https://doi.org/10.4224/40001227

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE. https://nrc-publications.canada.ca/eng/copyright

NRC Publications Archive Record / Notice des Archives des publications du CNRC :

https://nrc-publications.canada.ca/eng/view/object/?id=8688a83d-0d5c-457d-9e47-61d1faaf2fe6

https://publications-cnrc.canada.ca/fra/voir/objet/?id=8688a83d-0d5c-457d-9e47-61d1faaf2fe6

NRC Publications Archive

Archives des publications du CNRC

For the publisher’s version, please access the DOI link below./ Pour consulter la version de l’éditeur, utilisez le lien DOI ci-dessous.

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at

Consistent ice-crushing physics at small and large scales: from ice

skating to ice-induced vibration of structures

Consistent Ice-Crushing Physics at Small and Large Scales:

From Ice Skating to Ice-Induced Vibration of Structures

Robert Gagnon

Ocean, Coastal and River Engineering

National Research Council of Canada

St. John's, NL, Canada

Ocean, Coastal and River Engineering

Conceptual Model for Ice Crushing

(

Based on in situ experimental observations

)

Crushing apparatus with mirror for viewing the contact zone during experiments. (From Gagnon, 1994a)

Stainless steel crushing platen showing the configuration of pressure and temperature sensors and the liquid sensor. (From Gagnon, 1994a)

Schematic of the medium scale indentation apparatus used in the trench at Hobson’s Choice in 1990. (From Gagnon, 1998)

Frontal view of the flat rigid indentor showing the positions of the viewing window and the pressure sensors. (From Gagnon, 1998)

(a) Conceptual schematic of the ice

crushing test method; (b) Top view of

ice-holder; (c) Side view. (from Gagnon

and Bugden, 2007)

Schematics of the crushing platen (a) and

pressure sensor working principle (b).

(from Gagnon and Daley, 2005).

Ocean, Coastal and River Engineering

Images from three early studies of ice crushing behavior showing high pressure zones consisting of relatively intact ice

encompassed by low pressure pulverized/extruded ice. (Left) From Fransson and Olofsson, POAC 1991; (Center) From

Riska, POAC 1991; (Right) From Gagnon and Molgaard, Annals of Glaciology, 1991.

Ocean, Coastal and River Engineering

Figure 1. A pattern of sequential ice fractures in a two-dimensional ice

formation that is crushed by a plate from the top. Each fracture produces a

spall. (Reproduced from Daley 1992).

Lab Data

Sections of the displacement, pressure and load data from a test using the crushing

apparatus. (From Gagnon, 1994b)

Ice Crushing

Field Data

Time series of displacement (a), piston/diaphragm pressure sensor output (b), PVDF pressure sensor output (c) and load (d) for a segment of Ice Island test Tfr4. The displacement data has not been corrected to account for the ice compliance. The correction would make the gently sloping plateaus almost horizontal. (From Gagnon, 1998)

Lab Data

A section of the liquid sensor data from a test using the crushing apparatus. The test, and time segment, is the same as in the previous figure. (From Gagnon, 1994b)

Ocean, Coastal and River Engineering

1. High-speed imaging

– Thick section crushing lab test (side view)

Crushing Test

2. Very high-speed imaging

– Ice pyramid crushing (view through crushing platen)

Midas / fasttest_02b_C001S0001

Crushing Friction of Ice

a b A B G H cFig. 1. Schematics showing aspects of the ice behavior during the crushing-friction experiments.

(a) Schematic showing the essential characteristics of ice crushing against a flat rigid surface. (b) A 2D schematic depicting ice crushing against a platen surface with square columns. The ice has both a vertical and a horizontal component of movement relative to the crushing platen, where the resultant movement is as indicated. (c) A 3D schematic showing a small portion, a unit area containing one square column, of the view of the ice and platen shown in Fig. 1b. The schematic depicts the time-averaged general flow characteristics of the self-generating squeeze-film slurry as it moves from high-pressure regions, where it is generated, into the lower-pressure gap space and eventually out through the gap exits where low-pressure crushed ice is present. From Gagnon (2016).

