Publisher’s version / Version de l'éditeur:

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

International No-Dig Show Conference Proceedings [Proceedings], pp. 1-11,

2009-03-29

READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE.

https://nrc-publications.canada.ca/eng/copyright

NRC Publications Archive Record / Notice des Archives des publications du CNRC :

https://nrc-publications.canada.ca/eng/view/object/?id=fd144358-6bc0-4089-86cc-8bb8132e8d9d https://publications-cnrc.canada.ca/fra/voir/objet/?id=fd144358-6bc0-4089-86cc-8bb8132e8d9d

NRC Publications Archive

Archives des publications du CNRC

This publication could be one of several versions: author’s original, accepted manuscript or the publisher’s version. / La version de cette publication peut être l’une des suivantes : la version prépublication de l’auteur, la version acceptée du manuscrit ou la version de l’éditeur.

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at

GIS-based decision support system for evaluating costs and benefits

of sewer renewal technologies

http://www.nrc-cnrc.gc.ca/irc

GI S-ba se d de c ision support syst e m for e va lua t ing c ost s a nd be ne fit s

of se w e r re ne w a l t e c hnologie s

N R C C - 5 2 6 6 8

H a l f a w y , M . R . ; B a k e r , S .

M a r c h 2 0 0 9

A version of this document is published in / Une version de ce document se trouve dans:

International No-Dig Show Conference Proceedings, Toronto, ON, Mar. 29–

Apr. 2, 2009, pp. 1-11

The material in this document is covered by the provisions of the Copyright Act, by Canadian laws, policies, regulations and international agreements. Such provisions serve to identify the information source and, in specific instances, to prohibit reproduction of materials without written permission. For more information visit http://laws.justice.gc.ca/en/showtdm/cs/C-42

Les renseignements dans ce document sont protégés par la Loi sur le droit d'auteur, par les lois, les politiques et les règlements du Canada et des accords internationaux. Ces dispositions permettent d'identifier la source de l'information et, dans certains cas, d'interdire la copie de documents sans permission écrite. Pour obtenir de plus amples renseignements : http://lois.justice.gc.ca/fr/showtdm/cs/C-42

GIS-BASED DECISION SUPPORT SYSTEM FOR EVALUATING

COSTS AND BENEFITS OF SEWER RENEWAL TECHNOLOGIES

Mahmoud R. Halfawy1, and Samar Baker1

1 Department Centre for Sustainable Infrastructure Research, Institute for Research in

Construction, National Research Council of Canada, 6 Research Drive, Regina, SK, Canada.

ABSTRACT: Sewer renewal technologies are advancing rapidly, and becoming more efficient

and cost-effective. Different technologies exhibit different capabilities, limitations, costs, and benefits, which collectively serve as the main criteria for evaluating alternative options. This paper describes the development of a prototype GIS-based decision support system (DSS) for evaluating alternative sewer renewal technologies, including open-cut/trenchless replacement and structural/semi-structural/non-structural lining. The software quantitatively evaluates the applicability, costs, and benefits of alternative renewal technologies. Applicability is evaluated based on a set of criteria that include sewer characteristics (e.g., existing defects, diameter, material, depth, age, etc.), site conditions (e.g., soil type, groundwater level, work area requirements, traffic volume, etc.), along with other social and environmental factors. The expected cost and benefit of each applicable renewal technology are then estimated, and used to optimize the selection of the technologies with the best cost/benefit ratio. Costs are calculated in terms of direct and indirect cost. Benefits are calculated in terms of sewer service life prolongation. The paper also presents an example application of the prototype DSS using data sets from the City of Regina.

1. INTRODUCTION

The structural integrity of sewers deteriorates due to a wide range of reasons, including ageing, improper design and installation methods, inadequate maintenance, traffic conditions, sewage characteristics, surrounding soil condition, and groundwater fluctuations (WRc 2001a, Davies et al. 2001, WERF 2000, EPA 2007). Structural problems (e.g., cracks, sagging, corrosion, defect joints, etc.) typically lead to hydraulic inadequacy by causing excessive infiltration/inflow, thus reducing the hydraulic capacity of the network (InfraGuide 2003).

Renewal technologies are advancing rapidly and becoming more efficient and cost-effective. The use of trenchless methods has been steadily increasing around the world. New materials and construction methods are constantly introduced into the market, causing the process of evaluating these technologies and selecting the most appropriate solution to become a daunting task for municipal practitioners. This process remains, by far, heuristic and subjective, and is still largely performed in a manual fashion, with limited software support.

Renewal methods include a wide range of replacement and rehabilitation technologies. Replacement technologies are typically used when the sewer’s structural integrity is severely compromised, or to significantly increase its hydraulic capacity. Rehabilitation technologies aim to extend the sewer’s service life by restoring its structural integrity and improving its hydraulic performance, and are generally used when the sewer’s structural integrity and hydraulic capacity are not severely compromised.

Different renewal technologies exhibit different capabilities, limitations, costs, and benefits, which collectively serve as the main criteria for evaluating alternative options. The specific

characteristics of the sewer (e.g., material, diameter, depth, age, etc.) and site conditions (e.g., soil, groundwater table, traffic condition, etc.), along with other operational, social, and environmental factors typically determine the applicability and feasibility of alternative technologies in a particular situation. In any given scenario, some technologies are more suitable and cost-effective than others, and therefore, a systematic decision-making procedure for selecting feasible technologies is needed (WEF and ASCE 1994, WRc 2001, and InfraGuide 2005).

This paper proposes a decision-support model and GIS-based software tool that could potentially support the evaluation of alternative renewal technologies in any given scenario, taking into consideration the applicability, limitations, costs, and benefits of each possible technology. The proposed model defines a procedure to quantitatively assess and evaluate the costs and benefits of alternative renewal methods, which would reduce the subjectivity typically employed in the decision-making process. The implementation and example application of the software system is also presented.

2. DECISION SUPPORT MODELS FOR SELECTION OF SEWER RENEWAL TECHNOLOGIES

During the last decade, several procedures, guidelines, and decision models have been proposed to assist in the evaluation and selection of appropriate renewal technologies. A set of guidelines and best practices are provided in several manuals of best practices such as WEF and ASCE (1994), WERF (2000), WRc (2001), and InfraGuide (2003). InfraGuide (2003) proposed guidelines and a decision model for the selection of renewal technologies for new construction and in-line replacement of sewers. The approach uses a set of tables and forms with yes or no questions, to evaluate the technical compatibility of the renewal methods with the project requirements.

Abraham et al. (1998) proposed an integrated sewer management system that used probabilistic Markovian deterioration models and deterministic dynamic programming to optimize the selection of sewer rehabilitation techniques. Hastak and Gokhale (2000) developed a decision support model to assist in evaluating and selecting renewal technologies by qualitative evaluation of groups of criteria using the analytical hierarchy process (AHP). The criteria include user requirements and project-specific characteristics such as site and soil characteristics, condition of existing sewer, and design life of the new sewer. Fenner (2001) presented a review of several techniques employed in a number of countries for optimizing and prioritizing sewer rehabilitation strategies. Shehab-Eldeen and Moselhi (2001) described the development of a decision support system to assist in selecting appropriate trenchless rehabilitation methods for concrete and clay sewers based on sixteen criteria that cover technical and contractual requirements of the project. Diab and Morad (2001) proposed a multi-criteria approach for selecting appropriate rehabilitation methods for sewers. These criteria include hydraulic and structural performance, material durability, and direct and social costs. Plenker (2002) defined a decision support model based on a formalized weighing and ranking procedure that compares and ranks alternative methods, pair by pair, using multiple criteria. These criteria can be measured on different scales, and may include construction technology, environmental compatibility, economics, and legal aspects.

The Computer-Aided Rehabilitation of Sewer Networks research project (CARE-S 2007) was an international collaborative effort to develop a comprehensive suite of tools to support the rehabilitation planning activities. As part of this project, Baur et al. (2003) developed a multi-criteria approach for selecting the best renewal methods using the balancing and ranking procedure. More recently, Matthews and Allouche (2006) developed a software tool, titled the trenchless assessment guide (TAG) that can assist in evaluating the technical feasibility and expected risk levels of alternative renewal methods. The technical feasibility is evaluated based on the sewer characteristics and performance parameters, soil compatibility, and the viability of in-line replacement options. The risk levels are evaluated based factors such as the installation

parameters (sewer length, diameter, and depth), method compatibility with soil conditions, environmental impact, and owner’s experience with the methods. Jung and Sinha (2007) defined a method to quantitatively evaluate and compare direct, social, and environmental costs of open-cut and trenchless replacement methods. The authors emphasized the significant advantage of trenchless technologies in reducing social and environmental costs, and highlighted the need to develop a decision support system for the selection of appropriate technologies. The approach proposed in this paper builds on several of these earlier efforts, and attempts to harmonize and integrate several procedures into an integrated and flexible decision support model and software tool.

Technology selection criteria varied among different studies with some criteria related to renewal technologies limitations, social and environmental concerns, or operational or economical issues. Tuhovack et al. (2003) found when surveying several utilities in 9 European countries that direct and indirect cost and improvement after renewal are the main criteria preferred by decision makers. In addition, minimizing the effect on road users caused by traffic disruption and duration of rehabilitation work are also among the preferred criteria. The technique proposed in this paper builds on several of the earlier efforts, and attempts to harmonize and integrate several of these procedures into an integrated and flexible decision support model and software tool.

3. TAXONOMY OF SEWER RENEWAL TECHNOLOGIES

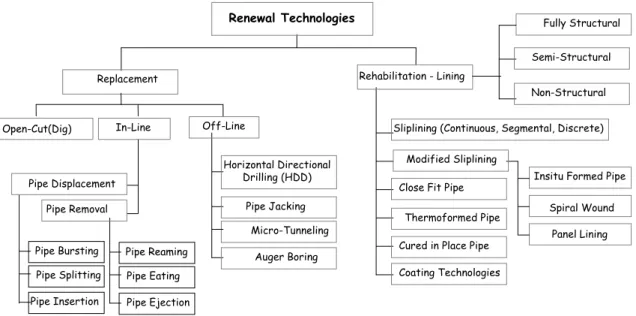

Figure 1 provides a classification of the technologies considered in this study. Renewal technologies include a wide range of replacement and rehabilitation methods. Replacement methods use either dig or trenchless technologies. Depending on the width and side support of the trench, dig technologies are usually classified as open cut or semi-open cut (Najafi 2004, Montero et al. 2002). Trenchless replacement methods include off-line and in-line replacement technologies. Off line replacement involve installing a new pipe in a new line underground without digging a trench for the entire length of the pipe (Montero et al. 2002). In-line replacement methods install a new pipe of the same diameter, or up to three times larger (Simicevic and Sterling 2001). In-line replacement technologies can be grouped into pipe displacement and pipe removal methods. The displacement methods involve destroying the old pipe or cutting and displacing it into the surrounding soil (Montero et al. 2002, ISTT 2006, Simicevic and Sterling 2001, Najafi 2004, Atkinson 2000), while removal methods involve removing the old pipe, in whole or in pieces, and installing a new pipe in place. The pipe removal methods are modifications of off-line replacement methods.

Rehabilitation technologies generally involve the installation or application of a new liner or coating inside the existing pipe. The most commonly used lining technologies include sliplining, modified sliplining, close fit pipe, thermoformed pipe, and cured-in-place pipe methods. Lining requires clearance between the new and the old pipes, and generally requires thorough cleaning of the existing pipe (ISTT 2006). Coating technologies (e.g., shotcrete and gunite) involve manual or mechanical application of a coating layer to the inner surface of the pipe mainly to prevent or delay deterioration and seal minor cracks.

Several rehabilitation methods can be designed to provide full structural, semi-structural, or non-structural capabilities. Design requirements for gravity liners are different from those for pressure liners. Liners for pressure pipelines (e.g., force mains or water mains) are designed to resist the internal pressure, while liners in gravity sewers are designed to mainly resist soil and groundwater loads (Heavens 2007). Based on the structural capabilities of the liner and its interaction with the host pipe, Gumbel et al. (2004) defined four rehabilitation classes for pressure pipelines: A, B, C and D. This classification combined earlier classifications defined by American Water Works Association (AWWA) and European Standards.

Insitu Formed Pipe Spiral Wound Panel Lining Pipe Displacement Pipe Removal Replacement

Sliplining (Continuous, Segmental, Discrete)

Cured in Place Pipe Close Fit Pipe

Thermoformed Pipe Coating Technologies Fully Structural Semi-Structural Non-Structural Renewal Technologies

Open-Cut(Dig) In-Line Off-Line

Horizontal Directional Drilling (HDD) Pipe Jacking Micro-Tunneling Auger Boring Rehabilitation - Lining Pipe Bursting Pipe Splitting Pipe Insertion Pipe Reaming Pipe Eating Pipe Ejection Modified Sliplining

Figure 1. Classification of sewer renewal technologies

Design standards of liners for gravity sewers are defined by American Society of Testing and Materials (ASTM) and by Water Research Council (WRc). The characteristics of these liners typically vary based on the bonding between the liner and the host sewer and the loads to be carried by the liner. ASTM defines two liner classes based on the condition of the pipeline: fully and partially deteriorated design (Najafi 2004). The WRc’s Sewer Rehabilitation Manual defines two main rehabilitation standards for gravity liners: Type I and Type II, which can be designed with additional check to provide additional structural capabilities for the liner (WRc 2001).

4. IDENTIFYING FEASIBLE RENEWAL CATEGORIES

An algorithm for optimal renewal planning of sewer networks was proposed by Halfawy et al. (2008). The algorithm determines the renewal actions (what assets to rehabilitate or replace, what methods to use, and when) for a specified planning horizon that would optimize the allocation of renewal budget by maximizing the network’s average condition and minimizing risk of failure, subject to condition, risk, and budget constraints. The algorithm starts by identifying and prioritizing candidate sewers for renewal. This involves classifying and subdividing the network into a set of homogeneous groups of sewers in terms of their current condition and deterioration pattern, as well as their criticality (or expected consequence of failure). Then, for each group, a renewal plan is developed for each planning period (e.g., one or more years). At the beginning of each period, condition indices are evaluated for each sewer using established deterioration models. The condition indices and deterioration models are used to estimate the remaining service life and calculate the likelihood of failure index. The consequence of failure is then determined, and used with the calculated likelihood of failure index to estimate the risk level of each sewer segment. Based on the condition and risk levels, sewers are prioritized according to the urgency of needed intervention. For each sewer on the priority list, feasible and cost-effective renewal technologies are selected based on their technical compatibility with the problem in hand and their economical merits. Then, a set of optimal renewal plans is generated using a multi-objective optimization approach, and further evaluated by the user to select the one that best meets the budget, condition, and risk constraints. The sections below discuss in detail the procedure for evaluating and selecting appropriate renewal technologies.

Renewal methods can generally be grouped into four main categories: replacement (conventional open cut or trenchless methods, with same or larger diameter), and full-structural, semi-structural,

and non-structural rehabilitation methods. Each renewal category includes a number of renewal technologies. Table 1 shows various categories and technologies for gravity sewers.

Table 1. Renewal categories and technologies for gravity sewers (Adapted from Najafi 2004, ISTT 2006, InfraGuide 2003)

Renewal Category Renewal Technologies

Replacement with same diameter size or larger

Semi and open cut/ pipe bursting/ pipe splitting/ pipe insertion/ pipe reaming/ pipe eating

Full-structural rehabilitation

Continuous sliplining / Segmental sliplining / Discrete sliplining / Fused & expanded/ Fold & form/ Deformed & reformed/ Spiral wound/ Panel lining/ Insitu formed pipe/ Cured in place pipe/ Underground coating & lining

Semi-structural rehabilitation

Continuous sliplining / Discrete sliplining / Fused & expanded/ Fold & form/ Deformed & reformed/ Spiral wound/ Panel lining/ Insitu formed pipe/ Cured in place pipe/ Underground coating & lining

Non-structural rehabilitation

Cured in place pipe/ Underground coating & lining

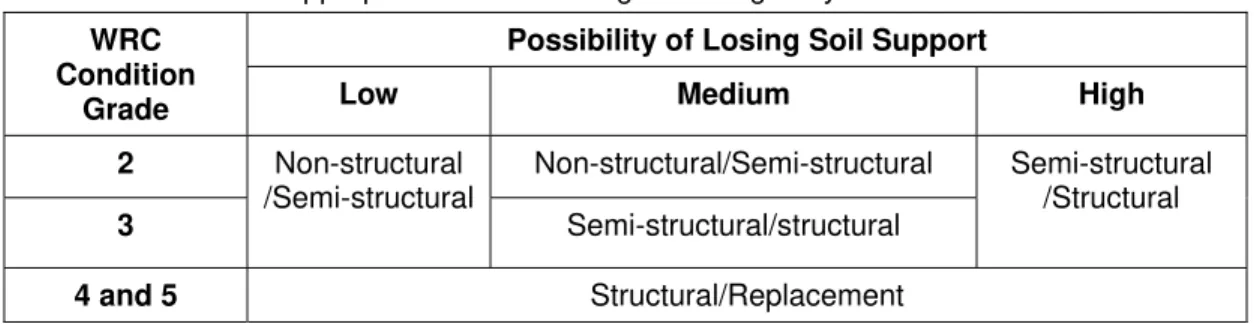

The criteria and guidelines for selecting renewal categories for pressure pipelines were provided in Gumbel et al. (2004) and Heavens (2007). However, there is a lack of similar guidelines for gravity sewers. The structural capabilities of required renewal categories for gravity sewers could be identified based on the pipe structural condition and the possibility of soil loss. The WRc condition grade can be used as an indicator of the sewer defect size. The possibility of surrounding soil loss can be assessed on a high, medium, and low scale. A “high” rating indicates that the sewer is expected to lose soil support and may experience accelerated deterioration or collapse in the near future; while a “low” rating indicates that the soil is expected to provide adequate support over the long term, with minimum or no effect on the sewer’s deterioration rate. The rate of soil loss would generally be higher in cohesionless soils and high levels of the groundwater, and lower in cohesive soils, especially where groundwater level fluctuations do not exist or occur below the sewer. The possibility of soil loss would also depend on the sewer defects size, where a larger defect size increases the rate of soil loss. Table 2 provides guidelines for selecting renewal categories based on the condition index and the possibility of soil loss.

Table 2. Selection of appropriate renewal categories for gravity sewers

WRC Condition

Grade

Possibility of Losing Soil Support

Low Medium High 2 Non-structural /Semi-structural Non-structural/Semi-structural Semi-structural /Structural 3 Semi-structural/structural 4 and 5 Structural/Replacement

Replacement is generally considered when collapse has occurred or is imminent, or when hydraulic capacity is inadequate. Sewers with current or predicted inadequate hydraulic capacity are typically replaced with pipes of larger diameter size. Otherwise, replacement is performed with a similar diameter pipe. Where collapse is not imminent, the residual structural capacity of the pipe should be considered in the design of the liner or coating (WRc 2001, Infraguide 2003). Full-structural and semi-structural rehabilitation is appropriate if the pipe’s structural integrity is severely compromised, but not yet collapsed (Infraguide 2003, Plenker 2002). Full-structural rehabilitation is appropriate if the pipe is currently unable to support hydrostatic pressure, and may not be able to support soil and traffic loads due to high deterioration rate or expected higher loading conditions. Semi-structural rehabilitation is appropriate if the pipe is unable, or will soon

be unable, to support the hydrostatic pressure. Non-structural rehabilitation is appropriate if the pipe has adequate structural capacity, and is used mainly to resist corrosion, minimize further deterioration, improve hydraulic conditions, and seal small cracks in gravity sewers (Najafi 2004, Heavens 2007).

5. ELIMINATION OF INAPPLICABLE METHODS

Once renewal categories are determined, the renewal methods within each category are further evaluated in terms of their “applicability.” The applicability criteria are mainly determined by the technology limitations and compatibility with the pipe physical characteristics, site characteristics, and other social or environmental criteria and user requirements. These criteria are used to “eliminate” inapplicable methods by comparing the specific job conditions with the technology limitations (e.g., existing or desired pipe material, diameter, depth of cover and profile, defects and condition state, number of service connections, surrounding soil type, groundwater level, and work area requirements). The applicability criteria are examined for each pipe to determine whether a particular renewal method should be eliminated to reduce the number of possible alternatives that need to be thoroughly evaluated.

In addition, a number of compatibility rules can be formalized to further guide the screening process. An example of these rules states that the mechanical folding and diameter reduction close fit pipe methods are only applicable for pressure pipes, while modified sliplining methods are only applicable for gravity pipes. Another rule states that pipes with non-circular cross section can only be rehabilitated using the modified sliplining (i.e., spiral wound, panel lining, and insitu formed pipe), the underground coating and lining, and the dig methods. Similar rules can be formulated and used in the elimination process to reflect environmental criteria or preferences of a particular utility.

6. EVALUATION OF DIRECT COSTS OF RENEWAL TECHNOLOGIES

In assessing the costs of renewal methods, all relevant costs (direct, social, and environmental costs) need to be considered. Najafi (2004) defined direct cost components to include the cost of pipe material, equipment, and labor, in addition to the cost of excavation, shoring, and sloping of trench or access pits, dewatering, spoil removal, road detouring, backfill and compaction, and road surface reinstatement. Also, the indirect cost components were defined to include temporary site facilities, traffic control, administration cost, and office overheads.

In this study, unit costs (cost per unit diameter per unit length) for various renewal methods were estimated based on a literature review of available cost data. Six main sources for that data were studied: Ariaratnam et al. (1999), USEPA (1999), Selvakumar et al. (2002), Zhao and Rajani (2002), Garcia et al. (2002), and Najafi (2004). Some of these studies consolidated costs from other studies (e.g. Ariaratnam et al. 1999, Selvakumar et al. 2002, and USEPA 1999). Zhao and Rajani 2002 collected and analyzed contract and historical cost data from the records of the “Jobs Let” section in the Trenchless Technology Magazine for the period between1993 and 2001. Other studies, for example, Montero et al. (2002), provided a cost formula to calculate the cost for several technologies such as conventional trench, shoring and trench box (semi open cut technologies), concrete sheet pile and cured in place pipe along with some repair techniques.

In compiling the costs reported in these studies, a number of issues were encountered. Costs were reported using different units (mm/m and in/ft), different currency (US and Canadian Dollar), and for different years (1999-2002). In some cases, costs of different technologies were aggregated under different groupings, or costs are not provided for all technologies considered in this study. For example, USEPA (1999) grouped close fit pipe and thermoformed pipe methods under a group called the modified cross section lining, and provided a cost range for the group. In this case, the figures provided for the group is considered to be the cost of thermoformed pipe

and close fit pipe methods. Also, Zhao and Rajani (2002) provided cost for relining without explicitly defining the relining method. Since lining methods can also be considered for relining, the cost was assumed to include all lining methods except CIPP and sliplining, where specific costs were provided. Also, no cost figures were reported in the literature for panel lining, spiral wound and insitu formed pipe. Therefore, the cost of relining provided by Zhao and Rajani (2002) is considered the cost of these renewal technologies. The cost figures provided by Ariaratnam et al. (1999) were relatively low compared to those in other studies, and therefore, they were not considered in this study.

Reported costs were approximated to establish consistent unit cost ranges for each renewal technology for different condition states and renewal categories. Unit costs were expressed in mm/m and Canadian dollars for the year 2005. Where no cost data were found for a particular renewal method, assumptions were made to estimate the unit cost of that method using the unit costs of comparable methods that use relatively similar installation techniques. Examples of these assumptions include: (1) Cost of pipe bursting is used for pipe splitting and pipe extraction; (2) Cost of horizontal directional drilling is used for pipe reaming; (3) Cost of microtunneling is used for pipe eating; (4) Cost of pipe jacking is used for pipe insertion, pipe ejection and segmental sliplining; (5) Same cost is used for continuous and discrete sliplining methods; (5) Same cost used for all close fit pipe methods; (6) Same cost is used for all thermoformed pipe methods; and (7) Cost of open cut is used for semi open cut.

Reported cost figures did not indicate the condition of the sewer prior to renewal. The increase of renewal costs with the deterioration of sewer condition grades has been reported in several studies (e.g., Macey 2001). InfraGuide (2004) reported that the City of Winnipeg estimated that the cost to rehabilitate a condition “5” sewer is three times higher than the cost of rehabilitating a condition “3” sewer. Also, reported cost figures did not indicate whether full structural, semi structural, or non-structural options were used. Therefore, unit costs were further adjusted to address the condition of sewer prior to renewal and the structural capabilities of the liner. This adjustment was made as follows: (1) The minimum cost figure available for a particular method is assumed to be the cost of non-structural lining of sewers with condition 2 or 3; (2) The maximum cost figure available for the method is assumed to be the cost of full-structural lining for sewers with condition 4 or 5; and (3) The cost of semi-structural lining of condition 2 or 3 sewers and the cost of full-structural lining of condition 3 sewer are assumed to range between the maximum and the minimum cost figures available. For example, if the reported cost of a renewal technology ranges between $0.5 and $1.5 per mm/m, we assumed that the non-structural liner for condition “2” would cost $0.5, while a structural liner for condition “4” or “5” will cost $1.5. In the same manner, the cost of a structural liner is expected to be higher than that of a semi- or non-structural liner, due to extra design, testing, and material costs. These unit costs can be used as default values, especially where accurate and specific data are not available, for performing order-of-magnitude estimates for comparative assessment of alternative technologies. The default costs could also be modified by a decision maker based on more accurate estimates, actual project experience, or specific site conditions.

Since the breakdown of total costs into direct and indirect cost components was not given in the reported costs, these costs were assumed to include both cost components. For more accurate cost estimates, social and environmental costs could also be estimated and added to the cost assessment of renewal options. A lifecycle cost component can also be estimated as the expected yearly maintenance cost throughout the service life discounted to the analysis year. However, the scope and purpose of the renewal plan would determine the level of accuracy required for the cost estimates. While project-level or short-term planning would require more accurate assessment of direct, social, environmental, and lifecycle costs; network-level or long-term planning could be reasonably conducted using approximate total cost figures such as those compiled or estimated from the literature. Once the cost and benefit of feasible renewal methods are determined, the renewal trade-offs can be further evaluated and optimized using the multi-objective optimization model to identify a set of feasible renewal solutions as described in (Halfawy et al. 2008).

7. EVALUATION OF RENEWAL TECHNOLOGIES BENEFITS

The expected benefits of each applicable method can be estimated and used to optimize the selection of the methods with the best cost/benefit ratio. Accurate assessment of the benefits should consider the post-rehabilitation impact of a renewal method or category on various defects, and modify the defect scoring and condition rating calculations accordingly. To date, there is no established way to accurately calculate expected condition improvements. Clearly, the development and validation of such a model would require significant pre- and post-rehabilitation data, which are not generally available.

Abraham et al. (1998) estimated the condition improvement in terms of extension of the sewer service life (e.g., shotcrete extends the service life by 20 years, while CIPP extends it by 50 years). Hulance et al. (2003) estimated improvement after renewal based on service life prolongation expected from different renewal methods. Prolongation in service life is estimated mainly based on the pipe or liner material and climate condition (hot or cold). For example, the service life for using CIPP and Thermoset plastics (Epoxy Resin, Polyester Resin, GRP) was estimated to be 50 years in both cold and hot climate, while the service life for continuous sliplining with thermoplastics was estimated to be 100+ years. However, Pipe ejection, Segmental sliplining, or underground coating and lining with cementitious material (e.g., cement mortar) was estimated to be 100+ years in cold climate and < 50 years in warm climate. The main drawback of this approach is that it assumes the same prolongation of service life regardless of the condition of the sewer prior to renewal or the renewal option used (e.g. non structural rehabilitation, or full structural rehabilitation).

In our proposed approach, benefits are estimated in terms of condition improvement (or recovery) by deducting certain values from the current condition index. There is no established way to accurately calculate expected sewer condition improvements, and therefore, the proposed approach assumes condition improvement values for each renewal category or renewal methods. Default values of 0.5, 1.0, and 2.0 are generally assumed for non-structural, semi-structural, and structural lining, respectively, while replacement restores the condition index to “1.0” by default. The default values can be overridden for a particular method as it is applied to a sewer or group of sewers. A more robust procedure would assess the impact of a renewal method or category on various defects, and modify the defect scoring and condition rating calculations accordingly.

