O

pen

A

rchive

T

OULOUSE

A

rchive

O

uverte (

OATAO

)

OATAO is an open access repository that collects the work of Toulouse researchers and

makes it freely available over the web where possible.

This is an author-deposited version published in :

http://oatao.univ-toulouse.fr/

Eprints ID : 13967

To link to this article :

DOI:10.1016/j.jeurceramsoc.2013.08.010

URL :

http://dx.doi.org/10.1016/j.jeurceramsoc.2013.08.010

To cite this version :

El Horr, Nahida and Guillemet-Fritsch, Sophie and Rousset, Abel

and Bordeneuve, Hélène and Tenailleau, Christophe Microstructure

of single-phase cobalt and manganese oxide spinel Mn3−xCoxO4

ceramics. (2014) Journal of the European Ceramic Society, vol. 34

(n° 2). pp. 317-326. ISSN 0955-2219

Any correspondance concerning this service should be sent to the repository

administrator: staff-oatao@listes-diff.inp-toulouse.fr

Microstructure

of

single-phase

cobalt

and

manganese

oxide

spinel

Mn

3−x

Co

x

O

4

ceramics

N.

El

Horr

∗,

S.

Guillemet-Fritsch,

A.

Rousset,

H.

Bordeneuve,

C.

Tenailleau

InstitutCarnotCIRIMAT,UniversitéPaulSabatier,UMRCNRS5085,118routedeNarbonne,31062ToulouseCedex9,France

Abstract

Thispaperreportsmicrostructuralstudiesofsingle-phaseMn3−xCoxO4(0.98≤x≤2.93)spinelceramicsusingtransmissionelectronmicroscopy

(TEM)andenergydispersiveX-rayspectroscopy(EDX).Theseceramicswereobtainedbyconventionalsinteringorbysparkplasmasintering (SPS)ofpowderspreparedbythermaldecompositionofcoprecipitatedoxalateprecursors.Forx<1.78orx≥1.78,themonophasicceramics correspondrespectivelytoquadratic(Q)orcubic(C)spinelstructure.TheferroelasticcharacterofthestructuralphasetransitionfromCtoQ ishighlightedbyspecificmicrostructuralfeatures.Theeffectofchemicalcompositionandheattreatmentconditionsonthemicrostructureand essentiallyonthepresenceandthecharacteristicsoftwinswereinvestigated.Thecoherenttwininterfacesareparallelto(112)planesintheQ cell.Twinscancorrespondto:tweeds,singlelamellae(widths:5–306nm)arrangedparalleltoeachother,largelamellae(widths:69–928nm) internallytwinnedandsometimesarrangedincyclicforms(triangularshapes).

Keywords:Cobaltmanganite;Sintering;Microstructure;Twins;Electronmicroscopy

1. Introduction

Manganites have been of great interest to materials

researchers since the 1950s.1–4 Indeed, in addition to their widerangeofchemicalcompositionsandtheirbroadvarietyof structuralphases(withahighnumberofpossiblecation distribu-tions),theycanalsoexhibitalargerangeofphysical,chemical, electric,magneticproperties,etc.

Mixed-valence transition-metal manganites with a spinel

structureMn3−xMexO4(Me=Co,Ni,Fe,Cu,Zn,CrandZr)are

knownasbasicmaterialsusedtomanufacturethermistorswith Negative Temperature Coefficient (NTC).5–9 This specificity makes themhighly attractivefor severaltechnology domains (microelectronics,optoelectronics,etc.)andtheyarethusused inmanyindustrialapplications10–17:temperaturesensors,time delayelements,infrareddetectors,voltageregulators,etc.

Apart from the numerousapplications arising from spinel manganites,itisimportanttonotethatthesematerialsarealso attractingconsiderableinterestinfundamentalresearchdueto

∗Correspondingauthor.Tel.:+33562258253;fax:+33562258277.

E-mailaddress:nahida.el-horr@iut-tlse3.fr(N.ElHorr).

the complexityof the relationshipsthat existbetween,firstly, the chemicalmethodsusedtopreparepowdersandceramics, secondly,the structures(andinparticularcationdistribution), microstructures(density,grainsize,grainmorphology,presence ofseveralphases,presenceofdefects:precipitates,twins,etc.) of the obtainedproducts andthirdly,theirmanyphysicaland chemical properties:electric,magnetic,etc. Judicious control oftheserelationshipscouldprovidenewwaystoobtainspinel manganiteswithcontrolledproperties.

The microstructureof spinelmanganiteceramics hasbeen

the subject of many studies,7–9,18–33 many of which were

performed in our laboratory. In most cases, these

mangan-ites are obtained by sintering powders prepared either by

hydrothermal methods (thermal decomposition of precursors

producedbycoprecipitation)orbytraditionalmethodsand

cor-respond tobinarysystems: Mn–Ni–O,Mn–Fe–O,Mn–Zn–O,

etc. to ternary systems: Mn–Ni–Co–O, Mn–Ni–Cu–O,

Mn–Ni–Zn–O, Mn–Ni–Zr–O, Mn–Ni–Fe–O, Mn–Ni–In–O,

etc.andsystemswithfourormorecations:Mn–Ni–Co–Al–O,

Mn–Ni–Co–Zn–O, Mn–Ni–Fe–Cr–O, Mn–Ni–Co–Cu–Si–O,

etc.

Amongstthesestudies,wenotethatthepresenceofdefects suchasprecipitatesortwins,inthesemanganites,andalsothe

characteristics oftheobservedtwins,depend onthechemical compositionofthesamplesandtheirheattreatmentconditions. Additionally,insomecases,thesedefectscanplayanimportant roleincontrollingtheelectricalpropertiesofmanganites.

Veryfewstudies34–41hadbeenperformedontheMn–Co–O systembeforetheworksconductedinourlaboratory.Theyhave

involved more detailed works on filmsand powders than on

ceramics. The recent works on Mn3−xCoxO4 ceramics done

inour laboratoryandwhichwere the subjectof several pub-lications, havefocused on structures (identificationof phases and cation distributions), along with magnetic and electrical properties.42–46Wenotethattheelectricalpropertiesstudies42,46 ofsingle-phaseMn3−xCoxO4spinelceramics,obtainedby

con-ventional sinteringor bySPS,hadshownthat theseceramics aresemiconductorsandpossessinterestingelectrical character-isticsmakingthemattractivematerialsforindustrialapplications as NTCthermistors.Also,thesestudiesshowedthat for mea-surements made at 25◦C, the minimum resistivity (ρ25◦C)

value is of about 387.cm for x=1.78 and thisρ25◦C value

increasesin amuchmoreintense manner onthe zonewhere

x<1.78(particularlyfor0.98≥x>1.54)thenonthezonewhere

x>1.78 (for x=0.98, ρ25◦C=49,552cm and for x=2.93,

ρ25◦C=5020cm).Electricalconductioncouldtakeplaceby

thepolaronshoppingbetweencations.

To ourknowledge, the workreportedinthisarticle corre-spondstothe firstmicrostructural study of cobaltmanganese oxideceramics,Mn3−xCoxO4.

