READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE. https://nrc-publications.canada.ca/eng/copyright

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

NRC Publications Archive

Archives des publications du CNRC

This publication could be one of several versions: author’s original, accepted manuscript or the publisher’s version. / La version de cette publication peut être l’une des suivantes : la version prépublication de l’auteur, la version acceptée du manuscrit ou la version de l’éditeur.

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at

Condensation in insulated masonry walls in summer

Wilson, A. G.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site

LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

NRC Publications Record / Notice d'Archives des publications de CNRC:

https://nrc-publications.canada.ca/eng/view/object/?id=6797b6df-495e-4915-b866-e5be29124f44

https://publications-cnrc.canada.ca/fra/voir/objet/?id=6797b6df-495e-4915-b866-e5be29124f44

Ser

TIIl

N2lt2

n o . 2 2 6

e . 2

BI,DG

N A T I O N A L R E S E A R C H C O U N C I L CANADA C O N S E I L N A T I O N A L D E R E C H E R C H E S8ff40

CONDENSATION IN INSULATED MASONRY \TALLS IN SUMMER b y A . G . W i l s o n

A N A , L Y Z E D

R I L E M / C I B S y r n p o s i u m , H e l s i n k i , 1 9 6 5 r r M o i s t u r e Problems in Buildingst' PREPRINT 2 - 7 T e c h n i c a l P a p e r | i o . 2 2 6 of the D i v i s i o n o f B u i l d i n g R e s e a r c h OTTAWA J u l y I 9 6 6 N R C 9 1 3 0 P r i c e l 0 c e n t s7t zz-qc (

o f B u i l d i n g R e s e a r c h o f t h e N a t i o n a l R e s e a r c h C o u n c i l . I t s h o u l d n o t b e r e p r o d u c e d i n w h o l e o r i n p a r t , w i t h o u t p e r r n i s -s i o n o f t h e o r i g i n a l p u b l i s h e r . T h e D i v i s i o n w o u l d b e g l a d t o b e o f a s s i s t a n c e i n o b t a i n i n g s u c h p e r r n i s s i o n . P u b l i c a t i o n s o f t h e D i v i s i o n o f B u i l d i n g R e s e a r c h r n a y b e o b t a i n e d b y r n a i l i n g t h e a p p r o p r i a t e r e r n i t t a n c e , ( a B a n k , E x p r e s s , o r P o s t O f f i c e l M o n e y O r d e r o r a c h e q u e r n a d e p a y -a b l e -a t p -a r i n O t t -a w -a , t o t h e R e c e i v e r G e n e r a l o f C a n a d a , c r e d i t N a t i o n a l R e s e a r c h C o u n c i l ) t o t h e N a t i o n a l R e s e a r c h C o u n c i l , O t t a w a . S t a r n p s a r e n o t a c c e p t a b l e . A c o u p o n s y s t e r n h a s b e e n i n t r o d u c e d t o r n a k e p a y -r n e n t s f o -r p u b l i c a t i o n s r e l a t i v e l y s i r n p l e . C c u p o n s a r e a v a i l -a b l e i n d e n o m i n -a t i o n s o f 5 , 2 5 a n d 5 0 c e n t s , a n d r n a y b e o b -t a i n e d b y r n a k i n g a r e r n i t t a n c e a s i n d i c a t e d a b o v e . T h e s e c o u p o n s r n a y b e u s e d f o r t h e p u r c h a s e o f a l l N a t i o n a l R e s e a r c h C o u n c i l p u b l i c a t i o n s , A l i s t o f a l l p u b l i c a t i o n a o f t h e D i v i s i o n o f B u i l d i n g R e s e a r c h i e a v a i l a b l e a n d r n a y b e o b -t a i n e d f r o m -t h e P u b l i c a -t i o n s S e c t i o n , D i v i s i o n o f B u i l d i n g R e s e a r c h , N a t i o n a l R e s e a r c h C o u n c i l , O t t a w a , C a n a d a .

