Any correspondence concerning this service should be sent to the repository administrator:

staff-oatao@listes-diff.inp-toulouse.fr

To link to this article:

DOI: 10.1016/j.cherd.2012.11.007

http://dx.doi.org/10.1016/j.cherd.2012.11.007

This is an author-deposited version published in:

http://oatao.univ-toulouse.fr/

Eprints ID: 9313

To cite this version:

Rodriguez, Philippe and Caussat, Brigitte and Ablitzer,

Carine and Iltis, Xavière and Brothier, Meryl Fluidization and coating of very

dense powders by fluidized bed chemical vapour deposition. (2012) Chemical

Engineering Research and Design . ISSN 0263-8762

O

pen

A

rchive

T

oulouse

A

rchive

O

uverte (

OATAO

)

OATAO is an open access repository that collects the work of Toulouse researchers and

makes it freely available over the web where possible.

Fluidization

and

coating

of

very

dense

powders

by

Fluidized

Bed

Chemical

Vapour

Deposition

Philippe

Rodriguez

a,

Brigitte

Caussat

b,∗,

Carine

Ablitzer

a,

Xavière

Iltis

a,

Méryl

Brothier

aaCEA,DEN,DEC,SPUA,LCU,Cadarache,F-13108Saint-Paul-lès-Durance,France

bUniversitédeToulouse,ENSIACET/INPToulouse,LGC–UMRCNRS55034alléeÉmileMonso,BP44362,31030ToulouseCedex,France

a

b

s

t

r

a

c

t

Thehydrodynamicbehaviourofaverydensetungstenpowder,75mminmediandiameterand19,300kg/m3ingrain

density,hasbeenstudiedinafluidizedbedatroomtemperatureusingnitrogenandargonascarriergas.Evenif fluidizationwasachieved,thesmallbedexpansionindicatedthatitwasimperfect.Then,thefluidizationwasstudied at400◦

CinordertoinvestigatethefeasibilityofcoatingthispowderbyFluidizedBedChemicalVapourDeposition (FBCVD).Inparticular,theinfluenceoftheH0/Dratio(initialfixedbedheighttoreactordiameter)onthebedthermal

behaviourwasanalyzed.Itappearedthatatleast1.5kgofpowder(correspondingtoaH0/Dratioof1.8)wasnecessary

toobtainanisothermalbedat400◦

C.Finally,firstresultsaboutaluminacoatingsonthetungstenpowderbyFBCVD fromaluminiumacetylacetonatearedetailed.Theyshowthatforthequitelowtemperaturestested,thecoatings areuniformonallbedparticlesandareformedofamorphouscarboncontainingalumina.Thisstudydemonstrates theefficiencytocombinefluidization(insteadofspoutedbed)andCVDtocoatsuchverydensepowders.

Keywords: CVD;Fluidization;Hydrodynamics;Densepowder;Alumina;Coating

1.

Introduction

Fluidizedbedtechnologyhaslongbeenrecognizedasan effi-cienttechniquetoperformgas–solidreactionandithasbeen employedinawiderangeofindustrialapplications.Coupled withChemicalVapourDeposition(CVD),gas–solidfluidization hasagreatpotentialtomodifythesurfacepropertiesof parti-clesortocreatenewmaterials(Balajietal.,2010;Vahlasetal., 2006).However,oneconstraintisthatthe powderstotreat mustbeabletofluidize.

Theavailableliteratureconcerningthefluidizationofvery densepowders(i.e.whosegraindensity exceedsthe upper limitofGeldart’sclassification,10,000kg/m3)isscarce.Itagaki

(1995) reported the fluidization oftungsten powder with a meandiameterrangingbetween3and5mm.WC–Co compos-itepowderswith200nmmean grainsizeweresynthesized using high temperature fluidization technology (Gong and Ouyang,2007).Nevertheless,theseworksconcernrelatively fine powders and we did not find reports concerning the

∗

Correspondingauthor.Tel.:+33534323632;fax:+33534323697. E-mailaddress:Brigitte.Caussat@ensiacet.fr(B.Caussat).

fluidization ofvery dense particles with a mean diameter of several tens ofmicrons. This fact is not really surpris-ing because forparticles with suchcharacteristics,contact betweengasandparticlesisgenerallyachievedinspoutedbed insteadoffluidizedbed(Geldart,1973;KuniiandLevenspiel, 1991).

