Publisher’s version / Version de l'éditeur:

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

ASHRAE Thermal Performance of the Exterior Envelopes of Whole Buildings XI

International Conference: 5 December 2010, Clearwater, Beach, FL. USA

[Proceedings], pp. 1-14, 2010-12-05

READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE.

https://nrc-publications.canada.ca/eng/copyright

NRC Publications Archive Record / Notice des Archives des publications du CNRC : https://nrc-publications.canada.ca/eng/view/object/?id=ea920d15-73df-4314-96a9-c15dbd3c3060 https://publications-cnrc.canada.ca/fra/voir/objet/?id=ea920d15-73df-4314-96a9-c15dbd3c3060

NRC Publications Archive

Archives des publications du CNRC

This publication could be one of several versions: author’s original, accepted manuscript or the publisher’s version. / La version de cette publication peut être l’une des suivantes : la version prépublication de l’auteur, la version acceptée du manuscrit ou la version de l’éditeur.

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at

Accelerated aging performance evaluation of 'smart vapor retarder'

Mukhopadhyaya, P.; Gatland II, S. D.; Di Lenardo, B.; Lackey, J. C.; Van

Reenen, D.; Normandin, N.

HU

http://www.nrc-cnrc.gc.ca/ircU

Ac c e le ra t e d a ging pe rform a nc e e va lua t ion of 'sm a rt va por re t a rde r'

N R C C - 5 4 0 0 6

M u k h o p a d h y a y a , P . ; G a t l a n d I I , S . D . ; D i

L e n a r d o , B . ; L a c k e y , J . C . ; V a n R e e n e n , D . ;

N o r m a n d i n , N .

M a y 2 0 1 0

A version of this document is published in / Une version de ce document se trouve dans:

ASHRAE Thermal Performance of the Exterior Envelopes of Whole Buildings

XI International Conference, Clearwater, Beach, FL., December 5-9, 2010, pp.

1-14

The material in this document is covered by the provisions of the Copyright Act, by Canadian laws, policies, regulations and international agreements. Such provisions serve to identify the information source and, in specific instances, to prohibit reproduction of materials without written permission. For more information visit http://laws.justice.gc.ca/en/showtdm/cs/C-42

Les renseignements dans ce document sont protégés par la Loi sur le droit d'auteur, par les lois, les politiques et les règlements du Canada et des accords internationaux. Ces dispositions permettent d'identifier la source de l'information et, dans certains cas, d'interdire la copie de documents sans permission écrite. Pour obtenir de plus amples renseignements : http://lois.justice.gc.ca/fr/showtdm/cs/C-42

Accelerated Aging Performance

Evaluation of ‘Smart Vapor

Retarder’

Phalguni Mukhopadhyaya, PhD Stanley D. Gatland II

Member ASHRAE

Bruno Di Lenardo John Lackey

David van Reenen

ABSTRACT

The ‘Smart Vapor Retarder (SVR)’ is primarily a vapor barrier membrane that is sensitive to ambient relative humidity (RH) and controls water vapor diffusion through the insulated exterior walls. This paper presents experimental findings from accelerated aging tests, simulating long-term performance indicators, on SVR and compares them with the similar observations made on traditional 6-mil poly (i.e. polyethylene) vapor and air barrier. Elevated temperature and ultra violet (UV) light were the two primary environmental agents used to accelerate the aging process. The performance of the vapor barrier was assessed from water vapor permeance, air permeance and tensile strength properties at various stages of aging. The results from these tests indicate that water vapor permeance, air permeance and mechanical properties of SVR do change due to accelerated aging. In aged SVR material, compared to the original specimens, the RH dependency of the water vapor permeance at higher RH levels appears to be less evident. However, overall performance of SVR, while compared to 6-mil poly, does not exhibit significant concerns about its accelerated weathering performance or serviceability.