8. SOFTWARE IMPLEMENTATION AND DEMONSTRATION

An integrated and modular software environment for integrated management of sewer networks has been under development during the past two years, in collaboration with the City of Regina, Saskatchewan, Canada. Several applications have already been developed and integrated into the environment. Examples include inventory data analysis, query, and reporting, condition assessment, deterioration modeling, risk assessment, asset prioritization, and renewal planning. The software environment was implemented as a set of loosely coupled applications, each addressing a specific process. Each application was implemented as an add-on to ESRI ArcGIS software using the ArcObjects class library (ESRI 2001). The modular architecture of the application would help accommodate future enhancement and extension of the application (Halfawy et al. 2002). This section describes the implementation of the renewal methods evaluation application based on the approach proposed above.

An object-oriented integrated data model for sewer and water networks were developed (Halfawy et al. 2006, Halfawy 2007, Halfawy 2008). The data model defined classes that represented spatial, inventory, inspection, condition, risk, and renewal data. The data model was defined using the Unified Modeling Language (UML) notation and was based on ESRI’s water utilities spatial data models. The UML data model was used to generate the database tables, fields, and data types. The implementation of the centralized integrated data repository is described in Halfawy and Figueroa (2006). The DSS was also designed to allow for easy customization to the

specific practices and rules used in a particular municipality. All data and settings that can be considered as municipality-specific (e.g., costs of renewal methods) were not hard-coded into the software and were stored in an external database for possible editing. For example, information about various renewal methods is stored in a database that can be customized to the specific practices and data available at a particular municipality.

The prototype DSS was used to develop renewal plans for a sewer network in the City of Regina. The City has an inventory of approximately 860 km of sanitary sewers and 755 km of storm sewers. The network was subdivided into a set of homogeneous groups. This example demonstrates the application of the proposed approach to one of these groups. The group was defined to include vitrified clay sanitary sewers, with 200 mm diameter, and constructed between 1950 and 1955. This group included 249 sewer segments with a total length of 19.86 km. The condition assessment, deterioration modeling, risk assessment, and asset prioritization applications were used to identify and prioritize the sewer segments that require intervention. This process is explained in detail in Halfawy et al. (2008). For the 249 sewers in this group, 11 sewers were found to need immediate intervention, 8 sewers with medium priority, 230 sewers with low priority. Sewers identified for renewal are then considered for further evaluation and optimization of possible renewal actions.

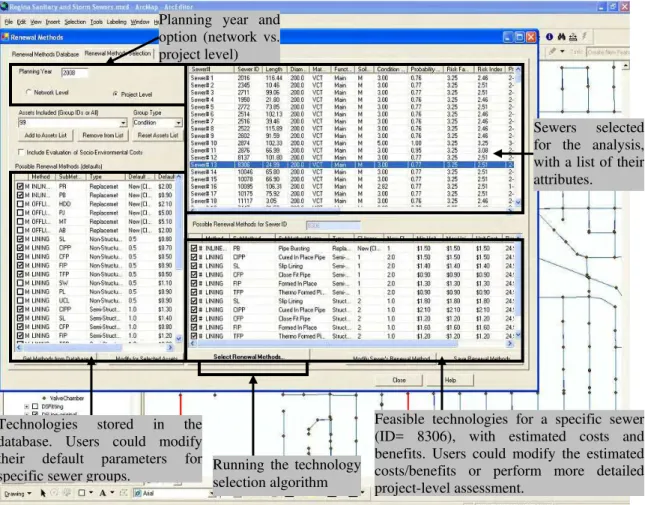

The renewal methods selection procedure starts by identifying the applicable renewal category for each sewer, and retrieving the methods within these categories from the renewal technologies database. This database stores default information about renewal methods including their limitations (diameter range, soil type, pipe material, etc.), expected condition improvement, and cost. The default cost and improvement values are specified for each condition grade, since these values would depend on the type and severity of the defects. The user can eliminate some renewal methods or override their default values as they apply to a particular sewer or sewer group. For each sewer in the group, the system will then evaluate the applicability of various renewal methods and calculate costs and condition improvements. Figure 2 shows a screenshot from the renewal methods evaluation DSS. The multi-objective optimization application was then used to identify optimal renewal plans.

9. CONCLUSIONS

Integrated renewal planning of sewer networks can play a critical role to improve aspects of management and operation. This paper presented an approach to support the evaluation of alternative renewal technologies for sewer networks, taking into consideration the applicability, limitations, costs, and benefits of each possible technology. The proposed approach has been implemented into a prototype decision-support system that has been under development and evaluation in collaboration with the City of Regina during the past two years. Substantial work still needs to be done to refine and extend the approach and fully develop the software. Through industrial partnerships, the approach and software will be further extended, refined, and tested.

