Publisher’s version / Version de l'éditeur:

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la

première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

Proceedings of 3rd International Water Mist Conference, pp. 1-10, 2003-09-01

READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE.

https://nrc-publications.canada.ca/eng/copyright

NRC Publications Archive Record / Notice des Archives des publications du CNRC : https://nrc-publications.canada.ca/eng/view/object/?id=398fa8d9-6f91-4d9c-bde2-b95f593ba260 https://publications-cnrc.canada.ca/fra/voir/objet/?id=398fa8d9-6f91-4d9c-bde2-b95f593ba260

NRC Publications Archive

Archives des publications du CNRC

This publication could be one of several versions: author’s original, accepted manuscript or the publisher’s version. / La version de cette publication peut être l’une des suivantes : la version prépublication de l’auteur, la version acceptée du manuscrit ou la version de l’éditeur.

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at

Suppression of cooking oil fires using water mist technology Liu, Z. G.; Kim, A. K.; Carpenter, D. W.

Suppression of cooking oil fires using water mist technology

Liu, Z.G.; Kim, A.K.; Carpenter, D.

NRCC-46615

A version of this document is published in / Une version de ce document se trouve dans : 3rd International Water Mist Conference, Madrid, Spain, Sept. 22-24, 2003, pp. 1-9

Suppression of Cooking Oil Fires using Water Mist Technology

International Water Mist Conference 2003 September 22 - 24, 2003, Madrid, Spain Zhigang Liu, Andrew K. Kim and Don Carpenter

Fire Risk Management Program Institute for Research in Construction National Research Council of Canada Ottawa, Ontario, CANADA, K1A 0R6 Phone: (613) 993-9555 Fax: (613) 954-0483

E-mail: andrew.kim@nrc-cnrc.gc.ca

INTRODUCTION

Water mist technology has gained re-newed interest over the last two decades for fire suppression. Through research and testing, the effectiveness of water mist

technology in suppressing fires has been shown in a number of application areas, and many new water mist systems have been developed for specific applications. One such new application area is the use of water mist in suppressing cooking oil fires.

The primary fire challenge in restaurant cooking areas is fat or cooking oil fires. In recent years, the development of high-efficiency cooking equipment with high energy input rates and the wide spread use of vegetable oils with high burning temperature have increased fire risks to life and property. These fires are hard to extinguish and easy to re-ignite [1, 2]. Cooking oil fires, due to their different behaviour from other types of liquid fuel fires, were recently re-classified into a new class of fire, Class K.

Previous studies showed that foam, powder and carbon dioxide are not as

effective in suppressing cooking oil fires as in suppressing other types of liquid fuel fires due to their limited cooling capacity [1, 2]. Currently, wet chemical agents are the primary means used to extinguish grease fires in cooking areas. They are effective in extinguishing these fires but may cause irritation to the skin and eyes and clean-up problems after fire extinguishment. The system cost of wet chemical agents is relatively high.

A water mist system has the potential to be a cost-effective suppression system for the cooking oil fires. However, currently there is little information available on the performance of water mist systems in extinguishing cooking oil fires. Therefore, a study was carried out to develop and evaluate a water mist system for effective suppression of cooking oil fires and prevention of re-ignition. The tasks involved in the study were to investigate the characteristics of cooking oil fires, to evaluate the fire suppression performance of the water mist system and to determine characteristics of the water mist

system (i.e. type of nozzle, discharge pressure, flow rate and nozzle location) required for effective suppression of cooking oil fires.

This paper describes the characteristics of cooking oil fires, the water mist system that was developed, test conditions and suppression performance of the system.

TEST FACILITIES AND PROCEDURES

A series of full-scale fire tests was conducted in a mock-up restaurant cooking area, in accordance with UL 300 “Standard for Fire Testing of Fire Extinguishing Systems for Protection of Restaurant Cooking Areas” [3].

A deep fat fryer was placed directly under an overhead hood. Its frying area was 305 mm x 381 mm (12 in x 15 in) and it had a capacity ranging from a minimum of 15 L (30 lb) to a maximum of 20 L (40 lb) of shortening. During each test, a fresh commercial vegetable oil (a mix of canola and soybean oils) with an auto-ignition temperature above 365oC (690oF) was used.

