Publisher’s version / Version de l'éditeur:

Technical Translation (National Research Council of Canada), 1971

READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE.

https://nrc-publications.canada.ca/eng/copyright

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

For the publisher’s version, please access the DOI link below./ Pour consulter la version de l’éditeur, utilisez le lien DOI ci-dessous.

https://doi.org/10.4224/20331451

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at

Effect of Air Currents in Moisture Migration and Condensation in Wood

Frame Structures

Torp, A.; Graee, T.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site

LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

NRC Publications Record / Notice d'Archives des publications de CNRC: https://nrc-publications.canada.ca/eng/view/object/?id=6db6f8c7-19b7-4f24-9ff5-25783a4d3fff https://publications-cnrc.canada.ca/fra/voir/objet/?id=6db6f8c7-19b7-4f24-9ff5-25783a4d3fff

THE EFFECT OF AIR CURRENTS IN MOISTURE MIGRATION

AND CONDENSATION IN WOOD FRAME STRUCTURES

L:

セNOt

/

1i).2-

4-NRC .JtTT -1478

NATIONAL RESEARCH COUNCIL OF CANADA

TECHNICAL TRANSLATION 1478

BY

A. TORP AND T. GRAEE

FROM

BYGG, 9 (1): 1 - 10. 1961

TRANSLATED BY

H. R. HAYES

THIS IS THE ONE HUNDRED AND NINETY· EIGHTH OF THE SERIES OF TRANSLATIONS PREPARED FOR THE DIVISION OF BUILDING RESEARCH

OTTAWA 1971

NRC TT -1478

Frame construction represents the major イセウゥ、・ョエゥ。ャ construction method in Canada and the Divition of Building Research maintains an ゥョエ・イ・セエ

in research work in other countries relating to moisture transportation and accuMulation inside wood frame walls and floors s ep ar-a ting d Lf'f'e r-en t environmental conditions.

The studies reported in this translation add further to the kncwLedge of moi s tu r-e mI z r-ation in

residential buf Ldf ng structures and to the development of practical solutions.

The Division is grateful to Mr. lLf;. Hayes of the Translations Section, National Research

Council, for translating this paper and Mr. G.B. Kuester of this Division who checked the translation.

Ottawa

Augu st 1971

N.B. Eutcheon, Direc tor.

Title:

TECHNICAL TRANSLATION

1478

The effect of air currents in moisture migration and condensation in wood frame structures

Hlオヲエウエイセュョゥョァ・イウ betydning for fUktighetsvandring

og kondensasjon i bindingsverkskonstruksjoner)

Authors: A. Torp and T. Graee

Reference: bケァァセ 9(1): 1-10, 1961

Translator: H. R. Hayes, Translations Section, National

..

A. Introduction

Moisture migration in building structures can occur in three different ways:

1. As water vapour by diffusion.

2. In liquid form in the capillaries and pores of the materials.

3.

In the form of vapour with air currents.Very extensive work has been devoted to elucidating the effects

of moisture migration by diffusion and capillary suction. Moisture

migration with air currents has aroused comparatively little interest. A series of observations under practical conditions has shown that our present knowledge of moisture migration patterns does not provide a satisfactory basis for theoretical calculations of

con-densation migration in every single case. Sometimes considerably

less moisture accumulation is observed than is indicated by calcu-lations, at other times the opposite is true.

In order to clarify this problem, the Norwegian Agricultural College has built a climate laboratory where moisture migration

can be investigated in a full-scale structure. In conjunction with

the climate laboratory, the Norwegian Building Research Institute has its own experimental house for the investigation of moisture

conditions in the structures of dwelling houses. The investigations

carried out by the climate laboratory are directed mainly at

clar-ifying problems relating to damp rooms. The climate laboratory

consists essentially of a cooling room built inside another room (Figure 1).

The temperature and atmospheric pressure of both rooms are controlled; in addition, the humidity of the surrounding room is

controlled. The effect of a variation in one of these factors can

be studied in the wall and floor panels of the cooling r00m.

Mois-ture conditions in the exterior wall panels can be studied with the

the inside. The climate laboratory is financed by the Norwegian Agricultural Scientific Research Council.

B. Pressure Conditions in the House

The aim of the first part of the investigations is to obtain a more precise knowledge of how moisture is affected by a difference

in atmospheric pressure on a structure. Under practical conditions,

a pressure drop can occur from the warm to the cold side or from the

cold to the warm side. The magnitude and direction of the pressure

drop depend on a number of factors, such as wind, internal and ex-ternal temperature conditions, ventilation and heating systems, etc.

Wind. The effect of wind on pressure conditions around the

house is comparatively well known from wind-tunnel tests (Flachsbart

1930 and 1932, Irminger and Npkkentved 1930 and 1936). Generally

speaking, on the side of the house facing the wind there is a pos-itive external pressure, whereas on the sheltered side the pressure

is negative (Figure 2). Leakages through cracks in the building

will affect the pressure conditions to the extent that in most cases the pressure within the building is below the barometric

pressure. Strong wind can cause a considerable drop in pressure.

