Publisher’s version / Version de l'éditeur:

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

2006 Combustion Meeting, Combustion Institute/Canadian Section [Proceedings], pp. 1-6, 2006-05-01

READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE.

https://nrc-publications.canada.ca/eng/copyright

NRC Publications Archive Record / Notice des Archives des publications du CNRC :

https://nrc-publications.canada.ca/eng/view/object/?id=7e226648-db4c-46d0-922a-81a94a130ed6 https://publications-cnrc.canada.ca/fra/voir/objet/?id=7e226648-db4c-46d0-922a-81a94a130ed6

NRC Publications Archive

Archives des publications du CNRC

This publication could be one of several versions: author’s original, accepted manuscript or the publisher’s version. / La version de cette publication peut être l’une des suivantes : la version prépublication de l’auteur, la version acceptée du manuscrit ou la version de l’éditeur.

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at Investigation of the performance of water mist in extinguishing pool fires of various sizes

http://irc.nrc-cnrc.gc.ca

Investigation of the performance of water mist in

extinguishing pool fires of various sizes

N R C C - 4 5 5 9 8

L i u , Z . ; C a r p e n t e r , D . ; K i m , A . K .

A version of this paper is published in / Une version de ce document se trouve dans: 2006 Combustion Meeting, Combustion

INVESTIGATION OF THE PERFORMANCE OF WATER MIST IN EXTINGUISHING POOL FIRES OF VARIOUS SIZES

Z. Liu, D. Carpenter and A. K. Kim

Fire Research Program, Institute for Research in Construction National Research Council of Canada, Ottawa, Canada, K1A 0R6

INTRODUCTION

Water mist that consists of small water droplets (Dv99 < 1000 μm) has

demonstrated its capabilities in providing protection for ships, office and residential buildings, heritage properties (wood stave churches, libraries), machinery spaces, gas turbine enclosures, bulk conveyors, flammable liquid storages, sub-floors of computer rooms, commercial cooking areas, and industrial oil cookers [1-3]. During suppression, the fire encountered can vary from a small pool fire in a commercial kitchen or in a fuel storage room to a large pool fire covering over ten square meters in an industrial oil cooker [1]. Currently, extrapolation of a basic water mist system for a new application or an application with different fire sizes is generally not permitted without further fire tests [4]. This is due to concerns over the performance consistency of water mist in fire suppression, which in turn is caused by a limited understanding of the interaction between water mist and flames. The requirement for testing each new variant increases the costs and time associated with the development and application of water mist fire suppression systems.

This paper presents data from experimental studies of water mist performance in extinguishing pool fires of various sizes, in conjunction with the protection of industrial oil cookers. During a series of full-scale fire experiments, the surface area of the pool fire was changed in both width and length. The impact of these changes in the pool size on the distribution of water droplets over the fuel surface and the flame load was investigated. In addition, the interaction between the water droplets and the flame plume during suppression was analyzed. Experimental results showed that the extinguishing performance of a water mist system could be correlated with an increase in pool fire size, if certain requirements were met. The information obtained in the experiments proved useful for establishing general application principles for local application water mist systems and for developing a methodology to extrapolate water mist systems for various applications.

EXPERIMENTAL APPARATUS AND PROCEDURE

Four large industrial oil cooker mock-ups of different sizes were built. The oil cooker consisted of a pan and a hood. Both ends of the hood were open. The hood of an oil cooker could be placed in two different positions: a hood-up and a hood-down position. The detailed information on the construction of four mock-ups is provided in reference [5].

The pans of the oil cooker Mock-ups #1 to #3 had the same width (1.22 m) and depth (0.343 m), but their lengths were 1.22 m, 3.0 m and 5.0 m, representing surface areas of 1.48 m2, 3.72 m2 and 6.1 m2 respectively. The pan of Mock-up #4 was 3.0 m long, 2.4 m wide and 0.343 m deep providing a surface area of 7.2 m2. The surface area of the four oil cookers and the associated heat release rates of the canola oil used in the study, are listed in Table 1.

Table 1. Oil surface areas of the industrial oil cooker mock-ups

Oil Cookers #1 #2 #3 #4

Oil Surface Area (m2) 1.48 3.72 6.1 7.2

Heat release rate (kW) 2,670 6,700 11,040 13,030 During the experiments fresh canola oil, used as the testing fuel, was introduced into the pan and then heated continuously at 5-8oC/min until it auto-ignited. After the flame had spread over the whole oil surface, the fire was allowed to burn freely for 30-45 seconds. For experiments involving Mock-ups #1 to #3, the external heating source for the oil pan was turned off in the freely burning period, while it remained on in the experiments involving Mock-up #4. The water mist discharge was activated manually at the end of the pre-burning period. After the fire was extinguished, the discharge of water mist was maintained for a time period to cool the cooking oil and prevent re-ignition.

