Publisher’s version / Version de l'éditeur:

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la

première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site

LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

Research Report (National Research Council of Canada. Institute for Research in

Construction), 2007-09-28

READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE.

https://nrc-publications.canada.ca/eng/copyright

NRC Publications Archive Record / Notice des Archives des publications du CNRC :

https://nrc-publications.canada.ca/eng/view/object/?id=3ae9431c-217d-4ec5-8c70-97443c3d67c1 https://publications-cnrc.canada.ca/fra/voir/objet/?id=3ae9431c-217d-4ec5-8c70-97443c3d67c1

NRC Publications Archive

Archives des publications du CNRC

For the publisher’s version, please access the DOI link below./ Pour consulter la version de l’éditeur, utilisez le lien DOI ci-dessous.

https://doi.org/10.4224/20377219

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at

Fire Scenario Tests in Fire Performance of Houses Test Facility - Data

Analysis

Su, J. Z.; Bwalya, A. C.; Lougheed, G. D.; Bénichou, N.; Taber, B. C.;

Thomas, J. R.

http://irc.nrc-cnrc.gc.ca

F i r e S c e n a r i o T e s t s i n F i r e P e r f o r m a n c e o f

H o u s e s T e s t F a c i l i t y – D a t a A n a l y s i s

I R C - R R - 2 1 0

S u , J . Z . ; B w a l y a , A . C . ; L o u g h e e d , G . D . ;

B é n i c h o u , N . ; T a b e r , B . C . ; T h o m a s , J . R .

S e p t e m b e r 2 8 , 2 0 0 7

The material in this document is covered by the provisions of the Copyright Act, by Canadian laws, policies, regulations and international agreements. Such provisions serve to identify the information source and, in specific instances, to prohibit reproduction of materials without written permission. For more information visit http://laws.justice.gc.ca/en/showtdm/cs/C-42

Les renseignements dans ce document sont protégés par la Loi sur le droit d'auteur, par les lois, les politiques et les règlements du Canada et des accords internationaux. Ces dispositions permettent d'identifier la source de l'information et, dans certains cas, d'interdire la copie de documents sans permission écrite. Pour obtenir de plus amples renseignements : http://lois.justice.gc.ca/fr/showtdm/cs/C-42

TABLE OF CONTENTS

PREFACE……….……….………….……….…………... ii

1 INTRODUCTION...1

2 TEST FACILITY ...1

3 TEST SETUP AND PROCEDURE ...4

3.1 Test Setup...4

3.2 Instrumentation ...6

3.3 Test Procedure...7

4 FIRE DEVELOPMENT AND TEMPERATURES IN THE FIRE ROOM ...7

4.1 Temperature Variation Across the Fire Room at 2.4 m height ...10

4.2 Comparison with Other Full-Scale Test Data ...12

5 TENABILITY ANALYSIS ...13

5.1 Exposure to Toxic Gases ...15

5.2 Exposure to Heat ...21

5.3 Visual Obscuration by Smoke ...23

5.4 Summary of Estimation of Time to Incapacitation ...24

5.5 Smoke Alarm Activation Times ...27

6 SUMMARY...28

7 REFERENCES...28

PREFACE

With the introduction of technological changes and innovations to building materials, design and construction practices in housing, the challenge is to determine the potential impacts of such changes on home fire safety. To help address this challenge, the Canadian Commission on Building and Fire Codes and the Canadian Commission on Construction Materials Evaluation asked the National Research Council Canada (NRC) to undertake research that will provide information to assist in the assessment of possible impacts.

In response, NRC’s Institute for Research in Construction (IRC) undertook to conduct research into fires in single-family dwellings with the primary objective of determining the impact of innovative residential construction products and systems on the fire safety of house occupants. This phase of the research includes two components:

1. Full-scale experiments to address how long egress routes within the house will remain viable from the perspective of tenability for occupants and structural integrity;

2. Literature review of related aspects, including evacuation of occupants, smoke alarm activation times, and statistics related to factors affecting fire-related deaths.

This research has been planned with multiple phases. This report addresses Phase 1 (2004 to 2007) of the study which focuses on basement fires and their impacts on the structural integrity of unprotected floor assemblies above a basement. It also looks at the impact upon egress routes, as well as smoke movement and tenability conditions within a house.

This report documents the analysis of the results of four full-scale fire scenario tests conducted in the Fire Performance of Houses facility with a fuel package in the basement living area of the test house. The fire scenarios were evaluated for use in future full-scale fire tests of

combustible floor assemblies in the Fire Performance of Houses facility.

NRC gratefully acknowledges the financial and technical support of the Special Interest Group on Fire Performance of Houses. This external advisory committee provided valuable input to the research and included representatives from the following organizations:

• Canada Mortgage and Housing Corporation • Canadian Automatic Sprinkler Association • Canadian Wood Council

• Cement Association of Canada • City of Calgary

• FPInnovations - Forintek Division

• North American Insulation Manufacturers Association

• Ontario Ministry of Community Safety and Correctional Services/Office of the Fire Marshal • Ontario Ministry of Municipal Affairs and Housing

• Wood I-Joist Manufacturers Association

The authors would like to acknowledge H. Cunningham (deceased), B. Di Lenardo, E. Gardin, J. Haysom, I. Oleszkiewicz, G. Proulx, and M. Sultan who served in the IRC steering committee for the project, and to acknowledge Don Carpenter, George Crampton, Eric Gibbs, Cameron McCartney, Michael Ryan and Michael Wright who contributed to the construction of the FPH test facility and assisted in conducting the fire tests.

