Publisher’s version / Version de l'éditeur: Building Practice Note, 1982-12-01

READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE.

https://nrc-publications.canada.ca/eng/copyright

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la

première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

NRC Publications Archive

Archives des publications du CNRC

For the publisher’s version, please access the DOI link below./ Pour consulter la version de l’éditeur, utilisez le lien DOI ci-dessous.

https://doi.org/10.4224/20331391

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at

Low energy Prairie housing : a survey of some essential features

Dumont, R. S.; Orr, H. W.; Lux, M. E.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

NRC Publications Record / Notice d'Archives des publications de CNRC: https://nrc-publications.canada.ca/eng/view/object/?id=f4e1e6d2-63f2-4ea9-9322-b24f965013e6 https://publications-cnrc.canada.ca/fra/voir/objet/?id=f4e1e6d2-63f2-4ea9-9322-b24f965013e6

LOU EUElGX PRAIRIE HOUSIIK

A

Survey of SomeEssential

Featur 8BLDG.

RES,,

t i a n

M Y

n

byI

83-

01-

1

2

ANALYZED

I

Division of Building Research, National Research Council of

CanadaT.Asu EFOEEI;P PRAIRIE B O U S ~ A Survey of Same Essential Feattfreu

R.S. D u m n t , H.W. Orr, H.E. Lux

In response to the r a p t d r i s e in energy prices since 1973, e f f o r t s Rave been d i r e c t e d to reducing energy consumption

in

a l l sectors of the economy. In the houstng sector, one approach which has developed has been the introductf on of houses which incorporate thermal improvements tothe envelope of the structure so as to dramatically reduce the

requirement f o r space heating. The h w s e s have been described by a variety of terms: "low energy hauses"l, ''super-insulated

house^"^,

"energy ef f i d e n t housesh3 or "lo-cal

.

This paper i s a condensation and simplification a!? more d e t a i l e d material found in References 5 , 6 and 8.The term which w i l l b used here i s "low energy houses". The

a d j e c t i v e "super-insulated" is incomplete as l o w energy houses may have a number of addf tional f eaturcs

-

a i r tightness, controiled v e n t i l a t i o n w i t h heat recovery, use of south-facing w i n d w s for s o l a r gain, and highe f f i c i e n c y heating systems

-

which are not encompassed by the adjective "superFnsuLated".The energy conservation features .employed i n most low energy holtses

in the P r a i t i e region have been air tightness, increased thicknesses of insulation, air-to-air heat exchangers and south-facing windows.

A

more d e t a i l e d description of such l a w energy houses i s foundin

Reference 5 .Although several approaches t o air tightness in residences are p o s s i b l e , the most popular method to date

in

the Prairie region has been the use o f polyethylene film as a combined air and vapour barrier.5S p e c i a l care is taken at a l l j o i n t s to ensure continuity of the air barrier. A low-priced butyl-based caulking material known as acoustical sealant has been used to s e a l the polyethylene sheets t o one another. Care is taken to ensure that eaeh j o i n t in the polyethylene is securely f i x e d between r i g i d members. In a d d i t i o n , windcws and doors w i t h

re1:atively good air seals are generally chosen.

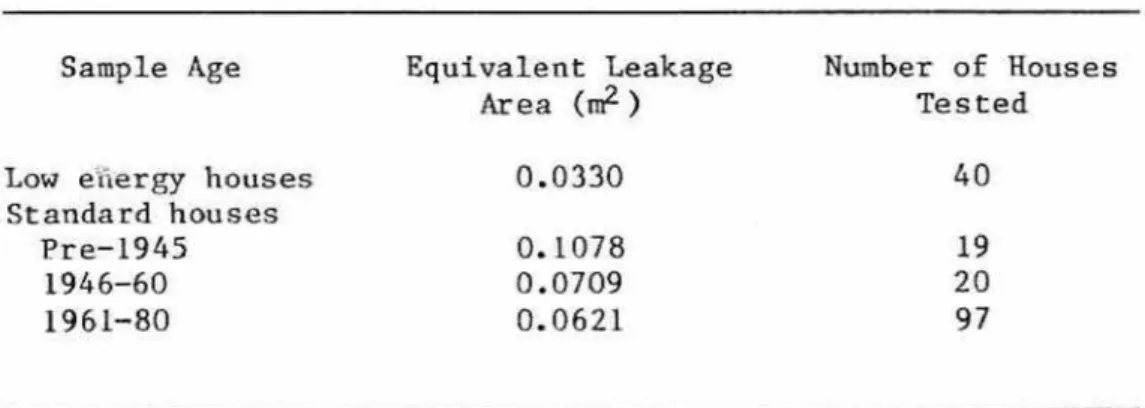

Some 40 law energy houses in Saskatoon, coaetructed using Lhese a i r t i g h t n e s s techniques, have been pressure-tested.6

