Publisher’s version / Version de l'éditeur:

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la

première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site

LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

Infra 2003: the Changing Infrastructure Rehabilitation Market: the Emergence of a New Dynamic [Proceedings], pp. 1-10, 2003-11-01

READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE. https://nrc-publications.canada.ca/eng/copyright

NRC Publications Archive Record / Notice des Archives des publications du CNRC : https://nrc-publications.canada.ca/eng/view/object/?id=b93ad99b-4665-4bf7-8ee1-ef28f25b7fbf https://publications-cnrc.canada.ca/fra/voir/objet/?id=b93ad99b-4665-4bf7-8ee1-ef28f25b7fbf

NRC Publications Archive

Archives des publications du CNRC

This publication could be one of several versions: author’s original, accepted manuscript or the publisher’s version. / La version de cette publication peut être l’une des suivantes : la version prépublication de l’auteur, la version acceptée du manuscrit ou la version de l’éditeur.

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at

Controlling the performance of sliplined pipe with grouting = L'impact de l'injection de coulis sur la performance lors de la réhabilitation d'une conduite par insertion conventionnelle

Controlling the performance of sliplined pipe with grouting = L’impact de l’injection de coulis sur la performance lors de la rehabilitation d’une conduite par insertion conventionnelle

Zhao, J.Q.; Daigle, L.; Willmets, M.

NRCC-46877

A version of this document is published in / Une version de ce document se trouve dans : Infra 2003 – The Changing Infrastructure Rehabilitation Market : The Emergence of a

New Dynamic, Montréal, Nov. 17-19, 2003, pp. 1-10

CONTROLLING THE PERFORMANCE OF SLIPLINED PIPE

WITH GROUTING

L’IMPACT DE L’INJECTION DE COULIS SUR LA PERFORMANCE LORS DE LA

RÉHABILITATION D’UNE CONDUITE PAR INSERTION CONVENTIONNELLE

Jack Q. Zhao, Ph.D., P.Eng. Senior Project Manager

Transportation, Utilities and Public Works Dept. City of Ottawa

Lyne Daigle, M.Sc., P.Eng. Technical Officer

Institute for Research in Construction National Research Council of Canada

and

Michael Willmets Project Manager

Transportation, Utilities and Public Works Dept. City of Ottawa INFRA 2003 November 17-19, 2003 Omni Mont-Royal Montréal, Québec

Retour/Back

ABSTRACT

Annulus grouting, or non-grouting, is often the question in the minds of municipal

engineers when considering trenchless sliplining technique for pipe rehabilitation. For ease of installation in sliplining rehabilitation, the outside diameter of the liner pipe is usually at least 10% smaller than the inside diameter of the host pipe, resulting in an annular space (or annulus) between the two pipes. Currently the decision on annulus grouting is mainly based on its impact on construction and cost.

Based on a three-year study on the performance of a sliplined water main in the City of Ottawa, the effect of the grout on the performance of slipline pipe is presented in this paper. The pros and cons are explained in terms of buckling resistance, potential shear failure at lateral connections, protection of liner pipe when the host pipe fails, load-carrying capacity and control of load-sharing. Furthermore, how grouting can be used to maximise the desired performance of slipline pipe, or to strengthen an existing culvert is suggested in the paper.

This paper fits well with the theme of INFRA 2003 as it shares proven solutions to sliplining rehabilitation and promotes innovation in construction to maximize pipe performance.

Keywords: trenchless, sliplining, rehabilitation, buried pipe, grout, performance

maximization, service life

RÉSUMÉ

Doit-on procéder ou non à l’injection de coulis dans l’espace annulaire ? C’est une question que se posent souvent les ingénieurs municipaux au moment de considérer le tubage

comme technique de réhabilitation de conduites. Pour faciliter l’insertion, le diamètre extérieur de la gaine doit être au moins 10 % plus petit que le diamètre intérieur de la conduite, ce qui crée un espace annulaire entre les deux tuyaux. Présentement, la décision d’injecter du coulis est principalement fondée sur son effet sur la construction et le coût. Basé sur étude d’une durée de trois ans sur le rendement d’une conduite d’aqueduc réhabilitée de la ville d’Ottawa, la présente conférence décrit l’effet du coulis sur le rendement de la conduite. On explique le pour et le contre en termes de résistance au flambage, de rupture par cisaillement potentielle aux raccordements latéraux, de protection de la gaine en cas de bris de la conduite, et de capacité et répartition de charge. On explique aussi comment on peut utiliser l’injection de coulis pour optimiser le rendement souhaité de la conduite réhabilitée ou pour consolider le ponceau en place.