2. Experimental

2.1. Samplepreparation

Ashasbeendescribedindetail byH.Bordeneuveetal.42, oxalic precursors, Mn1aCoaC2O4·nH2O,were first obtained

by the coprecipitation of an aqueous solution of ammonium

oxalateandamixtureofmanganeseandcobaltnitratesin pro-portionsvaryingaccordingtothechemicalcompositionofthe finalproduct.Thus,theresultingsolutionwasagedfor30min, thenfiltered,washedwithwateranddriedinairat90◦C.Oxide

powderswereproducedbythermaldecompositionof coprecip-itatedoxalateprecursors(inairat800◦C).Pelletsof6mmin

diameterwereobtainedbypressingoxidepowdersat500MPa. Afterthat,twotypesofsinteringwereused:conventional sinter-ingandSparkPlasmaSintering(SPS).Ashasbeenpreviously reportedindetail,42,47producingsingle-phasecobaltmanganese oxideceramicsisdifficulttoachieveandrequiresanadaptation of the sintering conditions according tothe desired chemical compositionofthesample.

Forx<1.78andtakingintoaccountthephasediagramofthe Mn3O4–Co3O4system(reportedinpreviousworks42,48),

single-phaseceramicpreparationisrestrictedbythemanystructural transformationstakingplaceatvarioustemperatures.Thus,as hasbeenpreviouslydescribed,42,47thesinteringprocessmustbe carriedoutathightemperature(between1160◦Cand1280◦C

inair,forthesampleswhicharetheobjectofthisstudy)inorder tobe placedinthe zone of thesinglecubic (C) spinelphase andto givethe ceramic sufficient densification.Additionally,

the samples must be quenched to avoid obtaining two-phase

samples.Infact,whentheyhavebeencooledatdifferentrates (i.e.thesampleshavenotbeenquenched),theobtainedceramics werebiphasic.Thetemperatureofquenchingcouldbealittle lowerthan the sintering temperature (but still in the domain ofthe singleCphase) toavoidcracking the samples.So,for

x<1.78,quadratic(Q)single-phaseceramicsweresuccessfully producedunderthesinteringconditionsreportedinTable2.

Forsamplescorrespondingtox=1.54andforwhichtheC spinelphaseexistsatlowertemperatures thanfor x<1.54(as hasbeendescribed previously),42,47 theSPSmethodhasalso beenused(Table2)inadditiontoconventionalsintering.

For x≥1.78, the preparation of single-phase ceramics is restrictedbythefact that thereduction ofthe Cspinelphase occursatlowertemperaturesthaninthedomainthatcorresponds tox<1.78,makingitdifficulttoobtainsingle-phaseceramics withhighdensities byconventional sintering.42,47 So,in this case,therearetwopossibilitiestoconductthesinteringofthe samples:

- conventional sintering with a sintering temperature higher thanthesamplereductiontemperaturebutwithacoolingrate lowenoughtoreoxidizethesample.

- SPS sintering which allowing us to decrease the optimum

sinteringtemperaturecomparedtotheconventionalmethod. Thesetwopossibilitieshaveproventobevalidforx=1.78, but,as the x value increases, the reoxidation of the samples becomesmoredifficultwiththeconventional method.So,for

x>1.78,onlytheSPSsinteringhasledtous,obtainingC single-phaseceramicswithhighdensities.42,47Allsinteringconditions arereportedinTable2.

ForSPSsintering,theapparatususedwasaSumitomo2080 (PNF2CNRSplatformavailableattheUniversityofToulouse, France).Theoxidepowderswerepre-compacted,thenplacedin agraphitedieandheatedundervacuumattemperaturesbetween 700and750◦C,dependingonsamplecompositionandundera

pressureof50MPa.Thepressurewasmaintainedconstantuntil theendofthedwelltimeat700or750◦C.Afterthat,thepressure

wasremoved,andthesamplewascooledtoroomtemperature byshuttingdownthepowersupply.Theresultingsampleswere polishedtoremovethe(Co,Mn)Othinlayerdepositedonsurface samplesduringsintering(ashasbeendescribedpreviously).42,47 Thedensificationvalues46ofobtainedsampleswerebetween 93%and94%forsamplessubjecttoconventionalsintering,and between95%and97%forthosesinteredbySPS(Table1).

2.2. Samplecharacterization

ABruckerD4powderdiffractometerwasusedtodetermine

sample X-ray diffraction (XRD) patterns. The

diffractome-ter operated with an emitting source of Cu (Ka1,a2

mean=1.5418 ˚A).

Wenoted thattheceramic samplessinteredbySPS,along withthosesinteredbyconventionalmethod,butwithlowcobalt contents, belong to brittle materials (like glass) and hence, the preparation of these samples for transmission electron

Table1

Sinteringconditions,spacegroupandcellparametersdeterminedbyXRD42,47ofMn

3xCoxO4ceramics.Therelativedensity46(dR),averagegrainsize(Dav)and

celldeformation(celldef)arealsoreported.

x Sinteringmethod dR(%) Phase Dav(mm) a′(nm) c(nm) c/a′ Celldefe(%)

0.98 conva 94 Qc 22 0.80956(3) 0.92052(4) 1.13706(9) 13.7 1.27 conv 93 Q 13.5 0.81163(5) 0.89743(7) 1.1057(2) 10.6 1.54 conv 93 Q 17.3 0.82258(3) 0.85998(4) 1.04547(9) 4.6 1.54 SPSb 95 Q 1.00 0.82250(2) 0.86020(4) 1.04584(7) 4.6 1.66 conv 94 Q 12.0 0.82481(4) 0.85081(4) 1.03152(9) 3.2 1.78 conv 94 Cd 10.0 0.83183(4) 1 1.78 SPS 95 C 0.67 0.83130(1) 1 1.99 SPS 95 C 0.56 0.82760(9) 1 2.22 SPS 97 C 0.44 0.82211(3) 1 2.93 SPS 96 C 0.34 0.80995(7) 1

aconv:conventionalmethod.

b SPS:Sparkplasmasintering.

cQ:quadraticwiththespacegroupI4

1/amd.

d C:cubicwiththespacegroupFd-3m.

eCelldef(%)=(c/a′

−1)×100.

microscopy(TEM) observations requires a lotof ability and resourcefulness.ThemethodusedforTEMsamplepreparation isasfollows:adiamondsaw(ESCIL3032-4)wasusedtoobtain asampleblockfromeachpellet,whichwasthenplacedinside abrasstube(offinediameter∼3mm)andboundwithanepoxy resin(GatanG1).Theresinwaspolymerizedat50◦Covernight,

then 500mm thick discs were collected by slicing the tube

using thesamediamondsaw.To makeeach sample

electron-transparent,i.e.,toreduceitsthicknesstoapproximately100nm,

each sample was mechanically polished (using ESCIL: ESC

300GTL),thenconcavedimplepolished(withaEA-Fishione

– model 2000 – polishing liquid: solution with diamond in

suspension)andfinallyionbeam-thinned(usingGATANPIPS).

TheceramicsampleswereobservedusingaJEOLJEM2010

electron microscope (200kV – emitter: single crystal LaB6

tip – maximum resolution: 0.23nm point–point and 0.14nm

line–line).Thechemicalcompositionofeachsamplewas ana-lyzedbothqualitativelyandquantitatively(simultaneouslywith TEMobservations)byusingaTracorVoyagerEnergy Disper-siveX-rayanalyzer(EDX).Probesizemaybereducedto7nm.

For each sample, granulometric analyses andtwin

lamel-lar thickness of TEM images were performed using imageJ

software.49

3. Results

AsisreportedinTable1,allobtainedsamplescorrespondto Cspinelstructure(Fd-3mspacegroup)forx≥1.78andtoQ spinelstructure(I41/amdspacegroup)forx<1.78.Tofacilitate

thecomparisonbetweenQandCspinelcells, theQcellwas convertedtoabiggerunitcellwitha′=a√2andc′=candthe

c/a′deformationwasevaluatedforeachsample.

3.1. Grainsizes(GSs)

BeforedescribingtheGSofceramicsamples,werecallthat theGSofinitialpowders,47forwhich0.98≤x≤2.93,presenta relativelywideGSdistributionandvaryasfollows:GSsareof

theorderofafewhundrednmforx=0.98.Theythenincrease withincreasingxfrom0.98to1.27,wheretheyreachamaximum

(without exceeding amaximum GS value of about 600nm).

Theythendecreaseasxvariesfrom1.27to2.72,thusreaching values closetoafew tensof nm.From thislattervalueof x, GSvaluesoncemoreincreaseuptox=2.93andbecomeofthe orderofafewhundrednm.

3.1.1. Sampleswithconventionalsintering (0.98≤x≤1.78)

TEM observations of the ceramic samples reveal that the

grainspossesspolyhedralshapesandaremostlyequiaxed.Each

sample presents a wide dispersion of GSs. Minimum GS is

aboutfewmicrons(1–4mm)forallsamplesbutmaximumGS is respectively40mm, 25mm, 33mmand19mmfor x=0.98,

x=1.27, 1.54 and1.78, accordingto the sintering conditions andthe GS ofthe initialpowders. Theaverage GSs(Dav) of

theseceramicsamplesarereportedinTable1.

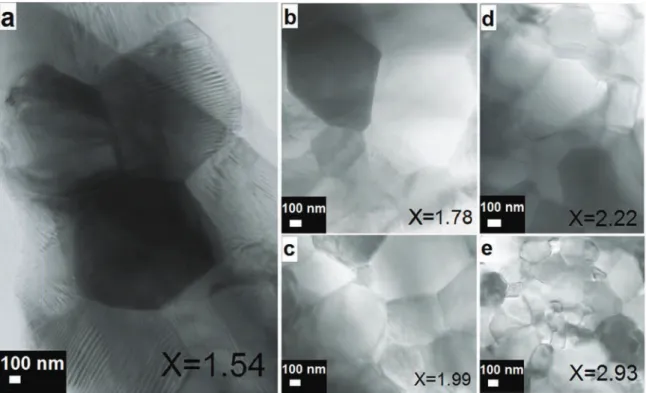

3.1.2. SampleswithSPSsintering(1.54≤x≤2.93)

These samples alsocontain grainswith polyhedralshapes

and which are mostly equiaxed. GSs are polydispersed and

verysmallcomparedtothoseofsamplesobtainedby

conven-tional sintering. They vary between 300nm and 1.7mm for

x=1.54 anddecrease systematically withincreasing xvalue, i.e.,withincreasingCocontent.Thus,theminimumand

max-imumGSvaluesarerespectively135–1210nm,103–1016nm,

95–781nm,and76–611nmforx=1.78,x=1.99,x=2.22and

x=2.93.TheGSvariationofthefinalsamplesisduetochanges insinteringconditionsandalsointheGSsoftheinitialpowders. TheDavvaluesoftheseceramicsarereportedinTable1.

3.2. Defects

Samples with x<1.78 show grainswith high densities of two-dimensionalstructuraldefects.Dependingontheconcerned sample,theselattercorrespondtosomeofthefollowingtypes ofdefects:

Fig.1.BrightfieldTEMimageofasinglequadraticphaseMn3−xCoxO4ceramic

sampleforx=1.27showingatriplejunctionandtheintensepresenceineach

grainoflargelamellae(LIT)whichareinternallytwinned(i.e.containingfine

lamellae(l)).

- twins,intheformoflamellae(L)paralleltoeachother(each lamellacorrespondstoasingleatomicdomain).

- largelamellae(LIT)whichareinternallytwinned(i.e.,

con-tainingfinelamellae(l)).

- tweeds(veryfinelamellaearrangedintwomutually perpen-diculardirections).

3.2.1. MonophasicsampleswithQstructure

AsingleQphasewasobtainedforsampleswithx<1.78that weresinteredbytheconventionalmethodorbySPSsintering. Thelatticeparametersandthec/a′ deformationofthese

sam-plesarereportedinTable1.Quantitativechemicalanalysisby

EDXhadshownthat each ofthesesamples ishomogeneous.

TheexperimentalvaluesofxarereportedinTable2.Theyfit wellwiththeexpectedvaluesofxcorrespondingtotheoretical chemicalcompositions.

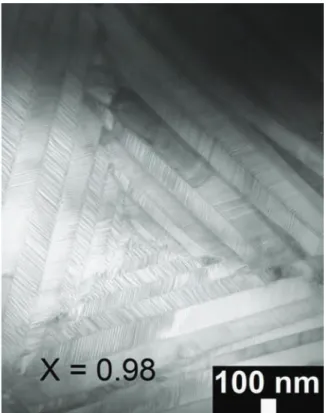

- sampleswith0.98≤x<1.54:Thesesamplescontainalmost LITlamellae(Figs.1 and2)andaresometimesarrangedin

cyclicformscorrespondingtotriangles(Fig.3).Toour knowl-edge,thistrianglearrangementshapeofLIT,correspondsto

Fig.2.BrightfieldTEMimageofasinglequadraticphaseMn3−xCoxO4ceramic

sampleforx=0.98showingthatthelamellae(LIT)aremuchlargerthanthose

ofceramicsamplewithx=1.27.

Fig.3.BrightfieldTEMimageofasinglequadraticphaseMn3−xCoxO4ceramic

sampleforx=0.98showingLITlamellaearrangedinacyclicform

correspond-ingtoatriangleobservedforthefirsttimeinmanganites.Thisarrangement

couldbeexplainedbytheexistenceofa3-foldsymmetryaxisintheCphase

(high-temperaturephase)withspacegroupFd-3m.

atypeofarrangementobservedforthefirsttimein mangan-ites. This arrangementcould beexplained bythe existence of a3-foldsymmetryaxisintheCphase(high-temperature phase)withspacegroupFd-3m.ThewidthsofLITandalso

thewidthsofthelfinelamellae(insideLIT)arereportedin

Table2.ThemaximumvalueofLITwidthisgreatlydecreased

withincreasingxvaluefrom0.98to1.27.

- sample withx=1.54sintered byconventional method:This samplecontainsonlyapproximatelyLlamellae(Fig.4).The formsoftheselamellaecorrespondtoeitherright-angledtwins (i.e., domains with practically right-angled twin walls) or needle-shaped twins (i.e.,the trajectories of the twinwalls arelikeneedles)(Fig.5).Thisisquitetypicalfora ferroelas-tictransition.50–53Thewidthsoftheselamellaearereported inTable2.

- sample withx=1.54sinteredbySPS:Thissamplecontains onlyLlamellae(Fig.6).Thelamellawidthsarereportedin Table2andaremuchfinerthanthoseofthesamplesintered bythe conventionalmethod.Thelatticeparametersandthe

c/a′deformationarealmostthesameasthoseobtainedwith

conventionalsinteringforx=1.54.Also,thetypeofstructural defectsdoesnotchangeandcorrespondstoLlamellae.Butthe SPSsinteringgeneratedasignificantdecreaseinGScompared toconventionalsintering,whichcouldbethecauseofthedrop inlamellawidths,aswasreportedintheliteratureconcerning theeffectofGSonthewidthsoftwinlamellae.54–57

Table2

Preparationconditions,structureandmicrostructuraldefectsformonophasicceramics.Thetheoretical(theor.)valuesofx(Cocontentinsamples)andtheexperimental

onesdeterminedbyenergydispersiveX-rayanalysis(EDX),arealsoreported.

x(theor.value) Sinteringmethod-sintering

temperature(◦C)

Coolingrate Phase Twintypes Lamellawidths

min–max(nm)

xvalueby

EDX

0.98 conva-1280 120◦C/handair-quenchedfromT=900◦C Qc L

ITe 77–928 0.95(3)

lf 3–13

1.27 conv-1180 120◦C/handair-quenchedfromT=800◦C Q LIT 69–409 1.25(5)

l 3–26

1.54 conv-1180 air-quenchedfromT=1180◦C Q Lg 12–306 1.54(3)

1.54 SPSb-750 cut-offofthefurnace Q L 5–45 1.55(3)

1.66 conv-1160 120◦C/handair-quenchedfromT=900◦C Q Th 2–14 1.64(3)

1.78 conv-1160 10◦C/hto400◦Cand20◦C/hto25◦C Cd Nodefects 1.75(4)

1.78 SPS-750 Cut-offofthefurnace C Nodefects 1.72(5)

1.99 SPS-750 Cut-offofthefurnace C Nodefects 1.97(4)

2.22 SPS-700 Cut-offofthefurnace C Nodefects 2.21(3)

2.93 SPS-700 Cut-offofthefurnace C Nodefects 2.91(6)

aconv:conventionalmethod.

b SPS:sparkplasmasintering.

cQ:quadraticphase.

d C:cubicphase.

eL

IT:largelamellaewhichareinternallytwinning.

fl:theinternaltwins,i.e.,twinswhichareinsideeachlargelamella.

g L:lamellaewithoutinternaltwins.

h T:tweed.

- samplewithx=1.66:Thissampleincludestweedswithhigh frequency(Fig.7).Thesetweeds are very fine withwidths varyingfrom2to14nm.

Consideringallsamples,thedomainwalls(DW)ofthe

inter-nal twins (l) and also the DW of domains with no internal

twins (L)belongtothe type-Imechanicaltwin,meaning that theatomicarrangementofonedomainisthemirrorreflection of theotherbythetwininterfaceplane, correspondingtothe (112) crystallographic plane for our samples. So,as hadbe showninapreviousstudy21,andmentionedinotherstudies,9,26 theseDW (i.e.,corresponding toLandl) constitutecoherent

Fig.4.BrightfieldTEMimageofasinglequadraticphaseMn3−xCoxO4ceramic

sampleforx=1.54(conventionallysintered)showingLlamellae(without

inter-naltwins)correspondingtoright-angledtwins(i.e.,domainswithpractically

right-angledtwinswalls).Themaximumvalueoftheirwidthsisaboutafew

hundredofnanometers.

twinboundaries.TheDW oftheLIT largelamellae,however,

formincoherenttwinboundaries.

Thetype-Imechanical112twinsareshowninthediffraction patternsreportedinFig.8.Thediagramsareindexedaccording totheQcell,andcorrespondtothezoneaxes[1¯10]and[1¯31]. The presence of twins insamplemicrostructures isshownin thesediagramsby asplitting ofthe reflectionscorresponding

Fig.5.BrightfieldTEMimageofasinglequadraticphaseMn3−xCoxO4ceramic

sampleforx=1.54(conventionallysintered)showingLlamellaecorresponding

toneedle-shapedtwins(i.e.thetrajectoriesofthetwinwallsarelikeneedles)

Fig.6.BrightfieldTEMimageofasinglequadraticphaseMn3−xCoxO4ceramic

sampleforx=1.54(sinteredbySPS)showingLlamellaethatareverymuch

finer(maximumwidthvalueisafewtensofnm)thanthoseofthesamplewith

thesamevalueofxbutconventionallysintered.

tothediffractionof zoneslocatedoneithersideofthe(112) twininterfaceplane(i.e.,thetwinboundary).Splitting magni-tudeincreaseswiththedistancefromthecenterofthepattern. Nonsplitreflectionscorrespond tocrystallographicrows per-pendiculartothe(112)twininterfaceplane.

3.2.2. MonophasicsampleswithCstructure

AsingleCphasewasobtainedforsampleswithx≥1.78and sinteredbySPSsinteringorbytheconventionalmethod(only forx=1.78).Thelatticeparametersofthesesamplesarereported inTable1.QuantitativechemicalanalysisbyEDXhadshown thateachofthesesamplesishomogeneous.AsshowninTable2, foreachsample,theexperimentalvalueofxfitswellwiththat correspondingtothetheoreticalchemicalcompositions.

These samples (i.e., x≥1.78) differ from previous sam-ples (i.e., 0.98≤x<1.78) in that they contain no defects (Figs.9and10).Wenotedthat,forx=1.78,thetwosintering methods(SPSandconventionalsintering)leadtotheproduction

Fig.7.BrightfieldTEMimageofasinglequadraticphaseMn3−xCoxO4ceramic

sampleforx=1.66showingthepresenceofdefectscorrespondingtotweeds

(veryfinelamellaewithwidthsofafewnm,andarrangedintwomutually

perpendiculardirections).

of samples free from defects (the only changes induced by

themodificationof thesintering method,correspondtoaGS variationofthefinalsamples,asmentionedabove).

4. Discussion

Single-phaseMn3−xCoxO4(0.98≤x≤2.93)spinelceramics presentavarietyofmicrostructuralcharacteristicsdependingon thesample’schemicalcomposition(i.e.,valueofx)andthetype ofheattreatmentappliedpriortoobtainingthefinalproduct.

