Publisher’s version / Version de l'éditeur:

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la

première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

Research Paper (National Research Council of Canada. Division of Building

Research); no. DBR-RP-280, 1966-01

READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE.

https://nrc-publications.canada.ca/eng/copyright

NRC Publications Archive Record / Notice des Archives des publications du CNRC : https://nrc-publications.canada.ca/eng/view/object/?id=7b784b84-e186-4dc1-8bfc-8945130c8bce https://publications-cnrc.canada.ca/fra/voir/objet/?id=7b784b84-e186-4dc1-8bfc-8945130c8bce

NRC Publications Archive

Archives des publications du CNRC

This publication could be one of several versions: author’s original, accepted manuscript or the publisher’s version. / La version de cette publication peut être l’une des suivantes : la version prépublication de l’auteur, la version acceptée du manuscrit ou la version de l’éditeur.

For the publisher’s version, please access the DOI link below./ Pour consulter la version de l’éditeur, utilisez le lien DOI ci-dessous.

https://doi.org/10.4224/40001488

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at

Hydrated portland cement and lightweight concrete at elevated

temperatures

Ser

TH1

N21r2

979%

-, 7 2 -no.

280 NATIONAL RESEARCH COUNCIL--

c . 2

CANADA

BZDG

CONSEIL NATIONAL DE RECHERCHES

Hydrated Portland Cement

and Lightweight Concrete

at Elevated Temperatures

Authorized Reprint from copyrighted JOURNAL, AMERICAN CONCRETE INSTITUTE

Vol. 63, No. 1, January 1966, p. 93-112

Research Paper No.

280

of the

Division of Building Research

OTTAWA

January 1966

A DES TEMPERATURES ELEVEES

SOMMAIRE

La relation entre les contraintes en compression et la deformation de ciment portland hydrate (ayant un rapport eau-ciment de 0.33) et d'un beton leger a ete etudiee a des temperatures elevees. Les proprietbs des deux materiaux ne semblent pas Gtre affectees par des temperatures allant jusqu'a 400" F. Au-dessus de cette tem- perature, le module d'hlasticith et l'effort ultime decroissent avec une augmentation de temperature. Ces changements htaient plus marques pour le ciment portland hydratk.

Title No. 63-4

Hydrated Portland Cement

and Lightweight Concrete

at Elevated Temperatures

By T. Z. HARMATHY and

1.

E. BERNDTThe stress-strain relationship in compression of hydrated portland cement (with a water-cement ratio o f 0.33) and a lightweight concrete was studied a t elevated temperatures. The properties o f both materials seemed t o be virtually unaffected b y temperature up t o about 400 F. Above this, the modulus o f elasticity and ultimate strength decreased with increasing temperature. These changes were more definite for hydrated portland cement.

Key words: cement; concrete; compressive strength; deformation; hy- drated cement; high temperature; lightweight concrete; modulus of elasticity; research; stress-strain curve; temperature.

IT IS NOW WIDELY ACCEPTED THAT in designing building elements the conditions arising not only in normal service but also under unusual circumstances, such as fire and earthquake, should be taken into account.

The success of designing building elements for a required fire endurance depends on how accurately certain properties of the com- ponent materials are known in the 0 to 2000 F temperature range. Con- crete is among the most commonly used building materials and de- serves priority in a program intended to develop the knowledge of the behavior of building materials at elevated temperatures. A com- prehensive study of some thermal and mechanical properties of hy- drated portland cement and concrete was therefore started in this laboratory a few years ago. Although it is still not complete, sufficient results are now available to justify this advance publication.

The behavior of a certain hydrated portland cement and a light- weight concrete in compression at elevated temperatures will be de- scribed. This may prove useful in predicting the stress deformation history of concrete constructions in fire. Although the information pre- sented here is strictly valid only for the materials and mixes described, the reader may find sufficient guidance in the literature to enable him to apply the results to somewhat different materials and mixes.

ACI member 1. Z. Harmathy has been research officer, Fire Section, Division of Building Research, National Research Council, Ottawa, Canada, since 1958. He obtained a degree in mechanical engineering from Budapest University of Technology in 1946. Mr. Harmathy's current research includes investigating the physical properties of building materials at elevated temperatures and the behavior of building elements in fire. He is the. author of several papers related to these subjects.

J. E. Berndt is technical officer, Fire Section, Division of Building Research, National Re- search Council, Ottawa, Canada. He joined the NRC in 1959 after obtaining a BS in Mathe- matical Physics i r o m Bishop's University. Since then, his research in fire endurance has included dilatometric and thermogravi~netric analyses in addition to the elevated temperature compression tests described in this paper.

For hydrated portland cement, porosity is the most important variable from the viewpoint of its mechanical properties. It may be calculated' if the original water-cement ratio and the degree of hydration are known. The degree of hydration, on the other hand, can be estimated by making use of the work of Copeland et al.,' and of T a ~ l i n . ~ Rela- tionships between the porosity and modulus of elasticity have been developed by M a c k e n ~ i e , ~ H a s ~ e l m a n , ~ , ~ and by Piatasik and Hassel- man.7 The effect of porosity on strength has been investigated by H a ~ s e l m a n . ~

Eshelbys and Hashin"l0 studied the modulus of elasticity of com- posite materials. Hashin's results may be applicable to concrete. The modulus of elasticity of concrete was the specific subject of study by LaRuel1 and Hirsch."

As hydrated portland cements and concretes exhibit a mixed elastic- plastic deformation at any load, even at room temperature, the classical theory of elasticity is rarely applicable in calculating the stress-defor- mation history of building elements made from these materials. To provide a realistic basis for any future stress-strain analysis concern- ing concrete constructions exposed to fire, the whole stress-strain relationship of the above-mentioned two materials was studied in the series to be reported here. Only the findings will be presented; and analysis of the results will be made elsewhere.

Certain characteristics of the stress-deformation curve of portland cement products at elevated temperatures have already been studied by a number of research workers. Grun and Beckmannl"ere prob- ably the first to examine the variation of the so-called "residual strength" of mortar with temperature up to 1650 F. They heated the specimens in a furnace for 2 hr, then let them cool in open atmosphere before the beginning of the compression test. Twenty-six years later MalhotraI4 published the results of a comprehensive investigation of the strength of concretes of various mixes and water-cement ratios. He examined both the actual strength in the 70 to 1100 F range and the residual strength, i.e., the strength of specimens allowed to

C O N C R E T E A T E L E V A T E D TEMPERATURES 95

TABLE I

-

CHEMICAL ANALYSIS AND COMPOUND COMPOSITION OF CEMENT USED IN HYDRATED PORTLAND CEMENT SPECIMENSOxide CaO, combined CaO, f r e e SiO? AhOs Fez03 MgO so3 Na20

+

KnO Ignition loss Insoluble residue Percent/

by weight Compound* CIS CeS C3A CtAF CaSOdFree MgO -1- CaO Alkalies Ignition loss Insoluble residue

Total

1

100.3 1 Total 1 98.4-

*C is an abbreviation f o r CaO, S f o r SiOn, A f o r A1203 and F for Fe.03. Thus, C3S means 3Ca0

.

SiOn, etc.Percent by weight -- .- . . 49.8 22.7 7.8 7.9

cool from the given temperature to room temperature. Seamann and WashalQtudied the modulus of elasticity and strength of various mor- tars and concretes up to 450 F. The specimens were included in a n insulated box or oven of controlled temperature during the tests. The modulus of elasticity of various concrete mixes was further investi- gated by PhilleolVn the 75 to 1400 F range by a dynamic method, and by Cruzli in the 75 to 1000 F range using an optical method. Finally, in a comprehensive paper Zoldnersl"ublished information on the residual compressive and flexural strength, as well as on the modulus of elasticity, of four different types of concretes.

! 4.1

3.7

Harada'" appears to be the only researcher who has so far studied the whole stress-strain relationship of concretes of various aggregates exposed to temperatures up to 1290 F. Although not stated in his papers it was the residual behavior of the concretes that Harada studied; in other words, he carried out the compression test after the specimens had cooled to room temperature.

HYDRATED PORTLAND CEMENT SPECIMENS

A Type I portland cement of 2890 c m y g specific surface was used. The chemical analysis, as supplied by the manufacturer and the cal- culated compound composition of the cement are given in Table l.

Generally, two specimens were prepared daily. Three parts (by weight) of portland cement were mixed with one part (by weight) of distilled water in an electric mixer. The fresh paste was placed into split brass molds, 1% in. inside diameter and 6 in. long, and rodded for a few minutes. Within 24 h r the molds were removed. The set portland cement cylinders were immediately transferred to a fog chamber for

*Harada, T., "Thermal Character of Concrete." (Private communication containing t h e English translation of some of Harada's papers.)

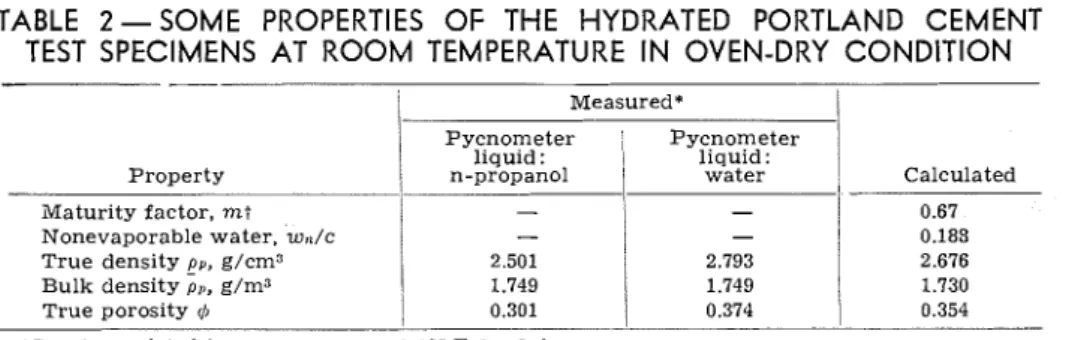

TABLE 2

-

SOME PROPERTIES OF THE HYDRATED PORTLAND CEMENT TEST SPECIMENS AT ROOM TEMPERATURE IN OVEN-DRY CONDITION-

i Measured* I Property Maturity factor, m; Nonevaporable water, w./c True density _pp, g/cmn Bulk density pn, g/m3 True porosity f/~ Pycnometer Pycnometer liquid : liquid: n-propano~I

water - i - 1 Calculated 0.67 0.185 2.676 1.730 0.354*Specimen dried in vacuum oven at 185 F for 6 days. :Estimated, using References 2 and 3.

maturing. At 28 days they were taken from the chamber and cut to 3%-in. lengths with a diamond saw. (Approximately 1%-in. pieces were removed from both ends of the cylinders.) In the specimens thus obtained three holes of about 0.03 in. diameter were drilled; one at the midheight and two at %-in. distances from the ends, all reaching the axis of the cylinders. After these operations the specimens were put into an oven for drying at 221 F for 24 h r and finally transferred to desiccators containing Mg (ClO.,),

.

2H,O for storage.The true density and bulk density of the matured and dried paste were determined both by direct measurements carried out according to ASTM '2135-47 and C20-46, respectively, and by calculations making use of the following formulas:

':':

The w,,lc ratio can be calculated approximately by the following empirical expression:

Knowing the true and bulk densities from either measuremeilts or calculations, the true porosity may be obtained as follows:

The results of various measurements and calculations are summarized in Table 2.

CONCRETE AT ELEVATED TEMPERATURES 97

Thermogravimetric and dila'cometric tests were also conducted on the hydrated portland cement paste. The thermogravimetric curve indi- cated 12.3 percent weight loss at 1600 F. If it is assumed that this loss was due entirely to the removal of nonevaporable water, and that

-

~ u , , / c = 0.188 (see Table 2 ) , a maturity factor m = 0.74 will result. This value is in fair agreement with that estimated previously (see also Table 2).

LICMTWEICHB CONCRETE SPECIMENS

The lightweight concrete specimens were cut from solid masonry units of 4 x 8 x 16 in. nominal size.

These units were prepared and submitted originally for a fire test, the report of which has subsequently been published.l"his material, of known manufacture and composition, was selected for further study. The following results are now reported with the agreement of the pro- ponents of the fire test, and information on the manufacture and ma- terials used is repeated in part for the convenience of the reader. In- formation about the concrete mix is given in Table 3.

The fresh masonry units were allowed to set at atmospheric condi- tions for 4 hr, then were steamed in a kiln at 180 F for 12 hr. The units were removed from the kiln 24 h r after the end of the steaming period.

Some relevant properties of the

units are eiven in Table 4.

-

TABLE 3-

LIGHTWEIGHT CON- The cement used in the mix was -- CRETE MIXan air-entrained portland cement Material

I

Lb per cu yd of 4000 sq cm per g specific surface. cement 282 The chemical analysis, as supplied Rotary kiln expandedWater

- 1716

by the manufacturer, and the cal- aggregate

i

culated compound composition of 222

the cement are given in Table 5.

,

2220 The expanded shale aggregatewas made from shale deposit by a rotary kiln process. Ninety-eight percent of the particles were grey in color. The unit weight of the aggregate in dry condition was 52.4 lb per cu ft when loose 59.5 lb per cu ft when rodded. The compound composition and the sieve analysis have been given in Reference 19.

A

diamond core drill was used to cut cylindrical samples of 1.9 in.TAGLE 4 - SOME PROPERTIES OF THE LIGHTWEIGHT CONCRETE

MASONRY UNITS Prouertv 1 Value - -- True density,

1

2.510 g/cm" ASTM C135-47 Bulk density, 1.210 g/cm3 ASTM E12-FIT True porosityI

0.518 cm'/cW Apparent porosity, 0.323 cm3/c&ASTM C20-46

1

Water absorption, ! 0.268 g/g ASTM C20-46 Apparent density.1

1.785 g/cm3 ASTM C20-46 --- i .-~.ATABLE 5 -CHEMICAL ANALYSIS AND COMPOUND COMPOSITION OF CEMENT USED IN LIGHTWEIGHT CONCRETE MASONRY UNITS

Oxide CaO, combined CaO, free SiO2 AlzOn Fe-O:! Mk-0 SO3 Na.0

+

K2O Ignition loss Total Percent - by welght Percent Compound*1

by weight c3s c.s CIA CtAF CaSO,Free MgO

+

CaO Alkalies Ignition lossTotal

1

98.3"See note below Table 1.

diameter from the masonry units, and a diamond saw to cut them to 3.8-in. lengths. Again, three 0.03-in. holes were drilled in the specimens, one at midheight and two in. from each end. Finally, the specimens were dried and stored in the same way as the hydrated portland cement specimens.

It is believed that after an initial 12 hr steam curing at 180 F and a subsequent 24 hr cooling period, the masonry units were stored at normal atmospheric conditions until the time of sampling. The age of the concrete at the time of drying was approximately 13% months.

TESTING PROCEDURE

The testing procedure was exactly the same for both the hydrated portland cement and lightweight concrete specimens. Compression tests were carried out on a universal screw-power testing machine equipped with an electric furnace. The temperature of the furnace was controlled by a time-proportion- ing controller via a load relay during the pretesting period, and by a man- ually-set variable transformer during the test in order to eliminate pick-up by the deformation measuring circuit of stray signals originating from the operation of the relay.

Special compression tools were designed and made from Inconel in this laboratory f o r transferring the load from the crosshead of the testing machine to the specimen within the furnace. The differential transformer of the deformation recording system was mounted underneath the furnace on small aluminum holders. These were fastened with screws to four extension arms welded to the upper and lower loading tools ( t w o to each) a t points close to the loading surfaces. The error resulting from the fact that the deformation record included some deformation of the compression tools was estimated to be always less than 1 percent.

A specimen with the loading assembly is shown in Fig. 1. When carrying out elevated temperature tests the stem of the upper loading tool was installed only after lowering the furnace onto the specimen assembly. To minimize the circulation .of air inside the furnace the gap between the stem of the loading tools and the furnace was partially filled with a fibrous insulation. Fig. 2 shows the whole testing assembly prior to an elevated temperature test.

CONCRETE AT ELEVATED TEMPERATURES 99

Each material was tested first a t room temperature. Subsequent tests cov- ered the 100 to 1400 F range at 100 F-deg increments. Generally, three tests employing fresh samples were carried out a t each elevated temperature level. These tests varied in the length of time elapsed between the beginning of the heating of the specimen and the beginning of the compression test. This period was chosen as 1, 4, and 24 hr, respectively, for the three tests.?' The time of heating as a variable to be studied was introduced to see whether a t certain temperature levels slowly developing chemical or structural changes could result in noticeably time-dependent mechanical properties. I t has been assumed that above 1000F these changes develop a t rather high rates and a r e com- pleted within 4 hr. For this reason tests preceded by 24-hr heating of the specimen were not contemplated for the 1100 to 1400 F range.

The temperature of the specimen was measured with three thermocouples inserted into 0.03-in. holes located as described in the previous sections. When

*The time required to raise the temperature of the specimen to the target level and to achieve a reasonably good temperature disribution took. in all cases, nearly 1 hr.

Fig. -Specimen and loading assembly

I. Specimen

2. Lower compression tool

3. Loading disc of upper com- pression tool

4. Stem of upper compression tool

5. Extension arms

6. Differential transformer

Fig. 2-Testing assembly

I. Testing machine

2. Furnace

3. Temperature controller

the test had been scheduled to be carried out a t temperatures not higher than

1000 F, the furnace was heated after the installation of the specimen. To achieve within 1 h r a reasonably good temperature distribution in the speci- men a t higher temperatures, the furnace and csmpression tools had to be preheated to about 800 F before the specimen was installed.

With two exceptions the average temperature of the specimen, as yielded by the three thermocouples, was always within k 1 4 F of the target temperature. With three exceptions the maximum deviation from the average temperature was always less than &17 F.

The tests were scheduled to be performed at a strain rate of 0.003 in. per in. min, approximately the value recommended by ASTM C39-61 for final loading. The actual rate of deformation (obtained by dividing the fractional deformation at fracture by the time cf fracture) was found to vary between

0.0012 and 0.0050 in. per in. min for hydrated portland cement specimens, and between 0.0025 and 0.0090 in. per in. min for lightweight concrete specimens.

TEST RESULTS

A typical force-deformation record obtained on the recorder of the testing machine is shown in Fig. 3. Because of some unusual features it was apparent that this record could not be regarded as a true force- deformation curve. In some cases the initial S-shaped section of the curve was much shorter or completely missing. Further study revealed that this was caused by an imperfect parallelism between the faces of the cylinders,'" resulting in (i) gradual imposition of the load, and

(ii) bending of the extension arms, and, in turn, false deformation signals. When the force-deformation record was evaluated, the initial section of the curve was replaced by the tangent to the curve at the point of inflection (point a in Fig. 3 ) . As the force-deformation curves of brittle materials are generally slightly concave to the deformation axis even in the initial section, it seems probable that the modulus of elasticity calculated from the Aa tangent is slightly different from that obtainable from perfect force-deformation records.

In some cases one or more horizontal steps appeared in the record similar to that shown at b in Fig. 3. These steps were probably caused by either cracking of the specimen or slipping of the compression tools and were disregarded when evaluating the record. Thus, the deformation at fracture was taken as the AB distance in the figure.

The point of fracture was taken as the point at which the force- deformation curve took a sharp downward trend (point e in Fig. 3 ) . In the majority of the tests carried out on lightweight concrete speci- mens, this point was reached after the force versus deformation curve passed through a maximum (point d ) , the ordinate of which was used to calculate the ultimate strength. In the hydrated portland cement

'kThe e n d s of t h e cylinders w e r e c u t v e r y carefully, b u t w e r e not capped. I t was thought t h a t t h e disintegration or craclcing of t h e capping m a t e r i a l a t elevated t e m p e r a t u r e might falsify the test result to a considerable degree

CONCRETE AT ELEVATED TEMPERATURES

U

D e f o r r n a t i o n

Fig. 3

-

Typical force-deformation recordspecimens the fracture generally occurred either at the maximum (at higher temperatures, as a rule) or at a point where the tangent to the force versus deformation curve was still positive (like point c in Fig. 3 ) .