Gap-exit flow to low-pressure region

Vertical ice movement

Square column

Platen Base

Platen sliding direction relative to ice Hard-zone ice

Squeeze-film slurry layer exerting high pressure on platen surface

Slurry flow lines

Low pressure slurry-filled gap

Slurry flow lines

Gap filled with ice/liquid slurry

Wet crushed ice (soft zone)

Intact ice (hard zone)

Horizontal ice movement

Vertical ice movement Resultant ice movement

Squeeze-film ice/liquid slurry layer

Crushing platen

1 mm

2 mm Vertical ice movement

Wet crushed ice (soft zone)

Intact ice (hard zone)

Squeeze-film ice/liquid slurry layer

Crushing platen Flow direction

Crushing Friction of Ice

a

A

b

B

C

D

E

F

G

H

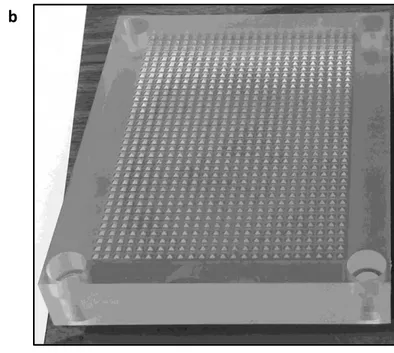

Fig. 2. Test apparatus photographs. (a) Photograph of the crushing-friction test setup. (A)

Vertically-oriented test-frame load cell for measuring the normal load; (B) Mirror; (C) Acrylic

crushing-platen; (D) Ice specimen in ice holder; (E) Rail-car assembly; (F) Load cell used to

measure the horizontal friction force; (G) Linear actuator used to slide the rail-car and ice sample

horizontally; (H) High-speed imaging camera. (b) Photograph of the acrylic platen with the array

of small regular square pyramids on its surface (platen dimensions: 166 mm x 129 mm x 25

mm). The pyramids were 1 mm in height and 2 mm wide at the base. The space between each

adjacent pyramid was 2 mm. The arithmetic average of the high-roughness profile for the surface

of the platen was 0.075 mm. From Gagnon (2016).

Crushing Friction of Ice

Fig. 3.

Main friction coefficient results for the tests

using the crushing platen with the array of square

pyramids.

(Top)

Friction

coefficient

versus

horizontal sliding speed. Tests corresponding to three

vertical crushing rates and five horizontal sliding

rates were conducted. The included data points

corresponding to the tests conducted using the two

flat steel plates represent averages of two tests in

each case, where the vertical crushing rate and

horizontal sliding speed were both set at 10 mm/s.

Scatter in the data, that is inherent in ice crushing

and friction experiments, amounted to about ± 15%.

(Bottom)

Friction coefficient versus gap

cross-sectional area. Granular ice was used for all tests

shown in this figure. From Gagnon (2016).

Crushing Friction of Ice

µ = n w P A / (A

max

L) = n w P H

2

V

h

/ (2 V

c

A

max

L) = V

h

/ V

c

x C

onstant

Where µ is the coefficient of friction, n is the number of square columns in the

hard-zone area, w is the area of a column face, P (~ 55 MPa) is the slurry

(squeeze-film) pressure on a column face on which ice is encroaching, L is the

normal crushing load, A

max

is a certain constant area, A is the cross-sectional

area of the gap where A

max

> A, H is the height of a column, V

h

is the

horizontal sliding speed and V

c

is the vertical crushing rate. Typical values for

the two unknown quantities in the equation, n and A

max

, are the mutually

Schematic illustrating the coupled Molikpaq–ice sheet system during dynamic interaction. The spring constant and mass of the Molikpaq are treated as fixed quantities whereas the spring constant and mass of the ice sheet are treated as effective quantities that vary according to the ice spalling frequency that is directly proportional to the ice sheet speed. Panel (a) shows a highlysimplified rendition of the situation where a mass (i.e. the mass of the structure combined with the effective mass of the ice) is situated be-tween two springs (one for the structure and one for the ice) and the ends of the springs are fixed. Panel b shows the complete situation where movement of the far-field ice is included along with the spall-induced surges of the structure and ice towards each other and the associated energy dissipation. Structure damping of the Molikpaq is also included.