r e than

5. 5 but l e s s than 10 m i n u t e s , i s highly a r b i t r a r y and f a r f r o m r a t i o n a l (Appendix B). It i s the r e s u l t of m a n y y e a r s of c o n t r o v e r s y and

c o m p r o m i s e i n ASTM c o m m i t t e e m e e t i n g s . M o r e logical m e t h o d s of

calculation have been suggested which would lead t o m u c h b e t t e r a g r e e m e n t between r a d i a n t panel and tunnel f u r n a c e r a t i n g s in the range 2 5 t o 100 within which f a l l m a n y of the conventionally painted wood products included i n t h i s study.

The e x c e s s i v e l y low o r high f l a m e - s p r e a d indexes obtained in r a d i a n t panel t e s t s on m a n y of the l e s s common m a t e r i a l s will not l i m i t its continuing u s e in acceptance testing of a i r c r a f t and m a r i n e m a t e r i a l s o r o t h e r specialized products. Where l i m i t e d amounts of m a t e r i a l a r e available i n investigational work, the g r e a t e r range of the radiant panel will give it s o m e advantages o v e r the P i t t s b u r g h Corning a p p a r a t u s . As d e m o n s t r a t e d i n t h i s study, however, m a n y of i t s r e s u l t s will be accepted but with r e s e r v a t i o n s .

REFERENCES

ASTM E 84-68. Surface Burning C h a r a c t e r i s t i c s of Building M a t e r i a l s .

ASTM E 162-67. Surface F l a m m a b i l i t y of M a t e r i a l s Using a Radiant E n e r g y Source.

ASTM E 286-65T. S u r f a c e F l a m m a b i l i t y of Building M a t e r i a l s Using a n 8 - f t ( 2 . 4 4 - m ) Tunnel F u r n a c e .

Levy, M.M. A Simplified Method f o r Determining F l a m e Spread. F i r e Technology, Vob.

3,

F e b r u a r y 1967.National Building Code of Canada 1965. P a r t 3, Use and Occupancy, p a r a g r a p h s 3.3.1.1 ( 7 ) , 3.3.4. 5 and 3.4.2.12 (1 ).

M c G u i r e , J.H. The Spread of F i r e i n C o r r i d o r s . F i r e Technology, Vol. 4, M a y 1968.

U n d e r w r i t e r s ' L a b o r a t o r i e s , Inc. Study of Smoke Ratings Developed i n Standard F i r e T e s t s i n Relation t o Visual

Observations. ULI Bulletin of R e s e a r c h No. 56, A p r i l 1965. G r o s s , D. and Loftus, J . J. Surface F l a m m a b i l i t y of F i r e - R e t a r d a n t and Conventional P a i n t A s s e m b l i e s . F i r e R e s e a r c h A b s t r a c t s and Reviews, Vol. 3, 1961.

G r o s s , D. and Loftus, J. J . F l a m e S p r e a d P r o p e r t i e s of

Building F i n i s h M a t e r i a l s . ASTM Bulletin No. 230, May 1958. Collishaw, A. H. F l a m e Spread T e s t s on F o a m P l a s t i c

M a t e r i a l s . Dept. of the A r m y (USA). Technical Report No. 4-71. October 1968.

V a n d e r s a l l , H. L. The Use of a S m a l l F l a m e Tunnel f o r

Evaluating F i r e Hazard. J o u r n a l of P a i n t Technology, Vol. 39, August 1967.