A wind speed of 2m/sec will result in a maximum positive pressure of approximately 0.25 mm (water gauge); the corresponding figures for wind of 4m/sec and lam/sec are approximately 1 mm and 6 mm (water gauge), respectively.

Temperature. If the temperature of a house differs from that

of the outside air, the atmospheric pressure on the structures will

also differ. This is explained by the fact that warm air is lighter

than cold air. Figure 3 shows a schematic representation of the

pressure conditions in a room which is warm in relation to the

surrounding air. In the upper portion of the room, the pressure

will be positive, in the lower portion, negative. With a temperature

difference of 300C between the internal and external air, in a room

of normal height there will be a positive pressure in the upper part of approximately 0.15 (water gauge), and a corresponding negative

through stairway, the pressure difference can be considerable. Under the aforementioned temperature conditions, in a room

approx-imately 5 m high, where the neutral pressure level lies along the

floor, as is often the case on account

0:

doors, etc., the positivepressure below the ceiling may be approximatley 0.6 mm (water gauge). Ventilation conditions also influence the atmospheric pressure

within the building in relation to the outside air. Extraction of

the ventilation air causes the pressure within the building to fall below atmospheric, while the intake of air has the opposite effect. With the intake of preheated air and the evacuation of ventilation air, the pressure conditions will depend on how the capacities of the systems are adjusted in relation to each other.

Heating systems with an outlet to a chimney will have virtually

the same effect as a ventilation system. A system which requires

large quantities of air for 」ッュ「オウエゥッョセ open fires, for example,

results in larger negative pressures than, say, an oil burner

system, which consumes small quantities of air. Central heating,

electrical heating, etc., will not 。ヲヲ・」セ the pressure conditions

in individual rooms.

The Norwegian Building Research iョウセゥエオエ・ has carried out basic

research on the volume of air passing through building materials

and structures (Gpanum, Svendsen and Tveit). The relevant figures

per m2 per hour per mm (water guage) are as follows: for cellulose

felt 5.7 mS, for wood fibreboard 0.54 m3, for weather protection

felt 0.004 mS• The passage of air through full scale structures

has also been investigated, and for stud walls of approximately the same type as those investigated in the climate laboratory the

approximate figure is 0.05 m3 per m2 per hour per mm (water gauge).

The amount of air passing through walls with penetrating floor joists is approximately ten times as great.

C. The Effect of Pressure Conditions on Moisture Migration

Tests were carried out to determine the effect of pressure differences on moisture migration and condensation in felt samples

and full scale structures. The tests were carred out in the period

1. Testing of felt samples

Investigations were carried out to determine whether a positive or negative pressure on the moist side has an effect on the

ac-cumulation of moisture in the structure. The tests were carried

out with boxes of the type described in Norwegian Standard 830. For experimental technical reasons, crystalline CaCl z was used

instead of saturated CaClz solution. The experimental layout is

shown in Figure 4. The area of the felt samples was 200 cm2 •

In three of the boxes a 0.5 mm hole was made. The opening was,

therefore, approximately 1/IOO,OOOth of the area of the felt sample,

or 0.1 cm2 per m2 •

A weather protection felt with a diffusion resistance of 9 m2

h.mm Hg/g was used for the tests.

The average weight increase of the boxes in mg per hour for various pressure differences is shown in Figure 5.

The temperature during the test periods was +150C, and the

relative humidity of the surrounding air approximately 85%.

The tests show that for dense felt pressure differences affect

the accumulation of moisture to a small extent only. Even with

such a large pressure drop as

±4

mm (water gauge) the accumulationof moisture is affected less than ±10%. The passage of air through

the pores of weather protection felt has, therefore, no appreciable effect on the moisture conditions in bUilding structures.

The effect of a 0.5 mm diameter hole on the accumulation of moisture was studied both with and without a pressure drop across

the felt. As shown in Figure 5, the accumulation of moisture is

practically the same for felt with and without puncturing when there

is no pressure drop across the felt. The holes which may form &n

a layer of felt on account of nails, etc., will therefore have no

appreciable effect on the passage of moisture so long as there &s

no pressure drop across the felt. A similar test carried out with

boxes covered with sheet metal shows the same tendency.

With a negative pressure on the moist side, the punctured boxes

without openings. The air flow from the dry to the moist side,

despite a pressure drop of

4

mm (water gauge), was not sUfficientlylarge to prevent moisture accumulation in the boxes.

With a positive pressure on the moist side, the punctured boxes manifest a very marked weight gain increment, approximately 20% per mm (water gauge), despite the fact that vapour diffusion through the felt presumably is less in this period as a consequence

of the higher relative humidity in the punctured boxes. 'l'hL;

sig-nifies that unintentional openings in the form of nail holes, joints in the felt, etc., can result in a considerable increase in the

accumulation of moisture when the pressure on the warm side is positive.