The installation of the deep fat fryer and the overhead hood, as well as the distance between the two, were based on manufacturers’ recommendations. The dimensions of the hood were 940 mm wide and 1676 mm long. One exhaust duct with 254 mm diameter was installed and connected to the hood. One exhaust fan was used to vent exhaust gas. Figure 1 shows the experimental set-up.

A thermocouple tree with five thermocouples was used to measure the

temperatures of the fire, the cooking oil, and the fryer metal surface (see Figure 1). The thermocouple used to measure the cooking oil temperature was located 25.4 mm (1 in.) below the grease surface and 80 mm (3.2 in.) away from the fryer’s side-wall.

A pressure transducer was installed in the pipe near the nozzle to monitor the discharge pressure of the water spray.

A water mist nozzle was located at the top front of the fryer, 370 mm away from the centre point, and aimed at the centre of the cooking area at an angle of 10 degrees. The distance of the nozzle from the fuel surface varied between 860 mm and 1100 mm in different experiments.

All test data were recorded by a data acquisition system. Two video cameras were used to obtain visual records of the experiment.

During the experiments, the deep fat fryer, filled with liquid cooking oil, was heated at a certain rate. When the cooking oil was heated to around 190oC, the cooking temperature splashing test was conducted and a 5 s discharge period was allowed with the fryer’s heating source remaining on. The changes in cooking oil temperature and

corresponding cooking oil splash caused by the water mist discharge were observed and recorded. After the oil auto-ignited, the fire was left to burn freely with the fryer’s

heating source remaining on for 2 minutes. During the 2 min free burning period, the cooking oil fire developed fully. At the end of the free burning period, the heating source was shut off and the water mist discharge was activated manually. After the fire was extinguished, the discharge of water mist was maintained for a certain period to cool the cooking oil and to prevent the re-ignition of the oil.

RESULTS AND DISCUSSION

A total of 12 full-scale fire experiments were conducted to study the extinguishing performance of three water mist systems with different spray characteristics (discharge pressure, flow rate, spray angle and droplet size). The effect of nozzle location on the water mist performance was also investigated. The three types of nozzles used in the test series were an impingement nozzle (nozzle #1), a hydraulic nozzle (nozzle #2), and a spiral nozzle (nozzle #3). The discharge pressures of the three systems varied from low pressure (2 bar) to high pressure (70 bar) and water flow rates varied from 1.4 Lpm to 28.3 Lpm. The droplet size varied from Dv0.9=120 microns to 350 microns, depending on

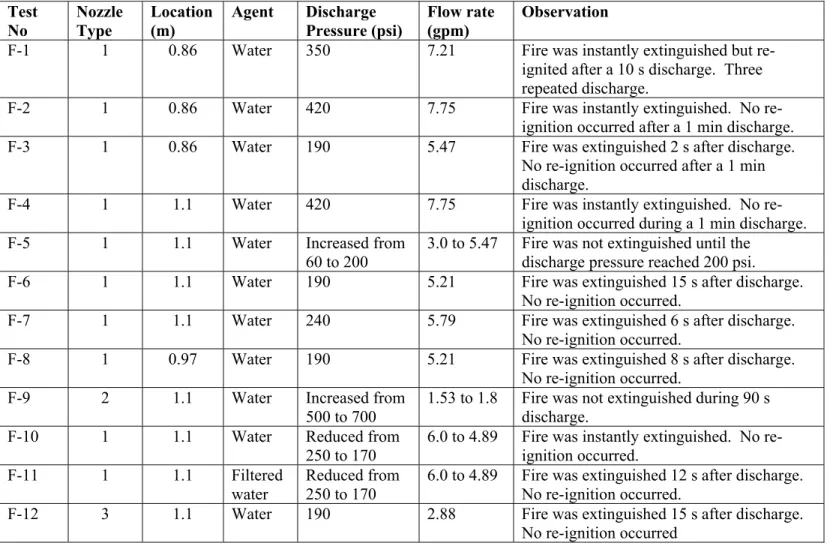

discharge pressure. The spray angles of these systems varied from 50 to 90 degrees. The experimental conditions and results are summarized in Table 1.