INTRODUCTION

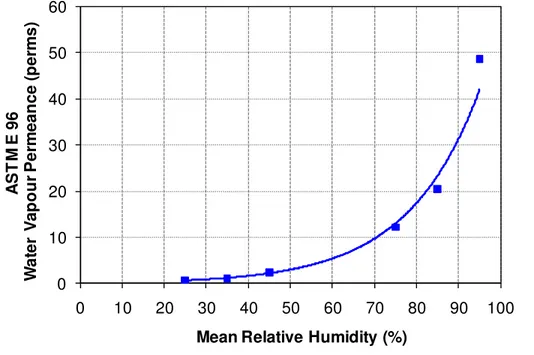

The ‘Smart Vapor Retarder’ (called hereafter as ‘SVR’) is an innovative proprietary 2 mil (50 µm) thick, nylon-6 vapor barrier that controls water vapor diffusion through the insulated exterior walls, as required by the National Building Code of Canada (NBC 2005), Subsection 9.25.4. Unlike more traditional vapor barrier like polyethylene film (≈ 6 mil or 150 µm thick), the water vapor permeance of SVR increases with increasing ambient relative humidity as shown in Figure 1. It has been demonstrated through hygrothermal simulation that the use of SVR and appropriate design methodology can lead to satisfactory moisture management performance of the of exterior wall systems in compliance with the NBC 2005 (Maref et al. 2008, 2009; Tariku et al. 2009). However, in order to ensure durability and serviceability of the exterior wall systems, it is also important to demonstrate satisfactory accelerated weathering water vapor transmission, air flow and mechanical performance of SVR, in response to various natural aging factors prevalent in the field applications.

This paper presents the critical analysis of the results obtained from the accelerated aging performance assessment conducted on SVR and traditional 6-mil poly vapor barrier, carried out at the National Research Council Canada - Institute for Research in Construction (NRC-IRC). 0 10 20 30 40 50 60 0 10 20 30 40 50 60 70 80 90 100 AS T M E 9 6 W a te r V a pour Pe rm e a nc e ( p e rm s )

Mean Relative Humidity (%)

Figure 1 Water vapor permeance (WVP) of smart vapor retarder vs. % mean relative humidity (Gatland, 2005).

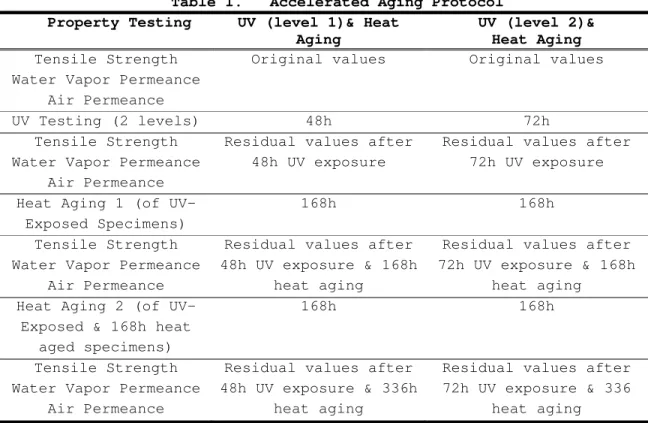

RESEARCH OBJECTIVE

The objective of this research was to carry out the accelerated aging tests on SVR and 6-mil poly and generate required information (i.e. water vapor permeance, air permeance and tensile strength) as stipulated in Table 1 of the Canadian Construction Materials Centre (CCMC) Technical Guide for ‘Vapor Barrier with RH-Dependent Water Vapor

Permeance’ (Di Lenardo et al. 2005). This technical guide was developed

based on the existing evaluation protocols for similar construction materials and experience of the NRC-IRC researchers dealing with the performance of building materials.

Table 1. Accelerated Aging Protocol Property Testing UV (level 1)& Heat

Aging

UV (level 2)& Heat Aging

Tensile Strength Water Vapor Permeance

Air Permeance

Original values Original values

UV Testing (2 levels) 48h 72h

Tensile Strength Water Vapor Permeance

Air Permeance

Residual values after 48h UV exposure

Residual values after 72h UV exposure Heat Aging 1 (of

UV-Exposed Specimens)

168h 168h Tensile Strength

Water Vapor Permeance Air Permeance

Residual values after 48h UV exposure & 168h

heat aging

Residual values after 72h UV exposure & 168h

heat aging Heat Aging 2 (of

UV-Exposed & 168h heat aged specimens)

168h 168h

Tensile Strength Water Vapor Permeance

Air Permeance

Residual values after 48h UV exposure & 336h

heat aging

Residual values after 72h UV exposure & 336

heat aging

EXPERIMENTAL PROGRAM

In order to determine the aging characteristics of SVR and 6-mil poly, three performance indicators, representing primary field performance requirements, were set for tracking any degradation before and after accelerated aging. These three essential performance indicators/material properties are: water vapor permeance, air permeance and tensile strength. The details of the durability protocol (i.e. accelerated aging process) and the characterized material properties are as outlined below.