2. Investigations with full-scale wall structures

The investigations were conducted in the wall and floor panels

of the cooling room (Figure 1). The temperature was +150C and the

relative humidity

85%

on the warm side of the structures; on thecold side the corresponding figures were セQUPc and 80 -

85%,

re-spectively. These temperatures and moisture conditions were constant

throughout the whole test period. In the first part of the test

period, the negative pressure on the warm side was on the average

approximateZy 0.4 mm (water ァ。オァ・Iセ while in the latter part of

the period the positive pressure in the heated space was on the

average approximateZy 0.5 mm (water gauge). The duration of the

periods was 171 and 140 days, respectively. The effect of positive

and negative pressures was studied for the following felt combin-ations:

Type 1. Weather protection felt against heated

space. Damp-proof felt against cold space.

Type 2. Weather protection felt against heated

space. Weather protection felt against cold

space.

Type

3.

Damp-proof felt against heated space. WeatherThere were four panels of each type, and two of these had a

completely open slit 10 cm wide at the top with ventilation on

the cold side. Figure

6

shows how test panels with and withoutventilation were assembled. At the conclusion of each test period,

the felt and insulating material of each individual panel with its

moisture content were weighed. It was then dried and weighed again.

In this way it was possible to measure the amount of moisture which 11ad accumulated in the test panel for periods when the pressure

wac p ou I t Lve or negative. Simultaneously with the wei[,;hinp;, the

thickness of the ice layer wac measured at a total of 42 points

in each panel. In order, where possible, to trace the development

of moisture during the course of the test periods, the solids of the wall panels were analyzed each week; however, the moisture formation in the panels was so varied that i t was difficult to form a clear picture of this process.

a. The effect of a ventilation gap

The effect of a ventilation gap at the top of the wall panels

is given in Table I for the period when the pressure on the warm

side was negative.

All ventilated panels have more moisture accumulation than

unventilated panels. In all likelihood, this can be attributed

to the formation of a condensation band on the outside of that

part of the warm side where the insulation has been removed. From

this band, some condensation water runs down along the warm panel and causes an increase in the accumulation of moisture.

In no case did ventilation of the panels prevent moisture

accumulation. The tests show, therefore, that an opening through

the insuZating materiaZ3 feZt3 and paneZ against the cold side,

at the top of the cooZing room walls, for example3 as is sometimes

recommended, will not prevent moisture formation in the walZ panels

when the insulation material fills the entire cavity.

Ventilated and unventilated panels were also compared after

a period of positive pressure on the warm side. An opening at the

top of the wall panels does not contribute significantly to the prevention of moisture accumulation under these conditions either.

If there is an air gap between the insulating material and the felt against the cold side, the ventilation afforded by this gap will contribute substantially to a reduction of moisture ac-cumulation. This is demonstrated in a later series of tests. b. The effect on moisture accumulation of different types of

felt against the cold side

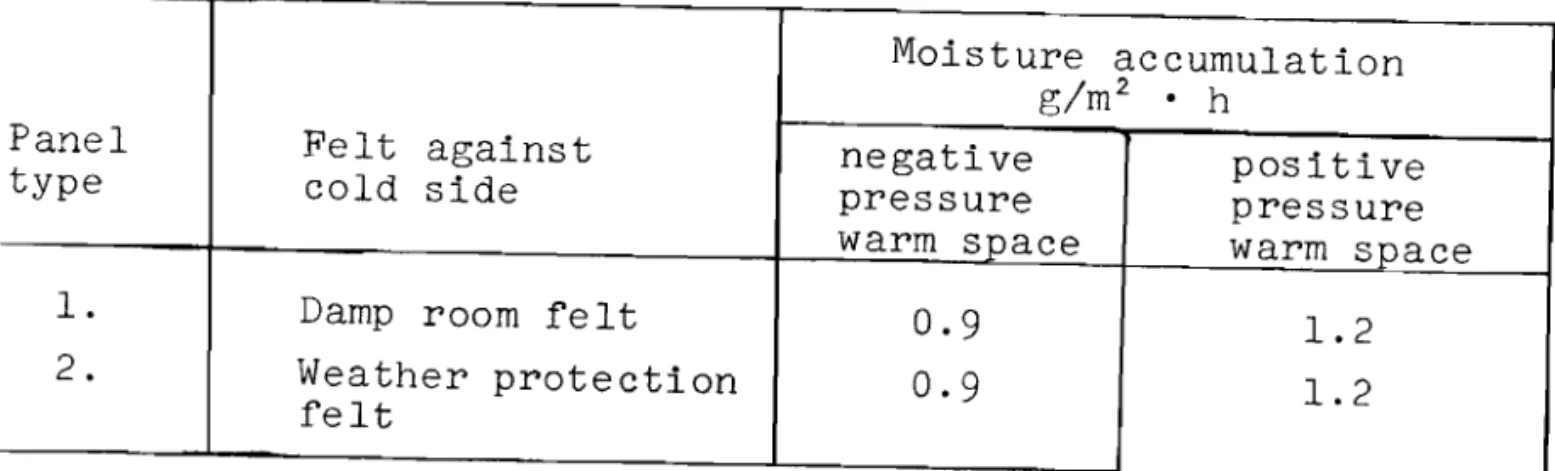

Two different types of felt, namely damp-proof felt and weather protection felt, were tested. Table II shows the moisture accumu-lation with positive and negative pressures on the warm side. The felt against the warm side was weather protection felt.