illltililillilllillt

i lililullluMmuufiu

6 1 3 2

2 - 7

CONDENSATION IN INSULATED MASONRY WALLS IN SUMMER

A . G . W I L S O N ' )

N a t i o n a l R e s e a r c h C o u n c i l

D i v i s i o n o f B u i l d i n g R e s e a r c h , B u i l d i n g S e r v i c e s S e c t i o n O t t a w a , C a n a d a

Masonry walls for residential construction in Canada require some form of insulation for wintertime comfort and fuel economy. ln order to achieve a thermal standard equivalent to that normally provided by insulated wood-frame construction, approximately 2 in. (5 cm) of insulation is needed. One method is to apply blanket or batt insulation on the inside of the masonry, between wood funing striPs that support the inside finish. It is normal practice to provide a vaPour barrier membrane ofl the inside of the insulation to control condensation due to outward moistute

movement in winter.

An additional consideration is the moisture seParation required, if any, between the masonry and the inner components of the wall. To study this question for conditions in central Canada, some insulated masonry test huts were constructed in Ottawa; these were heated and humidified in winter and observations were made of moisture conditions throughout the year. No moisture Problems were encountered in winter but some undesirable wetting conditions developed during the summer period. This paper describes the consEuction anangements and the moisture observa-tions.

DESCRIPTION OF WALLS

Each wall' arrangement was constructed in the form of a square hut having inside dimensions of approximataly 4 by 4ft (1'.2 by 1.2 m) in plan and 8 ft (2.4 m) high. The hurs were supported over openings incorporated in the top of underground iervice tunnels. The hut constructions can be divided into two grouPs as shown in Figure 1. In .the first group, rhe service tunnel was oriented apProximately north

')Head, Building Services Section, Division of Building Research, National Research Council, Ottawa, Canada.

P L A S T E R B O A R D V A P O U R B A R R I E R 2 ' ' X 2 ' ' F U R R t N G O N 1 6 " C E N T R E S 2 . ' M I N E R A L W O O L B A T T S B U I L D I N G P A P E R A N D r/z pARGtNG ltN HUr t qilLrl 8 " M A S O N R Y H A R D E O A R D V A P O U R B A R R I E R 2 " X 2 . ' F U R R I N G O N 1 6 " C E N T R E S 2 . . M I N E R A L W O O L E A T T S j / 2 " FlBREB0AR0 (til Hur 7 oilLrl S U I L D I N G P A P E R

7a arn spacr st/) eatcx

W E E P H O L E S

G R O U P I H U T S G R O U P 2 I { U T S

Figure 1. Construction details of test hut walls.

and south and the huts were 15 ft (4.6 m) apart, centre*to-cenEe, so that north and south walls were partly screened by adjacent huts. The insulated flat ,roofs overhung the walls by about 6 in. (L5 cm). In the second group, the hut spacing was the same but the service tunnel was oriented east and west, so that east and west walls were partly screened; the flat roofs had essentially no overhang and rain water was piped to the ground. Conditions inside the huts were maintained at approximately ?0oF (219q and 40 per cent relarive humidity throughout the winter months. During most summers, ttre roofs were raised about 2 in. (b cm) above th'e walls to permit some ventilation in order to prevent excessive inside temPeratures and humidity. A general view of the test hut installations is shown in Figures 2 and 3.

A11 masonry walls were the same type in that they employed an inner con-struction of mineral wool between wood fuming 2 in. (b cm) thick, a vapour barrier, and inside finish. The general arrangement of the components is shown in Figure 1. walls in Group 2 differed from Group L in that they incorporared a 3/4-in. (1.9 cm) air space on rhe inside of rhe masonry.

Walls in huts 1 and 2 were of solid masonry consisting of two wythes of clay brick 4 in. (10 cm) thick. The brick, which was manufacrured locally, had a high rate of water absorption and a moderate total absorption as measured by ASTM Method C6?. The mortar was a 1:1.:6 mix of cement, lime, and sand. In hut 1, the inner face of the brick had a L/2-n (1.9 cm) thick parging coat of cemenrr

2 - 7

F i g u r e 2 . G r o u p L h u t s .