Durability Protocol

UV Exposure Test

The specimens were tested for tensile strength, water vapor permeance and air permeance after UV-exposure testing and heat aging in accordance with the following protocols.

The specimens were exposed to UVA-340 lamps in a Q-UV apparatus operated in accordance with ASTM G 53. Each cycle of UV testing included both UV exposure and condensation as outlined below. Two sets of specimens were exposed to two different levels of UV testing, specifically:

Level 1 specimens were subjected to 48 h of UV/condensation (i.e. 4 cycles), and

Level 2 were subjected to 72 h UV/condensation (i.e. 6 cycles) with the following cycle:

8 hours of UV radiation at 60°C

4 hours of condensation at 40°C

Heat Aging

The specimens exposed to UV radiation were subsequently subjected to heat aging at 90°C in accordance with ASTM D 3045 (Heat Aging of Plastics Without Load) for one week (168 h) and subsequently another week (168 h).

Performance Indicators - Material Properties

Water Vapor Permeance (WVP)

Original WVP Before Aging - To characterize the vapor barrier

materials, WVP values at five different mean relative humidity (RH) levels (i.e. 25%, 35%, 45%, 85%, 95%) were determined according to the ASTM Standard E 96/E 96M - 05. Three (3) specimens were tested and averaged for each specified RH.

WVP After UV and Heat Aging - Nine (9) specimens were tested

according to the ASTM Standard E 96/E 96M - 05. Three specimens in accordance with Procedure A (25% mean RH), another three specimens in accordance with Procedure B (75% mean RH) and last three in accordance with Procedure B (85% mean RH).

Air Permeance

Three (3) specimens were tested according to the NRC/Building

Research Note No. 227 (Bomberg and Kumaran, 1985). Same specimens were used for both water vapor permeability and air permeability tests.

Tensile Strength

The tensile strength was determined on specimens 200 mm long by 25 mm wide in the machine direction, according to the ASTM Standard D 882, with an initial jaw separation of 100 mm. Five (5) specimens were tested and the results averaged.

Test Specimens

Smart Vapor Retarder (SVR)

Test specimens were prepared from SVR samples that were randomly collected by 3rd party. Four packages (P-1, P-2, P-3 and P-4) of folded

and rolled SVR were delivered to the laboratory. They were each 100 ft. long and 2 mil thick, as marked on the package, but had different widths (P-1: 12 ft. 4 in.; P-2: 10 ft. 4 in.; P-3: 9 ft. 4 in. & P-4: 8 ft. 4 in.). Four rectangular (full width and 18 in. long) pieces from four different packages were cut and six specimens were prepared for original (i.e. before accelerated aging) water vapor permeability and air permeability tests from different locations as shown in Figure 2. The tensile test specimens were cut out from the rest of the SVR sheets after taking out specimens for water vapor and air permeability tests. The test specimens for the other tests were prepared from the subsequent pieces cut out from different rolls as outlined below.

48 hours UV exposure – Package 4 (P-4)

48 hours UV + 168 hours @ 90 °C exposure – Package 3 (P-3) 48 hours UV + 336 hours @ 90 °C exposure – Package 1 (P-1) 72 hours UV exposure – Package 4 (P-4)

72 hours UV + 168 hours @ 90 °C exposure – Package 2 (P-2) 72 hours UV + 336 hours @ 90 °C exposure – Package 1 (P-1) 6-mil Poly

The 6-mil poly specimens, complying with CGSB 51.34-M86-CAN/CGSB AMD 1 Vapor Barrier, Polyethylene Sheet for Use in Building Construction, were randomly cut from a roll that had been recently used in a construction project.