During the period when the pressure in the heated space was negative, the moisture accumulation was 0.9 g/m2 • h, while during the period when the pressure in the heated space was positive, it was 1.2 g/m2 • h for both types of felt.

Under the aforementioned climatic conditions in the cooling room (7150C), there is no significant difference in the moisture accumulation when either type of felt is used on the cold side of the wall. With other temperature conditions on the cold side, the relationship will change. Felt against the cold side also has a considerable effect on the drying out of the panels. The イ・ウオャエウセ

エィ・イ・ヲッイ・セ must in no way be interpreted to mean that in practiae the density of the exterior felt is unimportant.

A negative pressure in a heated room causes a current of cold, dry air to pass through the wall. Under the pressure, temperature and moisture conditions which were investigated in this case, the air current did not result in the elimination of any appreciable part of the moisture whiah entered the wall by diffusion through the weather proteation felt. A positive pressure on the warm side produced an increase in moisture accumulation of

0.3

g/m2• h, or

approximately

50%,

when weather protection felt was used.On account of this high moisture accumulation in the panels containing weather protection felt on the cold side, three panels, which were very permeable (to diffusion) were also tested in the second test period when a positive pressure was applied to the

During the period when the warm side was exposed to a positive pressure there were comparatively large variations among individual

panels owing to unintentional air leakages. The types of structure

appearing as items 1, 2 and 3 of the table were tested in only one

panel each. Therefore, the results should be regarded as a guide

only.

The panel without felt on the cold side and the panel with

unimpregnated felt both show a high degree of moisture accumulation. The moisture settled on the panel as ice and frost and gradually

accumulated towards the interior of the insulating material. Where

the moisture formation in the open structure panels on the cold side is greater than in the comparatively dense panels, this may

be connected with the fact that the passage of air has also increased. During the period when the pressure on the warm side is positive,

the moisture formation will increase in proportion to the increase

in the passage of air. Even if the number of panels is small, the

tests show clearly that at temperatures of +l50C or less on the

cold side, the exterior panel alone is enough to produce moisture

accumulation in the walls under the given test conditions.

c. The effect of different types of felt on the warm side of the

wall

Two different types of felt, namely damp-proof felt and weather

protection felt, were tested on the warm side. Weather protection

felt was placed on the cold side.

Table IV shows the moisture accumulation with negative and positive pressures on the warm side.

In all cases, moisture accumulation was greatest in panels

with weather protection felt on the warm side. It was at least of

the order of 1.0 g/m2 • h. According to observations made in the

exterior wall panels around the climate laboratory, i t is estimated that the moisture will begin to run down along the felt when the

level of deposition reaches approximately 100 g/m2 • The wooden

struc-tures will then be gradually saturated with moisture. If a moisture

accumulation of 100 g/m2 is taken as the maximum in this type of

with weather protection felt on the warm side, a temperature of

7150C on the cold side, and a temperature of +150C and relative

humidity of

85%

on the warm side.With damp-proof felt and a negative pressure (0.4 mm water

gauge) on the warm side, the moisture accumulation is very small

and of no practical significance. When the panels were opened,

they appeared to be absolutely dry. On the other hand, with a

positive pressure on the warm side, a considerable amount of moisture

also accumulates in the panels which have damp-proof felt on the

warm side and weather protection felt on the cold side. Figure

7

shows ice and frost formation in a pair of test panels at the end of the period when a positive pressure was applied in the heated

space. The panel to the left has weather protection felt on the

warm side, and the panel to the right has damp-proof felt.

It was only in those panels which had damp-proof felt against

the Warm side and when the pressure in the heated space was above that of the cold space that the moisture accumulation in the wall panels came within satisfactory limits.

3.

The effect of pressure conditions on the moisture accumulationin the floor panels

The floor in the cooling room is raised approximately 180 em above the floor of the surrounding room so that warm, moist air

can circulate under it (Figure 1). The floor is made of

8"

planksand insulated with 10 ern of mineral wool. Different types of felt

are laid against the warm and cold sides, in a manner similar to

that used in the wall panel tests. A 10 ern air space is left between

the inSUlating material and the cold felt in the floor panels. The pressure conditions across the floor panel were somewhat

different from the average for the wall panels. Cold air being

heavier than warm air, when the pressure on the warm side is negative the indicated pressure difference will be increased by approximately

0.15 mm (water gauge). With a positive pressure on the warm side

there will be a corresponding reduction in the pressure difference. Therefore, for floor panels, we can estimate that during the period when the pressure on the warm side is negative there will be an

averaGe pressure difference of approximately 0.55 mm (water gauge), while during the period when the pressure on the warm side is positive

there will be an average pressure difference of approximately 0.35 mm (water gauge).