A number of thermocouple trees were placed along the centerline of the length of the mock-up to measure oil temperatures in the experiments involving Mock-ups #1 to #3. Each thermocouple tree had two thermocouples that were located, respectively, 5.1 cm and 10.2 cm above the bottom of the pan. The number of thermocouple trees and their locations in the pan were determined by the size of the oil cooker mock-up. In addition, a number of thermocouples were placed at the center of the oil pan and above the oil surface to measure the gas temperatures. For experiments involving Mock-up #4, three thermocouple trees were placed in the pan to measure oil and air/flame temperatures. Thermocouple tree #1 was placed in the center of the pan and thermocouple trees #2 and #3 were located 0.7 m apart from each other along the direction from the center of the pan to the southeast corner of the pan. Eight thermocouples (Type K, 18 gauge) were attached to each tree. The elevation of each thermocouple was 51 mm, 100 mm, 124mm, 165 mm, 254 mm, 381 mm, 681 mm and 981 mm above the bottom of the pan.

Two pressure gauges were used to monitor the discharge pressure of the water mist system. The first one was located in the inlet of the water mist piping system and another was located near one of the nozzles. Two heat flux meters (air-cooled) were used to measure the heat release rate of the fire. The heat flux meters were located 0.5 m away from the pan and 1.2 m and 1.90 m, respectively, above the floor. A number of video cameras were used in the experiments to record the testing process and to assist in the identification of water mist discharge time and fire extinguishing time. One flow meter was used to measure the water flow rate of the system.

WATER MIST SYSTEM AND ITS SPRAY PERFORMANCE

The water mist system used in the experiments consisted of a number of a single fluid nozzles and a piping system. Under a pressure of 550 kPa, 50% and 90% of the spray volume are in drops smaller than 250 and 380 microns, respectively. The spray angle of the nozzle is 150 degrees and not changed with an increase in discharge pressure.

The discharge pressure of the water mist system remained at 690 kPa in all of the tests involving four different sizes of oil cookers. The water flow rate of a nozzle was 36 L/min at 690 kPa discharge pressure. Its discharge distance from the nozzle tip to the bottom of the pan remained at 0.93 m. The spray coverage area per nozzle was 1.22 m (4 ft) wide x 1.22 m (4 ft) long for a single nozzle application and was extended to 1.22 m (4 ft) wide x 1.52 m (5 ft) long, when a multiple number of nozzles were used for a large oil surface. Each nozzle was installed in a vertical downward orientation inside the protected oil cooker. It was located at the center of its coverage area. The system and its operating conditions were arranged to ensure that with an increase in the oil pool surface size:

• The characteristics of the water mist discharge, such as water flow rate, drop size distribution, and spray pattern, velocity and angle, were unchanged; • The ratio of the water quantity discharged per oil surface area was unchanged; • The oil surface was completely covered by the water mist sprays.

0 4 8 12 16 20 24 28 32 36 40

Radial Distance of the Pan (cm)

0 20 40 60 80 100 120 140 160 W a te r D e n s it y (kg/ m 2.mi n )

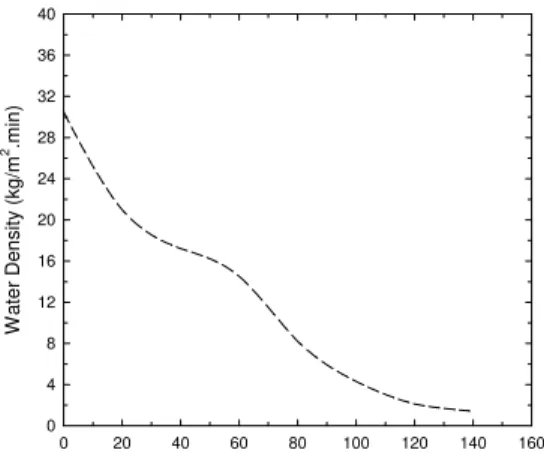

For Mock-up #1, one nozzle was located at the center of the pan. Figure 1 shows that the water mist covered the entire oil surface, but its density was not uniformly distributed over the oil surface. The water

density was high at the center of the pan and decreased quickly with an increase in the distance from the center of the pan.