SOME ABBREVIATIONS USED IN TABLES FSC f l a m e s p r e a d classification,

E

84 F C f u e l contributed,E

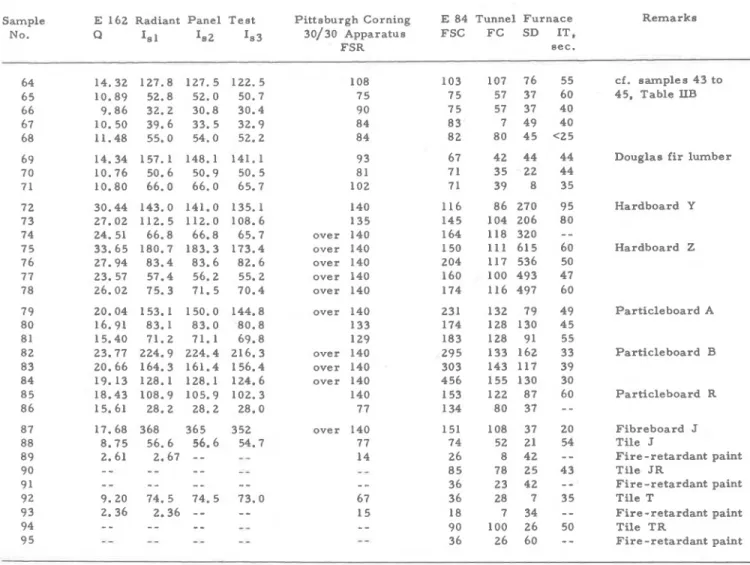

84 SD smoke density, E 84 IT ignition t i m e , E 84 FSR f l a m e s p r e a d rating, P i t t s b u r g h Corning f l a m e s p r e a d f a c t o r , E 162 h e a t evolution f a c t o r , E 162 f l a m e s p r e a d index, E 162T A B L E I

PITTSBURGH CORNING, RADIANT P A N E L AND TUNNEL FURNACE RATINGS ON MISCELLANEOUS MATERIALS S a m p l e No. M a t e r i a l F S R I s P C E 162-67 F S C I s * E 8 4 - 6 7 E 286-65T F i b r e b o a r d A, + - i n . , 14.7 pcf, unfinished F i b r e b o a r d A, ;-in., f a c t o r y finiah ( l a t e x p r i m e r ) rough s u r f a c e F i b r e b o a r d A, )-in., f a c t o r y f i n i s h ( l a t e x p r i m e r ) s m o o t h s u r f a c e o v e r 140 6 5 H a r d b o a r d , t e m p e r e d $-in. 63.3 pcf (NBS 150 etd)

H a r d b o a r d , t e m p e r e d $-in. (softwood pulp). 65.6 pcf

H a r d b o a r d , t e m p e r e d $-in. (softwood pulp), alkyd p r i m e r , 65.6 pcf

H a r d b o a r d eiding A, 0.367-in., 54.1 pcf, unfinished

H a r d b o a r d eiding B, 0.328-in., unfinished H a r d b o a r d siding C, 0.330 -in. , 58.7 pcf, unfinished

H a r d b o a r d siding C , 0.330-in., white alkyd p r i m e r ( f a c t o r y f i n i s h ) H a r d b o a r d siding D, 0.365-in., 59.0 pcf, unfinished H a r d b o a r d eiding Dl 0.350-in., 62.4 pcf. white g l o s s u r e t h a n e f i n i s h H a r d b o a r d siding Dl 0.353-in., 62.6 pcf, o v e r 140 o v e r 140 o v e r 140 131 g r e e n g l o s s u r e t h a n e f i n i s h P a r t i c l e b o a r d A, 0.750-in., 35.5 pcf, a s p e n p o p l a r f l a k e s P a r t i c l e b o a r d R, 0.760-in. , 46.7 pcf, m i x e d h a r d and softwood c h i p s P a r t i c l e b o a r d S, 0.688-in., 40.0 pcf, a s p e d b i r c h f l a k e s P a r t i c l e b o a r d X, 0.438-in.

,

41.4 pcf, b o r a t e f i r e - r e t a r d a n t t r e a t m e n t , a s p e n o v e r 140- -

- -

3 5 ULC* 3 5 F P LDouglas f i r plywood, $-in., f i r e r e t a r d a n t t r e Douglas f i r plywood, $-in., 2 c o a t s

i n t u m e s c e n t f. r . l a t e x paint Q 15-20 ULC

- -

2 5 ULC-

-

S t r a w r o o f b o a r d , 2-in., f i r e r e t a r d a n t c o r e and p a p e r s u r f a c e s M i n e r a l a c o u s t i c t i l e 5/8-in.. 27 pcf, white f a c t o r y f i n i s hDouglas f i r plywood, $-in., sanded Douglas f i r plywood, +-in., sanded Douglas f i r plywood, 3/4-in. , sanded. sapwood f a c e

Douglas f i r plywood, 3/4-in., s a n d e d , heartwood f a c e

- - 34 F P L

20-25 ULC

- -

Arnabilis f i r l u m b e r , 1 -in. Red pine l u m b e r , 1 -in.