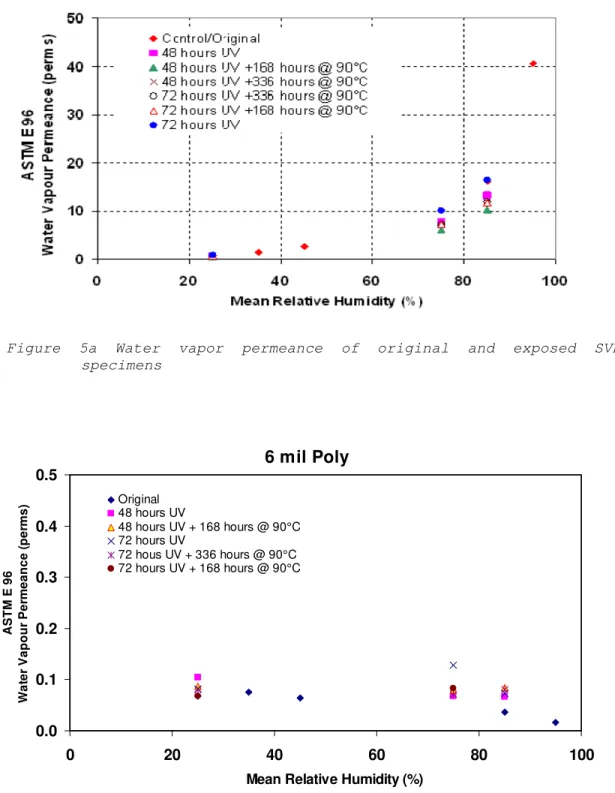

EXPERIMENTAL RESULTS AND DISCUSSION Water Vapor Permeance

The water vapor transmission characteristics of the original (i.e. before accelerated aging exposure) SVR specimens are shown in Figures 3. The typical water vapor transmission characteristics of the SVR specimens after accelerated aging tests are shown in Figures 4. The overall changes in water vapor permeance properties, of both SVR and 6-mil poly due to accelerated aging tests, are indicated in Figures 5a and 5b (take note of change in vertical axis scale). It is very evident from these results that changes in water vapor permeance values of SVR due to accelerated exposure tests were more than 15% and resulted in the reduction of water vapor permeance, possibly due to change in microstructure (annealing). This reduction of water vapor permeance in SVR (Figure 5a) appeared to be relatively more at higher relative humidity (RH). The water vapor permeance of original (i.e. before accelerated aging tests) 6-mil poly (Figure 5b) on the other hand had much lower (less than 0.1 perm), compared to SVR (0.9 to 50 perm), and

1 2 3 4 12 ft. 4 in. 18 in.

a

b

1 2 3 4 9 ft. 4 18 in. 1 2 3 4 10 ft. 4 18 in.c

d

1 2 3 4 8 ft. 4 18 in.e

f

P-1

P-2

P-3

P-4

Specimen L tiafter accelerated aging tests the water vapor permeance of 6-mil poly increased to marginally higher values (maximum ≈ 0.13 perm).

In general, the SVR specimens became more resistant to water vapor transmission (i.e. lower water vapor permeance) due to accelerated aging exposure tests. However, water vapor permeance values still increased with the increase of relative humidity. A comparison between the results obtained from the 48 and 72 hours UV exposure tests on SVR also indicates that prolonged exposure to UV and heat aging did not reduce the water vapor permeance of the SVR further. On the contrary, the water vapor permeance after 72 hours UV exposure was slightly higher than the same after 48 hours.

0 10 20 30 40 50 0 10 20 30 40 50 60 70 80 90 10 A S T M E 96 W a te r V a pour P e rm e a n c e (pe rm s )

Mean Relative Humidity (%) Smart Vapour Retarder (Original)

0 493-18-a

493-18-b 493-18-c Average

Figure 3 Water vapor permeance of original SVR specimens

0 10 20 30 40 50 0 10 20 30 40 50 60 70 80 90 100 AS T M E 9 6 W at e r V ap o u r P ermea n ce (p erms)

Mean Relative Humidity (%) Smart Vapour Retarder (48 hours UV) 493-46-a

493-46-b 493-46-c Average

Figure 5a Water vapor permeance of original and exposed SVR specimens

6 mil Poly

0.0 0.1 0.2 0.3 0.4 0.5 0 20 40 60 80 100Mean Relative Humidity (%)

ASTM E 9 6 W a te r Vapour Per m eance ( p er m s ) Original 48 hours UV 48 hours UV + 168 hours @ 90°C 72 hours UV 72 hous UV + 336 hours @ 90°C 72 hours UV + 168 hours @ 90°C

Figure 5b Water vapor permeance of original and exposed 6-mil poly specimens

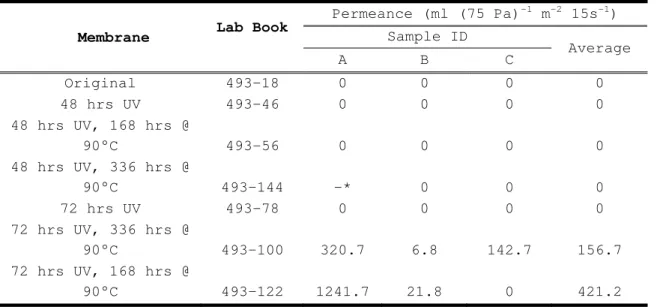

Air Permeance

The air permeance characteristics of the SVR specimens before and after accelerated exposure tests are shown in Table 2a and the same for 6-mil poly are shown in Table 2b. The SVR specimens were found to be very airtight (i.e. no measurable quantity of air passing through it) in most of the measurements. However, combined 72 hours UV and heat aging resulted in measurable air transmission through the SVR specimens. In addition, combined 48 hours UV and 336 hours heat aging also shattered one SVR specimen. In a similar vein, 6-mil poly also showed aging sensitivity to UV and UV-heat exposure (Table 2b). These observations clearly indicate that UV exposure during construction for both SVR and 6-mil poly needs to be kept to a minimum.

Table 2a. Air Permeance of SVR

Membrane Lab Book

Permeance (ml (75 Pa)-1 m-2 15s-1) Sample ID Average A B C Original 493-18 0 0 0 0 48 hrs UV 493-46 0 0 0 0 48 hrs UV, 168 hrs @ 90°C 493-56 0 0 0 0 48 hrs UV, 336 hrs @ 90°C 493-144 -* 0 0 0 72 hrs UV 493-78 0 0 0 0 72 hrs UV, 336 hrs @ 90°C 493-100 320.7 6.8 142.7 156.7 72 hrs UV, 168 hrs @ 90°C 493-122 1241.7 21.8 0 421.2

*NOTE: Specimen had shattered and could not be tested

Table 2b. Air Permeance of 6-mil Poly

Membrane Lab Book

Permeance (ml (75 Pa)-1 m-2 15s-1) Sample ID Average A B C Original 493-1 0 0 0 0 48 hrs UV 493-35 0 0 0 0 48 hrs UV, 168 hrs @ 90°C 493-67 0 0 0 0 72 hrs UV 493-89 0 0 3.1 1.04 72 hrs UV, 336 hrs @ 90°C 493-111 83551 02 0 2783.46 72 hrs UV, 168 hrs @ 90°C 493-133 02 0 0 0

