READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE. https://nrc-publications.canada.ca/eng/copyright

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

NRC Publications Archive

Archives des publications du CNRC

This publication could be one of several versions: author’s original, accepted manuscript or the publisher’s version. / La version de cette publication peut être l’une des suivantes : la version prépublication de l’auteur, la version acceptée du manuscrit ou la version de l’éditeur.

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at

Water mist fire suppression using cycling discharges

Kim, A. K.; Liu, Z. G.; Su, J. Z.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site

LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

NRC Publications Record / Notice d'Archives des publications de CNRC:

https://nrc-publications.canada.ca/eng/view/object/?id=b58e9e3c-b7f3-495e-862e-928b35a7d3de

https://publications-cnrc.canada.ca/fra/voir/objet/?id=b58e9e3c-b7f3-495e-862e-928b35a7d3de

http://www.nrc-cnrc.gc.ca/irc

Wa t e r m ist fire suppre ssion using c yc ling disc ha rge s

N R C C - 4 2 5 6 3

K i m , A . K . ; L i u , Z . G . ; S u , J . Z .

J u n e 1 9 9 9

A version of this document is published in / Une version de ce document se trouve dans:

Interflam '99, Edinburgh, Scotland, June 29-July 1, 1999, pp. 1349-1354

The material in this document is covered by the provisions of the Copyright Act, by Canadian laws, policies, regulations and international agreements. Such provisions serve to identify the information source and, in specific instances, to prohibit reproduction of materials without written permission. For more information visit http://laws.justice.gc.ca/en/showtdm/cs/C-42

Les renseignements dans ce document sont protégés par la Loi sur le droit d'auteur, par les lois, les politiques et les règlements du Canada et des accords internationaux. Ces dispositions permettent d'identifier la source de l'information et, dans certains cas, d'interdire la copie de documents sans permission écrite. Pour obtenir de plus amples renseignements : http://lois.justice.gc.ca/fr/showtdm/cs/C-42

-

,•

INTER FLAM '99

WATER MIST FIRE SUPPRESSION US!NG CYCLING

DISCHARGES

セ ,', . J /

Andrew K. Kim, Zhigang Liu, and Joseph Z. Su Fire Risk Management Program Institute for Research in Construction

National Research Council of Canada, Ottawa, Canada, KIA OR6

ABSTRACT

There is a continuing interest in the use of water mist fire suppression systems as a halon alternative. Recently, a series of full-scale fire tests of water mist systems was carried outbythe Fire Risk Management Program of the National Research Council of Canada (NRC). During the tests, two water mist discharge modes (continuous and cycling) were employed, The test results showed that the

use of the cycling discharge improved the efficacy of water mist in fire suppression, with a shorter

extinguishment time and a lower water requirement. The improvement of the efficacy of water mist in fire suppression using cycling discharge was attributed to the faster depletion rate of oxygen in the compartment and the recurrent dynamic mixing created by cycling discharge.

INTRODUCTION

Recent phase...()uts of halons and the search for alternative agents placed renewed attention"'Gfl water mist fire suppression systems!. Water mist fire suppression systems have demonstrated a number of advantages. such as no environmental impact and no toxicity. As a result, water mist technologies for fire suppression have progressed to a wide range of practical applications.

The Fire Risk Management Program of the National Research Council of Canada (NRC) has conducted a series of full-scale fire tests of water mist systems in an engine mock-up enclosure under 1rious fire scenarios with different fire sizes. types and locations. and different ventilation conditions. as"Well as two different water mist discharge modes: continuous and cycling. The cycling discharge hwolves a continuous alternation of the On and Off cycle of the water mist discharge. During the cycling'discharge. the water mist system was turned on for a short period of time, followed by a period キェ{セGoオエ water discharge; this cycle was repeated continuously until the end of the test. セ

The use of cycling discharge was initially reported in a paper discussing the use of water mist for the protection of gas turbine enclosuresz. It was anticipated that cycling water mist discharge could reduce the damage to critical turbine components caused by rapid spray cooling and would eliminate stress cracking or excessive defonnation. There is no report, however, discussing whether the extinguishing performance of the water mist system could be improved by the use of cycling discharge.

This paper reports the test results of the water mist system with different discharge modes. The test results show that the use of cycling discharge significantly improved the efficacy of water mist in fire suppression. with a shorter extinguishment time and less water requirement.

INTERFLAM '99

TEST FACILITY AND FIRE SCENARIOS

,

The test facility consisted of a specially-constructed compartment. a water distribution'"network,

and the necessary instruments to monitor and record test results.

Test Room

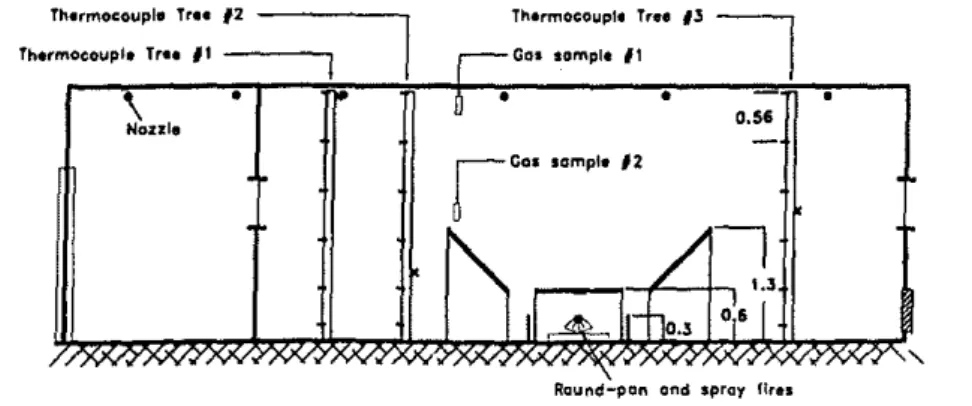

The full-scale testing of water mist was performed in a 121 m3compartment. A plan view and an

elevation view of the room are shown in Figures 1 and 2. The test room had a 2.0 m x 0.9 m foam-filled steel door and three 0.56 m2viewing windows made of Lexan. The room also had a 0.5 m x 0.5 m

pressure relief vent attached to a fan in the South wall near the floor. The flow rate of the exhaust fan

was0.737rolls.

A diesel engine mock-up, which was based on the fire test protocol reconunended by Factory Mutual Research CorporationJ, was used in the tests. As shown in Figures 1 and 2, a horizontal flat plate and steel baffles were placed in the test enclosure. The perimeter of the horizontal flat plate wasfiUed with 0.85

nun

thick galvanized sheet metal to simulate the lower portion of the turbine casing. The sheet metal(4m

width and4.5m

length) was installed to the steel plate at a45' angle. The space below the plate was partially shielded using 0.3 m highx0.3mlong sheet metal baffles.Instrumentation

Test data from a wide array of instrumentation was collectedby a data acquisition system. Three thermocouple trees, as shown in Figures1and2,were set up to measure room temperatures. Each tree contained six thermocouples at approximately0.56 m intervals in a vertical direction. To monitor the extinguishment of fires, thermocouples were placed at each fire location.

Two copper sampling ports,12

mrn

in diameter, were located in the West wall as shown in Figures1 and2, One sampling port was1.5m above the floor and0.3m into the room and was used to measure the concentrations of CO and CO2. Another sampling port was 2.8 m above the floor and 0.3 minto the

room and was used to measure the concentrations of O2,CO and CO2in the compartment.

Two video cameras were set up at the South and North windows to obtain visual records of the water mist discharge and the behaviour of the fires under suppression.

Water Mist System

Atwin·fluid water mist system, made by Securiplex Technologies Inc.· in Canada, was evaluated in the tests. A twin·fluid nozzle which has a flow capacity of 5 Umin and a spray angle of 90' was used. The nozzle had seven orifices which producedanon·uniform water flux distribution inside the90' spray envelope. The operating pressures of the nozzle for water and air were 5.78 bar and 5.57 bar, • Certain commercial products are identified in this paper in order to adequately specify the experimental procedure. In no case does such identification imply recommendations or endorsementbythe National Research Council, nor doesit imply that the product or material identified is the best available for the purpose.

INTER FLAM '99

respectively. The mass of air flow through the nozzle was approximately 5 to 8% ofthe mass flow of the water. The droplet size distribution of the water mist generatedbythenOlzlewas a Class IIspral.

Thepipenetwork layout for water and air in the compartment is shown:rin Figures QNセ 2. A total of fourteen nozzles were installed on the ceiling. The spacing of the nozzles was 1.63 m x 1.88 m. Two nozzles were located near the door in the test compartment. The total water discharge rate in the

compartment was70Lpm.

During the test series, two water discharge modes were employed: continuous and cycling. For cycling discharges. the frequency of water mist discharge was: 30 s on and 20 s off.

Fire Scenarios

The fire scenarios used in the tests included heptane pool fires and spray fires. All fires were shielded from the direct water spray by a solid metal plate. For large shielded pool fire tests, a heptane pool fire in a round pan, 0.7 m diameter, was placed under a table which produced a heat release rate of approximately 500 kW. For small heptane pool fire tests, three square·pans containing heptane fuel were placed under the table which produced a total heat output of 150 kW. For the shielded spray fire tests, one spray nozzle was placed under the table with an upward angle of 20' to strike a hot metal disc located at the centre of the table top. The heat release rate of the spray fire was approximately 500 kW. Test fires were allowed at least a 30 s pre·bum period. During the pre·bum period, the door was kept open to allow fresh air to enter the room. At the begining of the water mist discharge, the door was either kept open or closed, depending on the ventilation condition of the test.

TEST RESULTS AND DISCUSSION

The test results, including test conditions. extinguishing times, the amount of water required and water mist discharge mode are listed in Table1.

Table 1 shows that for three small

ウアオ。イ・セー。ョ

fires, adjoined together and placed under the table (Test'''' No.1), the continuous water mist discharge failed to extinguish the fires in the test. However, all three square·pan fires were extinguished by a cycling water mist discharge. The fire was extinguished at 180 s ,'., and the amount of water required was 140L. •.During the tests with a large shielded round·pan fIre. the water mist system performed much better with the cycling discharge compared to the continuous discharge. With the door closed, as shown in Table 1 (Test No.2), the shielded round-pan fire was extinguished at approximately the same time by both the ;continuous discharge and the cycling discharge. However. the amount of water required for extinguishing the fire was reduced from 130 L for the continuous discharge case to 90 L for the cycling (discharge case.

When the door of the compartment was kept open, continuous water mist discharge extinguished the lIarge shielded pan fire in 420 s. The cycling water mist discharge extinguished the same fire at 220 s, 'The amount of water required to extinguish the fire was reduced from 490 L to 160L.

INTER FLAM '99

When forced ventilation was applied to the test compartment by opening the door and running the ex.haust fan, continuous water mist discharge failed to ex.tinguish the large shielded pan fire. hッセ・キ・イN

the same fire under the same ventilation conditions was extinguished in 168 sbyusing the cyclingWater

mist discharge.

For the shielded heptane spray fire, there was little difference between the eoiltinuous water".mist

discharge and cycling discharge on the extinguishing performance when the door of the test compartment was kept closed. Under forced ventilation conditions, the cycling water mist discharge showed a substantial improvement in extinguishing the shielded spray fire compared to the continuous water mist discharge case. The shielded heptane spray fire was extinguished in 510 s by the continuous water mist discharge and the same fire was extinguished in 257 s by the cycling water mist discharge. The amount of water required was also reduced from 640 L to 200L.

The improvement in the efficacy of water mist in fire suppression using cycling discharges can be

attributed to the faster depletion rate of oxygen in the compartment. During the water mist Off cycle, the fire quickly recovered its strength and burned freely. resulting in a hot gas layer being fanned near the ceiling. In the following On cycle. the water mist spray evaporated qUickly as it passed through the hot gas layer. This increased the oxygen depletion rate in the test compartment.

Test results further showed that the use of a cycling discharge produced a recurring turbulent mixing in the compartment. as the large quantity of water vapour and combustion products were pushed down by the cycle of water spray. The recurrent turbulent mixing sharply increased the CO and CO2

concentrations near the floor, which effectively diluted the air and fuel vapour in the vicinity of a fire.

SUMMARY

The fire extinguishing perfonnance of the water mist system was substantially increased when a cycling discharge mode was used instead of a continuous discharge. When a fire challenge is small, water mist can easily extinguish the fire, thus. the improvement is small. However, even under those conditions, the amount of water required in the test to extinguish the fire was reduced by using the cycling discharge. For more challenging conditions, such as small fires and ventilated conditions, the use of cycling discharge significantly improved the fire extinguishing performance of the water mist system. The extinguishment times and the water requirements were substantially reduced with the use of cycling discharge. When cycling water mist discharge was used, more water vapour and combustion products were produced during the test, which increased the rate of oxygen depletion in the test compartment. In addition. the recurrent dynamic mixing created by cycling discharge effectively dilutes the oxygen and fuel vapour available for the fire.

ACKNOWLEDGMENTS

The financial support of National Defence Canada for this research is gratefully acknowledged. The contributions of Mr. George Crampton and Dr. M. Kanabus·Kaminska of the Fire Risk Management Program in constructing the test facility and conducting the fire tests are also acknowledged.

INTERFLAM '99

-

,REFERENCES

1. Liu, Zhigang and Kim, Andrew

K..

"Water Mist as a Halon Alternative: Its Status and Development", SFPE Engineering Seminar. "Life after Halon: Existing Systems andnNセL Designs",May. 1997, Los Angeles. CA, U.S.A.

.-2. Pepi, J.S .• "Performance Evaluation of a Low Pressure Water Mist System in a Marine Machinery Space with Open Doorway". Proceedings of Halon Options Technical Working Conference.

Albuquerque. NM, 1995. p. 424.

3. Factory Mutual Research Corporation, "Draft Perfonnance Requirements for Fine Water Spray

Systems for Protection of Machinery Spaces". Quincy. MA, 1996.

4. NFPA 750, "Standard for the InstaHation of Water Mist Fire Protection Systems 1996 edition", National Fire Protection Association, Quincy. MA, 1996.

Table 1 The Performance of Continuous and Cycling Discharge Water Mist System No Fire Type Fire Size Ventilation Test Results Test Results

(Continuous) (Cvelin.)

1 3 shielded all extinguished at

square-pan 150kW door closed not extinguished 180 s; 140 L water

2 I shielded extinguished at 114 s; extinguished at

round-pan 500 kW door closed 130 L water 115 s; 90 L water

1 I shielded extinguished at 420 s; extinguished at

round-pan 500 kW door ooened 490 L water 220 s; 160 L water

4 I shielded door extinguished at

round-pan 500 kW opened, not extinguished 168 s; 130 L water fan running

5 1 shielded extinguished at 113 s; extinguished at

spray 520kW door closed I30L water 130 s; lIO L water

6 I shielded door extinguished at 510 s; extinguished at

spray 520kW opened, 640 L water 257 s; 200 L water

fan running

INTERFlAM '99

'.7

,

-i\

7

11e Th.,l7\ocoupl, It..(12)-...

t'-Wlndow1\

Val

,h.,t

WlndO\re

)/b1e

,

4.321I

•

1.370•••

Wal.r ッョ、⦅セI

I

ven\

wQBセ

AIXHQヲセ

Thermocoupleャイセ

Thermocoupl, Ir••HGSIセ

7.'

Figure 1 Test fecilities, water distribution network and engine mock-up (Plan)

Rauru:!-pon and .proy Urn

tィッセBBーB T,..I '

I

rmocoupl, Tr..,.

I

rOO.lamPle 11\

0 D 0•

0.56 0 Nonl,-Ie..

lample 12GャQQセNiエQH

I

..

,

.;. I

" Tho(All dimensions jn metres)