Thepresentworkdealswiththehydrodynamicstudyofa tungstenpowderinfluidizedbedanditssubsequentalumina coatingbyFluidizedBedCVD.First,thefluidizationoftungsten powderatroomtemperatureandat400◦Cisdiscussed.Then,

firstresultsconcerningthealuminacoatingofthetungsten powderbyFluidizedBedCVDaredescribed.

2.

Experimental

Thefluidizationtestsofthetungstenpowderatroom tem-perature were carried out inacylindrical column madeof glasswithaninternaldiameterof0.05mandaheightof1m. AnInconelTMporousplatewasusedforthegasdistribution.

Fig.1–SchematicdiagramoftheFBCVDreactor.

Nitrogencarriergaswassuppliedtothebottomofthebed throughamassflowcontroller.Adifferential fastresponse pressuresensorwasusedtomeasurethetotalpressuredrop acrossthebed.ADasyLab®systemenabledtheon-line

acqui-sitionofthedifferentialpressure.

TheFluidized BedChemical Vapour Deposition (FBCVD) reactor wasmadeofaverticalcylindrical columnof stain-lesssteelandhadthesamedimensionsastheglasscolumn usedforfluidization tests. Fig.1provides aschematic dia-gramofthereactor.Thereactorwasexternallyheatedbya two-zoneelectricalfurnaceconnectedtoaPIDregulatorand totwothermocouplesfixedontheouterreactorwalls. Sev-eralthermocoupleswerealsobundledintoa6mmdiameter stainlesssteeltubeandplacedinsidethereactorinorderto monitorthebedtemperaturesatvariousheights.Thesame porous plate asin the glass column was usedfor the gas distributionandargonwasusedascarriergas.TheCVD pre-cursorwasevaporatedfromastainlesssteelvaporizerplaced inathermostatedbathandwasfedintothereactorthrough heatedlines topreventcondensation.Theargonflowrates supplieddirectlytothebottomofthereactorandthroughthe vaporizerwerecontrolledbymassflowcontrollers. AllCVD experimentswerecarriedoutatatmosphericpressure.A dif-ferentialfastresponsepressuresensorwithtapsunderthe distributorandtopofthecolumnwasusedtomeasurethe totalpressuredropacrossthebed.Moreoverforsecurity rea-sons,anabsolutepressuresensorallowedmonitoringthetotal pressurebelowthedistributor.Asfortheglasscolumnsetup, aDasyLab®

systemenabledtheon-lineacquisitionofthe dif-ferentialpressure,thetotalpressureandtheaxialprofileof bedtemperatures.TheFBCVDreactorwasalsousedto per-formtungstenpowderfluidizationtestsatroomtemperature andat400◦Cusingargonascarriergas.

Inthisstudy,tungstenpowder(T-1220)producedbyCERAC, Inc.andsuppliedbyNEYCOwasused.Accordingtothe char-acteristics provided by the producer, the grain density is 19,300kg/m3. Scanning electron microscopy (SEM)

observa-tionshighlightedthatparticlesarenon-sphericalandfaceted asshowninFig.2a.Theparticlesizedistribution(PSD) val-uesmeasuredbylaserscattering(performedwithaBeckman CoulterLSTM13320particlesizeanalyser)indicatedthatthe

distributionoftheparticlediametersD10/D90is50mm/105mm

withamediandiameter(D50)ofabout75mm;the

correspond-ingresultsareshowninFig.2b.

Thealuminacoatings were performedusingaluminium acetylacetonateAl(C5O2H7)3(99%)asasingle-source

MetalOr-ganic(MO)precursor.ItwaspurchasedfromStremChemicals, Inc.,undertheformofafinegreypowder.

Thefluidization hydrodynamics wasstudied byplotting the bed pressure drop and expansion versus increasing and decreasinggassuperficialvelocities.Anormalized bed

Fig.2–Characterizationofthetungstenpowderusedin thisstudy:(a)SEMmicrographand(b)particlesize distribution(PSD).

pressuredrop1P*wascalculatedbydividingthe experimen-tal bedpressure drop bythe theoretical bedpressure drop (equaltothebedweightpercolumncross-sectionalarea).A normalizedbedexpansionH*wasalsomeasuredastheratio betweentheaverageexpandedbedheightandthefixedbed height.Theseheightswere measuredusingarulefixedon theglasscolumnwalls,withuncertaintieslowerthan10%.