Tensile Strength

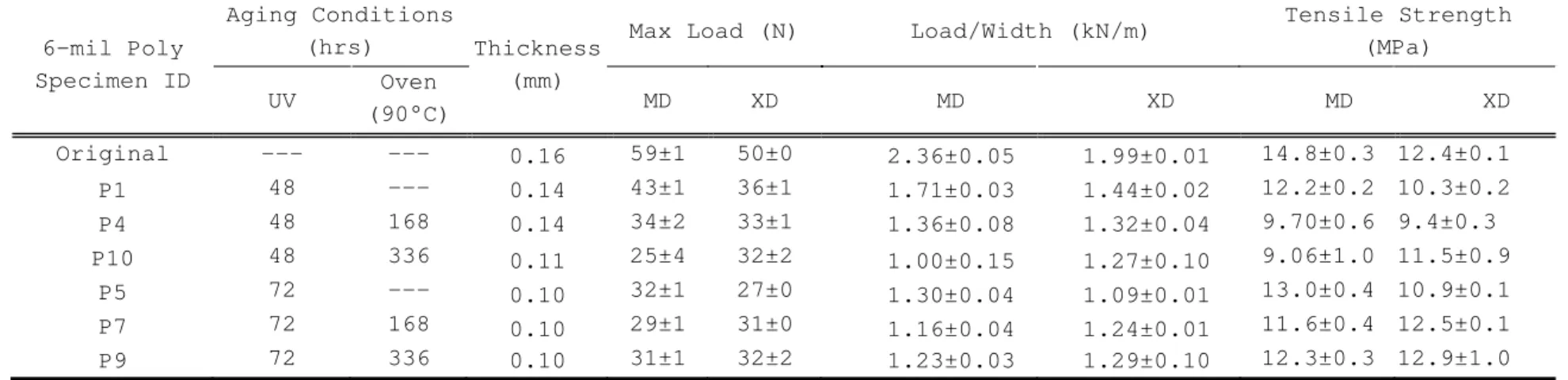

The results from the tensile tests on SVR and 6-mil poly specimens are shown in Tables 3a and 3b. Initially with 48 hours UV and 48 hours UV + 168 hours heat exposure, the tensile strength of SVR specimens increased to about a maximum of 15%. Thereafter due to further heat and/or UV exposure, the tensile strength of SVR specimens reduced considerably (more than 40%). However, while compared to tensile test results obtained from 6-mil poly (Table 3b) under similar conditions, it is evident that mechanical response of SVR, with higher tensile load bearing capacity than 6-mil poly, can provide the accelerated weathering performance of traditional 6-mil poly membranes for resistance to wind pressure.

Table 3a – SVR Tensile Tests Data NOTES: SVR Specimen ID Aging Conditions (hrs) Thickness (mm)

Max Load (N) Load/Width (kN/m) Tensile Strength (MPa) UV Heat (90°C) MD 1 XD2 MD XD MD XD Original --- --- 0.06 64±2 65±1 2.58±0.08 2.58±0.02 43±1 43±0 V1 48 --- 0.05 71±1 66±2 2.85±0.05 2.63±0.07 57±1 53±1 V4 48 168 0.05 73±9 76±1 2.92±0.37 3.02±0.03 58±7 60±1 V12 48 336 0.05 39±6 37±5 1.56±0.26 1.47±0.20 31±5 29±4 V6 72 --- 0.05 42±3 41±1 1.69±0.11 1.64±0.03 34±2 33±1 V8 72 168 0.05 49±12 42±5 1.97±0.50 1.66±0.21 39±10 33±4 V10 72 336 0.05 47±4 42±5 1.86±0.17 1.71±0.22 37±3 34±4

1. All tests were done in displacement control mode at a speed of 50mm/min with an initial grip separation of 100mm, as per the CCMC technical guide.

2. Specimen size was 200mm × 25mm.

3. Following specimens were excluded inform the calculations: Original – XD: Specimen #4; 72Hrs UV, 168Hrs at 90°C Oven – XD (V8): Specimen #3; 72Hrs UV, 336Hrs at 90°C Oven – MD (V10): Specimen #4; 72Hrs UV, 336Hrs at 90°C Oven – XD (V10): Specimen #5.

4. Specimens were not considered in calculations when their Force-Displacement curves deviated from the trend the other specimens had established.

5. Thickness decreased 0.01mm upon UV and/or heat exposure.

6. All SVR specimens heat aged in the oven broke by shattering (i.e. brittle) rather than tearing (only the original, V1, and V6 specimens broke by tearing).

7. Some of the V4 (48 hrs UV + 168 hrs oven/heat aged) specimens broke by shattering (i.e. brittle), instead of tearing like the original specimens.

8. All SVR specimens (original and aged) broke. The maximum load (and thus load/width and tensile strength) increased with aging, but the extensions at break decreased.

1 MD: Machine direction 2

Table 3b. 6-mil Poly Tensile Tests Data 6-mil Poly Specimen ID Aging Conditions (hrs) Thickness (mm)