Wall c o v e r i n g , P V C f o a m , 0.08-in., 1 5 pcf, c e m e n t e d t o g y p s u m b o a r d C a r p e t . wool, s t a p l e d t o 3/8-in. g y p s u m b o a r d C a r p e t , nylon, s a m e backing C a r p e t , c e l l u l o s e t r i a c e t a t e f i b e r , s a m e backing C a r p e t , polypropylene f i b e r , s a m e backing C a r p e t , a c r y l i c f i b e r , s a m e backing 119 o v e r 140 o v e r 140

: T y p i c a l l i s t i n g s f r o m "List of M a t e r i a l s a n d Equipment," U n d e r w r i t e r s ' L a b o r a t o r i e s of Canada.

S c a r b o r o u g h . Ontario.

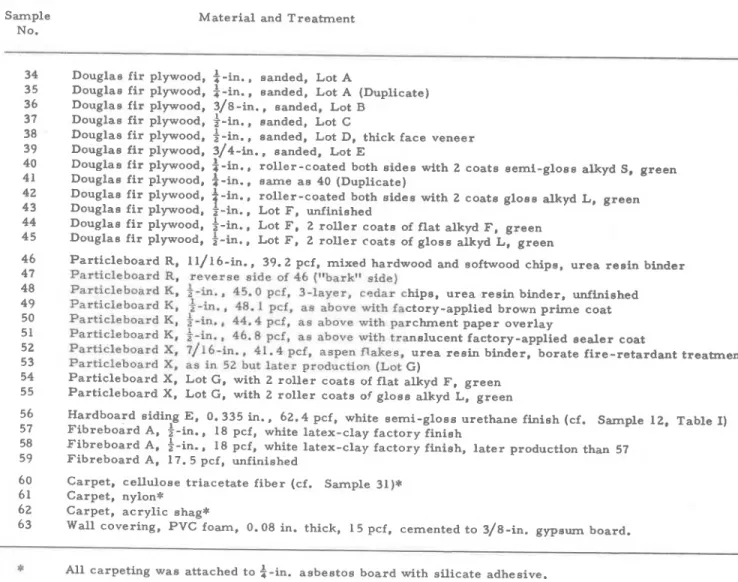

TABLE 1ZA Sample No. 34 3 5 36 3 7 38 39 40 41 42 4 3 44 45 46 47 48 49 50 5 1 52 5 3 54 55 56 57 58 59 60 6 1 62 63

MATERIALS LLST AND TREATMENT

Material and Treatment

Douglas f i r plywood, f -in., sanded, Lot A

Douglas f i r plywood, $-in., sanded, Lot A (Duplicate) Douglas f i r plywood, :/8-in., sanded, Lot B

Douglas f i r plywood, f-in., sanded, Lot C

Douglas f i r plywood, $-in., sanded, Lot D, thick face veneer Douglas f i r plywood, :/4-in., sanded, Lot E

Douglas fir plywood, 3-in., roller-coated both sides with 2 coats semi-gloss alkyd S, green Douglas f i r plywood, 4-in., same a s 40 (Duplicate)

Douglas fir plywood,

1

-in.,

roller -coated both side s with 2 coats gloss alkyd L, green Douglas f i r plywood, f-in., Lot F , unfinishedDouglas f i r plywood, +-in., Lot F, 2 roller coats of flat alkyd F, green Douglas f i r plywood, f-in., Lot F, 2 roller coats of gloss alkyd L, green

Particleboard R, 11/16-in., 39.2 pcf, mixed hardwood and softwood chips, urea r e s i n binder Particleboard R, reverse a i d e of 46 (t'bark'' a i d e )

Particleboard K, $-in., 45.0 pcT, 3-layer, cedar chips, u r e a resin binder, unfinished Particleboard K, *-in.

,

48.1 pcl, as above w i t h factory-applied brown p r i m e coat Particleboard K , $-in., 44.4 pcf, a 8 above w i t h parchment paper overlayParticleboard K, h - i n . , 4 6 . 8 pcf, as above with translucent factory-applied s e a l e r coat

Particleboard X, 7/ 16-h. , 4 1.4 pcf, aspen flakes, u r e a resin binder, borate fire-retardant treatment Particleboard X, as i n 52 but later production (Lot G)

Particleboard X, Lot G, with 2 r o l l e r coats of flat alkyd F, green Particleboard X, Lot G, with 2 roller coats of gloss alkyd L, green

Hardboard siding E , 0.335 in., 62.4 pcf, white semi-gloss urethane finish (cf. Sample 12, Table I) ~ i b r e b o a r d A, )-in., 18 pcf, white latex-clay factory finish

Fibreboard A, f -in., 18 pcf, white latex-clay factory finish. l a t e r production than 57 Fibreboard A, 17.5 pcf, unfinished

Carpet, cellulose triacetate fiber (cf. Sample 31)* Carpet, nylon*

Carpet, acrylic shag*

Wall covering, PVC foam, 0.08 in. thick, 15 pcf, cemented t o 3/8-in. gypsum board.