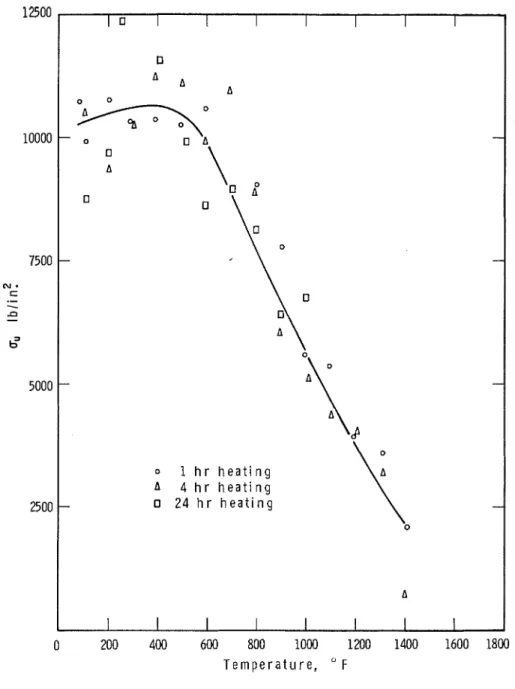

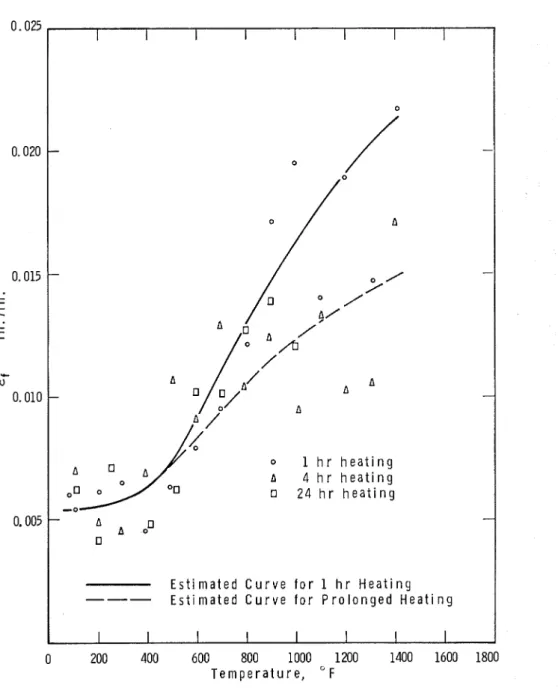

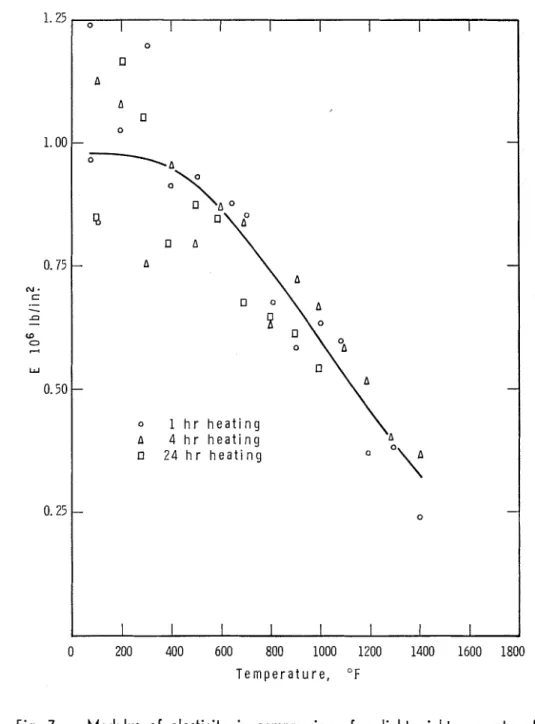

Some important characteristics of the two materials are plotted against the temperature in Fig. 4, 5, 6, 7, 8, and 9. The spread of the points representing values calculated from the force-deformation rec- ords is very marked. The curves drawn in the graphs have been based partially on judgment and may not represent the "best curves" through the points. The general stress-strain-temperature relationships plotted in Fig. 10 and 11 have been based on these curves.

Because of the significant spread of the points it was difficult to evaluate the effect of the time of heating on the various properties. It seems probable that it does not affect the modulus of elasticity and ultimate strength to any appreciable degree. For hydrated portland cement the deformation a t fracture seemed to be lower if the specimen was heated for more than 1 h r a t temperatures higher than 500F (see Fig. 6). Some loss in the plasticity of this material with lengthy heating may be associated with the formation of additional bonds be- tween certain constituent atoms.

0 200 400 600 800 1000 1200 1400 1600 1800 T e m p e r a t u r e , " F I 01 I I I I I I

n A

-

0 1 h r h e a t i n g A 4 h r h e a t i n g o 0 2 4 h r h e a t i n g-

0-

0-

\

-

A-

O O\4

Fig. 4 - Modulus of elasticity in compression of hydrated cement

(w,/c = 0.33) a t elevafed temperatures

CONCRETE AT ELEVATED TEMPERATURES

0 200 400 600 800 1000 1200 1400 1600 1800

Temperature, " F

Fig. 5

-

Ultimate strength in compression of hydrated cement ( w , / cI I I I I I

I

--

--

A b A - - b b 0 2 4 h r h e a t i n g - 0-

b-

A onn

E s t i m a t e d C u r v e f o r 1 h r H e a t i n g---

E s t i m a t e d C u r v e f o r P r o l o n g e d H e a t i n g I I I I I I II

0 200 400 600 800 1000 1200 1400 1600 1800 T e m p e r a t u r e , " FFig. 6

-

Deformation a t fracture in compression o f hydrated portland cementCONCRETE A T ELEVATED TEMPERATURES 0 1 h r h e a t i n g A 4 h r h e a t i n g

n

2 4 h r h e a t i n g 0 200 400 600 800 1000 1200 1400 1600 1800 T e m p e r a t u r e , O FFig. 7

-

Modulus of elasticity in compression of a lightweight concrete of expanded shale aggregate a+ elevated temperaturesFig. 0 1 h r h e a t i n g A 4 h r h e a t i n g 24 h r h e a t i n g 0 200 400 600 800 1000 1200 1400 1600 1800 Temperature, " F

8- Ultimate strength in compression of a lightweight concrete of expanded shale aggregate a t elevated temperatures

CONCRETE AT ELEVATED TEMPERATURES 0 1

h r h e a t i n g

A 4h r h e a t i n g

n

24h r h e a t i n g

0 200 400 600 800 1000 1200 1400 1600 1800T e m p e r a t u r e ,

" FFig. 9

-

Deformation a t fracture in compression of a lightweight concrete of expanded shale aggregate a t elevated temperaturesr

Fig. 10

-

The stress-strain relationship in compression of hydrated portland cement (w,/c = 0.33) a t elevated temperaturesIn general, there seemed to be little change in the properties of the materials up to about 400F, a finding that seems to be in agreement with the results of Seamann and Washa14 and partially with those of Zoldners;17 but it seems to contradict the results of Philleo15 and Cruz.lG,* When any comparison is made, however, one should keep in mind that words like "concrete" or "mortar" may have very specific meanings in the common usage of language, but actually cover large groups of materials, sometimes with markedly different physical properties.

CONCLUSIONS

Cylindrical specimens (1.75 in. diameter x 3.5 in.) of hydrated port- land cement (w,/c = 0.33) and cylindrical speciments (1.9 in. diameter x 3.8 in.) of a lightweight concrete were subjected to compression tests at elevated temperatures up to 1400 F. After evaluation of the force- deformation records the following conclusions could be drawn:

*The results of Philleo and Cruz may be attributable to the presence of a supposedly significant amount of evaporable water In the specimens at the time of testing.

CONCRETE AT ELEVATED TEMPERATURES

Fig. I I

-

The stress-strain relationship in compression of a lightweight concrete of expanded shale aggregate a t elevated temperatures( a t any duration of heating)

1. There are marked individual differences in the characteristics of seemingly identical specimens under similar environmental conditions.

2. There is little change in the properties of both materials up to about 400 F under the described test conditions.

3. Above 500 F there is a gradual decrease in the modulus of elasticity and ultimate strength and an increase in the deformation a t fracture with increase in temperature.

4. These changes are more rapid in hydrated portland cement than in lightweight concrete.

5. Above 500 F prolonged heating seems to reduce the plasticity of hydrated portland cement.

ACKNOWLEDGMENT

The authors wish to thank R. Kerekes for his cooperation in the experimental work. This paper is a contribution from the Division of Building Research, National Research Council, Canada, and is published with the approval of the director of the Division.

REFERENCES

1. Powers, T. C., "Properties of Cement Paste and Concrete," Proceedings, Fourth International Symposium on the Chemistry of Cement, Washington, D.C., V. 11, 1960, pp. 577-614 (National Bureau of Standards, Monograph 43, Sept. 1962).

2. Copeland, L. E.; Kantro, D. L.; and Verbeck, G., "Chemistry of Hydration of Portland Cement," Proceedings, Fourth International Symposium on the Chemistry of Cement, Washington, D.C., V. I, 1960, pp. 429-468 (National Bureau of Standards, Monograph 43, Aug. 1962).

3. Taplin, J. H., "A Method for Following the Hydration Reaction in Port- land Cement Paste," Australian Journal of Applied Science (East Melbourne), V. 10, 1959, p. 329.

4. Mackenzie, J. K., "The Elastic Constants of a Solid Containing Spherical Holes," Proceedings, Physical Society ,London, V. B63, No. 2, 1950.

5. Hasselman, D. P. H., "On the Porosity Dependence of the Elastic Moduli of p ~ l ~ c r y s t a l l i n e Refractory Materials," Journal, American Ceramic Society, V. 45, No. 9, Sept. 1962, pp. 452-453.

6. Hasselman, D. P. H., "Relation Between Effects of Porosity on Strength and on Young's Modulus of Elasticity of Polycrystalline Materials," Journal, American Ceramic Society, V. 46, NO. 11, Nov. 1963, pp. 564-565.

7. Piatasik, R. S., and Hasselman, D. P. H., "Effect of Open and Closed Pores on Young's Modulus of Polycrystalline Ceramics," Journal, American Ceramic Society, V. 47, No. 1, Jan. 1964, pp. 50-51.

8. Eshelby, J. D., "The Determination of the Elastic Field of an Ellipsoidal Inclusion and Related Problems," Proceedings, Royal Society, London, V. 241A,

1957, p. 376.

9. Hashin, Z., "The Moduli of an Elastic Solid, Containing Spherical Particles of Another Elastic Material," Proceedings, International Union of Theoretical and Applied Mechanics Symposium on Non-homogeneity in Elasticity and Plasticity (Warsaw), No. 17, 1958, Pergamon Press, New York, 1959, p. 463.

10. Hashin, Z., "The Elastic Moduli of Heterogeneous Materials, Transactions, American Society of Mechanical Engineers, V. 84E, 1962, p. 143.

11. LaRue, H. A., "Modulus of Elasticity of Aggregates and Its Effect on Con- crete," Proceedings, ASTM, Philadelphia, V. 46, 1946, pp. 1298-1310.

12. Hirsch, T. J., "Modulus of Elasticity of Concrete Affected by Moduli of Cement Paste Matrix and Aggregate," ACI JOURNAL, Proceedings V. 59, No.

3, 1962, pp. 427-452.