Two to four nozzles were installed inside Mock-ups #2 to #4, respectively, based on their pool sizes and the above three requirements. The nozzles were placed over the pool according to the spray coverage area per nozzle. Even so, experimental results showed that the water density distribution

Figure 1. Water density distribution over the oil pan in Mock-up #1

was not uniformly distributed over the oil surface and its distribution was different from that generated by the single nozzle in Mock-up #1 due to the overlap of the water

mist coverage from the multiple nozzles. Maximum water density was located beneath the nozzles and in the areas between the nozzles where the water spray patterns overlapped. The water density at the corner of the pan was the lowest.

FIRE EXPERIMENTAL RESULTS AND DISCUSSION

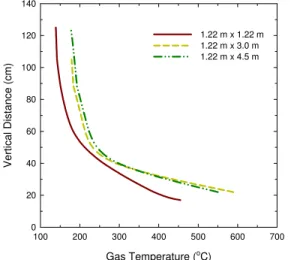

The full-scale fire experiments were conducted under the room temperature. The oil was heated and auto-ignited at temperatures ranging from 351oC to 361oC. The fire was allowed to burn freely for 30 to 45 seconds before the activation of the water mist system. Fire developed very quickly during free burning. For the experiments involving Mock-up #1, the flame spread over the oil surface but its fire plume did not reach the hood of the cooker during free burning. When the width of the pool pan remained at 1.22 m, the total heat release rate of the fire increased fire with an increase in the length of the oil pan. However, the flame height over the oil pool did not show a significant increase. Figure 2 shows the variation of gas temperatures along the vertical distance that was measured at the centers of three different sizes of oil pools. The gas temperature was high near the oil surface and then decreased along the vertical distance. The gas temperatures over the center of the pan with a size of 1.22 m by 1.22 m were lower than those with longer length oil pans. The difference in gas temperature, however, was less than 10 degrees with an increase in the length of the oil pan from 3 m to 4.5m. When the pool size increased in both width and length from 1.22 m by 1.22 m to 2.4 m by 3.0 m, the fire developed more quickly during free burning as the external heating source remained on to heat the oil in the pan. A large fire plume reached the hood and spread under the ceiling of the hood. The gas temperature in the oil pool showed a different trend as compared to that observed in the smaller pool fires. The temperatures were not only high near the oil surface but also near the ceiling of the hood as the flame spread and was partially confined inside the oil cooker hood.

Gas Temperature (oC) 100 200 300 400 500 600 700 Ve rti c al Dist ance (cm ) 0 20 40 60 80 100 120 140 1.22 m x 1.22 m 1.22 m x 3.0 m 1.22 m x 4.5 m

Distance from Center of Oil Pan (cm)

0 200 400 600 800 1000 1200 1400 T e m per atur e ( oC) 100 200 300 400 500 600 700 800 6 cm 38.1 cm vertical distance above oil

Figure 3. Variation of gas temperatures with changes in distance from the center of the pool along the pan’s length

Figure 2. Variation of gas temperatures at the center of oil pool with an increase in the length of the pool with Mock-ups #1, #2 & #3.

Figure 3 shows the variation of gas temperatures from the center of the oil pan to its edge in Mock-up #4 during pre-burning. The gas temperature was high at the center of the oil pan but it decreased quickly with an increase in distance from the center of the

oil pan. The difference in temperature between the center and edge of the pool was approximately 400oC. It indicated that the flame load, such as flame temperature and fire plume momentum, was not distributed uniformly over the oil surface but mainly located at the center of the pool. According to the distribution of the flame load, water drops could more easily reach the fuel surface at the edge of the pool than at the center of the pool, when they penetrated through the fire plume.

The experimental results showed that all of the oil fires in the experiments involving four different sizes of pool fires and two hood positions were extinguished by the water mist system. Its extinguishment performance varied with the hood position and oil surface size. For all the fire experiments conducted, the extinguishing time was shortened, when the hood was placed from the ‘up’ position to the ‘down’ position, although the fire grew more quickly at the hood-down position than at the hood-up position, as more heat was confined inside the oil cooker. This is because the amount of hot gases and flames accumulated near the ceiling that could not be hit by water mist was reduced with the hood at the “down” position.