F.igrure, 3;-..Group:2 huts.

lime, and sand in proportions of 1:1:3; a layer of asphaltsaturated felt building paper having a permeance of about 3 permsl) was installed between the masonry and furring. These components were omitted in hut 2 and the wood, furring was placed in direct''contact with the brick. Hut 3 was constructed similarly except that,rthe masonry: was 8-' by 8- by 16-in. (20 by 20 by 40 cm) hollow lightweight concrete blocks with four elliptical cores per block. The concrete blocks were of slag aggregate and were coated on the weather side with a wash coat of white portland cement followed by one coat of white portland cement-base painl

Mineral wool batts used in Group J. huts incorporated an inner paper membrane, with a vapour permeance of about 25 perms, that was stapled to the inner surface of the wood furring. A separate vapour banier membrane, with a vapour permeance of about 0.45 perms, was applied over this, followed by the inside finish ofgypsum board.

The masonry in Group 2 huts consisted of a single wythe of clay brick. The brick units were tl-1/2 in. long by 5-l/2 in. wide (28 by 14 cm). They were from a different source than those used in huts 1, and, 2 but were somewhat similar in absorption characteristics. The mortar consisted of lime and sand in 1:3 pro-portions.

In all Group 2 walls, nominal L- by Z-in. (2.5 by 5 cm) vertical wood furring strips were fastened to the inside surface of the brick to form the 3/4-iu (1.9 cm) air space. In hut.4, strips of moisture-resistant building paper were applied between the furring and brick: in other Group 2 huts, the funing was applied directly to the briclc A layer of asphalt felt sheathing paper (vapour permeance approximately 6 perms) was applied to the inner surface of the 1- by 2-in. (2.5 by 5 cm) furring in all Group 2 walls. This was followed directly by 2- by 2-iu (5 by 5 cm) wood funing in huts 4, 5, and 6. In hut 1, a Layer of U?-in. (1.3 cm) wood fibreboard was placed between the sheating paper and the iflner furring to simulate the ar-rangement of materials in typical brick-veneer consfiuction.

Mineral wool batts in hut 4 incorporated an inner paper membrane with a permeance of about 0. 3 perms; this was followed by a vapour barrier paper (permeance about 0.6 perms) applied over the face of the 2- by 2-in. (5 by 5 cm) furring, and an inside finish of t/Z-in. (1.3 cm) gypsum board. In huts 5, 6, and 7, the mineral wool had no inner membrane and a 2-mil (0.05 mm) polyethylene vapour barrier (permeance of 0.2 perms) was used; the inside finish was 1/4-in. (0.6 cm) hardboard.

There was no wood blocking at the top of the 3/4-in. (1.9 cm) air space in hut 4; thus the spaces were open to outside at the top during the summer, when the roof'was raised. The weep holes at the boftom of the space, which were present in all Group 2 walls, did not contribute to venting of the space since they were connected to measuring bottles. The blocking at the top was also omitted in hut 5 and, in addition, openings with a diameter of 5/8-in (1.56 cm) were provided through the brick at the centre of each fe-in (41 cm) wide space, top and bottom. In this way, the spaces were vented throughout the year, with in-creased venting area during the summer. There was blocking at the top of the spaces, in huts 6 and 7, so that no venting occurred even with the roof raised in summer.

Measurements were made of the moisture content of some of the wood furring strips in all huts, using permanently installed brass electrodes in conjunction with a calibrated resistancetype wood moisture meter. Thermocouples were installed adjacent to the electrodes so that the necessary temperature corrections could be applied to the meter readings. Weather records were taken daily at both test hut

2 - 7

installations. These included some measurements of the horizontal comPonent of raln with gauges facing the principal directions at the site of the Group 2 huts; similar gauges were used to obtain records of rain striking the walls.OBSERVATIONS