Cet exposé cadre bien avec le thème d’INFRA 2003 puisqu’il informe au sujet des solutions éprouvées en réhabilitation par tubage et qu’il favorise l’innovation en construction visant l’optimisation du rendement des conduites.

2

Introduction

Sliplining is a method for rehabilitating buried pipe by inserting a new liner pipe into an existing pipe (or host pipe). Sliplining does not require excavation except at a few locations necessary for insertion or connection purposes. Thus, sliplining rehabilitation offers many of the advantages common to trenchless technologies, namely less disturbance to nearby buried utilities and the environment, less damage to road pavement, shorter construction periods and less disruption to traffic and local residents. In 1999, the City of Ottawa benefited, in terms of construction schedule and cost savings, from sliplining rehabilitation of a 915-mm diameter water mains in the downtown core (Daigle et al. 2002).

For ease of installation, the outside diameter of the liner pipe is usually at least 10% smaller than the inside diameter of the host pipe, resulting in an annulus. This annulus may or may not be grouted (Figure 1). Currently, there is insufficient information on the advantages and disadvantages of grouting the annulus due to lack of understanding of the impact of

grouting. The effect of grout in the annulus on the structural performance of the pipe is usually ignored (Hickle and Glasgow 1997) and the initial construction cost may be the determination factor on grouting or not.

This paper examines the role the grout plays in a grouted sliplined pipe, in terms of short-term and long-short-term performance. The pros and cons of grouting outlined in this paper will enable system owners, designers and suppliers to make informed decisions for future sliplining rehabilitation.

Structural Difference between Grouted and Ungrouted

As shown in Figure 1, an ungrouted sliplined pipe consists of two pipes, one inside another with little interaction between them. The existing host pipe resists the external earth load as long as it retains its structural integrity. The new liner pipe resists the internal hydrostatic loading conditions (normal operating, surge and vacuum pressures) and also the external hydrostatic pressure due to leakage in the host pipe.

In a grouted sliplined pipe, the host and liner pipes interact through the grouted annulus, resulting in a composite behaviour. Loads are shared among the three elements: host pipe, grout and liner pipe. This load sharing depends primarily on the bonding characteristics at the interfaces and relative stiffness of the pipe rings. Even without bonding at the interfaces, load sharing still takes place (Zhao and Daigle 2001).

Advantages of Using Grout

Using grout to increase buckling resistance

Buckling of the flexible liner pipe may occur under internal vacuum in water mains or under external hydrostatic loading in gravity sewers. The critical buckling pressure for plastic pipe can be determined by (Jenkins and Kroll 1981; Szpak 1981):

(1)

where pcb is the critical buckling pressure, E the modulus of elasticity, µ the Poisson ratio, DR the dimension ratio (OD/wall thickness), ODmin and ODmax the minimum and maximum

outside diameter of the pipe. Eq. 1 is used to rate HDPE pipes for buckling resistance according to the duration of loading since the modulus of elasticity is time dependant. Pipe

3 max min 3 2 1 1 2 − = OD OD DR E pcb µ Annular space Grouted Ungrouted

Cast iron pipe / grout interface

Liner pipe / grout interface Liner pipe

Cast iron pipe

4 suppliers provide allowable buckling pressures of unsupported HDPE pipe for various dimension ratios (Driscopipe 1996; Sclairpipe 1996).

When a flexible (such as HDPE) pipe is buried directly in the ground, it gains lateral support from the surrounding soils, and thus can resist a higher buckling load (Jenkins and Kroll 1981; Meldt 1982; Driscopipe 1996; Sclairpipe 1996). In sliplining installations, grouting the annulus between the liner and host pipe also provides such support to the liner pipe: the support comes from the host pipe that has settled well in the soil. For instance, if the deformation of an HDPE pipe is limited to less than 5% by grouting, the critical buckling pressure can be doubled (Driscopipe 1996). Jenkins and Kroll (1981) point out that at least 80% fill in grouting the annulus is required in order to achieve a higher buckling resistance. Grouting the annulus also minimizes the buckling potential due to water accumulation in the annulus and freeze-up when the pipe is installed within the frost susceptible depth in cold regions.