Area of Oil Pan (m2)

0 1 2 3 4 5 6 7 8 E x ti ng uis h ing Ti m e (S) 0 1 2 3 4 5 6 7 8

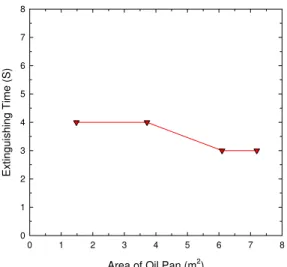

Figure 4. Variation of extinguishing time with area of the oil pan, when the hood was at the ‘down’ position

The fire extinguishment process by the water mist was similar for the four different sizes of oil pools. With the

discharge of water mist, the fire was controlled and large amount of steams were generated. The fire was extinguished once the fuel was cooled by the water mist to the point that the generated fuel vapour could not maintain the flame over the fuel surface. Experimental results showed that under the present system installation configuration, an increase in the pool size did not result in an increase in the extinguishing time, when the water mist system met three requirements (i.e., unchanged water mist characteristics, unchanged water quantity per oil surface and complete oil surface coverage). As shown in Figure 4 with the results of the experiments in the hood-down position, the fire with the smallest surface area using one water mist nozzle located at the center of the

oil pool proved to be the most challenging one to extinguish. Larger pool fires with multiple nozzles were extinguished more quickly than smaller pool fires.

Previous studies [1, 3, 5] suggested that in order to extinguish an open pool fire, water mist must be able to penetrate through the flame and to reach the oil surface for cooling the flame and the fuel surface. Therefore, the spatial variations between the distribution of water drops and the flame loads over the fuel surface, such as water drop velocity relative to flame plume velocity, and temperature difference between water drops and the flame plume, are important factors to determine the water mist performance in extinguishing the various sizes of pool fires. As indicated in the experiments, the

flame load was located mainly at the center of the pool. The water density also did not distribute uniformly over the oil surface, and its distribution pattern changed with the size of the pan if the water mist coverage area per nozzle was unchanged. For Mock-up #1, one nozzle was placed at its center. Water drops discharged from the nozzle directly faced the strong upward fire plume during suppression. Many water drops could be carried away or lost in the fire plume before reaching the oil surface, resulting in a relatively long extinguishing time. With an increase in the pool size, more nozzles were used but they were not located at the center of the oil surface. Although the fire size or flame load increased with an increase in the pool size, most of the water drops discharged from the nozzles could avoid facing the upward fire plume and quickly reach and cool the oil surface during suppression. As a result, an increase in the pool size did not result in an increase in the extinguishing time.

CONCLUSIONS

The flame load, such as flame temperature and fire plume momentum, was mainly located at the center of the pool. The water density was also not uniformly distributed over the oil surface and its distribution pattern changed with the pool size if the water mist coverage area per nozzle was unchanged. The extinguishing times did not increase with an increase in the pool size, when a system and its operating conditions were arranged to ensure that with an increase in the pool surface size, the characteristics of water mist discharged and the ratio of the water quantity discharged per pool area were unchanged, as well as the pool was completely covered by the water mist sprays.

ACKLOWDGEMENTS

The study was conducted under a joint research project between CAFS Unit, Inc. and the National Research Council of Canada. The authors would like to acknowledge the assistance of Mr. Ping-Li Yen of CAFS Unit, Inc. in this work. The authors would also like to thank all the other NRC staff involved in this project for their contributions.

REFERENCES

1. Liu, Z. and Kim, A. K., “A Review of Water Mist Fire Suppression Systems – Application Studies,” J. of Fire Protection. Engineering, 11 (1), 2001

2. Back, G. G., “An Overview of Water Mist Fire Suppression System Technology,” Proceedings: Halon Alternatives Working Conference, Albuquerque, USA, 1994 3. Mawhinney, J. R., Back, G. G., “Water Mist Fire Suppression Systems,” Chapter 14,

Section 4, The SFPE Handbook of Fire Protection Engineering, 3rd Edition, 2002 4. Yu, H. Z., Dobson, P. H., Ferron, R. C. Barsamian, M. Hanna and V. Gameiro, “An

Extrapolation Methodology for Pool Fire Extinguishment by Local Application Water Mist Systems,” 7th International Sym. On Fire Safety Science, Worcester, USA, 2002 5. Liu, Z., Carpenter, D.W., Kim, A.K. "Research on water mist fire suppression

systems for industrial oil cooker protection," 9th Fire Suppression & Detection Research Application Symposium, Orlando, USA, January 2005