TABLE LIB

COMPARISON OF FLAME SPREAD TESTS

Sample E 162 Radiant Panel T e s t Pittsburgh Corning E 84 Tunnel Furnace R e m a r k s No. Q Isl IS2 Is3 30/30Apparatus FSC F C SD IT,

FS R sec. over 140 over 140 over 140 over 140

-

- over 140- -

7 7137 126 47 59 f-in. fir plywood 145 119 51 7 0 7-in. f . fir plywood

130 104 72 60 3/8-in, f i r plywood 94 108 47 65 1 .

f-in. fir plywaod

119 121 40 64 $-in. fir plywood 84 7 5 29 47 3/4-in. fir plywood 175 96 60 39 165 92 61 28 211 92 52 2 3 93 93 64 48 ;-in. f i r plywood 73 49 72 34 80 73 79 24 91 96 100 60 158 121 109 60 131 115 75

- -

31 28 14-

-

no flame front 56 35 27- -

no flame front 46 27 0 6 5 67 40 35 4 5 611 4 5 62 30 72 27 132 150 1000 33 - - 7 41 7 1 1 8 <5 cf. Sample 28 F l a s h flame Sustained flameTABLE YUA

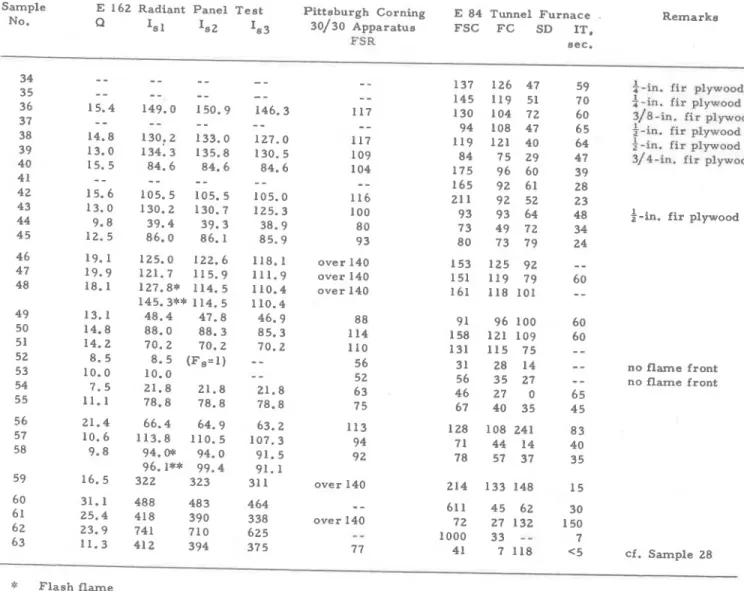

MATEFUALS LIST AND TREATMENT Sample Material and Treatment

No.

64 Douglas f i r plywood, f -in. unfinished

65 Douglas f i r plywood, +-in. plus one coat flat alkyd F, g r e e n 66 Douglas f i r plywood, $-in. plus two coats flat alkyd F , g r e e n 67 Douglas f i r plywood, $-in. plus t h r e e coats flat alkyd F, g r e e n

68 Douglas f i r plywood, $-in. plus one coat flat alkyd F and one coat semi-gloss alkyd D, g r e e n 69* Douglas f i r lumber, nominal 1 x 4 T & G (3/4 x 3 i in. ) Grade C and better

70 Douglas f i r lumber, plus one coat flat alkyd F, g r e e n

7 1 Douglas f i r lumber, plus one coat flat alkyd F and one coat semi-gloss alkyd D, green 72 Hardboard Y, nominal *-in. (0.230 in. ), screenback type, 62.3 pcf, unfinished 73 Hardboard Y, plus one coat flat alkyd F , green