Themorphologyandthecompositionoftheinitialpowder andofthecoatedparticleswereobservedbyscanningelectron microscopycoupledwithEDSanalyses(PhilipsXL30FEGand LEO435VP).

3.

Fluidization

study

of

tungsten

powder

Thehydrodynamic study ofthe tungsten powder had two mainobjectives.First,theabilitytofluidizeofthispowderwas notobvious.Indeed,duetoitsveryhighdensity,thispowder cannotbepositionedintotheGeldart’sclassification(Geldart, 1973).However,itiswell-knownthatcontactbetweengasand Geldart’sgroupDparticles,i.e.eitherlargeordenseparticles, isgenerallyachievedinspoutedbedinsteadoffluidizedbed (KuniiandLevenspiel,1991).Second,andaftervalidationof thefirstpoint,wehadtodeterminethenecessary experimen-talconditionstoobtain afluidizedbedwithatemperature stabilizedatleastat400◦Cwhichwasthelowertemperature

limittoobtainanefficientdecompositionofoursingle-source CVDprecursor.Forthispoint,wecarefullystudiedthe influ-enceoftheH0/Dratio(initialfixedbedheighttoreactorinner diameter)onthebedthermalbehaviour.Ouraimwastoobtain bedtemperaturesasisothermalaspossiblesincetemperature isakeyparametertoobtainuniformcoatingsbyCVD.

Anexampleofthe fluidizationresultsobtainedatroom temperatureusing1.3kgofpowderisillustratedinFig.3.

Theexperimentalplotsobtainedfornormalizedbed pres-suredropversusdecreasinggasvelocity(Fig.3a),coupledwith observationsofthe hydrodynamicsofthe bed throughthe glasscolumn,provethatfluidizationwasreached(Kuniiand Levenspiel,1991).Usingnitrogenascarriergas,themeasured minimumfluidizationvelocity(Umf)iscloseto4.2cm/s.Evenif

fluidizationwasreached,thislatterremaineddifficultas indi-catedbythehysteresisobservedbetweenexperimentalpoints obtainedfornormalizedbedpressuredropversusincreasing anddecreasinggasvelocities(WeberandHrenya,2007).The factthatfluidizationisimperfectwasconfirmedbythevery lowbedexpansionobserved,i.e.only10%forafullyfluidized bed,asillustratedinFig.3b.Thisisprobablyduetothevery highvalueofpowderdensityandtoalesserextent,tothefact thatparticlesarenotspherical(KuniiandLevenspiel,1991).

AsshowninFig.3a,forthetestsperformedintheglass columnwithnitrogenascarriergas,1P*hasneverreached exactlythetheoreticalbedpressuredropplateau.This phe-nomenoncouldbeexplainedbythefactthatalowpercentage oftungstenparticles weredepositedontotheglasscolumn wallsand,duetotheveryhighdensityoftungstenparticles, thiscouldhavesignificantlychangedthebedweightandthe correspondingtheoreticalbedpressuredrop.Moreover,when experimentswerecarriedoutwith1.3kgormoreoftungsten powder,thebedpressuredropswereclosedtothedifferential fastresponsepressuresensorupperlimit.Thistechnological limitationcould haveincreasedtheexperimental measure-menterrorsforthehighestgasvelocities.Itisworthnoting thatforalltheexperimentscarriedoutinthestainlesssteel reactorwithargonascarriergasandwithoutexperimental

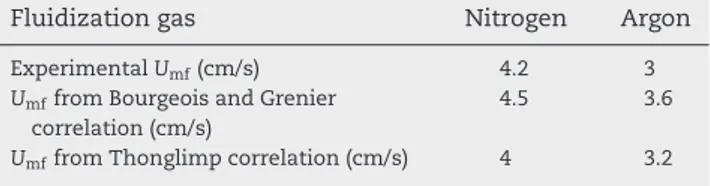

Table1–Comparisonbetweenexperimentalminimum fluidizationvelocitiesinN2andArandcalculatedones

fromtwoclassicalcorrelations.