A

fan was p l a c e d in the doorway of the house, s u b j e c t i n g it to a negative pressure up t o about 100 Pa. The volume f 1- of a i r was recorded, and an equivalent leakage area calculated a c c o r d i n g to the Canadian General Standards Board standard. The results of these pressure t e s t s are reproduced i nTable 1 , along with the results averaged from some standard houses not Incorporating the special air tightness features. The low energy houses had an average equivalent leakage area 47% lower than t h e standard

houses. Because of this, it has generally been found necessary t o provide controlled v e n t i l a t i o n t o maintain a i r q u a l i t y .

With aLr tightness it is possible to utilize an air-to-air heat exchanger; heat From the exhaust a i r stream preheats the i n c o d n g a i r . 8

I n t y p i c a l houses in Western Canada, heat exchangers wlth a design air F l o w capacity in t h e range of 30 t o I00 L/S ( 6 0 to 200 cfm) have been

L n s t a l l e d . T h e r e are several Cartadian manufacturers of domestic air-to- a i r heat e x c h a n g e r s , and a large number of North American and European

I n areas with sub-zero temperatures, the heat exchangers are generally equipped with automatic defrost cycles to remove frost: and i c e buildups w i t h i n the u n i t s . Tn a sample of 5 heat exchangers tested by

Lawrence Berkeley Laboratory, approximately 4 3 to 75% of t h e available sensible heat was transferred from the outgoing to the f n c o d n g air. l o

The second element in the low energy house strategy 1 s the use of

h l g h l e v e l s of insulation. In Western Canada, l o w energy houses have g e n e r a l l y used s p e c i a l l y t h i c k wall constructions to incorporate

i n s u l a t i o n thicknesses approximately two to three t i m e 6 the minimin standard. T a b l e 2 gives the insulation levels used on most of the l o w energy houses.

A large number of wall designs have emerged to accommodate the h i g h insulation l e v e l s . There are 3 w a l l t y p e s in w i d e s t use, w i t h several combfnations and variations:

1. S i n g l e stud walls using exterior insulating sheathing boards, 2. S i n g l e s t u d walls using i n t e r i o r horizontal wood strapping, 3. Double s t u d

The lat cer two d e s i g n s of t e n incorporate the a1 r-vapour barrier within the w a l l structure. The three w a l l designs are shown in Figure 1 .

By locating t h e air-vapour barrier as shorn in the l a t t e r two wall d e s i g n s , the barrier is more readily p r o t e c t e d from penetrations by electrical wiring and plumbing, and from damage by subsequent t r a d e s during construction. A more d e t a i l e d d e s c r i p t i o n of s i n g l e - and double- s t u d w a l l construction is given in Reference 8.

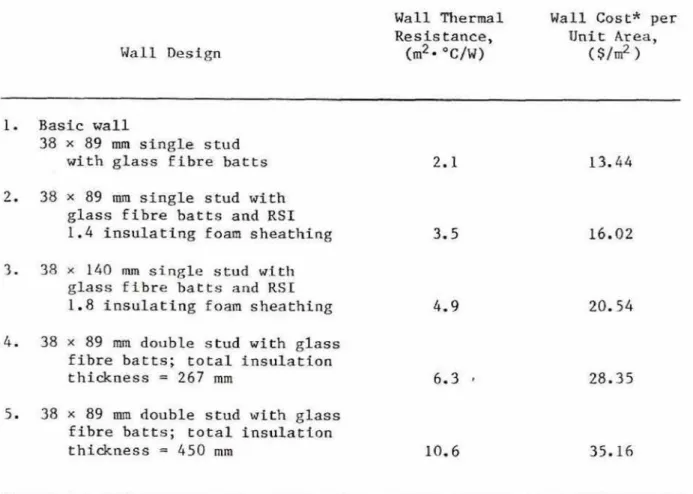

In Table 3, figures f r o m a paper by Dumont and Orr on the c o s t ( i n 1978-81) of insulated wood frame walls with t h e m 1 resistance values varying from R S I 2.1 ( ~ 1 2 ) to R S I 10.6 (R6O) are reproduced.8