As shown in Table 1, the water mist system with nozzle #2, which had a low flow rate and small spray coverage, was unable to extinguish the cooking oil fire; however, the other two systems with nozzles #1 and #3, which had relatively high flow rates and large spray angles, effectively extinguished the fires. The extinguishing time ranged from 1 to 15 s after discharge, depending on discharge pressure, flow rate and nozzle location. An increase in discharge pressure or reduction in the nozzle distance from the fuel surface improved water mist effectiveness against the cooking oil fire by increasing the spray momentum and the amount of sprays hitting the fire.

Experiments showed that the cooking oil fire was very challenging to extinguish. The auto-ignition temperature of the cooking oil measured in the experiments varied from 365oC to 372oC. During the 2 min free burning period, the fire developed from a small

fire attached to the oil surface to a large one reaching the overhead hood. The fire growth rate accelerated after the first minute of free burning. With a large fire over the oil

surface, the oil was further heated to beyond its auto-ignition temperature during the free burning period. The highest oil temperature measured in the experiments was 403oC, which was 38oC higher than its initial auto-ignition temperature. Also, the auto-ignition temperature of the oil decreased during fire suppression, because of the change in oil composition during the free burning and fire suppression period. This resulted in re-ignition of the oil at a lower temperature. In an experiment with short periods of water mist discharge, auto-re-ignition of the cooking oil occurred twice, shortly after the water mist discharge was discontinued, as shown in Figure 2. The first auto-re-ignition

occurred at a temperature of 330oC and the second one was at a temperature of

approximately 300oC. The lowest auto-re-ignition oil temperature was approximately 65oC lower than its original auto-ignition temperature, and approximately 100oC lower than the oil temperature at the end of the free burning period. Therefore, in order to

properly extinguish the cooking oil fire, the suppressant must have effective cooling to bring the oil temperature to below its auto-re-ignition temperature.

Water mist suppresses the fires mainly by physical means: cooling the fire plume, cooling/wetting the fuel, displacing the oxygen and fuel vapour, and radiant heat

attenuation as fine water droplets rapidly absorb heat from fire and hot surfaces, and evaporate to steam. The cooking oil fires as an open fire cannot be extinguished by water mist by reducing oxygen concentration to its critical level for combustion, because of sufficient oxygen supply available near the oil fire. They are extinguished only when a high percentage of fine water droplets enters the fire plume and cools the flame, as well as cooling the oil temperature to below its auto-re-ignition temperature.

As shown in Figure 3, the oil and fire temperatures are high during the free burning period. With the activation of the water mist system, the fire temperatures furthest from the fuel surface (Thermocouples 3 and 4) were reduced quickly, indicating that the fire size was reduced. The fire temperature near the fuel surface (Thermocouple 2) was also reduced with water mist discharge but at a slow rate. It took 15 s for the water mist to extinguish the fire. During fire suppression, the oil temperature

(Thermocouple 1) did not change much, because most of the water droplets were quickly evaporated into steam in the fire plume before they could reach the liquid oil surface. After fire suppression, water droplets were able to directly hit the fuel surface and cool the oil, resulting in a substantial reduction in the oil temperature. Since the oil was very hot, it took more than 20 s for water mist to cool the oil to below 300oC. When the oil was cooled to below its auto-ignition temperature, no auto-re-ignition of the oil occurred. These test results indicate that the cooling of the fire plume and the oil are the

predominant mechanisms for water mist to extinguish a cooking oil fire.

Experiments showed that several factors of the water mist system, including the spray momentum, the spray coverage area and its water flow rate, determined whether the water mist would be successful in suppressing cooking oil fires. The fully developed cooking oil fire created a large upward flame plume over the fryer, and only those sprays with high momentum could penetrate the fire plume and reach the fuel surface, whereas fine water droplets with low momentum would be carried away by the strong upward fire plume. Furthermore, in order to extinguish the fire, the amount of water spray should be sufficient enough to cool the flame and oil temperatures to below its auto-ignition temperature. The effective water mist spray coverage would control the fire size and minimize the heat transfer from the flame to the oil, thus reducing the burning rate of the oil.