Table V shows the moisture accumulation in the floor panels with negative and positive pressures on the warm side.

The floor panels in the cooling room have the warm side

under-neath and the cold side on top. During the period when the pressure

on the warm side is positive, the conditions will, in principle, correspond to those obtaining in the floors between heated space and loft, flat roof without a loft, and the like.

During the period when the pressure on the warm side was

neg-ative, there was never any moisture accumulation of significance.

This may be due to the fact that the moisture which had spread in through the felt on the warm side and into the cavity was carried

out again by an air current in the opposite direction. This gives

us reason to assume that the air current between the insulating material and the cold felt has a favourable effect in this respect. Moreover, the passage of air in the floor panels was probably greater than in the wall panels on account of accidental leakages.

When the pressure on the warm side is positive, the moisture

accumulation on the floor surfaces is very great: 2 - 3 g/m2 • h.

If the maximum permissible moisture accumulation in this case is

also set at 100 g/m2 , this level will be reached in the course of

30 - 50 hours, i.e., 1 - 2 days. At the end of the test period,

in the course of 140 days, 9 - 14 kg of water per m2 accumulated

in the form of frost and ice in the floor panels. The felt against

the cold side was covered by a thick layer of frost and ice (Figures

8

and9)

and in a few of the panels the cavity was partly filledas well.

The types of felt on the warm and cold sides had little effect

on the moisture accumulation. The panel with damp-proof felt

against the warm side had slightly less moisture accumulation than the other panels, but moisture migration by air currents undoubtedly

out at a temperature of 7150C on the cold side. At higher temper-atures, the type of felt against the cold side is more important.

When the moisture accumulation in these panels during the period of positive pressure in the heated space is this great, it may be due to unintentional leakages at the intersection of floor and wall, or faulty clamping of the felt joints onto the beams. Insofar as the workmanship was concerned, this was done with as much care as in the case of the wall panels and as well as could

be expected in normal practice. There is reason to assume that

the air leakages at the intersection of floor and wall quickly worsen when a joint is formed between the felt in the wall and the

felt in the floor. In the floor panels of the cooling room, the

effect of this joint will be greater than under the conditions usually encountered in practice, since all the floor panels butt

against the wall panels on one or two sides. This also agrees

with the previously cited studies of Granum, Svendsen and Tveit

(1954), which show a considerable decrease in the amount of air

passing through wall panels with penetrating floor joists. In

heated houses, barns, or industrial bUildings, there is often a positive pressure on the warm side, the cold side being on top,

as in this test. There are, therefore, grounds for considerable

concern over the installation of felt in the roof of such bUildings,

especially i f there is a high moisture content in the air. 'I'he

best guarantee against harmful effects of this nature is obtained by maintaining the pressure on the warm side slightly below the

pressure on the cold side, for example, by taking in cold air

through the ceiling of such bUildings.

4.

Moisture distribution in the wall panelsAt the end of each test period, the thickness of the ice

for-mation was measured at different points. Ice formed on the cold

felt only, except in isolated cases where stray air currents caused by excess pressure on the warm side had been disproportionately

large. Gradually, as the frost and ice layer increased in thickness,

a. Pattern of the vapour pressure curve

Figure 10 shows the temperature, the saturation pressure and the calculated vapour pressure across one of the wall panels of

the climate laboratory with weather protection felt on both sides.

As shown on the chart, the calculated vapour pressure curve is higher than the saturation pressure curve for the whole of the

outer half of the wall panels. Nowhere is the actual vapour pressure

higher than the saturation pressure. That is to say, the saturation

pressure in the boundary layer between the insulating material and the felt on the cold side is decisive for the pattern of the vapour pressure curve.

The drop in vapour pressure in each individual layer of the wall is proportional to the vapour resistance in the same layer. Therefore, in determining the actual vapour pressure curve for this structure, it is necessary to take a starting point on the interior vapour pressure and the calculated saturation pressure

on the exterior felt. The vapour pressure curve is easily

con-structed according to the above-mentioned priciples. The actual

vapour pressure curve is shown as a dotted line in Figure 10. viith

this shape of vapour pressure curve it is clear that moisture

for-mation can occur only on cold felt. Moisture will only occur

in-side the insulating material when it builds up from the cold in-side. The displacement of the actual vapour pressure curve in relation to the originally estimated curve is also important for calculating

the amount of moisture which diffuses into the wall. The amount of

diffused water vapour is proportional to the pressure drop across

the layer. On account of the displacement of the vapour pressure

curve, the actual vapour pressure on the interior felt in this

case is

5.4

mm Hg, as opposed to the originally calculated 3.0 mm.The quantity of vapour which diffuses into the wall will for this reason be apprOXimately 80% higher in this case than is indicated

by calculation methods which are sometimes used. The relative

humidity on the cavity side of the felt against the heated space will also be very low on account of the shape of the vapour pressure curve.