74 Hardboard Y, plus one coat flat alkyd F and one coat gloss alkyd L, green 7 5 Hardboard Z, nominal f -in. (0.218 in. ) screenback, 61.2 pcf, unfinished 76 Hardboard Z, plus one coat flat alkyd F, green

7 7 Hardboard Z, plus two coats flat alkyd F , green

7 8 Hardboard Z, plus one coat flat alkyd F and one coat gloss alkyd L

Particleboard A, 0. 500 in aspen poplar flakes, u r e a r e s i n binder, 36.8 pcf Particleboard A, plus one coat flat alkyd F , green

Particleboard A, plus one coat flat alkyd F and one coat gloss alkyd L , g r e e n Particleboard B, 0.625 in. aspen flakes, phenolic binder, 40.6 pcf

Particleboard B, plus one coat flat alkyd F , green

Particleboard B, plus one coat flat alkyd F and one coat gloss alkyd L, g r e e n

Particleboard R, 0.500 in., mixed hard and softwood chips, u r e a resin, 44.6 pcf ( s e e Sample 46, Table LIB)

Particleboard R, plus two coats flat alkyd F, g r e e n Fibreboard J , nom. 7/16 in. 17.2 pcf, unfinished

Fibreboard ceiling tile J , 12 x 12 x $ in. plain, white decorative finish

Fibreboard ceiling tile J, plus r o l l e r coat of intumescent latex paint Q (300 s q ft/gal) Fibreboard ceiling tile JR, 12 x 12 x $, "Random" acoustic drilling, white decorative finish Fibreboard ceiling tile JR, plus r o l l e r coat of intumescent latex paint Q (300 sq ft/gal) Fibreboard ceiling tile T, 12 x 12 x f in., plain white decorative finish

Fibreboard ceiling tile T, plus r o l l e r coat of intumescent latex paint Q (300 s q ft/gal)

Fibreboard ceiling tile TR, 12 x 12 x $ in. "Random" acoustic drilling, white decorative finish Fibreboard ceiling tile TR, plus r o l l e r coat of intumescent latex paint Q (300 sq ft/gal)

+

Standard substrate f o r testing f i r e retardant paints for i n t e r i o r combustible surfaces.**

All ceiling t i l e s (i. e. Nos. 88 t o 95) w e r e mounted on 3/4 x 1 5/8-in. Douglas f i r framing in accordance with Appendix A1.

,

ASTM E 84-68.TABLE IIIB

COMPARISON OF FLAME SPREAD TESTS

S a m ~ l e E 162 Radiant Panel T e s t Pittsburgh Corning E 84 Tunnel Furnace R e m a r k s

NO. Q Is1 I s 2 I s 3 30/30 Apparatus- FSC FC SD IT,

FSR sec. over over over over over over over over over over cf. s a m p l e s 4 3 to 45. Table IIB Douglas f i r l u m b e r Hardboard Y Hardboard Z P a r t i c l e b o a r d A P a r t i c l e b o a r d B P a r t i c l e b o a r d R F i b r e b o a r d J Tile J F i r e - r e t a r d a n t paint Tile J R F i r e - r e t a r d a n t paint Tile T F i r e - r e t a r d a n t paint Tile T R F i r e - r e t a r d a n t paint

Figure 2

-

Pittsburgh Corning apparatus with flow meter and typical sample.Figure 3

-

Top view of Pittsburgh Corning apparatus showing burner, viewing port, and light.Figure 4

-

DBR tunnel furnace f r o m vent end. A: photocell and lamp assembly f o r smoke measurement; B: instrument panel andcontrols; C: pyrometer for measuring floor temperatures.

Figure 5 Close -up of tunnel furnace. A: cover; B: port f o r measuring a i r velocity.

e Figure

6

-

Radiant panel apparatus.A A: sample and holder;

B: stack,

"4

--_, -- ..--

Figure 7

-

Radiant panel apparatus.A: the radiant panel; I

B: switches for timing I I

PANELS

-

4

'

X

8 '

E 162 SAMPLES

-

6

X

18

I/*"PITTSBURGH CORNING SAMPLES (C)

-

4

5/gW

X

2g5/8"

FIGURE

8

SAMPLING P L A N

APPENDIX A

Calculations f o r the Pittsburgh Corning 30/30 T e s t Samples conditioned a t 48 t o 52 p e r cent

R.H.,

68 to 70 deg F.Propane flow t o F i s h e r 3-902P B u r n e r

-

-

1050 cc/min (90 ~ t u / m i n ) F l a m e spread on $-in. asbestos-cement board: 3 in. (blank)Calibration: Sample No. 38

Time, s e c 3/4-in. kiln-dried

z-in.