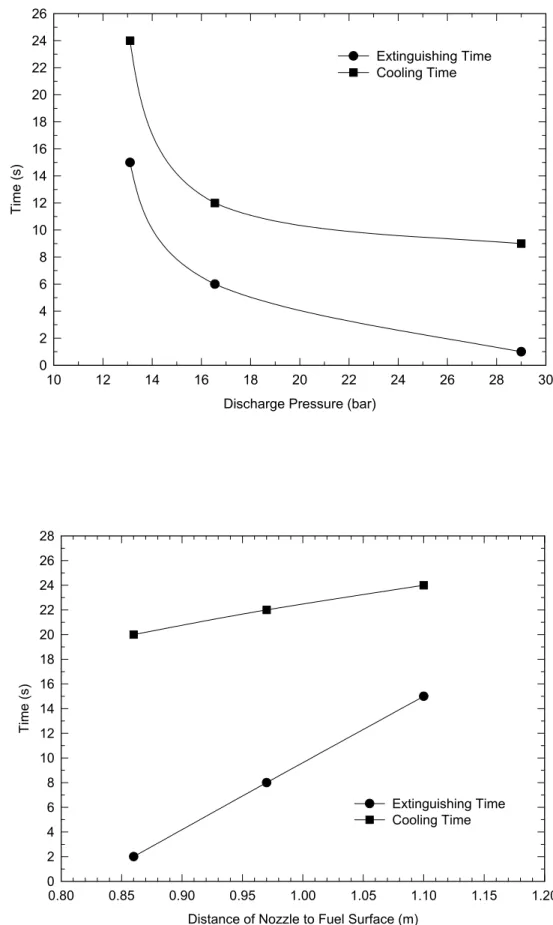

For example, the amount of water spray hitting the fire plume increased

significantly with discharge pressure due to the increase in the water flow rate and spray momentum. As a result, the extinguishing times for cooking oil fires and the time required to cool the oil from its burning temperature to below its auto-re-ignition

temperature of 300oC are significantly reduced with increase in the discharge pressure, as shown in Figure 4, when the distance between the nozzle and oil surface was maintained at 1.1 m.

Moving the nozzle closer to the fryer will reduce the loss in spray momentum and increase the amount of water droplets hitting the fire. Figure 5 shows that the fire

extinguishing times and the time required to cool the oil from its burning temperature to below its auto-re-ignition temperature of 300oC are linearly decreased with the reduction in the nozzle distance from the fuel surface, when the discharge pressure was maintained at approximately 190 psi.

During fire suppression, no burning droplets of the cooking oil were dispersed outside the fryer, and the oil temperature did not show any substantial reduction during fire suppression until the fire was extinguished. The experimental results indicated that these fine water droplets, when they penetrated into the fire plume, did not have enough momentum to penetrate the oil surface and to splash the burning cooking oil outside the fryer.

After fire suppression, however, some oil droplets were splashed outside the fryer during the continued water spray in some experiments. This was because, after fire extinguishment, water droplets could directly hit the oil surface and some droplets would penetrate into the oil instead of being evaporated. These water droplets were quickly heated by the hot oil, resulting in the formation of bubbles. These bubbles bursted violently splashing oil into the outside of the fryer. With a low discharge pressure and short discharge period, most of the water droplets hitting the oil surface evaporated quickly before they could penetrate into the oil, resulting in less splashing of the oil.

CONCLUSIONS

A cooking oil fire, compared to other types of liquid fires, is difficult to extinguish, because it burns at high temperature and re-ignite easily. During 2 min of free burning, the cooking oil fire fully developed and the highest oil temperature measured in the tests was 403oC, and 38oC higher than its initial auto-ignition

temperature. The lowest oil auto-re-ignition temperature in the tests was approximately 65oC lower than its original auto-ignition temperature, and approximately 100oC lower than the oil temperature at the end of the free burning period.

With proper design and operation, water mist is capable of extinguishing a cooking oil fire and preventing its re-ignition. The predominant extinguishing

mechanism of water mist on cooking oil fires is the cooling of the fire plume and the oil. The spray momentum, the spray coverage area and the flow rate are the three most important factors affecting the extinguishment of the cooking oil fire by water mist.