If the saturation pressure is consistently above the calculated vapour pressure, no displacement of the vapour pressure curve will occur at all.

b. Distribution of deposited ice

Figure 11 illustrates the ice formation in panels with weather

protection felt on both sides (type 2) at the end of the period

during which the pressure on the warm side was negative. Panels

139 and 149 were not ventilated, while panels 144 and 153 have a

10 cm wide open slit on top. As shown in Figure 11, there is

relatively little variation in the thickness of the ice layer, which

usually reaches a maximum about

5

cm from the supports and decreasessomewhat towards the centre and out towards the supports. The

thick-ness of the ice layer for practical purposes is considered normal

up to 1 - 2 cm from the opening in the ventilated wall panels. In

this test the insulating material did not have a lO cm wide, complete10

open slit in it; the felt and panel against the cold side had a

meas-urable influence on the moisture formation at a greater distance than

5 cm from the opening. This method of preventing condensation in

the cooling room walls must therefore be considered unsuitable. During the period when pressure on the warm side was positive, the moisture formation took a somewhat different form from that

observed during the period when the pressure was negative. Figure

12 shows the thickness of the ice layer for the panels shown in Figure 11 at the end of the period when pressure on the warm side was positive.

In this case, the moisture formation is much more uneven than

in the preceding period. The positive pressure on the warm side

has resulted in warm moist air permeating through unintentional openings into the structures, and the condensation of moisture in the vicinity of those places where leakage has occured.

D. The Effect of Pressure Ratios on Condensation and Moisture Migration under Conditions Encountered in Practice

Systematic investigations of the effect of pressure conditions on moisture migration and condensation encountered in practice rlave

not been carried out previously. Finne (1959) mentions several

cases of heavy condensation formation mainly attributable to moisture migration by air currents in industrial building structures and the like.

On investigating the durability and upkeep of wooden structures in a large number of barns, a clear relationship was established

between ventilation and structural durability. In addition to

elim-inating moisture, ventilation also causes a negative pressure in the

room. In this way warm moist air is prevented from seeping into the

structures. This explains why the floor of a barn with penetrating

beams is especially subject to damage. Figure 13 shows how fresh

air has streamed in through cracks at the intersection of wall and

ceiling and in a wall corner. The barn was well ventilated and the

negative pressure under the roof was approximately 0.2 mm (water

gauge). If the barn had been unventilated, the air stream would

have gone in the opposite direction and caused condensation to form

on the cold side. Figure 14 shows how the wall stud has rotted at

the intersection of the wall and vaulted roof of a cow barn. The

part above the wall is covered with ice and frost from condensed

water vapour. If the wooden roof is put on without felt, a large

amount of moist air could escape through the cracks. Some of the

moisture would penetrate the insulating material, which would then become saturated (Figure 15).

Large cracks, for example around leaky hatches and the like, could result in the upward displacement and condensation of large

quantities of moist air. Figure 16 shows frost formation above

the fore-hatch of the barn, and Figure 17 shows frost formation towards the centre of the loft.

Figure 18 shows ice on the eaves of a barrack which formed as a result of warm moist air seeping out through cracks, the moisture condensing on the eaves, etc.

Condensation between the panes of double windows in a

farm-house is often caused by air currents. Under conditions which

produce a higher pressure on the warm side than the pressure of the outside air, the air between the panes will leak out and

mois-ture will settle on the outside window pane. Experience shows that

in a 2-storey house, for example, which has an open stairway between

the first and second floors, condensation is more prevalent on the

second floor. Furthermore, it is apparent that condensation will

occur primarily on the lee side of the house.

E. Summary

Experience in practice has shown that our present knowledge of the patterns of moisture migration in bUilding structures does not provide an adequate theoretical basis for the calculation of

moisture conditions. One of the reasons for this is that, in

addi-tion to diffusion and capillary sucaddi-tion, moisture can be transported

by random air currents. This factor has not been taken into account

in calculations.

The significance of air currents for moisture transportation in wood frame structures is studied in a climate laboratory at

the Norwegian Agricultural College. The tests are carried out both

on felt samples and full scale structures. The temperature on the

warm side is

+15

0C and the relative humidity85%.

The temperatureon the cold side is +150C. Thus, the test conditions correspond

to those obtaining in a room with high humidity when the outside temperature is low.

The tests show that air currents can carry large quantities

of moisture, which penetrate the structures. Particularly large

quantities of moisture are found in the floors. Damp-proof feZt

on the warm side is not sufficient to prevent moisture formation

under the given test conditions3 i f at the same time the atmospheric

pressure on the warm side is not slightly negative. The type of

felt on the cold side, under the above temperature conditions, did not have any appreciable effect on the moisture formation; neither

did a 10 em wide opening at the top of the wall panels have any significant effect on moisture accumulation.