Technologies stored in the database. Users could modify their default parameters for specific sewer groups.

Sewers selected for the analysis, with a list of their attributes.

Feasible technologies for a specific sewer (ID= 8306), with estimated costs and benefits. Users could modify the estimated costs/benefits or perform more detailed project-level assessment.

Planning year and option (network vs. project level)

Running the technology selection algorithm

Figure 2. A screenshot of the renewal technologies evaluation and selection module

10. REFERENCES

Abraham, D., Wirahadikusumah, R., Short, T.J., and Shahbahrami, S. (1998). Optimization modeling for sewer network management, J. Construction Eng and Management, 124 (5), pp.402-410.

Ariaratnam S.T., Lueke J.S. and Allouche E.N., 1999 “Utilization of trenchless construction methods by Canadian municipalities” ASCE J. Construction Eng. and Management, Vol. 125, No.2.

Atkinson, K. (2000). Sewer Rehabilitation Techniques” Subterra Systems, Dorset, UK http://www.hrwallingford.co.uk/projects/SEWER/sewer_home/S2d18.pdf

ESRI. (2001). Environmental Systems Research Institute, Exploring. ArcObjects, Vol. 1 & 2, Redlands, California.

Garcia C., Abraham D., Gokhlae S., and Iseley T. (2002). Rehabilitation alternatives for concrete and brick sewers. ASCE Practice Periodical on Structural Design and Construction, 7(4).

Gumbel, J., Elzink W., Heavens, J. (2004). The rehabilitation of pressure pipelines: key issues in the design and selection of renovation technologies. International NO-DIG 2004 Hamburg. http://www.insituform.com/ (June 2008).

Halfawy, M., Dridi, L., and Baker, S. (2008). An Integrated Decision Support System for Optimal Renewal Planning of Sewer Networks. Accepted for publication by the ASCE J. Computing in Civil Eng., In Press.

Halfawy, M. (2007). Integration of Municipal infrastructure management processes: challenges and solutions,” J. Computing in Civil Eng., 22(3), 216-229.

Halfawy, M. and Figueroa, R. (2006). Developing enterprise GIS-based data repositories for municipal infrastructure asset management, Proc., Joint International Conference on Computing and Decision Making in Civil and Building Eng., Montreal, Canada.

Halfawy, M., Pyzoha, D., and El-Hosseiny, T. (2002). An integrated framework for GIS-Based civil infrastructure management systems, Proceedings of the Canadian Society for Civil Engineers (CSCE) Conference, Montreal, Canada.

Heavens, J.W., 2007 “The trenchless Renovation of potable water pipelines” Insituform Technologies (www.insituform.com)

InfraGuide. (2003). Selection of Technologies for Sewer Rehabilitation and Replacement, National Research Council, Canada.

International Society for Trenchless Technology (ISTT), 2006 “Trenchless guidelines” http://www.istt.com/index.cfm?menuID=74 (September 2007)

Montero C., Villanueva A., Raclavsky J., Sulcova V., Leif Sigurd H. and Freni G. (2002). Wastewater rehabilitation technology survey, Computer Aided Rehabilitation of sewer Networks (CARE-S), report D12.

Najafi, M. (2004). Trenchless technology: Pipeline and Utility Design, Construction, and renewal, McGraw-Hill.

Plenker, T. (2002). Computer aided decision support on choosing the right technology for sewer rehabilitation. Water Science & Technology, 46(6), 403–410.

Selvakumar A., Clark R., and Sivaganesan M. (2002). Cost of water supply distribution system rehabilitation. United Stated Environmental Protection Agency (USEPA) EPA/600/JA-02/406.

Simicevic, J. and Sterling, R. L. (2001). Guideline for Pipe Bursting. TTC technical report # 2001.02, prepared for U.S. Army Corps of Engineers, Vicksburg, MS 39180 http://www.ttc.latech.edu/publications/guidelines_pb_im_pr/bursting.pdf

United States Environmental Protection Agency (USEPA). (1999). Collection Systems O&M Fact Sheet: Trenchless Sewer Rehabilitation. Office of Water, Washington, D.C. EPA 832-F-99-032 http://www.epa.gov/owm/mtb/rehabl.pdf

WEF and ASCE. (1994). Existing sewer evaluation and rehabilitation,” WEF Manual of Practice FD-6 and ASCE Manual and Report on Engineering Practice No. 62, 1992.

WRc. (2001). Sewerage Rehabilitation Manual, Fourth Edition, Volumes I & II, Water Research Centre, UK.

Zhao, J.Q., and Rajani, B. (2002). Construction and rehabilitation costs for buried pipe with a focus on trenchless technologies. National Research Council, Institute for Research in Construction, Ottawa, Canada.