REFERENCES

1. Edwards, N., “A New Class of Fire,” Fire Prevention, Vol. 310, p. 8, June 1998. 2. Voelkert, C., “Out of the Frying Pan …,” Fire Prevention, Vol. 314, pp. 24-26,

3. UL 300, “Fire Testing of Fire Extinguishing Systems for Protection of Restaurant Cooking Areas,” Underwriters Laboratories Inc., 1996.

Table 1 Full-Scale Fire Test Conditions and Results Test No Nozzle Type Location (m) Agent Discharge Pressure (psi) Flow rate (gpm) Observation

F-1 1 0.86 Water 350 7.21 Fire was instantly extinguished but re-ignited after a 10 s discharge. Three repeated discharge.

F-2 1 0.86 Water 420 7.75 Fire was instantly extinguished. No re-ignition occurred after a 1 min discharge. F-3 1 0.86 Water 190 5.47 Fire was extinguished 2 s after discharge.

No re-ignition occurred after a 1 min discharge.

F-4 1 1.1 Water 420 7.75 Fire was instantly extinguished. No re-ignition occurred during a 1 min discharge. F-5 1 1.1 Water Increased from

60 to 200

3.0 to 5.47 Fire was not extinguished until the discharge pressure reached 200 psi. F-6 1 1.1 Water 190 5.21 Fire was extinguished 15 s after discharge.

No re-ignition occurred.

F-7 1 1.1 Water 240 5.79 Fire was extinguished 6 s after discharge. No re-ignition occurred.

F-8 1 0.97 Water 190 5.21 Fire was extinguished 8 s after discharge. No re-ignition occurred.

F-9 2 1.1 Water Increased from 500 to 700

1.53 to 1.8 Fire was not extinguished during 90 s discharge.

F-10 1 1.1 Water Reduced from 250 to 170

6.0 to 4.89 Fire was instantly extinguished. No re-ignition occurred.

F-11 1 1.1 Filtered water

Reduced from 250 to 170

6.0 to 4.89 Fire was extinguished 12 s after discharge. No re-ignition occurred.

F-12 3 1.1 Water 190 2.88 Fire was extinguished 15 s after discharge. No re-ignition occurred

Time (s) 200 220 240 260 280 300 320 340 360 380 400 Tem per at ur e ( o C) 0 100 200 300 400 500 600 700 800 900 fryer surface fire #4 fire #3 fire #2 oil Temperature auto-ignition discharge auto-re-ignition 1 g w Time (s) 240 260 280 300 320 340 360 380 400 420 440 460 Te mp erat ure ( o C) 0 100 200 300 400 500 600 700 800 fryer surface flame #4 flame #3 flame #2 oil Temperature discharge extinguishing ignition discharge stop

Figure 8 The variation of oil and fire temperatures with time (Nozzle #2, 13 bar)

Figure 3 Variations of oil and fire temperatures with time during suppression

Figure a The variation of oil and fire temperatures with time, when the cookin oil fire as suppressed by water mist during short discharge periods

Figure 2 Oil and fire temperatures with time, when the cooking oil fire was suppressed by water mist in a short period

Discharge Pressure (bar) 10 12 14 16 18 20 22 24 26 28 30 Time (s) 0 2 4 6 8 10 12 14 16 18 20 22 24 26 Extinguishing Time Cooling Time 2

Figure 1 The variation of extinguishing time and cooling time from oil burning temperature to its auto-ignition temperature with discharge pressure

(nozzle #3)

Figure 4 Variations of the extinguishing time and the cooling time of the oil to below its auto-re-ignition temperature with the discharge pressure

Distance of Nozzle to Fuel Surface (m)

0.80 0.85 0.90 0.95 1.00 1.05 1.10 1.15 1.20 Ti m e (s ) 0 2 4 6 8 10 12 14 16 18 20 22 24 26 28 Extinguishing Time Cooling Time T t 1

Figure 14 he variation of extinguishing time and cooling time from oil burning temperature o its auto-ignition temperature with change in nozzle distance (nozzle #3,

3 bar discharge pressure)

Figure 5 Variations of the extinguishing time and the cooling time of the oil to below its auto-re-ignition temperature with the nozzle distance