Fluidizationgas Nitrogen Argon

ExperimentalUmf(cm/s) 4.2 3

UmffromBourgeoisandGrenier

correlation(cm/s)

4.5 3.6

UmffromThonglimpcorrelation(cm/s) 4 3.2

limitationconcerningthedifferentialpressuresensor,a flu-idizationplateauclosetothetheoreticalvaluewasobserved. Using argon ascarriergas,the measuredminimum flu-idization velocity is close to 3cm/s. Table 1 compares the experimental Umf in N2 and Ar withthose obtained using

twoclassicalcorrelations,thatofBourgeoisandGrenier(1968) andthatofThonglimpetal.(1984),basedonReynoldsand Archimededimensionlessgroups.Thecalculatedvaluesare veryclosetotheexperimentalones,showingthegood accu-racyoftheexperimentalmeasurements.Whenanalysingthe influenceofthegasphysicalpropertiesonthevariouspartsof thecorrelations,itclearlyappearsthattheUmfvalueinAris lowerthanthatinN2becauseofthehigherviscosityofargon.

Oncewehavedemonstratedthatitwaspossibletofluidize thistungstenpowder,thesecondstepofthehydrodynamic studywastodeterminetheoptimalexperimentalconditions toobtainafluidizedbedwithatemperaturestabilizedatleast at400◦C.Forourapplication,lowbedweightsarerequired.

Then, the aim ofthis experimental part was to obtain an isothermalandfullyfluidizedbedofparticleswiththelowest possiblebedweight.Thermalprofileswererecordedfor vari-ousbedweights.Table2detailsthecorrespondencebetween bedweights,bed heightsandH0/Dratiosandalsoprovides

the imposed wall temperatures, the resulting bed thermal gradient and bed temperature at 2.5cm above the distrib-utor after2h 30 of heating. Experiments were carried out in the FBCVD reactor using preheated argon at 120◦C as

carriergas.

Analysesofthermalprofiles showed thatforthe lowest bedheightsstudied(i.e.H0/D<1),thetargetbedtemperature

(400◦C) could not bereached. Even after2h 30 ofheating

process andfurnaceset pointfixedat800◦C,thebed

tem-peraturestagnatedatabout330◦C.OnlyH

0/Dratios higher

thanorequalto1allowedreachingabedtemperaturearound 400◦C.However, forH

0/D ratiosof1, the furnaceset point

had to befixed at850◦C and the bed wasnot isothermal.

Indeed,thermal gradients1Tbetweenthe bottomandthe topofthebedreached50◦Cwhichisunacceptablefor

sub-sequentCVDcoating.ItiswellknownthathighertheH0/D

ratiois,betterthethermalandmasstransfersare,andthat H0/Dratiosupto4–5aregenerallyusedforFBCVDcoatings

(Vahlasetal.,2006).Suchvalueswereobviouslyimpossibleto carryoutbecauseaH0/Dratioof4correspondstoabedweight

ashighas3.4kg,whichwasnotconceivableforpreliminary testsandforourfurtherapplication.So,acompromisehad tobefoundbetweenanacceptablethermalbehaviouranda reasonablebedweight.Forbedweightsof1.5kg correspond-ing toH0/Dratios of1.8, asatisfactory thermalprofile was

obtainedwithabedtemperaturestabilizedaround400◦Cafter

2hofheatingprocessandfurnacesetpointfixedat750◦C.The

ratiobetweenthegasvelocityat400◦Candtheminimum

flu-idizationvelocity(Ug/Umf)wasfixedatapproximately3.5.For

suchexperimentalparameters, thebedwasisothermal:1T betweenthebottomandthetopofthebedwaslessthan2◦C.

Fig.3–Normalized(a)pressuredropand(b)expansionversusdecreasingnitrogensuperficialvelocitiesforabedof tungstenpowder.

Theimportantgapbetweenthereactorwallsandthebed tem-peraturescouldbeexplainedbytheverylowbedexpansions measured,asshowninFig.3b:only10%ofexpansionfora fullyfluidizedbedoftungstenparticleswhereasstandard val-uesobtainedformoreconventionalpowdersgenerallyrange between30and40%(KuniiandLevenspiel,1991).Thesevery low values imply low thermal transfers between particles and reactor walls. We haveverified that these bed expan-sionsfollowthecorrelationofRichardsonandZaki(1954)for Reynoldsnumberslowerthan0.3.Thisgoodagreementshows thegoodaccuracyofmeasurementsandindicatesthatthese lowvaluesareduetothedensityofthepowder.