The interior of the north and south walls of huts L to 3 were first examined in early October, t-U2 years after erection. Thorough wetting of the outer surface of the vapour barrier and the inner surface of the insulation membrane was noted on the south walls of huts I and 2z there was no significant wetting of the north walls. No wetting was noted in hut 3. The interior finish was removed from the north and south walls in mid-August of the following year. Again, most of the outer surface of the vapour barrier in huts 7 and, 2 was very wet on the south side with no visible moisture on the north side. In hut 3, there were some slight patches of moisture on the outer surface of the vapour barrier in the south wall and none in the north. In JuIy of the next yeat, the observations for north and south walls were similar, with wetting in hut 2 being most pronounced. The other walls of this hut were also examined; water that had condensed on the vapour bartier of the east wall had been sufficient to flow to the floor and wet the framing and wall board. Deterioration of vapour banier and insulation membranes, and of furring and wall board at lower levels, was well advanced; it may have been accelerated by high interior temperatures during the first two summem since roofs had not been raised for ventilation. Wetting conditions in the west wall were similar although less severe. No condensation was observed during examination of inner components of north and south walls of Group t huts on two occasions in late winter.

Measurements were taken of the moisture content of the wood furring in north and south walls of huts 1 to 3, using the resistance meter; all huts showed very similar trends. Moisture content of the wood in the winter period was low in both north and south walls, generally less than 10 per cent by weight with little fluctuation: it would begin to rise in April or May and would fluctuate widely with relatively high values throughout the summer and fall; low winter values were obtained by December. Peak values in the summer and fall exceeded 20 per cent in the south walls of all huts; values near the top of the wall were smaller than those at lower levels, due to the roof overhang. Peak values in the north walls were generally somewhat smaller than those in the south, although the moisture content trends were similar. The differences in condensation conditions that were actually observed in the summer were not reflected in the moisture content values of the wood.

In hut 4, moisture content was measured in inner and outer fuming in all four walls. Variations in moisture content with time were similar to those noted in huts 1 to 3. During the winter period, the moisture content of the outer furring strips was usually about 15 per cent, slightly above that of the inner furring. Fluctuations

BARS SHO* FAIN COI.LECTED II'I, D R I V I N G R A ] N G A I I G E S $ O U i I T E D O N { A L L S F

E r s

'u= r o

@ u 5 E F o = 2 ss

0 . 4 0 . 3 o . 2 0 . 1 0 0 . 4 0 . 3 0 . 2 0 . 1 0 F 2 z o G=

o ts z o & o z 4 G;

Figure 4. Moisture content of outer wood funing, north walls" huts 5 and 6.

in spring-to-fall values varied with the direction of exposure, and could usually be related to the records of driving rain; peak vatrues exceeded 2E per cent in many instancesi the val,ues for the outer furring oft the north wall were significantly higher than for the inner furring, while values for the inner funing were usually higher on the south walh on east and west walls there was usually little difference between inner and outer values.

The inner wall components of hut 4 were dismantled in early October, 5 years after erection. At that time, a heavy accumulation of water droplets was observed on the outer surfaees of the sepaw;te, vapour barrier and inner surface of ttre batt mernbtane orrer the wholg of the sdattf raall- SimiIaF wefting $ra$ noed cver parrs of the easE and west walls; the north r*all componeuts were dry. There was no indication of significanr deterioradon in any of the four exposures.

In huts 5, 6, and ?, moisture conditions at the polyethylene vapour banier were observed regtrlarly during the summer. Water droplets were noted on the outside of the vapour barrier of the unvented walls (hurs 6 and ?) from spring to fall on all but the north exposure. With warm, sunny weather following a period of wet weather, there was sufficient water to flow to the boftom of the walls and wet wood members. Moisture accurnulation was generally greatest on the east wall, followed by west and south. No significant wetting of the vapour bamier was observed on any of the vented walls of hut 5.