References

1. Babbitt, J. D. The Physics of Condensation in Buildings.

National Research Council, Bul. No.2, 1952.

2. Cammerer, W. F. and Durhamrner, W. Die Berechnung der

Darnpdiffusions- Vorgange im Baulichen Warme- und Kalteschutz und die dafur zwecksmassigsten

Mess-und Rechnungsgrossen. Gesundheits Ingenieur.

Heft 19/20, 1950.

3. Dick, J. B. Roof condensation in an air-conditioned

factory. J.I.H.V.E. 21, 1954.

4. Edenholm, H. FUktighetsvandring och fuktighetsfordelning

i byggnadsvaggar (Moisture migration and moisture

distribution in the walls of buildings).

Medd. Statens forskningskommitte for Lantmannabyggnader nr. 5. Kap IV, Lund, 1945.

5. Finne, Eirik Kondens i yttervegger (Condensation in

exterior walls). Bygg nr. 4, 1959.

6. Finne, Eirik Kondensteknisk uheldige konstruksjoner

(Unfavourable structures from the point of view of

condensation characteristics). Bygg nr. 9, 1959.

7. Flachsbart, O. Winddruck auf geschlossene und offene Gebaude.

Ergebnisse der Aeoradynarnischen Versuchsanstalt zu Gottingen, Lieferung 4, 1932.

8.

Granum, H., Svendsen, S. D. and Tveit, A. Lette treveggersvindtetthet (Wind resistance of light-weight wooden

walls), Norges byggforskningsinstitutt, report nr. 7,

Oslo, 1954.

9. Granum, Hans Kondensproblemer i hus (Condensation problems

in the house). Bygg nr 2, 1953.

10. Hanson, R. Fukt i yttervaggar och yttertak (Moisture in

exterior walls and roof). Byggmasteren nr. B 10, 1957,

nr. B 12, 1957, nr. B 1, 1958 and nr. B 3, 1958.

11. Irminger, J. O. V. and nセォォ・ョエカ・、L C. Vindtrykk pg byggninger

(Wind pressure on bUildings). iョァ・ョゥセイカゥ、・ョウォ。「・ャゥァ・

skrifter nr. 24, kセ「・ョィ。カョL 1936.

12. Johanson, C. H. and Persson, G. Berakning av fUktfordelning

och fUktvandring i yttervaggar (Estimating moisture

distribution and moi§ture migration in exterior walls).

Teknisk Tidsskrift, Arg. 79, 1949.

13. Joy, F. A. and Fairbanks, D. R. Effect of unbalanced air

pressure on permeance. Heating, Piping and Air

14. Joy, F. A., Queer, E. R. and Schreiner, R. E. Water Vapor

Transfer through Building Materials. Pennsylvania

State College, Eng. Exp. Station Bul. 61.

15. Krischer, 0., Wissman, W. and Kart, W.

Feuchtigkeitsinnwirk-ung auf Baustoffe aus der umgebenen Luft. Gesundheits

Ingenieur (79), Heft 5, 1958.

16. Raiss, Wilhelm H. Rietschels Lehrbuch der Heiz- und

Luftung-stechnik, Berlin 1958.

17. Rowley, F. B., Algren, Axel B., Lund, Clarence E. Condensation

of moisture and its relation to building construction and

operation. University of Minnesota. Eng. Station, Bul.

no. 18. Minneapolis 1941.

18. Torp, aウ「ェセイョ Om kondensasjon i vegger rundt husdyrrom

(Concerning condensation in barn walls). Norsk

Landbruk nr. 20 and 21, 1950.

19. Torp, A. and Graee, T. kッョカ・ォウェッョウウエイセュョゥョァ・イ i

isolasjons-materialer (Convection currents in insulating materials).

Bygg nr. 8, 1956.

20. Tveit, A. Vanndampdiffusjonstall for papp og trefiberplater

(Water vapour diffusion values for felt and wood

fibre-boards). Norges oyggforskn. institutt. Report nr. 9,

1954.

21. Watzinger, A. Die Feuchtigkeitswanderung in isolierten

Table I

MOisture accumulation in grams per m2 per hour

(g/m2 • h) for ventilated and unventilated wall

panels with negative pressure against the warm side of the walls

Moisture accumulation Panel g/m2

.

h Difference Type Ventilated Unventilated g/m2.

h Panel Panel 1. 1.0 0.7 0.3 2. 1.0 0.9 0.1 3. 0.04 0.03 0.01 Table IIMoisture accumulation in wall panels with different types of felt on the cold side

of the wall. The felt against the warm

side was weather protection felt

Moisture accumulation

g/m2

.

hPanel Felt against negative

positive

type cold side pressure

pressure

warm space warm space

1. Damp room felt 0.9

1.2

2. Weather protection 0.9

1.2 felt

Table III

Moisture accumulation in wall panels with dissimilar density on the cold

side. Weather protection felt against

warm side. Positive pressure in

heated space

Structure, cold side

1. No felt, panel only

2. Unimpregnated felt, panel

3.

Asphalt glued impregnatedporous wood fibreboard and panel

4.

Weather protection feltand panel

5.

Damp-proof felt and panelTable IV Moisture accumulation g/m2 • h 1.8

1.5

1.0 1.2 1.2Moisture accumulation with different types of felt on the warm side of the

wall. Weather protection felt against

the cold side

Moisture accumulation

g/m2

.

hPanel, Felt against warm

type side Positive Pressure, Negative Pressure,

heated space heated space

2. Weather protection 0.9 1.2

felt

Table V

Moisture accumulation in the floor panels with negative and positive pressures on the warm side

Moisture accumulation

g/m2

.

hPanel, Felt, warm side Felt, cold side

Negative Positive

type

pressure, pressure,

warm, side warm, side

l . Wea.ther protec-Damp-proof felt 0.0 3.4 tion felt 2. Weather protec-Weather protec- 0.0 3.4

tion felt tion felt

3. Damp-proof felt

Weather protec- 0.0

2.6 tion felt

s

Fig. 1

Climate laboratory and Norwegian Building Research Institute's house for condensation research

1. Refrigeration plant

2. Refrigeration unit, upper part removed

3.

Ventilators for regulating air pressure4.

Exterior test panels5.

Gangway6. Space containing warm moist air

7.

Interior test panels8.

Refrigerated space - two panels removed9. Water evaporator

10. Heating unit

Wind セ

Section

wゥョ、セ

Fig. 2

Pressure conditions around an enclosed bUilding exposed to wind (Flachsbart)

0.15

mm\0.15

mm w.g. negative internal pressureFig.

3

Pressure conditions in a heated room with the neutral layer at haJf the room height

U} Cl> >< (".J...., Pres sure re g. ッセセイG b :

HlN]Zsセyセセpッウゥエゥカ・

U) ( jセBゥSョ・ァ。エゥカ・ Cl> E-; Layout ヲイoュセエセ aboveセpイ・ウウオイ・

Hose , 1 _'IV r-eg. room

Test box Box for drying

air for press. reg. Layout from side

Fig.

4

Experimental layout for testing the effect of pressure conditions

on vapour diffusion through felt

unctured axes npunctured axes P

/b

/

/

V

0/

/

,

1/

..

u

セセ

セM b セNNMMM ',,-. 1 lD 10"'1 .1JI tQI ,1,1 -\D Press. in box, mm w.g. Wt.inc.mg. fJO Fig.5

Average weight increase in mg per hour for punctured and unpunctured boxes

Fig.

6

Wall panel structures with

without lation

Fig.

7

Moisture accumulation in panel with weather protection felt (left) and panel with damp-proof felt (right) on warm side.,

Te::lpo ra tun:

°c

-r-r

' i ;.:&=1]1

1

1 : -MAiᄋセ

I;;

- H ' - - - ;:-

エセョ i I'" 3/".PFLnel--':-=:"':=-,i

-1:---1_.

-r':

Weather protectiOll fcltf--l=i1-=-:1:r:::=_l:;

10 em llli::.er;:d 101001セNャ]ZエZMM I

I

t

\lcather prQtectic.n felt=-

:j:-===

---:j:- .·Zセ セ I , - - 't-1---1.tD

"'·,.ne1

=til: -- ---

サセMセM

Zセ

- -1,-

----ii/-

1- -- -

'0Kゥセ

_uNiセ

セャ

gn

- r-;

Nセ

.,;

Vapour pressure. CUll Hg' I

:jf1J

13セ ,t LNMセセ Saturation pressure IZセ - ---i' ..h _ . _ _ . _

'--J1,J--, 1[' - , I II . ' - - GZMMMMMMMセMセMc。ャ」オャFエャG、 vapour pressure I0セMMMMlIi:

.

オスセZQLᆪ CUrTe 9セMMMMQ:':

MMMMセM MOセA I iActual vapour , I ' I 1.I I eセMMQZGMGMMMイMMG セ pressure CUM'eセエ]iMMセO

5'---

1,--1ャセM

" L __[セ

セ[iG

: -I-3-' I " " ,-;i----tf ---

=it

Fig. 10Temperature, saturation pressure and vapour pressure across wall panels

Panel/32 Panel 144 Panel 142 Panell53

I ID ID

Fig. 11

Thickness of ice formation in mm of four cooling room wall panels at end of period during Which

warm side was exposed to negative pressure. Weather protection felt on both sides

Fig. 12

Thickness of ice formation in mm of four cooling room wall panels at end of period during Which

warm side was exposed to positive pressure. Weather protection felt on both sides

leaks

in corner at intersection

of roof and walls of well-Fig.

15

Frozen sawdust and rotten beam in stab le ceiling.

No felt and poor ventilation

-above a leaky fore-hatch in an unventilated barn