We recall that for x<1.78 or x≥1.78, the monophasic ceramicscorrespondtoQ(I41/amdspacegroup)orC(Fd-3m

spacegroup)spinelstructuresrespectively. Qphasearisesby thestructuraltransitionofCphaseinagreementwiththephase diagram of the Mn3O4–Co3O4 system.42,48 This structural

Fig.8.Selectedareaelectrondiffraction(SAED)patternsofasinglequadraticphaseMn3xCoxO4ceramicsampleforx=1.54:(a)alongthezoneaxis[1¯31],(b)

alongthezoneaxis[1¯10],and(c)shematicreproductionofapartof(b).Thesepatternsexhibitsplittingofspots(insuchawaythattherearespotscorrespondingto

thematrixandotherspotscorrespondingtotwinswhicharedeductedfromthefirstonesbyreflectionfromaplanemirrorcoincidingwiththetwininterfaceplane).

Thereflectionsthatarenotsplitcorrespondtocrystallographicrowsperpendiculartothe(112)twininterfaceplane.Themagnitudeofsplittingincreaseswiththe

Fig.9.BrightfieldTEMimagesofallsamplessinteredbySPS:(a)forx=1.54,(b)forx=1.78,(c)forx=1.99,(d)forx=2.22,and(e)forx=2.93.Theyshowthat

forx≥1.78,notwinsdefectswereobservedinthesinglecubicphaseceramicsamples,unlikethecaseofthesinglequadraticphaseceramicsamplewithx=1.54

andwhichcontainstwinslamellae,L.

phasetransitioniscausedbythecooperativeJahn–Tellereffect asinothermanganitecompounds.21,22,26,58,59 TheCstructure isstableonlyathightemperaturesandcannotbeobservedat roomtemperatureafterquenchinginthemanganese-richoxide. Thegrainshapesofthesamplesarepolyhedralandequiaxed, inaccordancewiththeidentifiedcrystallographiccells:Ccell orQcellwithparametersclosetothoseofCcell(sincethereis verylittledifferencebetweena′(a′=a√2)andcparametersofQ

cell).GSsvarydependingonsinteringtypeandconditions,and alsoontheGSsoftheinitialpowders.Whenxvaluevariesfrom 0.98to1.27,thedropinmaximumGSfrom40to25mmcould beduetothedecrease insinteringtemperature from1280◦C

to1180◦Caswellastothedecreaseinquenchingtemperature

from900◦Cto800◦C.Whenxchangesfrom1.27to1.54,the

maximumGSincreasesfrom25to33mm,despitethedecrease ininitialpowderGSandthiscouldbeduetotheincreaseofthe

Fig.10.BrightfieldTEMimageofasinglecubicphaseMn3−xCoxO4ceramic

sampleforx=1.78(conventionallysintered)showingatriplejunctionandthe

absenceineachgrainoftwindefects.

quenchingtemperaturefrom800◦Cto1180◦C.Forx=1.78the

maximumGS isdiminished comparedtothatof x=1.54and

thusisreducedto19mm.Thiscouldbeduetothedecreasein GSof theinitialpowders,as wellas tothechange incooling conditions(quenchingforx=1.54andslowcoolingtoambient temperatureforx=1.78).

For ceramic samples obtained by SPS (i.e., x=1.54 and

x≥1.78)theGSsaremuchsmallerthanthosesinteredbythe conventional methodandarerelativelysimilartothoseof the initialpowders,whichispredictableduetothefactthatSPS sin-teringgreatlyreducesvolumediffusion(i.e.,graincoarsening) comparedtoconventionalsintering.60–63

Forx<1.78,twinsarewellpresentinallceramicsamples, buttheydifferintheircharacteristics fromsampletosample. Theexistenceoftwinsinthesesamplescouldbeduetothefact that the structural transition is ferroelastic,as it isin Mn3O4

hausmannite.21Infact,ferroelastictransition,whichbelongsto ferroic transitions,isabletoproduce structuraldomainswith different orientation states under adapted conditions.64–68 In thiscase,structuraldomainsoccurinmaterialstoaccommodate the constraints accompanying the phase transition since the latterleads,amongstothers,toareductionofcrystallographic symmetryelementsandadeformationofthe crystallographic cell evaluated by the value of c/a′ (a′ (i.e., a√2) and c

corresponds to Q cell parameters) with respect to the high-temperature phase. The twins arising in this case are called transformation twins. We can also note that the structure of the samplesstudied inthiswork, obeythefact that thepoint

group symmetryof the low-temperature phase(4/mmm) isa

thusthestructuraltransitionofthesesamplesbelongstoAizu speciesm3mF4/mmminhisnomenclatureofferroelasticphase transitions.67 The results obtained from electron microscopy revealed thatthe twins observedinthesesamplescorrespond to 112 twins (i.e.,the twin interface plane is(112)). These results are in conformity withthe theoretical predictions65,66 about the (hkl) twininterface planes that may exist when a ferroelasticphasetransition occursfromCphasewith(m3m)

pointgroupsymmetrytoQphasewith(4/mmm) pointgroup

symmetry (h, k and l are the Miller indices). Considering

changes in the characteristics of twins for x<1.78, we can mention that the mainfactorswhich couldhave an effecton thesevariationsare:

- increaseincelldeformationc/a′.

- thefactthatthechemicalcompositionofthesampleisnearor farfromthecompositioncorrespondingtothephase transi-tion.Foroursamplesthiscompositioncorrespondstox=1.78 asindicatedbythephasediagramoftheMn3O4–Co3O4

sys-temreportedinpreviousworks.48 - thevariationofGSs.

For x=1.66, TEM observations indicate the existence, in

thissample, of tweeddomains shownbya modulatedimage

contrast in two directions withwidths on the orderof a few nm.Thisresult could beattributed tothefact that the chem-ical composition of thissample is closeto that of the phase transition (i.e., x=1.78) and thus could be noted as one of thefeatureshighlightingtheferroelasticcharacterofthephase transition inMn3−xCoxO4.Thisis becausemany

experimen-talandtheoreticalstudieshaveshowntheapparitionoftweeds whenapproachingthephasetransitioninthecaseof ferroelas-tictransitions.26,55,64,68–70Amongthevariousinterpretationsin thisregardandtakingintoaccountthatthesampleusedinthis

study hasan homogeneouschemical composition(within the

resolutionoftheanalyses)andcontainsonlyonephase,wenote thattheobservedtweedscouldberelatedtothefactthat,close tothephasetransition,DWmotionleadsthemicrostructureto assumeastablearrangementcorrespondingtoaminimumfree energy value (including elastic energy) and whichis consis-tentwithstrainsinducedbythephasetransformation.Thus,this arrangementisestablishedwiththetweedmicrostructureandis compatiblewiththec/a′sampledeformationwhichisofabout

3.15%andisthelowestvaluecomparedtothoseoftheothers sampleswithx<1.78.