I f i r plywood, r e d oak (7.0% M. C. ) LotD

F l a m e Travel, in. 20 40 6 0 80 100 120 140 160 180 200 220 240Avg. max. flame s p r e a d F l a m e No. FSR (by definition) (Coefficient

=

9 7 11 12.5 1 3 14 15. 5 15 16. 5 16.5 18 17.5 18.5 19 18.5 19 19.5 19.5 19 20.5 18 20.5 18.5 20.5 19.0 20.5 16.0 17.5 112 123 Average 117APPENDIX B

1

Calculations f o r E 84 Tunnel T e s t on Sample No. 38, ,-in.

Fir Plywood, Lot D, and o t h e r C a s e s Sample conditioned a t 4070 R. H.

,

73 t o 75 deg FG a s flow r a t e

=

4.399 s c f m=

4408 ~ t u / m i n . , c o r r e c t e d f o r b a r o m e t r i c p r e s s u r eInitial floor temps. : 105 and 95 deg F (14. 5 and 24-ft points) F i n a l floor temps: 340 and 298 deg F. Max t e m p (10-min. m a r k ) :

-1250 deg

F

Ignition time: 64 s e c F l a m e spread: 5 ft a t 1.50 rnin 8 ft a t 1.80 rnin 11 ft a t 2.30 rnin 1 3 f t a t 2. 50 rnin 1 5 ft a t 3.00 rnin 16 ft a t 4.25 rnin Visual end point: 4.50 rnin T i m e t o 980 deg F: 3.88 rninEquivalent r e d oak time: 5.3 5 rnin 53 5 T h e r e f o r e FSC

=

-

=

119 4.50-

F u e l Contributed (75 d e ~ F b a s e line) A r e a under t e m p e r a t u r e c u r v e 32.40 sq in. A r e a , blank fuel c u r v eNet a r e a , $-in. f i r plywood

Net a r e a , r e d oak flooring 14.10

1710

-

121 F C (fuel contributed)=

-

-

14.10

Smoke Densitv A r e a under smoke c u r v e

Blank c o r r e c t i o n (1 0-min. run) 1

Net a r e a , z-in. f i r plywood Net a r e a , r e d oak flooring

3.01 sq in. 0.45

-

2. 56 6.40 2 5 6 SD (smoke density)=

-

= 40 6.40-

Other Cases (flame s ~ r e a d )

(1) F o r m a t e r i a l s on which the flame spreads 19$ ft in m o r e than 5$ but not m o r e than 10 min.

,

the flame -spread classification shall be 100 t i m e s 5Q min. divided by the time, t, that the1

flame spreads 19; f t plus the difference of 100 minus this result, i. e.

,

FSC

=

50+

275/t.(2) F o r m a t e r i a l s on which the flame spreads l e s s than 19$ ft and then c e a s e s t o advance, o r recedes, in a 10-min. t e s t period:

(a) when the extreme flame distance, d, i s m o r e than 13$ f t

and l e s s than 195 ft the classification shall be 100 t i m e s 51 min t i m e s the distance, d, divided by 19; ft t i m e s 10 min.

,

plusi

the difference of 100 minus this result, i. e.,

FSC

=

50+

1.41 d(b) When the extreme flame distance, d, i s 1 3 i ft o r l e s s the classification shall be 100 t i m e s the distance d divided by 194 ft, i.e.

APPENDIX

CCalculations f o r the Radiant Panel T e s t on Sample 38,

-

Specimen 1-D of $-in. Fir Plywood, Lot D.Sample conditioned a t 48 to 52 per cent R. H., 68 t o 70 deg

F.

T i m e s to reach successive 3-in. marks: t3 = 0.732 min.

t,

=

1.191=

1.675 t12=

2.490 tl,=

4.006Maximum temperature attained in stack: 319 deg C

Base temperature with asbestos-cement board: 202 deg C.

Isl =

Fs.Q=

138.1Is, =

143.1Is, =

134.2Averages for four specimens: