Publisher’s version / Version de l'éditeur:

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

Paper (National Research Council of Canada. Division of Building Research); no.

DBR-P-712, 1976-05-01

READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE. https://nrc-publications.canada.ca/eng/copyright

NRC Publications Archive Record / Notice des Archives des publications du CNRC :

https://nrc-publications.canada.ca/eng/view/object/?id=5fe45535-fad5-4f0d-8152-7ce443e44031 https://publications-cnrc.canada.ca/fra/voir/objet/?id=5fe45535-fad5-4f0d-8152-7ce443e44031

NRC Publications Archive

Archives des publications du CNRC

This publication could be one of several versions: author’s original, accepted manuscript or the publisher’s version. / La version de cette publication peut être l’une des suivantes : la version prépublication de l’auteur, la version acceptée du manuscrit ou la version de l’éditeur.

For the publisher’s version, please access the DOI link below./ Pour consulter la version de l’éditeur, utilisez le lien DOI ci-dessous.

https://doi.org/10.4224/40001672

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at

Some aspects of carpet flammability testing

S e r

TH1

N21d

National Research

Conseil national

"O' 712

l*

Council Canada

c. 2

de recherche Canada

BLDG

-

P" 7

ANALYZED

SOME ASPECTS OF CARPET FLAMMABILITY TESTING

by A.

RoseReprinted from Fire Retardants

Proceedings of 1976 International Symposium on Flammability and Fire Retardants

p. 99 118

DBR Paper No.

712

Division of Building Research

11 nlexiete que tr'es peu de correlations e n t r e l e s rCsultats publies 3 p a r t i r de plusieure essaia suggerks pour l'inflam- mabilitC du tapis. Dane cette communication, c e r t a i n e s eingularitCe du comportement au feu de c e r t a i n s melanges d e f i b r e e eont examin6ee et d e s limitations possibles sont sugg6rCee pour des e s s a i s 3 petite echelle. L16valuation d e l a propagation de la flamme e e t considBrBe poasiblement moine importante que celle de l a furnee, a u moins a u Canada.

SOME ASPECTS OF CARPET FLAMMABILITY TESTING

A. Rose

National Research Council of Canada Ottawa, Ontario K I A

U

R6; CanadaABSTRACT

There is very little correlation between published results from the many suggested tests for carpet flammability. In this paper, some of the oddities in fire performance of certain fibre

I blends are examined and possible limitations of small-scale tests suggested. The evaluation of

flame spread is considered, in Canada a t least, possibly less important than that of smoke.

Carpets are complex structures, both physically and chemically. The diversity in approach to the problem of testing their flammability is probably greater than for any other single type

I of building or furnishing material. Tests intended for conventional building materials have been

used unquestioningly for carpets. A few examples of the global differences in approach are I outlined in Table 1 "Tabulation of Carpet Tests"; the Swedish Br6 test i s an example of the

most unusual approach (Figure 1). I

With a few notable exceptions in the U.S.A. and the U.K., the more widely recognized small-scale tests have not been compared with each other or correlated with more realistic large-scale tests or simulated fire situations. This is no doubt caused by cost considerations, which alone would discourage such extensive comparisons.

In this paper, some of the tests now being suggested by U.S. agencies are discussed in the light of the existing Canadian standard (ULC S102.2 - 1975) and i t s role in determining the acceptability of carpets in meeting the relevant requirements of the National Building Code of Canada. In the case of contract carpets intended for use in corridors and exits of high-rise buildings, rejection by the Canadian test is more frequently due to high SD (smoke developed) ratings than to high FSC (flame spread classification).

ROOM AND CORRIDOR TESTS

C. H. Yuill, formerly of Southwest Research Institute (SWRI), originated the technique of testing floor coverings on the floor of the ASTM E84 tunnel furnace. He carried out a number Reprinted from F I R E RETARDANTS: Proceedings of 1976 International Symposium on Flammability and Fire Retardants

Table 1. Tabulation of Carpet Tests. I . V e r t i c a l Flame T e s t s (Gas Burner Sources]

A . Sample V e r t i c a l , Burner a t 450

(1) German DIN 54332-6 c l a s s e s 105 x 240 mm on ACB 15, 5 , 30 s e c exposure (2)

Swiss

SNV 198897 (1973) - 70 x 250 mn on ACB 5 c l a s s e s ( a i r gap) 45 s e c exposure B. Sanple V e r t i c a l , Burner V e r t i c a l (1) FAR 25.853 (U.S.) 12 x 12 i n . 30 o r 12 s e c exposure (both f a c e s ) I I . P i l o t e d R a d i a n t 2 n i t i a n S w r c e sA. Sample I l o r i z o n t a l , Source a t 30' ( f a c e down)

(1) l h e Armstrong/NBS Flooring Radiant Panel 200 x 1000 mn

Source AS'M El62 Panel a t 49O0C

B. Sample H o r i z o n t a l , Source V e r t i c a l

(1) Proposed IS0 Standard (Revised) 150 x 800 mm

El62 Panel (long a x i s v e r t i c a l ) s 800°C

C. UK Radiant Panel T e s t B.S. 476, P a r t 7 (1971)*

3 x 3 f t panel

-

800°C 9 x 3 6 i n . 15 minD. Sample and Source a t 4S0

(1) French "Epiradiateur"'+ 300 x 400 mm 475 W c i r c u l a r source 20 min ( f a c e down)

E. I t a l i a n Merchant Navy S p e c i f i c a t i o n (4 c l a s s e s )

E l e c t r i c a l l y h e a t e d ASTM El62 Panel - 800.C 150 x 450 m 15 min

111. Swedish Tunnel T e s t SBN U37:18 Br6 ( F i g . 1)

Pine Crib (40-44 gm) - Slope 30' 400 x 1000 mm Wind Velocity 2 m/s

IV. UL S u b j e c t 992 Chamber

Burner a t 22" t o h o r i z o n t a l 22 x 96 i n . 500 Btu/min, 100 fpm a i r flow (153 cfm)

V. ASTM EM-70 (ULC 5102-1975) 20 i n . by 25 f t 5000 Btu/min. 240 fpm (360 cfm) 10 min

VI. ULC S102.2-1975 17 i n . by 25 f t 5000 Btu/min, 240 fpm (360 cfm) 10 min (on f l o o r )

*

Also used i n modified form by Belgium and Holland.

** Supplemented by UK B.S. 476, P a r t 7, f o r h i g h e r f l a m m a b i l i t i e s .

of "short corridor" tests and simulated hospital room burnouts which were very informative,

11-31 but the results were correlated with those of tests on the ceiling of the E84 tunnel with the materials fastened, by means of a silicate adhesive, to 114-in. high-density asbestos-cement board (HDACB), and hence not related to the burnout tests. The test on the ceiling has been criticized as being neither realistic nor reproducible, but SWRl has carried out thousands of such tests for the U.S. carpet industry and even some Canadian companies. It has also done tests on the floor for Canadian applicants.

Figure 1. Modified Swedish roofing test Br6

(see Table 1 ).

Full-scale corridor tests have been carried out by the National Bureau of Standards [4, 51

and by the Illinois Institute of Technology Research Institute (IITRI). The tests by the latter, sponsored by the (U.S.) Carpet and Rug Institute, differed in many respects from the NBS program in size of enclosure, type of lining materials on walls and ceiling, fuel source and

input, size of specimen, and ventilation (Figures 2, 3). Their conclusions were at variance on

the probability of sustained propagation or flashover for essentially similar carpets [61.. Originally the NBS work in both "model" and full-scale corridors was aimed at determining the minimum energy input required to produce sustained propagation.

THE FLOORING RADIANT PANEL TEST

The flooring radiant panel (FRP) test was originally developed by Zabawsky of Armstrong Cork and advanced by Hartzell of that company while attached to NBS as an industrial fellow.

The flooring radiant panel test (Figures 4, 5) in i t s NBS form measures, in W/cmZ, the

radiation level at the point on the specimen where flaming ceases or reaches i t s maximum

spread. This level has been designated as the "critical radiant flux," (CRF) (Figure 6).

Results of extensive round-robin testing indicate that the repeatability and reproducibility (20 and 35 percent, respectively, to 95 percent confidence limits) are probably adequate for

research and development work. Whether the test will be acceptable for regulatory purposes i s

somewhat conjectural.

NBS personnel have examined in the FRP apparatus carpets that had been tested in their full-scale and model corridor work, and also some that were involved in well-documented fires resulting in loss of life. Their concern i s with the hazards of carpets in corridors of hospitals and public buildings and with setting critical radiant flux minima based on their analysis of

r - - - i I I

I-ICCESS

DOOR I I I 1 I I I -,,-I----

AtXLSS DWII OBSERVATION W I N D O W S 4 I I--- I--C---~ I' )---5'-6"+2'-~l''-( -. . . - . ---

so'CORRIDOR NORTH WALL

I * , , ..,Yl,n;', 01 l l r b l A * L 1 1 1 4 , vCurlChLLY F n W LLll IN(> ( 0 I .

.

I I0 / C- . . . .~ - - w, - . . . -.

T I I ~ I I M O C W L E SI-

-- LOClfrD IN IWRWOOUmowrr 0 SMOKE MI TERS

p n o r rur~cs CORRIDOR SOUTH WALL O RADIOMETER

@+

.-1;::i.:

?

:no:

.

I::

2'

I

4 ollc+FNn,cu * , N W S

CORRIDOR FLOOR

-

CRlOS+

% O M - 4NBS C O R R I D O R EXP. I l T R l C O R R I D O R EXP. P R O P A N E E t l E R G Y R A T E e u r n 125,000 WOOD C R l 0 S R o c m STUlmin 0 2 O r n 1 n 40,000 BTUfm in W A L L LOSS- 10,000 B T U / m l n \ P i l o t I g n ~ t ~ o n Window ( 3 4 6 1 EXHAUST r n 0 ^ l ~ 0 W1nd.w ( A I R R E Q ' D " . ~ O - ~ O I ~ / ~ ~ I ~ ) ( A I R R E Q ' D - 9 8 1 b / m 1 n ) Rod.& 0 . 5 w / c m 2 ( 3 4 6 ) op door , I !+/c,2 OD. lcor

CORRIDOR ~ w A L L s - ~ / ~ ' GYPSUM BOARD 3 "

I

r

VILLCS-FIRE B S I C K ( " ~ l k e " P L A S T E R ) OR GYPSUM B 3 A R D CONSTRUCTION FLOOR- T R A N S I T E / BRICK FLOOR -COVCRETEC E l L l Y G h 5 / i ' GYPSUM B O A R D

IL

CEILING- A I P T l T O S B O A R DI1 of 14 Tests Resulted ~n F l a n e o v e r I o f II T e s t s R e ~ u l T e d ~n F l a r r c o v e r 2 o f 14 S p r e a d - loll.

I o f 14 S p r e o d - 2 11 10 a1 11 S p r t a d 5 t o 14 1t S C A L E 0 l I n z l f l

Figure 3. Comparison of NBS and IITR I corridor conditions (Reference 5).

their full-scale corridor results. This approach does not take into account, however, the possibility of fire issuing from beneath a closed door into a ventilated corridor, as has happened in a few cases in apartment and hotel fires, and as shown by the laboratory demonstrations by the Australian Experimental Building Station of penetration beneath fire doors under which synthetic-fibre carpets were installed.

In setting these CRF minima, NBS was interested in the conditions represented by radiant heating of the carpet specimen by flames issuing into the corridor from the open door of the fire room. In the early stages of the crib fire in the abutting room, which has 24 sq f t of carpet between cribs and corridor, air flows into the doorway a t floor level as well as through the floor vents. A t the peak of the fire development air movement may be static or outward. This may produce fuel-rich combustion products a t the corridor ceiling which can contribute to overall propagation and flameover [6] with correspondingly low oxygen levels (Figure 3).

SPEC TR

( A I M E D AT PANEL)

Figure 4. Original flooring radiant panel apparatus (Reference 7).

Figure 5. Original flooring radiant panel enclosed (Reference 7).

THE UL 992 CHAMBER TEST

The U L Subject 992 Chamber Test

[8]

(Figure 7), like the FRP test, has been submittedfor acceptance balloting to ASTM Committee E5. It was developed by Underwriters' Laboratories Incorporated (ULI) a t the request of the U.S. Department of Health, Education and Welfare (DHEW). A round-robin test [9] involving four laboratories was carried out under

1 0 0 c m P R I N C I P A L E L E M E N T S F L A M E / I G N I T I O N / I I S P E C I M E N

n

I N C l D E N l R A D I A N T E N E R G YFigure 6. Flooring radiant 'panel test

-

calculation of critical radiant flux (Reference 1 1 ).126"

VELOCITY T A P

AIR ACCESS FOR VELOCITV PROBE

HONEY COMB BURIED 118"

: / ,

. A , ,. . - - . ...- . ..

i 3 r -

. . . - . . - - . . < - . . . . .

L R E M O V A B L E PLATFORM WATER O U T L E T DAMPER

9

-

1

I

SECTION A.A

Figure 7. Sectional views of U L 992 chamber (Reference 8).

the supervision of NBS. Disparities arising in the comparison were ascribed to differences in air velocity (initially 100 fpm), which is essentially uncontrolled after ignition of the burner.

bimodal distribution (Figure 8), not unlike that encountered under certain conditions in the NBS Model Corridor work by Denyes and Quintiere [ l o ] . This may make the UL 992 test a rather costly "go-no-go" test, whereas the FRP test, which a t least has potential continuity of scale, can be used to set minimum levels for various fire loads and occupancies by consensus.

B

I

PROPAGATION LESS THAN

I

(

SELF-SUSTAINING BURNING 48"-

BURNING I S NOT1

I

PROPAGATION TO 96" SELF-SUSTAININGI -

w= I

I-

I

:

I

I

DISTRIBUTION OF TEST-

FLAME P R O P A G A T I O N I N D E X - C H A M B E RFigure 8. Distribution of flame propagation index results - UL 992 chamber (from Canadian Carpet Institute brief to Associate Com-

mittee on the National Building Code, September 1971).

FURTHER LIMITATIONS OF FRP AND UL 992 TESTS

Among the more serious weaknesses in both of these tests, apart from their inability to measure smoke, are their unrealistic time scales. In the FRP test the radiant panel temperature has been reduced from the 670°C of the original Armstrong Cork apparatus (which was sufficient to bring nylon and polypropylene to a molten state before ignition) to 490 k 10°C.

Even with the now-prescribed warmup to 150°C for the chamber and a 2-min. preheat of the specimen before swinging the pilot burner into contact with the surface, the rate of propagation for carpets of average flammability may be a few centimetres per minute. This propagation is against the convective airflow into the box.

In the UL 992 chamber test the induced airflow is 153 cfm and the burner fuel input 500 Btulmin. In the E84 and ULC S102.2 tests the corresponding rates are 360 cfm and 4500-5000 Btulmin. The rate of propagation in the UL 992 test may be only incheslminute

(as compared with the 5 to 20 ftlmin. in the ULC S102.2 test for most carpets), even if the

flame spread reaches the end of the 8-ft chamber. The flame propagation index in the UL 992

test i s calculated on either a time or distance basis, similar to the method used in the E84 test.

Another disadvantage of the FRP and UL 992 tests is that the specimens are normally laid

on cold 114-in. HDACB. This makes their behaviour very sensitive to the effects of undercushioning or even a plywood base. In the ULC 992 test, felt undercushioning may induce a ten to fifteen-fold increase in the nominal flame propagation index on HDACB. In the

F RP test, reductions of from 10 to 95 percent in the critical radiant flux are possible (Figure

9). These are in many cases much larger than would be predicted from either the full-scale or

model corridor tests a t NBS [ 1 1

I

.

Figure 9. Effect of cushion pad on critical radiant flux of contract carpet products (Reference 11 ).

LIMITATIONS OF THE CANADIAN TEST (ULC S102.2)

The Canadian standard test ( U LC S 102.2 - 1975) [ 121 has some disadvantages, apart from

i t s size and cost. Except for some acrylic carpets, where change in SD may be positive or

negative, the effect of undercushioning on FSC and SD is usually not large. This insensitivity may be entirely due to the specified preheating of the brick floor of the furnace and the resultant thermal gradients in floor and walls, or to the high Btulmin. input. These would seem to be the only possible explanations.

The U LC S102.2 test can, of course, be carried out on HDACB over the preheated floor to

simulate conditions in a gluedown installation, but it then becomes much more onerous and

expensive. Some form of forced-drying equipment for the glued-up assemblies is almost essential if a reasonable rate of testing i s to be maintained and adequate repeatability ensured.

In tests on HDACB, the reductions in FSC and SD for heavy carpets (pile weights over 28 ozlsq yd) show no consistency. The percentage reductions in FSC are certainly not as great as the corresponding changes in the relevant indices of the small-scale (FRP and UL 992) tests.

Further work is required to establish the repeatability of tests on HDACB i f this modification

i s to be considered for incorporation in U LC S102.2.

Whether the results of the Canadian standard test are meaningful is a subject for informed

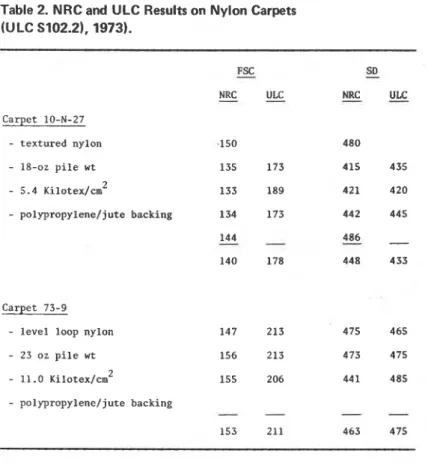

debate. This is equally true of its reproducibility. Agreement between DBR and ULC for nylon carpets with pile weights of 18 and 23 ozlsq yd has been encouraging, considering the differences in construction between the two tunnels (Table 2). Repeatability (within

laboratory) for both FSC and SD has been more than adequate, as research 1131 and many

commercial tests a t DB R have shown.

Table 2. NRC and ULC Results on Nylon Carpets (ULC S102.2), 1973). FSC

-

SD-

NRC K-y-- -

NRC UU: Carpet 10-N-27 - textured nylon ,150 480 - 18-02 pile wt 135 173 415 435 - 5.4 Kilotex/ciu2 133 189 421 420 - polypropylene/jute backing 134 173 442 445 144- -

-

486-

140 178 448 433 Carpet 73-9- level loop nylon 147 213 475 465

- 23 oz pile wt 156 213 473 475

- 11.0 Kilotex/cm2 155 206 441 485

- polypropylene/jute backing

-

-

- -

153 211 463 475

This level of repeatability has not been claimed or demonstrated by the advocates of some "minitests" (excluding the FRP and ULC 992). The FRP and corridor work a t NBS has not, with two exceptions, been correlated, directly or indirectly, with the results of tunnel tests on the floor.

In some other small-scale tests, the ranking of carpets, particularly heavy all-wool types, appears to be out of line with the findings of large-scale tests and real fire experience. In any case, such carpets should be checked out in other tests for reasons which will be stated later.

SMOKE MEASUREMENT

Before discussing some of the results of tunnel tests on a variety of carpets, it is perhaps

emphasized [I31 , the evaluation of SD by integration of an arithmetical obscuration-time curve is inherently unsound a t high smoke levels, levels which were never anticipated in the early stages of E84 development.

Christian and Waterman [I41 have stated that the value resulting from integration of the optical density-time curve for a tunnel furnace run is more likely to correlate with measurements of smoke from corridor tests of a given lining material than the results of NBS smoke chamber tests on the same material. The former approach is the ultimate goal of the ASTM E05.04 Task Group on the revision of ASTM E84; i t s value in the case of carpet tests on the floor is obvious. In spite of structural differences good agreement is possible between laboratories, for example, in tests of a foam-backed carpet on the ceiling of the furnace, as shown by the results of the NBS-organized round-robin tests in 1972 [16], (Table 3).

Table 3. NBS Round Robin Tests

-

1972 ASTM E84 Results.Material - Level loop nylon carpet (NBS #7), pile weight 20 ozlsq yd, polypropylene primary, fire-retardant foam rubber back, total weight 89 oz/sq yd, silicate-glued to HDACB

TUNNEL

-

FSC SD -D (NRC) 208 140

222 206

220 (217) 156 (167)

ULC S102.2 (D) 162 482

THE NBS SMOKE CHAMBER

Installation of the NBS smoke chamber [I61 represents a costly investment and may, in future, require modifications to permit horizontal rather than vertical mounting of thermoplastics and carpet specimens. Although many are being used, this chamber has not been accepted by ASTM as the basis for a standard method. I t has been given tentative status by NFPA. In the meantime, DHEW and other agencies are using it for rating hospital floor

coverings. A Dm limit (flaming exposure) of 450 for carpet and a standard undercushion has been proposed.

SOME ULC S102.2 RESULTS

A number of temperature and obscuration-time curves from DBR tests [I31 and more recent work are presented in Figures 10 to 13. The peculiarities in the curves for such "non-melting" fibres as wool and acrylic are evident. They are perhaps related to low decomposition temperatures [ l o ] , low ignition times (IT, in seconds), rapid evolution of volatiles and fuel-rich conditions in the early stages of the test, followed by momentary fuel depletion and oxygen deficiency.

The curves reflect the pause-retreat behaviour of some carpets made from these fibres as the flame front reaches the 12- to 14-ft mark in the tunnel (17.5 to 19.5 f t from the fire end). A

similar pause may occur, in spite of their much longer ignition times, with nylon and polypropylene carpets, being more pronounced the heavier the pile. The irregular advance is

only indicated, however, by a slight inflexion or minor peak in the temperature-time curve and none in the obscuration-time curve.

Whether these maxima and inflexions reflect some real fire performance characteristic of a given carpet construction and composition or merely a particular combination of tunnel conditions (temperature, airflow, volatiles, oxygen depletion, radiation from smoke) is not known.

The results of tests on wool/ny Ion, wool/polypropy lene and wool/viscose/ny Ion blends, presented in Figures 11 to 13, suggest that the interaction of non-melting wool with thermoplastic nylon or polypropylene produces some interesting effects. Light wool carpets (22 oz tufted), which do not "intumesce" strongly, may have temperature-time curves with two minor but distinct peaks before reaching the maximum, but still give fairly regular obscuration-time curves.

In the case of woollnylon, wool/polypropylene, and nylon/acrylic blends, the ignition times and FSC values are not additive, although from tests a t DBR the SD values may be roughly additive. The IT of the more readily ignitable fibre appears to control the result in every case, including triacetatelpolypropylene blends.

A year ago it might have been said that nylon or polypropylene "interferes" with that odorous and frothy or spongy intumescence which, in heavy wool carpets, apparently protects the backing or undercushioning to give low FSC and SD ratings. This assumption was shattered, however, when two heavy wool carpets, in both the natural and dyed condition, failed to exhibit this intumescence (Table 4). The manufacturer stated that the pile fibre had not been given any special treatment in any of the four samples.

Tests a t DBR have shown that the fireretardant treatment of heavy wool pile by the International Wool Secretariat ( I WS) zirconium mordant process ("Flame- Resist") also inhibits this intumescence. For carpets intended to be tested using the Canadian test, this treatment would be self-defeating to some degree, notwithstanding the results of small-scale tests reported by Benisek [17]. The IT is not significantly increased by the treatment, but the initial rate of propagation is very low, followed by a rapid and sustained advance.

In the light of these vagaries in the fire performance of carpets, it i s suggested that the advocates of the more widely accepted small- and medium-scale tests prove that their methods can detect some of the phenomena occurring, for instance, in the burning of blended fibre

T E M P , x 100 OF M I L L I V O L T S CARPET 9 - N - 1 9 21 oz NYLON, T U F T E D L E V E L L O O P TEMP, x 100 O F M I L L I V O L T S C A R P E T 7 5 - 5 32 oz N Y L O N , T U F T E D R I P P L E LOOP T E M P , x 100 OF M I L L I V O L T S CAR-PET. 7 6 : z 5 5 oz NYLON , T U F T E D P L U S H -. TEMP, x 100 OF M I L L I V O L T S C A R P E T 5 - A - 2 6 2 2 oz ACRYLIC , T U F T E D P A T T E R N E D L O O P

10

,

ICr--- I-

8 I T z 5 3 z Z r-

6 f S C . 2 2 0 5 6 - W W 5-

I- C 2 Oo ' I : ! [ 2 4 6 8 10 TEMP, x 1 0 0 ' ~ MILLIVOLTS C A R P E T I - P - 3 2 0 o z P P T U F T E D L E V E L L O O P 10-1 I I , ' I . ' 10- 1 1 . 4 9 za

- 5 r 6 FSC= 1625

6 W W 2 SD = 535r 4

I- + 2 2 ' 0 0 8 0 ' 2 I4 OC! 2 4 6 8 I 10 TEMP, x 100 OF M I L L I V O L T S C A R P E T 7 6 - 1 1 280z P P T U F T F D L E V E L L O O P l O , , I ~ ' l , I 0 I T 1 2 2 7 8 5 Z 6 FSC - 2 0 95

6 W W 2 4 --

2 I- F 2 2:--

0 4 8 I 2 14-

0

o

L

21

.

4'

1

6m

8

a

1

l od

TEMP, x 1 0 0 OF MILLIVOLTSCARPET 7 5 - 1 3 4 28 oz WILTON P L U S H , 5 0 / 5 0 WOOL / P P

10- - . , . . I0

z e

- I T = 2 4 z 8 I 6 FSC=177 6 - W W 4z

C C 2-

Oo I : i l Y 2 4 6 B 10 TEMP, x 100 OF M I L L I V O L T S C A R P E T 74 - 7 3 31 oz C U T / U N C U T W I L T O N , 5 0 / 5 0 WOOL / P PT E M P , x 100 OF M I L L I V O L T S

CARPET 2 - W - 7 33 oz WILTON P L U S H , WOOL, JUTE /COTTON BACK

TEMP, x I 0 0 OF M I L L I V O L T S C A R P E T 5 ~ W - 1 3 2 2 oz T U F T E D L E V E L L O O P , WOOL - - - - - l o r

,

,

Z 8 ' I T = 2 4 Z_ 8 I.

6 W 2 4 C 2 O O :2 ' . 4 . " 6 10 TEMP, x 100 OF.

M I L L I V O L T SCARPET 75-174 36 oz AXMINSTER P L U S H 8 0 / 2 0 F R WOOL / N Y L O N

TEMP, r 100 OF M I L L I V O L T S

C A R P E T 7 5 - 130 36 nz A X M I N S T E R PLUSH 8 0 1 2 0 WOOL /NYLON

10 i . ( * " ~ I 0 1 1 ' 1 1 1 I 8 - I T = I ~

-

-

Z 8 $011505

6-

Wr

4 --

I- 2 -I

--

0 ~ '2 " "4 " '6 8 10 TEMP, x 100 OF MILLIVOLTSCARPET 7 5 - 6 2 34 oz WILTON P L U S H , 8 0 / 2 0 WOOL / N Y L O N

101

,

,

, ,

,

, ,

,

,

8 - I T 2 2 0 Z 5 6 FSC-152 - - I0 TEMP, x 100 OF M I L L I V O L T S C A R P E T 7 5 - 6 3 4 0 oz WILTON P L U S H , 8 0 / 2 0 W O n L / N Y L O N 10 1 1 1 7 ' 1 1 1 Z - 8 5 0 ~ 3 5 5 Z r 6 FSCz2274

6 W 4 Wz

2 4 C C 2 K O O ~ ~ I ' I I U 2 4 6 8 10 TEMP, x 100 O F MILLIVOLTS CARPET 7 5 - 1 4 5 2 4 oz WILTON P L U S H 5 0 / 5 0 V . 0 0 L L N Y L O N 10 1 . . I 10 8 8 I T 13 7,

6 FSC.230 6 W I 4 W 4 t- Cz

2 2 ' 0 4 ' 8 1 0 12 ' 14 o ~ '2 " '4 I r6 ' d8 10 2 TEMP, x 100 OF M I L L I V O L T S C A R P E T 74 - 124 32 oz WlLTON P L U S H 4 0 / 4 0 / 2 0 WOOL/VISCOSE/NYLONTable 4. Wool Carpets: ULC S102.2 Results.