For economy reasons, batt or l o o s e fill i n s u l a t i o n has generazly been used i n ceiling applications. Glass f i b r e batts, sometimes w i t h one

of the rigid sheathlng insulations, are most often used for walls. For basement

walls,

the preserved wood foundation system incorporating glass f i b r e batts has became gnpnlar. With concrete basement walls, the mast papular techdque has been the use of g l a s s f i b r e batte in a wooden stud wall located on the i n s f d e of the: concrete wall. A number of bu-llders have incorporated additional exterior rigid imu-lation on the above-grade portion of coacrete basement walls, When concrete basement floors are insulated, r i g i d polystyrene, often o f the closed cell extruded variety, has been laf d below the poured coacrete. With crawl space desighs under wooden floors, glass f i b r e batts have been most of ten used.The third element in the l o w energy strategy is the use of windows

facing south f o r p a s s i v e solar gain.8 In new house construction the fayout of the house is planned so that about 75% or more of the windows are on the south side of t h e house. Host of the l o w energy houses b u i l t to date use standard gypsum board w a l l s and c e i l i n g s , and wooden floors. In some designs, an attempt has been mde t o increase the t h e m 1

capacity of interior elements t o absorb solar heat gains from the south w i n d w s , If large south w i n d m s are used, wide t e q e r a t u r e swings may

result.

A relatively small amount of south window area has been used on m o s t of t h e houses. T y p i c a l l y , the r a t i o is 6% south window area t o total floor area. On houses with a total f l o o r area of 200 %quare metres i n c l u d i n g the basement, approximatlely 12 square metres of s o u t h windm are used.

To improve the net heat contrltbution from south-facing windows, t r i p l e glazing or insulating shutters may be i n s t a l l e d , Roof overhangs or awnings can prevent excessive heat gain during the sumraer months, by reducing direct solar radiation incident on the south w i n d w s . A f i x e d window overhang is often positioned so as to allow full sun into the south w f n d w s from t h e beginning of Movmber to the f i r s t part of

February. The ideal exterior shading would be movable, but f o r architectural reasons and simplicity an overhang is generally fixed.

The amount of beat gained from south-facing windows varies d t h l o c a t i o n and time of year. Averaged over the heating season it m y account for 25 to 50% of the total space heat required.

Internal heat gains w i l L o f t e n contribute a very s u b s t a n t i a l fractiod of the space heating requirement in l m energy'houses. The t y p i c a l household in Canada has an internal heat gain rate of about 1 kilcrwatt averaged over a 24-hour period. The heat sources are lights, appliances, domestic hot water usage, and body heat from occupants. For a family of

4

or 5 people, it is not uncommon in lm enex= houses f o rthe i n t e r n a l heat gains to provide about 40% of the annual space hear requirement.

As the efficiency of home appliances and domestic hot water systems improves, it is l i k e l y that t)ae i n t e r n a l

heat

gains will d e c l i n esomewhat.

P K g P O ~ C E RESULTS

A number of studies have been done on the performance of l o w energy houses.

A

1980 paper presents the r e s u l t s of a group a£ 1 3low

energg houses in ~aakataon-I Over a one-year p e r i o d , the meafruced space heating energy conamp tfoa of the 13 houses averaged 218 MJ/d ( 5 . 6 kWh/f9

1,

as compared w i t h the average for pre-1970 houses, of 632MJ/d

(16.3 kWh/f t2). Over t h e one-year moni torlng period, the number of

heating degree days accumulated was 5663"C-days (reference 1 8 ° C ) . In todays's C1982) energy prices, the c o a t of space heating would range from about $600 to $1500 per year or higher, for canventiorral houses and about one t h i r d of that for the lw energy houses. The m o s t enerw-ef f f c i e n t house in the group had an energy consumption for space heating equal t o

121 MJ/m2 (3-1 kWh/ft2) for that period,

A number of d e s i g n errors have been identified as responsible for r e l a t i v e l y high energy coasunption on several of the '1- energy' houses. Theae included ;

I . Eacessfve glass area on the south, resulting i n large ngght-time heat losses, and overheating on sunny days;

2. Low insulation levels fn the basement walls and floors, l e a d i n g to high heat losses on a seasanal basts;

3. Inadequate a i r tightnese levels due to Zmproper detailing, or

improper i n s t a l l a t i o n of the air-vapour barrier;

4. Use 01 double glazing i n s t e a d of t r i p l e glazing

or

double glazing w i t h night insulation on the windam;5.