4.

FBCVD

of

alumina

on

tungsten

powder

Usingtheexperimentalparametersdescribedintheprevious section inparticular1.5kgofpowderforeachrun,we suc-cessfully performed the FBCVD ofalumina on several sets oftungstenpowderbyvaryingbedtemperature,carriergas flowratesentthroughthevaporizer lineandcoating dura-tion.Alltheresultsdetailedbelowarerepresentativeofthe wholeresultsobtained.

Fig. 4 shows a typical thermal profile obtained during CVDexperiments.Theheatingprocesswasorganizedintwo steps of1h, inorder to progressively increase the powder

Table2–Bedweights,bedheights,H0/Dratios,imposedwalltemperatures,measuredbedthermalgradientsandbed

temperaturesat2.5cmabovethedistributorafter2h30ofheating.

Bedweight (kg)

Bedheight (cm)

H0/Dratio Walltemperature

(◦C)

Bedthermal gradient(◦C)

Bedtemperature2.5cm abovethedistributor(◦C)

0.4 2.4 0.48 800 >50 350 0.6 3.6 0.72 800 >50 350 0.85 5.1 1.01 850 50 410 1 5.9 1.19 850 20 410 1.5 8.9 1.78 750 <2 420 1.7 10.1 2.02 700 <2 420

Fig.4–TypicalbedthermalprofileandtheoreticalbedpressuredropobtainedduringFBCVDofaluminaontungsten powder(heightsabovethedistributorforthermocoupleTC1:1cm,TC2:2.5cm,TC3:5cm,TC4:7cm).

temperature without over heating the reactor walls. The isothermalbehaviourofthebedappearsinFig.4,sincethe fourthermocouplesplacedinsidetheparticle bedat differ-ent heights indicated the same temperature values. Once the desired coating temperature was reached, the coating procedure began. We noticed a slightdecrease of the bed temperatureduringthefirstminutesofcoating.Thismaybe relatedtotheprecursordecompositionthatrequiresenergy supply.Atthebeginningofthecoating,thenecessaryenergy isprovidedbythefluidizedbed,leadingtoaslightdecrease of its temperature. Then, after a few minutes of heating regulation,thebedtemperatureisstabilized.

AsillustratedinFig.4,theexperimentalnormalizedbed pressuredrop (calledExp.DeltaP*)wascalculated and com-pared with the theoretical normalized bed pressure drop (called Th. DeltaP*) during all experiments. The obtained results clearly indicate that the tungsten particle bed remainedfullyfluidizedduringallruns.

After experiments, the difference between coated and uncoated particles is obvious to the naked eye. Whereas uncoated particles are metallic grey, the coated particles exhibited a brown tint. This colour could be surprising for alumina coatings. However, several works, in which aluminacoatingswereobtainedfromaluminium acetylacet-onateprecursorinourrangeoftemperature,i.e.390–450◦C,

have reported that obtained films exhibited orange-claret (Minkina, 1993), golden brown (Nable et al., 2003) or tan and dark tan (Nguyen et al., 2002) tints. These colours could beexplained byan aluminafilm contaminationdue to carbon and pyrolysis by-products incorporation. The chemicalreactionsleadingtoaluminadepositionfrom alu-minium acetyl acetonate are complex and poorly known (Minkina, 1993; Devi et al., 2002; Singh and Shivashankar, 2002; Pflitsch et al., 2007). Under argon, some simplified reactions have been proposed (Rhoten and Devore, 1997), considering that Al(acac)3 first decomposes in the gas

phase:

Al(C5H7O2)3→Al(C5H7O2)2OH+C5H6O (R1)

Then, thegaseous intermediate canreact on surfaceto formalumina:

2Al(C5H7O2)2OH →Al2O3+2C5H8O2+2C5H6O+H2O (R2)

Some studies have shown that carbon incorporation is favouredatlowtemperatureduetoanincomplete decomposi-tionofthereactivespeciesintoAl2O3onthesubstratesurface

(Devietal.,2002;Pflitschetal.,2007).