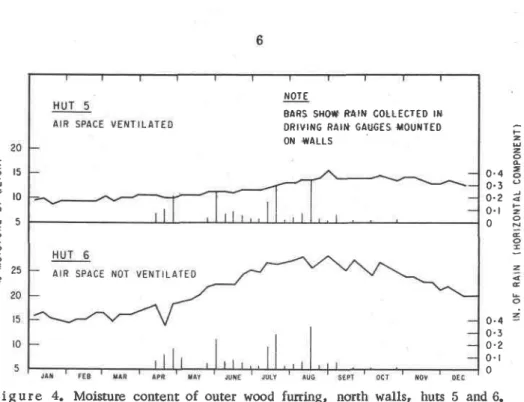

Moisture content of the furring strip was measured on north and south walls only. The pattem for huts 6 and 7 was similar to ttrat for hut 4; maximum values in summer exceeded 20 per cent on the south exposure and 25 per cent on the

2 - 7

north; north wall values were usually higher than south wall values, which were less than 20 per cent during most of the summer. Furring suip moisture contents in hut 5 generally did not exceed 15 per cent on either exposure. Figure 4 shows typical paftems of furring stdp moisftf,e content values for huts 5 and 6 selected to show the effect of venting.

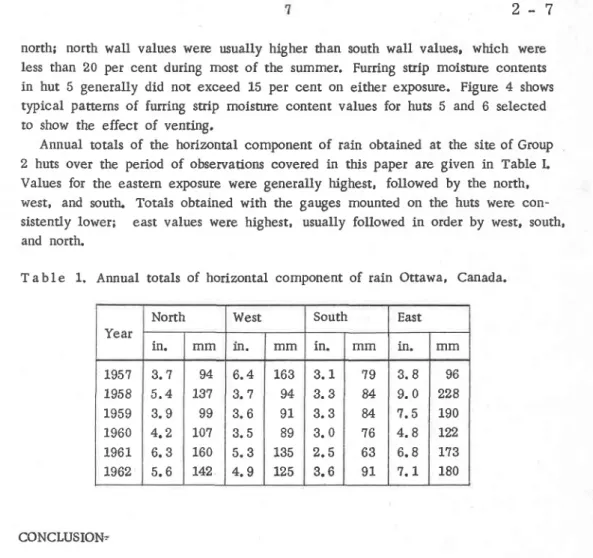

Annual totals of the horizontal component of rain obtained at the site of Group 2 huts over the period of observations covered in this paper are given in Table I. Values for the eastern exposure were generally highest, followed by the north, west, and souttL Totals obtained with the gauges mounted on the huts were con-sistently lower; east values were highest, usually followed in order by west, south, and north.

Table L. Annual totals of horizontal component of rain Ottawa, Canada.

Year

North West South EaSt

in. mm

rn

mm ln. mm ln. mm 195? r.958 1 9 5 9 1960 1961 t962 3 . 7 5 . 4 3 . 9 4 . 2 6 . 3 o . o 94 L37 9 9 10? 160 1426 . 4

3 . 7

o . o3 . 5

5 . 3

4 . 9

163 94 9 1 89 135 L25 3 . 1 3 . 3 3 . 3 3 . 0 2 . 5 3 . 6 '19 84 84 ' l o 6 3 9 1 3 . 8 9 . 0 ' 1 . 5 4 . 8 6 . 8 7 . L 96 228 190 L22 1?3 180 CONCLUSIOI$.Moisture contained in masonry walls exposed to the sun is transferred by diffusion toward the inside of the building in summer. This vapour trnovement can result in condensation of water in the insulation and on the vaporu barrier of walls incorpora-ting permeable insulation on the inside of the masonry. Under adverse conditions' the amount of condensation can be sufficlent to encouage deterioration of inner components.of the'wall. -Problems arising ;ftorn this tource can be avoided by using" an exterior cladding that is not readily wetted by rain, or where absorptive masonry is used, by ventilating with outside air between the masonry and inner components. Such venting may also result in less wetting of masonry during driving rain con-ditions, by equaiizing air pressures across it, and in more rapid drying of wetted masonry during dry weather.

This paper is a contribution from the Division of Building Research. National Research Council of Canbda and is published with the approval of the Director of the Divislon.