13. Griin, R., and Beckman, H., "The Behaviour of Cement Aggregates and Concrete a t High Temperatures," Cement and Cement Manufacture, V. 3, No. 3,

1930, p. 430.

14. Malhotra, H. L., "The Effect of Temperature on the Compressive Strength of Concrete," Magazine of Concrete Research (London), V. 8, No. 22, 1956, pp. 85-94.

15. Seamann, J. C., and Washa, G. W., "Variation of Mortar and Concrete Properties with Temperature," ACI JOURNAL, Proceedings V. 54, No. 5, Nov.

1957, pp. 385-396.

16. Philleo, R., "Some Physical Properties of Concrete at High Temperatures," ACI JOURNAL, Proceedings V. 54, No. 10, Apr. 1958, pp. 857-864.

17. Cruz, C. R., "An Optical Method for Determining the Elastic Constants of Concrete," Journal, PCA Research and Development Laboratories, V. 4, No. 2 May 1962. pp 24-32.

CONCRETE AT ELEVATED TEMPERATURES 11 1

18. Zoldners, N. G., "Effect of High Temperatures on Concretes Incorporating Different Aggregates," Proceedings, ASTM, Philadelphia, V. 60, 1960, p. 1087.

19. Blanchard, J. A. C., and Harmathy, T. Z., "Fire Test of a Non-Bearing Wall Built from Solid Masonry Units of Rotary Kiln Expanded Shale Aggre- gate," NRC 7662, Division of Building Research, National Research Council, Ottawa, Jan. 1964.

APPENDIX

N O T A T I O N

c = cement in anhydrous state, g E = modulus of elasticity i n com-

pression, psi

m = maturity factor, dimensionless w o = water in fresh paste, g -

WTL = nonevaporable water in paste

a t infinitely long time after the beginning of hydration, g

Greek letters

E = unit deformation i n compres- sion, in. per in.

-

p = true density, g/cm"

-

p = bulk density, g/cm"

rs = unit stress in compression, psi

= true porosity, dimensionless

Subscripts

c = of anhydrous cement

f = a t fracture

n = of nonevaporable water

p = of portland cement paste

u ultimate

w = of water

Note: I n general, pc = 3.15 gIcm3 and p,, = 1.22 g/cm".

Received b y the Institute June 2, 1965. Title No. 63-4 is a part of copyrighted JOURNAL of the American Concrete Institute, Proceedings V. 63, No. 1, Jan. 1966. Separate prints are

available at 60 cents each, cash with order.

American Concrete Institute, P.O. Box 4754, Redford Station, Detroit, Michigan 48219

Discussion of this paper should reach ACI headquarters in triplicate by Apr. 1, 1966, for publication in the September 1 9 6 6 JOURNAL.

(See p. iii for details.)

Sinopsis

-

RBsum6-

ZusammenfassungCernento Portland Hidratado y Concreto de Peso Ligero a Elevadas Temperaturas

S e estudio a elevadas temperaturas la relaci6n esfuerzo-deformaci6n e n compresi6n del cemento portland hidratado (con una relaci6n agua-cement0 d e 0.33) y de un concreto de peso ligero. Las propiedades de ambos materiales parecen no haber sido virtualmente afectadas por temperaturas cerca de 10s 204C. Arriba de ksta, el m6dulo de elasticidad y la resistencia a l a rotura disminuyen con increment0 de temperatura. Estos cambios fueron m5s definitivos para cemento portland hidratado.

Ciment Portland Hydrate et Beton Leger a des Temperatures Elevees

La relation entre les contraintes en compression e t la deformation de ciment portland hydrate (ayant un rapport eau-ciment de 0,33) e t d'un bCton leger a ete Ctudiee ?I des temperatures elevbes. Les proprietes des deux matkriaux ne semblent pas Ctre affectees par des temperatures allant jusqu'g 204 C. Au- dessus de cette temperature, le module d'6lasticitC e t l'effort ultime dhcroissent avec une augmentation de temperature. Ces changements etaient plus marques pour le ciment portland hydrate.

Hydrierter Portland-Zement und Leichtbeton bei erhohten Temperaturen

Die Druckspannung-Deformation-Beziehung fiir hydrierten Portland-Zement (mit Wasser-Zement Verhaltnis 0,33) und einen Leichtbeton wurde bei erhijhten Temperaturen untersucht. Die Eigenschaften beider Materien scheinten von Temperatur bis zu ungefahr 2Q4C unbeinflusst zu sein. Dariiber, verringerten sich das Elastizitatsmodul und die Druckfestigkeit bei steigender Temperatur. Diese Xnderungen waren mehr bestimmt bei dem hydrierten Portland-Zement.