Moreover,attheserelativelowtemperatures,aluminium oxidefilmsobtainedbyMOCVD(i.e.CVDfromaMetalOrganic precursor) aremainly amorphous(Nable et al.,2003a).The uniformtintofparticlesafterdepositionindicatesthatall par-ticleswereuniformlytreated.ThishasbeenconfirmedbySEM, asdetailedbelow.

Thedepositedmasswassolowthatitwasnotpossible tomeasureit bybedweighingbeforeand afterdeposition. Asaconsequence,thedepositionyield,theratiobetweenthe massesofdepositedAlandofsublimatedAl,isverylow.This isprobablyduetothelowbedtemperaturetested,leadingto weakprecursordecomposition.

In order to study the differences between coated and uncoatedparticlesatmicroscopicscale,allthesampleshave beenobservedbySEMcoupledwithEDSanalyses.The sur-facemorphologyofuncoatedtungstenparticlesisrelatively smoothasshowninFig.5a.Moreover,EDSanalysesperformed onuncoatedsamplesshowthedifferentcharacteristicpeaks oftungstenand,forsomeparticles,thepeakofoxygen.This latterisprobablyduetoapartialoxidationoftungstenpowder duringhandlingunderair.

The SEM analyses of coated particles (Fig. 5b) exhibit pronouncedmorphologicdifferences:thesurfaceroughness is clearly increased and the presence of a coating film is obvious.EvenifAlKa peakispartiallyoverlappedbyWMa

peakandthataluminafilmsareverythin(probablylessthan 100nmaccording tocalculatedfilmthicknessesfrom mass balances), EDS analyses on coated samples show oxygen, carbon and aluminium peaks. Tungsten was alsodetected becauseEDSanalysesconcernthicknesseshigherthanthose of alumina deposits. The relative comparison of the EDS

Fig.5–SEMmicrographsandcorrespondingEDSanalyses of(a)uncoatedand(b)aluminacoatedtungstenpowder.

spectraofuncoatedandcoatedparticles indicates that,on these latter, an alumina film with carbon impurities was obtained. This result is in good accordance with previous worksreportedinliterature,asalreadymentioned(Minkina, 1993;Nableetal.,2003).

The average layer thickness was measured from SEM observationsofcrushedcoatedpowderusingabackscattered electron(BSE)detector.Acharacteristicexampleofresultsis giveninFig.6.Thefilmthicknessappearstobelowerthan 100nm and uniform onthe particle surfaceand from one particletoanother.SomeICP-AESmeasurementshavebeen attempted,but duetothisverylowthickness,theydidnot

Fig.6–SEMobservationsofcrushedcoatedpowderusinga backscatteredelectron(BSE)detector(thearrowsshowthe depositedfilm).

provide anyquantitativeresultabout thefilmcomposition, exceptthefactthataluminiumiswelldepositedonthe pow-dersurface.

5.

Conclusion

The fluidization of a very dense powder (i.e. whose grain density exceeds the upper limit of Geldart’s classification, 10,000kg/m3)wassuccessfullydemonstrated,whichcouldnot

bepredictedfromGeldart’sdiagram.Thisworkwasperformed using tungsten particles of75mm inmedian diameterand 19,300kg/m3ingraindensity.

Theexperimentalminimumfluidizationvelocitiesandbed expansionsinnitrogenandargonweredeterminedand com-paredwiththeoreticalcorrelations.Theresultsshowedthat, eveniffluidizationisachieved,thebedexpansionisverylow duethepowderhighdensity,involvinglowthermaltransfers betweenpowderandreactorwalls.However,theanalysisof axialthermalprofilesfordifferentbedweightsallowed find-ingexperimentalparametersinsuringisothermalconditions compatiblewithFluidizedBedChemicalVapourDepositionof aluminaat400◦C.

First characterizations of samples after CVD suggest thataluminafilmsformedfromaluminiumacetylacetonate Al(C5O2H7)3 as single sourceprecursor are probably

amor-phous and carbon contaminated. In spite of the low bed expansion, allparticlesappeartobeuniformly coated.The depositthicknessislowerthan100nm,certainlyduetothe lowtemperaturetestedinvolvingweakprecursor decompo-sition.Asfarasweknow,thisstudyisprobablythefirstone todemonstratetheefficiencytocombinefluidization(instead ofspoutedbed)andCVDtocoatsuchverydensepowdersof severaltensofmicronsindiameter.Additionalexperiments areplannedtotesthigherdepositiontemperaturesinorderto limitcarboncontamination.

Acknowledgements

TheauthorswouldliketothankMichelMolinier,Etienne Pre-vot,MarieLineDeSolanfromLGCandHélèneRouquettefrom CEAfortheirtechnicalsupport.

Balaji,S.,Du,J.,White,C.M.,Ydstie,B.E.,2010.Multi-scale modelingandcontroloffluidizedbedsfortheproductionof solargradesilicon.PowderTechnol.199,23–31.

Bourgeois,P.,Grenier,P.,1968.Theratioofterminalvelocityto minimumfluidizationvelocityforsphericalparticles.Can.J. Chem.Eng.46,325–331.

Devi,A.,Shivashankar,S.A.,Samuelson,A.G.,2002.MOCVDof aluminiumoxidefilmsusingaluminiumb-diketonatesas precursors.J.Phys.IV12,139–146.

Geldart,D.,1973.Typesofgasfluidization.PowderTechnol.7, 285–292.

Gong,N.,Ouyang,Y.,2007.Thestudyofsynchronous

reduction-carbonizationofV2O3,Cr2O3andW–Cocomposite

oxidesinfluidization.Mater.Sci.Forum534/536,1245–1248. Itagaki,T.,1995.CoatingofHfContungstenpowderbyfluidized

bedCVD.J.Jpn.Inst.Met.59,1157–1164.

Kunii,D.,Levenspiel,O.,1991.FluidizationEngineering,2nded. Butterworth-HeinemannLtd.,Newton,MA,USA.

Minkina,V.G.,1993.Studyofthepyrolysiskineticsofaluminum acetylacetonateinthegaseous-phase.Inorg.Mater.29, 1400–1401.

Nable,J.C.,Gulbinska,M.K.,Kmetz,M.A.,Suib,S.L.,Galasso,F.S., 2003.Aluminumoxideandchromiumoxidecoatingson ceramicfibersviaMOCVD.Chem.Mater.15,4823–4829. Nable,J.,Gulbinska,M.,Suib,S.L.,Galasso,F.,2003a.Aluminum

oxidecoatingonnickelsubstratebymetalorganicchemical vapordeposition.Surf.Coat.Technol.173,74–80.

Nguyen,Q.T.,KidderJr.,J.N.,Ehrman,S.H.,2002.Hybrid

gas-to-particleconversionandchemicalvapordepositionfor

theproductionofporousaluminafilms.ThinSolidFilms410, 42–52.

Pflitsch,C.,Viefhaus,D.,Bergmann,U.,Atakan,B.,2007. Organometallicvapourdepositionofcrystallinealuminium oxidefilmsonstainlesssteelsubstrates.ThinSolidFilms515, 3653–3660.

Richardson,J.F.,Zaki,W.N.,1954.Sedimentationandfluidization: partI.Trans.Inst.Chem.Eng.32,35–53.

Rhoten,M.C.,Devore,T.C.,1997.Evolvedgasphaseanalysis investigationinthereactionbetween

Tris(2,4-pentanedionato)aluminiumandwatervapourin ChemicalVaporDepositionprocessestoproducealumina. Chem.Mater.9,1757–1764.

Singh,M.P.,Shivashankar,S.A.,2002.LowpressureMOCVDof Al2O3filmsusingaluminiumacetylacetonateasprecursor:

nucleationandgrowth.Surf.Coat.Technol.161, 135–143.

Thonglimp,V.,Hiquily,N.,Laguérie,C.,1984.Minimumvelocity offluidizationandexpansionofgasfluidizedbeds.Powder Technol.38,233–253.

Vahlas,C.,Caussat,B.,Serp,Ph.,Angelopoulos,G.,2006. PrinciplesandapplicationsofCVDpowdertechnology.Mater. Sci.Eng.Res.53(1–2),1–72.

Weber,M.W.,Hrenya,C.M.,2007.Computationalstudyof pressure-drophysteresisinfluidizedbeds.PowderTechnol. 177,170–184.