PILE

CARPET CONSTRUCTION STYLE W. IT FSC SD

2-W-6 Wilton Cut/uncut 4 0 24 30 36

2-W-7 Wilton Plush 3 3 26 10 38

5-W-13 , Tufted Level loop 2 2 19 175 467 75-1 Wilton (undyed) Loop 42 2 1 125 400 75-93 Wilton (dyed) Loop 42 23 131 220 75-2 Wilton (undyed) Loop 70 24 133 407 75-94 Wilton (dyed) Loop 70 24 119 261

76-5 Wilton Plush 35 19 175 290

75-136 Axminster F.R. Plush 36 20 75 152 (I.W.S. "Flame-

Resist" Process)

styles, and that they can rank carpets realistically, with or without undercushioning. They should also show that their tests can detect the effects of changes in carpet construction and

fire-retardant levels as readily as the much-maligned ULC S102.2 test. The FRP results in

Figure 9 suggest that the use of undercushioning will be severely restricted in certain areas i f

they are taken a t face value with no consideration of rate of propagation. In Canada the use of undercushioning with carpets in corridors is common.

Table 5. ULC S102.2 Tests on Wool Blends.

OTHER

FIBRE PILE

CARPET CONSTRUCTION STYLE (a)

.

IT FSC SD 74-145 Wilton Plush 50NY 24 16 221 334 75-61~

II 1 1 I I 19 25 197 172 75-62 I 1 ,I 20NY 34 18 125 150 75-63 I I 1 1 1 1 40 20 152 392'

74-122 1 1 I I 20NY/40V 32 15 237 117 74-73 I I Cut/uncut 50PP 31 25 177 478 75-134 1 1 Plush ~t 28 22 209 410 75-130 Axminster 1 1 20NY 36 19 181 338 ' 1 1 75-174* I I 1 1 36 24 100 197IWS "Flame-Resist" process on wool fraction. (a) NY

-

nylon; PP-

polypropylene; V-

viscose.FUTURE TRENDS

It is not unreasonable to predict that, if present trends in carpet technology and the use of

those of smoke evolution and toxicity. The only exceptions will then be in such special cases

as the interim floor covering standard of the Marine Safety Branch, Transport Canada, or in the aviation field.

In the meantime, the 1975 edition of the National Building Code of Canada imposes certain FSC and SD limits on floor coverings in corridors, stairwells and elevator cars in high-rise buildings. These limits can be met by many contract carpets (except heavy polypropylene) with the present "state-of-theart".

Whatever the limitations of ULC S102.2, the potential testing load for the two tunnel furnaces in Canada has been substantially reduced by the generic acceptance for Building Code purposes of tufted nylon carpets of 18 to 26 ozlsq yd and woven wool carpets over 33 oz/sq yd pile weight, even with felt undercushions up to 40 oz/sq yd in weight, without testing [ 1 81

.

In high-rise buildings in areas other than corridors, stairwells and elevators, the National Building Code of Canada requires only that the pill test [19-211 be passed. This test will be required for all floor coverings, including residential qualities, on 1 July 1976 by the Department of Consumer and Corporate Affairs.

In assessing the future of ULC S102.2, it i s important to recall that the results of tests on the floor rank carpets in substantially the same order as tests on the ceiling with felt or foam backings [ 131

.

On average, FSC values tend to be lower and SD values higher on the floor.Modification of ULC S102.2 by insulating the HDACB face of the cover with a suitably durable lightweight refractory board, coated to reduce smoke absorption, is being studied. Earlier work with linings of low density (40 Iblcu ft) ACB or coated mineral ceiling tile indicated that such insulation would significantly raise the FSC, lower the SD and improve the agreement between the two test modes. Calibration and the selection of a suitable standard material present problems. The influence of undercushioning is not significantly accentuated by the insulation of the cover.

Quintiere and Huggett [6] have calculated that in the E84 test about 40 percent of the burner energy input i s lost within the first 15 f t from the burner at a steady mass flow of input air. Thus in the ULC S102.2 test, with an uninsulated cover, the loss could be higher, leading t o even lower temperatures, t o smoky combustion in the fuel-rich conditions prevailing at some stages, and to the usual smoke deposition on the cover. This deposition i s minimized by the use of efficient insulation.

Quintiere and Raines [22] have shown that at constant draft the mass airflow i s reduced 20 to 30 percent from the initial rate during tests of carpets on floor or ceiling. This, together with the thermal effects already mentioned, may explain some of the peculiarities in the performance of acrylic, wool and heavy nylon or propylene carpets in ULC S102.2 tests (Figure 14).

COOPERATION WITH ONTARIO RESEARCH FOUNDATION

The Division of Building Research i s now engaged in a cooperative project with the Ontario Research Foundation funded by the Canadian Carpet Institute and involving up to 36 carpets; FRP and S102.2 flammability results will be compared, as well as S102.2 SD and NBS smoke chamber results. If the outcome of this work, after objective analysis, i s such that the FRP test gains acceptance as a potential national standard in Canada, then S102.2 may fall into a backup role. I t could still function as a "referee" method where the large specimen size permits a better averaging effect and better detection of the effects of changes in construction and fire retardant levels.

i

T377 NYLON CARPET, FLOOR-MOUNTEDTIME (MINI

Figure 14. Variation in mass air flow during tunnel test (floor mounting) (Reference 22).

REFERENCES

1. C. H. Yuill, Floor Coverings: What is the Fire Hazard? Fire Journal, Vol. 61, No. 1, January 1967. 2. C. H. Yuill, The Flammability of Floor Coverings. J. Fire & Flammability, Vol. 1, January 1970. 3. C. H. Yuill, Fire Tests -The Credibility Gap. Standardization News, Vol. 1, No. 6, June 1973.

4. C. Huggett, Carpet Flammability and the NBS Corridor Fire Program. Standardization News, Vol. 1, NO. 5, May 1973.

5. J. G. Quintiere, A Characterization and Analysis of NBS Corridor Fire Experiments in Order to Evaluate the Behaviour and Performance of Floor Covering Materials. National Bureau of Standards, NBSlR 75-691, June 1975.

6. J. G. Quintiere, and C. Huggett, An Evaluation of Flame Spread Test Methods for Floor Covering Materials. National Bureau of Standards Special Publication 41 1 (Fire Safety Research) November 1974. 7. L. G. Hartzell, Development of a Radiant Panel Test for Flooring Materials. National Bureau of Standards

NBSlR 74-495, May 1974.

8. H. S. Engerman, Floor Covering Systems

-

A Test for Flame Propagation Index. J. Fire & Flammability, Vol. 2, January 1971.9. C. Huggett, and T. G. Lee. Investigation of Carpet Flammability Test Methods, National Bureau of Standards, NBS Report 10 585, September 1971.

10. W. Denyes, and J. G. Quintiere. Experimental and Analytical Studies of Floor Covering Flammability with a Model Corridor, National Bureau of Standards NBSlR 73-199, May 1973.

11. I. A. Benjamin, and C. H. Adams. The Flooring Radiant Panel Test and Proposed Criteria. Fire Journal, Vol. 70, No. 2, March 1976.

12. Standard Test Method for Fire Hazard Classification of Flooring and Floor Covering Materials, Under- writers' Laboratories of Canada, ULC S102.2 - 1975 (formerly CSA B54.9 - 1972).

13. A. Rose, Tests of Soft Floor Coverings Using a 25-Foot Tunnel Furnace, Fire Study No. 33, Division of Building Research, National Research Council, NRC 13918, March 1974.

14. W. J. Christian, and T. E. Waterman, Ability of Small-Scale Tests to Predict Full-Scale Smoke Production, Fire Technology, Vol. 7, No. 4, November 1971.

Coverings. National Bureau of Standards, NBSlR 73-125, March 1973.

16. D. Gross, J. J. Loftus, and A. F. Robertson, Method for Measuring Smoke from Burning Materials, ASTM Special Technical Publication 422, 1966.

17. L. Benisek, Burning Behaviour of Carpets: The Advantages of Wool and Flame-Resistant Wool. Textile Research Journal, Vol. 45, No. 5, May 1975.

18. Fire-Performance Ratings 1975: Supplement No. 2 to the National Building Code of Canada. National Research Council of Canada, Associate Committee on the National Building Code.

19. Standard Method of Test for Flammability of Finished Textile Floor Coverings. ASTM D2859-70T. 20. "Flame Resistance - Methenamine Table Test" Method 27.6P in Canadian Standard Textile Test

Methods, Canadian Government Specifications Board 4-GP-2.

21. Standard for Flammability of Soft Floor Coverings - Sampling Plans, Canadian Government Specifica- tions Board 4-GP-155, January 1974.

22. J. G. Qunitiere, and J. W. Raines, Thermal and Flow Characteristics of the ASTM E84 TunnelTest Method, National Bureau of Standards, NBSlR 75-705, September 1975.

This paper is a contribution f r o m the Division of Building Research, National Research Council of Canada and is published with the al~proval of the Director of the Division.

Thie publication i e being distributed by the Division of Building R e e e a r c h of the National R e e e a r c h Council of Canada. I t ehould not b e reproduced i n whole o r in p a r t without permieeion of the original publisher. The Di- vision would be glad to b e of a e e i e t a n c e i n obtaining such permieeion.

Publications of thd Division m a y b e obtained by m a i l - ing the a p p r o p r i a t e r e m i t t a n c e (a Bank, Expreee, o r P o e t Office Money O r d e r , o r a cheque, m a d e payable t o the R e c e i v e r G e n e r a l of Canada, c r e d i t NRC) to the National R e e e a r c h Council of Canada, Ottawa. K1A OR6

.

Stamps a r e not acceptable.A l i e t of a l l publications of the Division is available and m a y b e obtained f r o m the Publications Section, Division of Building R e s e a r c h , National R e e e a r c h Council of Canada. Ottawa. KtA OR 6.