Max Load (N) Load/Width (kN/m) Tensile Strength

(MPa) UV Oven (90°C) MD XD MD XD MD XD Original --- --- 0.16 59±1 50±0 2.36±0.05 1.99±0.01 14.8±0.3 12.4±0.1 P1 48 --- 0.14 43±1 36±1 1.71±0.03 1.44±0.02 12.2±0.2 10.3±0.2 P4 48 168 0.14 34±2 33±1 1.36±0.08 1.32±0.04 9.70±0.6 9.4±0.3 P10 48 336 0.11 25±4 32±2 1.00±0.15 1.27±0.10 9.06±1.0 11.5±0.9 P5 72 --- 0.10 32±1 27±0 1.30±0.04 1.09±0.01 13.0±0.4 10.9±0.1 P7 72 168 0.10 29±1 31±0 1.16±0.04 1.24±0.01 11.6±0.4 12.5±0.1 P9 72 336 0.10 31±1 32±2 1.23±0.03 1.29±0.10 12.3±0.3 12.9±1.0

NOTE: 1. All 6-mil poly samples aged in the oven broke normally (the Control, P1, and P5 did not break before the travel limit of the machine was reached)

SUMMARY OF OBSERVATIONS

In this study the possible aging or durability assessment of innovative proprietary 2 mil (50 µm) thick ‘Smart Vapor Retarder’ or ‘SVR’, to be used as vapor/air barrier in exterior building envelope constructions but not exposed directly to outdoor conditions, has been carried out, using purpose-designed accelerated aging test protocol, and compared with the performance of a more traditional vapor barrier 6-mil (150 µm) poly.

The accelerated aging tests show that SVR material, designed as an interior vapor/air barrier, is sensitive to extreme environmental exposure conditions, not applicable for indoor applications, comprising of ultra-violet (UV) light and elevated temperature.

The mechanical, water vapor permeance and air permeance properties do change under controlled and prolonged laboratory simulated extreme exposure conditions.

In the aged SVR material, compared to the original specimens, the relative humidity (RH) dependency of the water vapor permeance at higher RH levels appears to be less evident.

However, overall accelerated weathering performance of SVR is found to be equivalent or better compared to traditional 6-mil poly to function as dual vapor and air barrier.

REFERENCES

ASTM D3045-92. 2003. Standard Practice for Heat Aging of Plastics Without Load. ASTM International. 100 Barr Harbor Drive. PO Box C700. West Conshohocken. PA. 19428-2959. USA.

ASTM D882-09. Standard Test Method for Tensile Properties of Thin Plastic Sheeting. ASTM International. 100 Barr Harbor Drive. PO Box C700. West Conshohocken. PA. 19428-2959. USA.

ASTM E96/E96M-05. Standard Test Methods for Water Vapor Transmission of Materials. ASTM International. 100 Barr Harbor Drive. PO Box C700. West Conshohocken. PA. 19428-2959. USA.

ASTM G53-96. 1996. Practice for Operating Light- and Water-Exposure Apparatus (Fluorescent UV-Condensation Type) for Exposure of Non-metallic Materials. ASTM International. 100 Barr Harbor Drive. PO Box C700. West Conshohocken. PA. 19428-2959. USA.

Bomberg, M. T. and Kumaran, M.K. 1985. A Test Method to Determine Air Flow Resistance of Exterior Membranes and Sheathings. National Research Council Canada – Institute for Research in Construction, Building Research Note, Vol. 227: 1-14.

Di Lenardo, B., Lacasse, M. A., Maref, W., Mukhopadhyaya, P., and Tariku, F. 2005. Technical Guide for Vapour Barrier with RH-Dependent Water Vapour Permeance. MasterFormat Section: 07264. National Research Council Canada. Institute for Research in Construction.

Gatland II, S. D. 2005. Comparison of Water Vapor Permeance Data of Common Interior Building Materials in North American Wall Systems. 10th Canadian Conference on Building Science and Technology, Ottawa, 182-194.

Maref, W., Tariku, F., Di Lenardo, B., and Gatland, S. D. 2009. Hygrothermal Performance of Exterior Wall Systems Using an Innovative Vapour Retarder in Canadian Climate. NRCC-50563. 4th International Building Physics Conference, Istanbul, Turkey, 1-8.

National Building Code of Canada (NBC). 2005. National Research Council Canada. Institute for Research in Construction. Ottawa. Ontario. Canada.

Tariku, F., Maref, W., Di Lenardo, B. and Gatland, S. 2009. Hygrothermal Performance of RH-dependent Vapour Retarder in a Canadian Coastal Climate. 12th Canadian Conference on Building Science and Technology - Montreal, Quebec, Canada, 347-358.