Using grout to control load-sharing

It is common to design the liner pipe as though the host pipe and the grout make no contribution to resisting loads (Hickle and Glasgow 1997). This approach assumes full deterioration of the host pipe. In reality, a water main may be rehabilitated long before it reaches the state of full deterioration. The decision to rehabilitate usually depends on whether or not the break rate has surpassed a tolerance level (for example three

breaks/km/year). Even when the tolerance level is exceeded, the pipe may still be only partially deteriorated.

Based on this premise, a load-sharing theory has been developed that includes the liner pipe ring, the grout ring and the host pipe ring (Zhao and Daigle 2001). For the case of no bonding at the interfaces between the three pipe rings, an external load is shared as:

(2)

where Pi is the load portion (kN/m) on a ring in the sliplined pipe, Pext the total external

load (kN/m) on the pipe, and ψi the stiffness factor. Subscripts 1, 2 and 3 denote liner

pipe, grout and host pipe, respectively. An internal load is shared as:

(3) ext i i P P 3 2 1 ψ ψ ψ +ψ + = i=1,2,3 int 1 3 2 1 q D D q i i i ξ ξ ξ ξ + + = i=1,2,3

where qi is the pressure (kPa) on a ring in the sliplined pipe, qint the total internal pressure

(kPa) in the pipe, and ξi the rigidity factor (Zhao and Daigle 2001). Stiffness factor and

rigidity factors are defined as:

(4)

(5) where I is the section modulus, r the mean radius, t the wall thickness and D the mean diameter of the pipe ring.

The grout can therefore be used to change both stiffness factor and rigidity factors by altering its properties (i.e., E) and thickness (t), which leads to the control of load-sharing in the sliplined pipe.

Using grout to increase load-carrying capacity

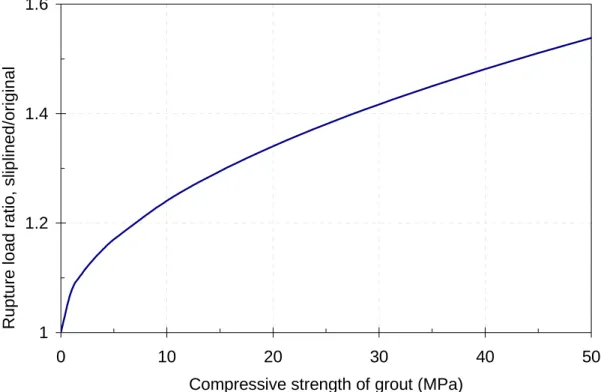

The load-sharing theory shows that the strength of the grout in the annulus of a sliplined pipe has a significant effect on the rupture strengthof the pipe, even though there is no bonding at the interfaces between the three pipe rings. No bonding represents the worst case whereas full bonding represents the best case in terms of pipe strength. The strength of the sliplined pipe with no bonding can be estimated as:

(6)

where R/R3 is the ratio of the rupture strength of the composite pipe to that of the host pipe

alone, ρ2 the density of the grout, and f2 the compressive strength of the grout at 28 days.

Figure 2 is a plot of Eq. 6 and as shown, the rupture strength of the composite pipe increases with the increase in grout strength.

+ + = 3 2 5 . 1 2 3 2 3 3 3 2 3 1 3 1 3 3 3 1 3 043 . 0 1 E f r r t t E E r r t t R R ρ 3 r EI = ψ D Et = ξ

6 The thickness and strength of the grout are controllable design parameters that can be used to achieve a desired performance. When a culvert under a roadway is in need of

rehabilitation, sliplining with grout may be considered to strengthen the culvert structure. Using grout to minimize risk of shear failure at lateral connections