Poor window overhang d e s i g n on the south windows, resulting .in undes f rable shading of these windms during the heating Seasdn.COST OF EMKRCX COHSgaflATZ~ MEASURES

Although a number of owners of low energy houses have b u i l t or purchased their homes for reasons of increased comfort or ease o f

heating, the reductions in heating b f l l s have been a major factor. The

1981 paper "Cast of Energy Conservation Measures for New FI~tlsing"~ presents incremental cost figures far energy conservation features such

as increased air tightness

,

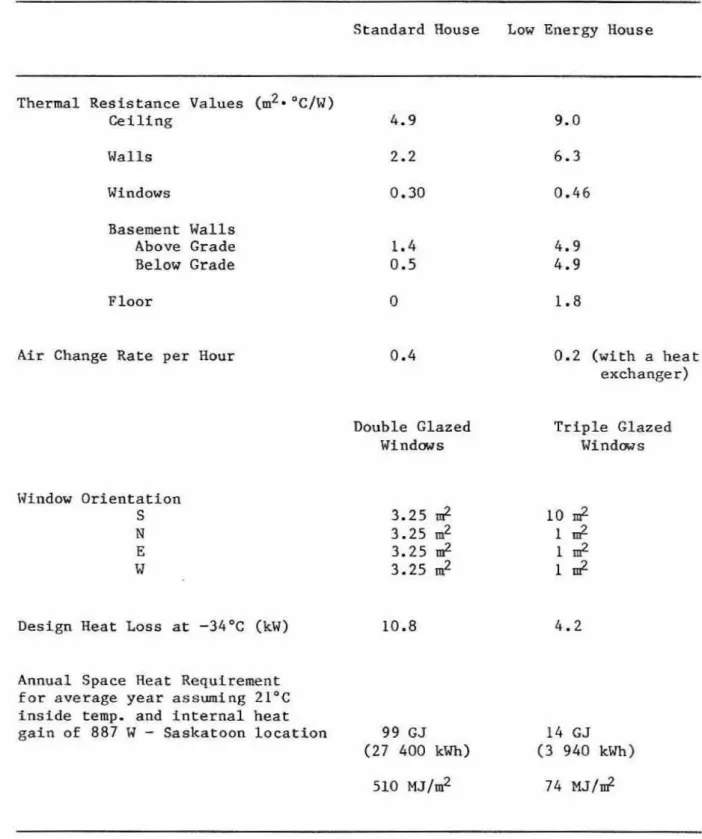

heat exchangers, i m p roved wall, c e t l i n g and floor i n s u l a t i o n , and the use of t r i p l e glazing.In

that p a p e r , a t a b l epresents the thermal properties of a theoretical house b u i l t to mTn5mum standards and then upgraded. The annual space heating requirement of the house has been reduced from 510

HJ/&

to74

MJ/& p e r year. The cost ofthese improvements was $5020 (approximately LOX of the construction price of the house). Table

4

ahow8 the energy conservation features which can be used t o obtain this reduction in consumption.On a number of the low energy housea, there have been savings in the

cost af i n s t a l l i n g a heatlng system, as the peak heat requirements are

subs tantially reduced compared t o standard housing, In the example mentioned above, the design heat leas of the house was reduced f r o m

10.8 kW f o r the minimum standard house to

4.2

kWfor

the low energy houseat an o u t s i d e temperature of

-34°C.

The

l o w

energy houses b u i l t t o date have achieved considerable reductions in their requir-nts for space heating.A number

oftechnical d e v e l o p n t s could further improve the cost effectfveness of the houses. P a r t i c u l a r l y needed is a windaw with an improved thermal resistance value compared with those presently available.

A

t r i p l e glazed wind- with 12.7 mm air spaces has a t h e m 1 resistance equal to about 0.57 I$"c/w;

this compares unfavourably with wall and c e i l i n gresistance values in the range of 5 to

LO

2

*c/W, achieved on low energy houses. A number of other developments could irrprove t h e cost-effectiveness of these houses, including volume production of air-to-air heat exchangers which vould reduce their cost. As of 1982, the i n s t a l l e d

c o s t of a heat exchanger was appraximately $750-$1000 for a t y p i c a l residence.

On a number of low energy houses, the annual water heating bill exceeds the space beating bill, indicating another possible srea for development a d savings.

1. Dunmat, R.S., O r r , H.W., Hedlin,

C.P.

and Mkuhon,J.T.