Whenxdecreasesfrom1.66to1.54,thechemical composi-tionofthesamplebecomesalittlebitfarfromthatofthephase transitionandtheTEMobservationsrevealthatthemodulated microstructureisentirelyreplacedbytwindomains correspond-ing toparallel Llamellae.Asmentioned above,for thesame chemical composition (i.e., x=1.54), the decrease in lamella widthsofthesamplesinteredbySPScomparedtothoseofthe sampleobtainedbyconventionalsinteringcouldbeduetothe decreaseinGSsinducedbySPSsintering,inaccordancewith that hasbeen reportedintheliterature.54–57 Forbothsamples (i.e., SPS and conventionally sintered samples), the value of thec/a′deformationisofabout4.6%,notexcessivelylargein

comparisontothoseoftheothersampleswithlowervaluesof

x.However,whenxdecreasesfrom1.54to1.27,theincreasein straincausedbytheenhancementofthec/a′valuecouldleadto

enlargementofthelamellaeaswellastheformationinsidethem ofnewfinetwinlamellael,correspondingtointernaltwinning. In fact,as has been reportedinthe literature,71 for asample microstructure, there are potential sites for the formation of twinsandwhenthedeformationincreases,twinsareformedat thesesites.Thus,theincreaseindeformationwhengoingfrom 1.54to1.27,could generateanincrease inthetwininterface energy and then the activation of the sites that give rise to internaltwins.Theoccurrenceoftheselattersispromotedby theincreaseinthewidthsoftheinitialtwinlamellae.

Then,adecreaseinxfrom1.27to0.98isalsoaccompanied byanincreaseinc/a′ deformation,whichcouldbecontribute,

on the one hand, to a large increase in width of the (LIT)

lamellae(morethantwicethe widthofthe (LIT)lamellaefor

x=1.27)andontheotherhand,tothe apparitionof newfine internaltwins(i.e.,totheincreaseininternaltwindensity)and couldultimatelyleadtointernaltwinwidthsalittlethinnerthan forx=1.27.Also forx=0.98the LITlamellaearesometimes

arrangedincyclicformscorrespondingparticularlytotriangular shapesobservedforthefirsttimeinmanganites.Intheliterature, twinsforwhicharrangementshapesarelikethree-pointedstars, nottriangles,havebeenreportedforferroelasticphase transi-tionsandhavebeenattributedtothelossofthe3-foldaxisof thehigh-temperaturephase.66

Furthermore,itiswellknownthattheactivation energyof incoherentDWismuchhigherthanthatofcoherentDW.21,26,72 Thus,asignificantincreaseinactivationenergycausedbythe presenceofincoherentDWcouldleadtoadecreaseincation siteexchange.Inlightofthefactthatalargeproportionofthe materialvolumecorrespondstoDW,theincoherentoneswhich arepresentwhenx<1.54couldcontribute,inadditiontoother factors(relatedtocationdistributionsandwhicharementioned inpreviousworks),42,46tothefactthatthevariationin electri-calresistivityoftheseceramicsshowsaverylargeincreasefor 0.98≤x<1.54.

Forx≥1.78,nodefectswereobservedintheseceramic sam-ples withC spinel structure (for x=1.78, this result remains validfor both samples, i.e., SPS andconventionally sintered samples).Thiscouldbeduetotheabsenceofphasetransition for thesechemicalcompositionsas it hasbeen shownbythe phasediagramoftheMn3O4–Co3O4system.48

5. Conclusion

Themicrostructureof cobaltmanganeseoxide ceramicsis presented, for the first time, inthis paper. The studied sam-plescorrespondtosinglephaseMn3−xCoxO4(0.98≤x≤2.93) spinelceramicsandtheirmicrostructuresweredeterminedusing

TEMandEDX.Theywereobtainedbyconventionalsintering

orbySPSofpowders(elaboratedbythermaldecompositionof coprecipitatedoxalateprecursors).SingleQphaseandsingleC phasewereobtained respectivelyforx<1.78 andx≥1.78.Q phaseoccursbythe structuraltransition of Cphasein agree-mentwiththephasediagramoftheMn3O4–Co3O4system.48

The structural transition of these samples belongs to Aizu speciesm3mF4/mmminhisnomenclatureofferroelasticphase transitions.67 Samples with x<1.78 show grains with high domaindensities(i.e.twindensities)whichcouldbeduetothe factthatthestructural transitionisferroelastic.Coherenttwin interfaceplanesareparallelto(112)planesintheQcellwhichis inaccordancewiththeoreticalpredictions65,66foraferroelastic phasetransitionoccuringfromCphasewith(m3m)pointgroup

symmetrytoQphasewith(4/mmm)pointgroupsymmetry.

The twins that are present in ceramic samples with

x<1.78,correspondto:tweeds,singlelamellae,i.e.,L(widths: 5–306nm) arranged parallelto each other(and whose forms correspondtoeitherright-angledtwinsorneedle-shapedtwins), largelamellae,i.e.,LIT(widths:69–928nm)internallytwinned

andsometimesarrangedincyclicformscorrespondingto trian-gularshapesobservedforthefirsttimeinmanganites.Variations inthecharacteristicsoftwinswereinvestigatedinrelationto:the variationofthecelldeformationc/a′,thefactthatthechemical

composition of the sample is near or far from the composi-tion corresponding tothe phase transition (i.e., x=1.78) and the GS variations. The incoherenttwin interfacespresent for

x<1.54couldhaveaneffect(inadditiontoothereffectsrelated tocationdistributions andmentioned inprevious works42,46) on the important increase in electricalresistivity for x<1.54 becauseitiswell-knownthattheactivationenergyofan inco-herenttwininterfaceisverymuchhigherthanthatofcoherent twininterface.

Nodefectswereobservedinceramicsamplescorresponding toCphase(i.e.,x≥1.78)whichcouldberelatedtotheabsence ofphasetransitionforthesechemicalcompositions.

Acknowledgments

The authors would like to thank Mr. Laurent Weingarten

(ServiceCommundeMicroscopieElectroniqueTEMSCAN–

UniversitéPaul Sabatier – Toulouse) for his kindhelpinthe preparationofsamplesforTEMobservations.

References

1.Van Santen JH, Jonker GH. Electrical conductivity of ferromag-netic compounds of manganese with perovskite structure. Physica

1950;16(7–8):599–600.

2.FinchGI,SinhaAPB,SinhaKP.Crystaldistortioninferrite-manganites.

ProRSocLondAMathPhysSci1957;242(1228):28–35.

3.Goodenough JB, Loeb AL. Theory of ionic ordering, crystal distor-tion,andmagneticexchangeduetocovalentforcesinspinels.PhysRev

1955;98(2):391–408.

4.ZenerC.Interactionsbetweenthedshellsinthetransitionmetals.PhysRev

1951;81:440–4.

5.CaffinJP,RoussetA,CarnetR,LagrangeA.ChemicalpreparationofNTC thermistorswithlowresistivityandhighstability.In:VencenziniP,editor.

HighTechCeramics.Amsterdam:Elsevier;1987.p.1743–51.

6.Guillemet-FritschS,ChanelC,SarriasJ,BayonneS,RoussetA,AlcobeX, etal.Structure,thermalstabilityandelectricalpropertiesofzincmanganites.

SolidStateIonics2000;128(1–4):233–42.

7.JabryE, BoissierG,RoussetA,CarnetR,Lagrange A.Preparation of semiconductingceramics(NTCthermistors)bychemicalmethod.JPhys Colloques1986;47:C1843–847.

8.RoussetA,LegrosR,LagrangeA.Recentprogressinthefabricationof ceramicnegativetemperature coefficientthermistors.J EurCeram Soc

1994;13(3):185–95.

9.BattaultT,LegrosR,BrieuM,CoudercJJ,BernardL,RoussetA.Correlation betweenmicrostructureandageingofironmanganitethermistors.JPhys III(France)1997;7(5):979–92.

10.MetzR. Electrical properties of N.T.C. thermistors made of mangan-iteceramicsofgeneralspinelstructure:Mn3−x−x′MxNx′O4(0≤x+x′≤1; Mand NbeingNi,CoorCu).Agingphenomenonstudy.JMaterSci

2000;35:4705–11.

11.SachseHB.Semiconductingtemperaturesensorsandtheirapplications. NewYork:Wiley;1975.

12.UmadeviP,NagendraCL.Preparationandcharacterisationoftransition metaloxidemicro-thermistorsandtheirapplicationtoimmersedthermistor bolometerinfrareddetectors.SensActuatorsAPhys2002;96(2):114–24.

13.KopiaLP,LeeIIIRB.Thermistorbolometerscanningradiometer: applica-tionsandflightexperience.OptEng1992;31(1):156–65.

14.SheftelIT.Thermistors.Moscow:Nauka;1973.

15.Aleksi´cOS,Nikoli´cPM,Simi´cMN,Pejovi´cV ˇZ,Vasiljevi´c-Radovi´cDG. Resistivityversusgeometryrelationinbulk-sinteredandthickfilm MnCoFe-oxidethermistors.In:Stojanovi´cBD,SkorokhodVV,Nikoli´cMV,editors.

Advancedscienceandtechnologyofsintering.NewYork:Kluwer Aca-demic,PlenumPublishers;1999.p.425–30.

16.Aleksi´cOS,Savi´cSM,Lukovi´cMD,Radulovi´cKT,Luki´cLS.Segmented thermistorsprintedbyNTCnanometricpasteandappliedinvolumeair-flow sensors.MaterSciForum2006;518:247–52.

17.EdwardsL,MurthyR.Versatilethermistorsforwide-rangingapplications.

Electrotechnology1987;15:89–91.

18.MetzR,BrieuM,LegrosR,RoussetA.Intergranularphasesin electro-ceramics.JPhysColloques1990;51:C11003–1008.

19.BrieuM, CoudercJJ, Rousset A, Legros R. TEM characterization of nickelandnickel–cobaltmanganiteceramics.JEurCeramSoc1993;11(2): 171–7.

20.RoussetA,LagrangeA,BrieuM,CoudercJJ,LegrosR.Influencedela microstructuresurlastabilitéélectriquedesthermistancesCTN.JPhysIII (France)1993;3:833–45.

21.CoudercJJ,FritschS,BrieuM,VanderschaeveG,FagotM,RoussetA.A transmissionelectronmicroscopystudyoflatticedefectsinMn3O4 haus-mannite.PhilMagB1974;70(5):1077–94.

22.CoudercJJ,FritschS,BrieuM,VanderschaeveG.Atransmissionelectron microscopystudyofaccomodationtwinsinBa–Ni–Mnoxides.PhilMagA

1996;74(6):1351–65.

23.FritschS,SarriasJ,BrieuM,CoudercJJ,BaudourJL,SnoeckE,etal. Corre-lationbetweenthestructure,themicrostructureandtheelectricalproperties ofnickelmanganitenegativetemperaturecoefficient(NTC)thermistors.

SolidStateIonics1998;109:229–37.

24.MartinDeVidalesJL,Garcia-ChainP,RojasRM,VilaE,Garcia-Martinez O.Preparationandcharacterizationofspinel-typeMn–Ni–Co–Onegative temperaturecoefficientceramicthermistors.JMaterSci1998;33:1491–6.

25.ChanelC.Optimisationdescaractéristiquesstructurales,microstructurales etélectriquesdesmanganitesdenickel,dezincetdenickel-zincenvuede l’applicationauxthermistancesàcoefficientdetempératurenégatif(CTN). ThèsedeDoctoratdel‘UniversitédeToulouse;1998.

26.MetzmacherC,GroenWA,ReaneyIM.Microstructureandelectrical prop-ertiesofMn–Ni–Inspinels.PhysStatSol2000;181:369–86.

27.Park K. Microstructure and electrical properties of Ni1.0Mn2−xZrxO4 (0≤x≤1.0)negativetemperaturecoefficientthermistors.MaterSciEng B2003;104:9–14.

28.ParkK,HanIH.EffectofAl2O3additiononthemicrostructureandelectrical propertiesofMn0.37Ni0.3Co0.33−xAlxO4 (0≤x≤0.03)NTCthermistors.

MaterSciEngB2005;119:55–60.

29.ParkK,LeeJK,KimSJ,SeoWS,ChoWS,LeeCW,etal.TheeffectofZnon themicrostructureandelectricalpropertiesofMn1.17−xCo0.93Co0.9ZnxO4 (0≤x≤0.075)NTCthermistors.JAlloysCompd2009;467:310–6.

30.Bodak O, Akselrud P, Demchenko P, Kotur B, Mrooz O, Hadzaman I, et al. Microstructure, crystal structure and electrical properties of Cu0.1Ni0.8Co0.2Mn1.9O4ceramicsobtainedatdifferentsinteringconditions.

31.VargheseJM,SeemaA,DayasKR.Ni–Mn–Fe–Cr–Onegative tempera-turecoefficientthermistorcompositions:correlationbetweenprocessing conditions and electrical characteristics. J Electroceram 2009;22(4): 436–41.

32.Park K. Fabrication and electrical properties of Mn–Ni–Co–Cu–Si oxides negative temperature coefficient thermistors. J Am Ceram Soc

2005;88(4):862–6.

33.VargheseJM,SeemaA,DayasKR.Microstructuralelectricalandreliability aspectsofchromiumdopedNi–Mn–Fe–ONTCthermistormaterials.Mater SciEngB2008;149:47–52.

34.BorgesFMM,MeloDMA,CâmaraMSA,MartinelliAE,SoaresJM,de AraújoJH,etal.MagneticbehaviorofnanocrystallineMnCo2O4spinels.J

MagnMagnMater2006;302:273–7.

35.Vasil’evGP,PakhomovLA,RyabovaLA.Structuralandelectrical prop-erties of d.c. sputtered MnCo2O4 films. Thin Solid Films 1980;66: 119–24.

36.RiosE,PoilleratG,KoenigJF,GautierJL,ChartierP.Preparationand char-acterizationofthinCo3O4andMnCo2O4filmspreparedonglass/SnO2:F byspraypyrolysisat150◦Cfortheoxygenelectrode.ThinSolidFilms 1995;264:18–24.

37.Martinde VidalesJL,VilaE, RojasRM,Garcia-MartinezO.Thermal behaviorinairandreactivityinacidmediumofcobaltmanganesespinels MnxCo3−xO4 (1≤x≤3) synthesized atlow temperature. Chem Mater

1995;7(9):1716–21.

38.KolomietsBT,SheftelJ,KurlinaE.Electricalpropertiesofsomecompound oxidesemiconductors.SovPhysTechPhys1957;2:40–58.

39.WickhamDG,CroftWJ.Crystallographicandmagneticpropertiesof sev-eralspinelscontainingtrivalentja-1044manganese.JPhysChemSolids

1958;7:351–60.

40.JabryEH,RoussetA,LagrangeA.Preparation andcharacterization of manganeseandcobaltbasedsemiconductingceramics.PhaseTransitions

1988;13(1–4):63–71.

41.Buhl R. Manganites spinelles purs d‘éléments de transition prépara-tionsetstructurescristallographiques.JPhysChemSolidsA1969;30(4): 805–12.

42.BordeneuveH,Guillemet-FritschS,RoussetA,ShuurmanS,PoulainV. Structureandelectricalpropertiesofsingle-phasecobaltmanganeseoxide spinelsMn3−xCoxO4 sinteredclassicallyandbysparkplasmasintering (SPS).JSolidStateChem2009;182(2):396–401.

43.BordeneuveH, Tenailleau C, Guillemet-Fritsch S, SmithR, Suard E, RoussetA.StructuralvariationsandcationdistributionsinMn3−xCoxO4 (0≤x≤3)denseceramicsusingneutrondiffractiondata.SolidStateSci

2010;12(3):379–86.

44.BordeneuveH,RoussetA,TenailleauC,Guillemet-FritschS.Cation distri-butioninmanganesecobaltitespinelsCo3−xMnxO4(0≤x≤1)determined bythermalanalysis.JThermalAnalCalorim2010;101(1):137–42.

45.Guillemet-FritschS,TenailleauC,BordeneuveH,RoussetA.Magnetic propertiesofcobaltandmanganeseoxidespinelceramics.AdvSciTech

2010;67:143–8.

46.RoussetA,TenailleauC,DufourP,BordeneuveH,PasquetI, Guillemet-FritschS,etal.ElectricalpropertiesofMn3−xCoxO4(0≤x≤3)ceramics: aninterestingsystemfornegativetemperaturecoefficientthermistors.IntJ ApplCeramTechnol2013;10(1):175–85.

47.BordeneuveH.EtudedusystèmeMn3−xCoxO4(0≤x≤3)sousformede poudresetdecéramiques.Structure,microstructure,propriétésmagnétiques etélectriques.ApplicationsauxthermistancesàCoefficientdeTempérature Négatif(C.T.N.).ThèsedeDoctoratdel‘UniversitédeToulouse;2009.

48.AukrustE,MuanA.Thermodynamicpropertiesofsolidsolutions with spinel-typestructure.I:ThesystemCo3O4–Mn3O4.TransMetSocAIME 1964;230:378–82.

49.AbramoffMD,MagelhaesPJ,RamSJ.ImageprocessingwithImageJ.

BiophotonicsInt2004;11(7):36–42.

50.Salje EKH, Ishibashi Y. Mesoscopic structures in ferroelastic crys-tals: needle twins and right-angled domains. J Phys Condens Matter

1996;8:8477–95.

51.SaljeEKH,BuckleyA,VanTendelooG,IshibashiY,NordJrG.L.Needle twinsandright-angledtwinsinminerals:comparisonbetweenexperiment andtheory.AmMineral1998;83:811–22.

52.BuckleyA,RiveraJP,SaljeEKH.TwinstructuresintetragonalSrTiO3:the ferroelasticphasetransitionandtheformationofneedledomains.JAppl Phys1999;86(3):1653–6.

53.OrlovskayaN,BrowningN,NichollsA.Ferroelasticityinmixed conduct-ingLaCoO3basedperovskites:aferroelasticphasetransition.ActaMater 2003;51:5063–71.

54.ZhuL,RuanH,LiX,DaoM,GaoH,LuJ.Modelinggrainsizedependent optimaltwinspacingforachievingultimatehighstrengthandrelatedhigh ductilityinnanotwinnedmetals.ActaMater2011;59(14):5544–57.

55.Salje EKH. Phase transitions in ferroelastic and coelastic crystals. CambridgeUniversityPress;1990.

56.CaoW,RandallCA.Grainsizeanddomainsizerelationsinbulkceramic ferroelectricmaterials.JPhysChemSolids1996;57(10):1499–505.

57.El-DanafE,KalidindiSR,DohertyRD.Influenceofgrainsizeand stacking-faultenergyondeformationtwinninginfccmetals.MetallMaterTransA

1999;30:1223–33.

58.RobbrechtGG,Henriet-IserentantCM.Onthelatticeparametersandthe tetragonaldistortionofthecopperandcadmiummanganitesystems.Phys StatusSolidi(b)1970;41(1):K43–6.

59.GautierJL,MezaE,SilvaE,LamasC,SilvaC.EffectoftheZnNiyMn2−yO4 (0≤y≤1)spinelcompositiononelectrochemicallithiuminsertion.JSolid StateElectrochem1997;1(2):126–33.

60.HungríaT,GalyJ,CastroA.Sparkplasmasinteringasausefultechnique tothenanostructurationofpiezo-ferroelectricmaterials.AdvEngMater

2009;11(8):615–31.

61.Chaim R, Shen Z. Grain sizecontrol by pressure application regime during spark plasma sintering of Nd-YAG nanopowders. J Mater Sci

2008;43:5023–7.

62.RajeswariK,HareeshUS,SubasriR,ChakravartyDibyendu,JohnsonR. Comparativeevaluationofsparkplasma(SPS),microwave(MWS),two stagesintering(TSS)andconventionalsintering(CRH)onthedensification andmicrostructuralevolutionoffullystabilizedzirconiaceramics.SciSinter

2010;42:259–67.

63.Lu K. Nanoparticulate materials: synthesis, characterization and processing.Wiley;2013.

64.SaljeEKH,HaywardSA,LeeWT.Ferroelasticphasetransitions:structure andmicrostructure.ActaCrystallogrA2005;61(1):3–18.

65.Sapriel J. Domain-wall orientations in ferroelastics. Phys Rev B

1975;12:5128–40.

66.BoulesteixC.Asurveyofdomainsanddomainwallsgeneratedby crys-tallographicphasetransitionscausingachangeofthelattice.PhysStatus Solidi(a)1984;86(1):11–42.

67.AizuK.Possiblespeciesofferromagnetic,ferroelectricandferroelastic crystals.PhysRevB1970;2:754–72.

68.Tagantsev AK, Cross TL.Domains in ferroic crystals and thin films. Springer;2010.

69.MengX,Baba-KishiKZ,PangGKH,ChanHL,ChoyCL,LuoHS.Tweed domainsin ferroelectricswith compositionsatthemorphotropic phase boundary.PhilMagLett2004;84(3):191–7.

70.TribaudinoM,BennaP,BrunoE.I1–I2/cphasetransitioninalkaline-earth feldspars:evidencefromTEMobservationsofSr-richfeldsparsalongthe CaAl2Si2O8–SrA12Si2O8join.AmMineral1995;80:907–15.

71.PutnisA.Introductiontomineralsciences.CambridgeUniversityPress; 1992.

72.PriesterL.Lesjointsdegrainsdelathéorieàl’ingénierie.EDPSciences; 2006.