When a portion of the pipeline is subjected to a temperature change (e.g., at ditch crossings, at shallow depths, or in the vicinity of a valve chamber), a plastic liner pipe contracts or expands much more (e.g., polyethylene pipe expands or contracts 10 times more) than a host pipe made of cast iron, steel or concrete. This differential thermal movement has a significant impact on lateral connections and could cause shear-offs (Meldt 1982). Grout in the annulus can provide frictional restraint along its length and as a result, minimize this differential movement. It is recommended that in an ungrouted pipeline, a portion of the annular space be grouted near lateral connections for shear protection (Driscopipe 1996; Meldt 1982). Furthermore, ungrouted pipe may pose more challenges to future cut-ins for installing additional service connections than the grouted pipe. In this respect, challenges

1 1.2 1.4 1.6

0 10 20 30 40 50

Compressive strength of grout (MPa)

R

upture load ratio, sliplined/original

are to grout the annulus around the new connection with effective control of the grouting length in an existing sliplined pipe. In the case of grouted pipe, the grout is already in place, thus making future connection easier to install.

Using grout to protect liner pipe

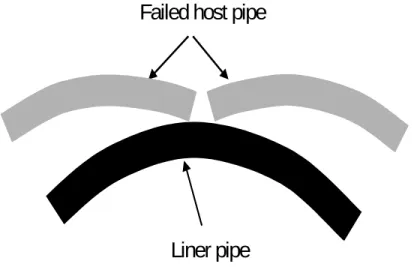

The time of host pipe failure is difficult to forecast, but when it fails, fractured pieces of the host pipe may create point loads (hinging of failed pieces) on the liner pipe in an ungrouted pipe (Figure 3). As a result, stress concentration and local deformation may exceed the limits of the liner pipe, leading to failure (Jenkins and Kroll 1981). Such undesirable point loads are avoided in a grouted pipe where the grout in the annulus protects the liner pipe. Therefore, grout in the annulus enhances the durability of the pipe.

Using grout to increase service life

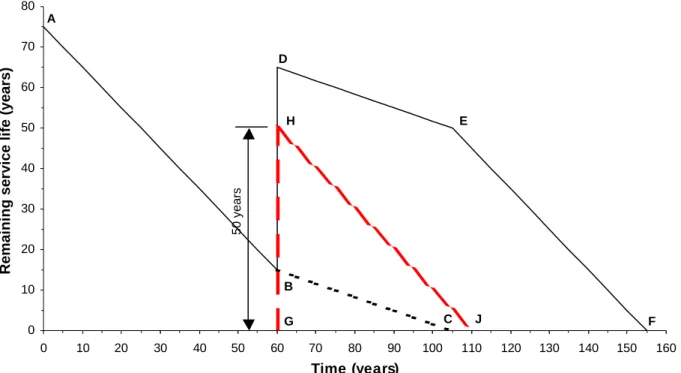

An important benefit of using grout in sliplined pipe is to increase its service life. To explain this concept, a simple linear deterioration curve is assumed for all pipe materials. That is, for a pipe that has a design service life of 75 years, it is assumed that the pipe has a service life of 75 years when installed and deteriorates linearly to 0 year in 75 years. To illustrate this concept, a water main pipe with an original service life of 75 years, is

assumed to be sliplined at the age of 60 (15 years of remaining service life) (Figure 4). The liner pipe is assumed to have a design service life of 50 years.

Failed host pipe

Liner pipe

8 As shown in Figure 4, the water main’s service life declines from Point A to Point B during its 60 years of service. When it is sliplined, two scenarios exist – grouted and ungrouted annulus. For the case of grouted annulus, the service life of the grouted pipe jumps from Point B to Point D by 50 years. The internal and external loads are shared mostly by the host pipe, and the grout. The thickness and the strength of the grout determine the load sharing.

Under reduced loading, the host pipe will have a slower rate of deterioration (Line BC) than before (Line AB). During this period of time, the liner pipe is subjected to a small percentage of its design loading and thus is not expected to deteriorate. The liner pipe goes from Point D to Point E (parallel to Line BC). When the host pipe reaches Point C, it is fully deteriorated. From there on the liner pipe takes the full external and internal loads and then deteriorates from Point E to Point F.

For the ungrouted case, the liner and host pipes follow their own deterioration curves, i.e., the service life curves of the two pipes cannot be added together. Due to reduced loading, the host pipe deteriorates at a slower rate. For argument sake, assume the host pipe follows Line BC (same as for the grouted case). The liner pipe is subjected to full internal loading. Therefore, it starts deteriorating from Point H to Point J linearly. It is fully deteriorated in

0 10 20 30 40 50 60 70 80 0 10 20 30 40 50 60 70 80 90 100 110 120 130 140 150 160 Time (years) R e mai n in g ser v ice l if e (year s) 50 years A B C E D F G H J

50 years. Failure of the host pipe may pose concentrated loads on the liner pipe as discussed earlier and accelerate its deterioration.