'7kasured Energy Consmptfon af a Groupaf

Low

Energy Houses", Proceeding,1980 Annual Meeting, Solar Energy S o c i e t y of Canada, 1980.

2. Shurcliff,

W.A.

Superinsulated Houses and Double Envelope Rouses, BridcHouse

Publishing Company, 34 Essex Street, Andover,Massachusetts 01810

U.S.A.,

1981.3. Energy Efficient Housing: A Prairie Approach, O f f i c e of Energy Conservation, Department of Mneral Resources, 1914 Hadltorr. Street, Regina, Saskatchewan, 19810.

4. Shick, W.L., Jones,

LA.,

Rarris, W.S., allti Kouzo, S. "Technical Mote 14: Details and Engineering h a l y s i s of the I l l i n o i s Lo-Cal House", Small Homes Council,Buflding

Research Council, Universityof I l l i n o i s , Urbna, 51801 U.S.A., 1979.

5. Orr, R.W., "Design and Construction

of

Low Energy HousesIn

Saskatchewan", M v i s i o n of Buildfng Research, National Research

Council of Canada, Buflding Prgctice Note 30, Ottawa, 1982.

6 . Dumonr, R.S., Orr,

H.W.,

and F i g l e y , D.A.,"Air

TightnessP i e a s u r e n t s of Detached Houses in the Saakatooa Area", Division of B u i l d i n g Research, National Research Council of Canada,

Building

Research & t e 178, O t t a w a ,

1981.

7.

Determination of Airtightness of Buildings by the FanDepressurization

Method.

Cauadian General Standards Board, Draft Standard 149-GP-10, CGSB, Ottawa, CanadaK1A

iG6, 1981.8. humat, R.S. and O r r , H.W. "Cost of Energy Conservation Measures for Hew lbusing", Divfsion of B u i l d i n g Research, National Research Council of Canada, Building Research Note 176, Ottawa, 1982.

9. Shurcliff, W.A. Air-to-Air Heat Exchangers for Houses Published by W.A. Shurclif f

,

19 Appleton Street, Cambridge, Ebsaachusetts 02138U.S.A.,

1981.10. Fbsk, W.J., Roseme, G.D. and Hollowell, C.D. "Performance of & s i & n r i a l Atrto-Air &at Exchangers: T e s t Methods and R e s u l t s " ,

TABLE 1 PRESSITI;1E TEST RESULTS FOR A SAMPLE OF HOUSES IN SASKATOOM

Sample Age

Low eiiergy houses Standard houses Pre-1945 1946-60 19 6 1-80 Equivalent Leakage Area (u?) Number of Houses T e s t e d

TABLE 2 THERMAL RESISTANCE LEVELS USED ON LOW ENERGY HOUSES

Walls A b o v e Grade C e i l i n g s

W a l l s B e l o w Grade

Floors (Over C r a w l Spaces)

Floors (Under Conctete) Windm Shutters

TABLE 3

WALL

COSTS FOR INCREASING IWSULATION LEVELS Wall D e s i g n Wall Thermal RE s is t ance,

(m2* OCIW) Wall Cost* p e r Unf t Area,t

s/d 1

1. Basic wall 38 x 89 mm single s t u d with glass f i b r e batts2. 38 x 89 mm s i n g l e stud with glass fibre batts and RSI 1.6 insulating foam sheathing 3. 38 x 140 mm s i n g l e s t u d w i t h

glass f i b r e bat t s and R S I

1.8 insulatfng foam sheathing

4. 38 x 89 mm double stud w i t h glass fibre b a t t s ; total i n s u l a t i o n thickness = 267 mm

5. 38 K 89 mm double stud with glass f i b r e b a t t s ; t o t a l insulation thickness = 450 mm

*Excluding cost of interior gypsum board and exterior f i n i s h , but- i n c l u d i n g

c o s t s for extra finishing work and extra roof and siding t o accomdate the greater w a l l thickness.

TABLE

4 EFFECT OF U P W I N G A STANDARD HOUSE TO A TAW EHERGY HOUSE Standard HouseLow

Energy HouseThem1 Resistance Values (m2*

'CIW)

Q i l f ng 4.9 Walls Windows Basement Walls Above Grade B e l o w Grade Floor

. A i r Change Rate p e r Hour 0.2 ( w i t h a heat

-changer) Double Glazed Windaws T r i p l e Glazed Windms Wlndow Orientation S

N

EW

Design Beat LOSS at: -34%

(W)

Annual Space fieat Requirement

for average year a s s d d g 21°C

Inside temp- aud internal heat gain of 887