This qualitative comparison shows that the grouted pipe may last much longer (up to 45 years in the assumed case) than the ungrouted pipe.

It should be pointed out that pipe deterioration is a complicated and undefined process. It depends on many factors such as loading condition, pipe material, pipe’s internal and external environment. Determining the deterioration curve of pipe remains a challenge to researchers.

Disadvantages of Using Grout

Grouting operation can pose a number of challenges and requires careful engineering design. For instance, achieving 100% grouting in the annulus may by difficult. There are added costs associated with grouting the annulus during sliplining rehabilitation. These costs attribute to mix design, grout injection set-up and procedure, blocking off holes and openings and protection of the liner pipe from buckling under injection pressure.

Stephens (1996) provides some useful guidelines for grouting the annulus in sliplined pipe, including criteria for grout mix, set time, grouting method and procedure, and injection procedure and pressure. Proper curing time needs to be considered in the project schedule as well. Filling the liner pipe with water and maintaining it at a proper pressure is a

practical means to prevent the liner pipe from buckling and floating during grout injection. This measure may be combined with leakage testing that is normally required of a water main before the pipe is returned to service.

Summary and Discussions

Sliplining is an effective rehabilitation method for buried pipe. However, the role of the grout in the annulus is often neglected. This paper explains the role the grout plays in sliplined pipe and presents some options that are available to designers in controlling the performance of such a pipe. More specifically, grout in the annulus:

• increases the buckling resistance of the liner pipe,

• increases the load carrying capacity,

• can be used to control load-sharing proportions,

• eliminates sharp loading edges on the liner pipe from failed host pipe,

• reduces longitudinal movements due to differential temperatures, thus minimizing shear-off potentials at lateral connections, and

10 The disadvantages of grouting in sliplined pipe are:

• increased construction cost and longer installation time,

• potential collapse of liner pipe during grout injection,

• blocking of all openings that may allow grout to escape during pouring, and

• requirement of a proper grout injection procedure.

System owners constantly strive to strike a balance between maximizing the performance of a buried pipe and minimizing the cost. The benefits of grouting the annulus in sliplined pipe may well outweigh the additional construction cost. Understanding the pros and cons of grouting by all stakeholders (systems owners, designers, as well as grout and pipe suppliers) will also promote innovative designs that will take full advantage of trenchless sliplining rehabilitation.

References

Daigle, L., Zhao, J.Q., Willmets, M. and Potvin, D. 2002. Field performance of a sliplined watermain, North American No-Dig 2002 Conf., April 28 - 31, Montreal, PQ. Canada.

Driscopipe. 1996. Systems Design. Phillips Driscopipe.

Hickle, J.E. and Glasgow, K.L. 1997. Design and installation of large diameter slipliner pipe in Lakeland, Florida. Proceedings of Trenchless Pipeline Projects: Practical

Applications, Boston, MA, US, June 8-11, pp. 382-389.

Jenkins, C.F. and Kroll, A.E. 1981. External hydrostatic loading of polyethylene pipe.

Proc. of the Int. Conf. on Underground Plastic Pipe, J. Schrock (ed.), American

Society of Civil Engineers. pp. 527-541.

Meldt, R. 1982. The strength of HDPE pipes for the renovation of pipelines by sliplining.

Proc. of the 5th Int. Conf., Plastics Pipes, University of York, UK, September 8-10.

Sclairpipe. 1996. High Density Polyethylene Pipe Systems Design. KWH Pipe.

Stephens, P.J. 1996. Project guidelines for slipline grouting, No-Dig Engineering, Vol. 3, No. 2.

Szpak, E. 1981. Polyethylene pipe subjected to external pressure. Proc. of the Int. Conf. on

Underground Plastic Pipe, J. Schrock (ed.), American Society of Civil Engineers.

pp. 373-384.

Zhao, J.Q. and Daigle, L. 2001. Structural performance of sliplined watermain, Canadian