FIRE SCENARIO TESTS IN FIRE PERFORMANCE OF HOUSES TEST FACILITY — DATA ANALYSIS

J.Z. Su, A.C. Bwalya, G.D. Lougheed, N. Bénichou, B.C. Taber, J.R. Thomas

1 INTRODUCTION

A series of fire tests were conducted in NRC’s Fire Performance of Houses (FPH) test facility in order to evaluate various fire scenarios for use in the FPH project. The experiments, which were conducted with non-combustible room linings, investigated the effect of fuel quantity, ventilation and other parameters on fire growth and tenability conditions in the test house. The experimental data obtained from the full-scale fire scenario tests were compiled in a separate report [1]. This report provides an analysis of the results of the tests. One or more of the fire scenarios evaluated during these tests will be selected for use in subsequent tests with

unprotected floor assemblies within the Fire Performance of Houses project. The selected fire scenarios will be required to provide a reproducible and relatively severe fire exposure from a fast-growing basement fire lasting up to 30 minutes.

2 TEST

FACILITY

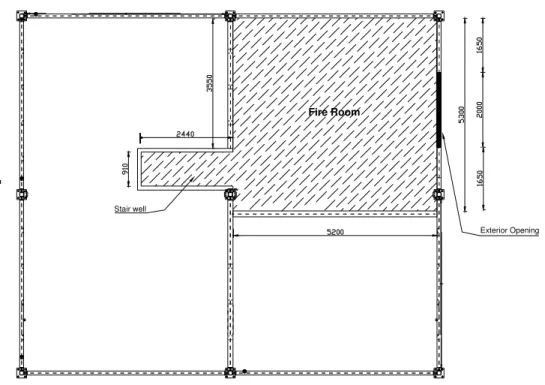

The Fire Performance of Houses test facility was designed to represent a typical two-storey detached single-family house with a basement. A detailed description of the facility including the layout of the instrumentation can be found in a separate report [1]. Figure 1 is an elevation view showing the levels of the test facility: basement, first storey and second storey. Each of the three levels has a floor area of 95 m2 and a ceiling height of 2.4 m.

Figure 1. The test facility.

The layout of the basement is shown in Figure 2. The basement was partitioned to create a fire room representing a 27.6 m2 basement living area. This was the average size of basement compartments based on survey results [2]. The walls and ceiling of the fire room were lined with non-combustible cement boards in all of the tests. An empty stairwell enclosure (without a

staircase) led from the fire room in the basement to the first storey. For the fire scenario tests, there was no real structural floor installed above the fire room. The floor area above the fire room was covered with 2 layers of non-combustible cement board without any additional load. In future tests of structural floor assemblies, the floor assembly to be tested will be constructed on the 1st storey directly above the fire room.

A rectangular exterior opening measuring 2.0 m wide by 0.5 m high and located 1.8 m above the floor was provided in the south wall of the fire room. The size of the opening is equivalent to the area of two typical basement windows (1.0 x 0.5 m). A noncombustible panel was used to cover the opening. A 0.91 m wide by 2.05 m high door opening located on north wall of the fire room led into the empty stairwell enclosure. At the top of this stairwell, a 0.81 m wide by 2.05 m high doorway led into the first storey. Tests were conduced with a door in this doorway in the closed position (closed doorway) or without the door in this doorway (open doorway), depending on the fire scenario.

The first storey had an open layout with no partitions, as shown in Figure 3. A 0.89 m wide by 2.07 m high doorway led to the exterior.

The layout of the 2nd storey is shown in Figure 4. It was partitioned to contain two identical bedrooms, which were connected by a corridor. The door of the southeast bedroom remained closed whereas the door on the southwest bedroom was kept open for all tests. Each bedroom doorway was 0.81 m wide by 2.05 m high.

Fire Room

Stair well

Exterior Opening

N

Stair well

Exterior door 890 x 2070

door 810 x 2050

FIGURE 3. First storey plan view (all dimensions in mm).

South East Bedroom 4470 X 3750 C o rr id o r 4 4 5 0 X 1 1 0 0

South West Bedroom 4470 X 3750

N

door 810 x 2050

3

TEST SETUP AND PROCEDURE

3.1 Test Setup

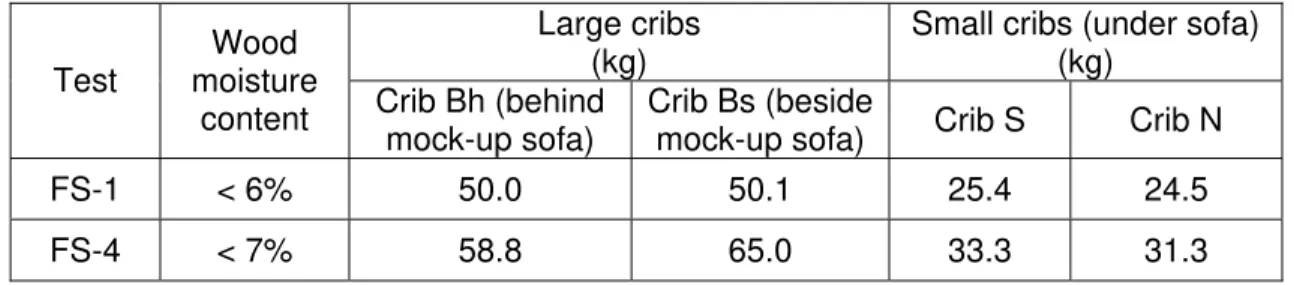

Table 1 gives the fire load and the state of the openings in the basement for each test. One mock-up sofa was used in each of the tests, whereas the wood cribs were only used in Tests FS-1 and FS-4. The mock-up sofa was constructed with 6 blocks of flexible polyurethane foam (with a density of 32.8 kg/m3) placed on a metal frame and each block was 610 mm long by 610 mm wide and 100 mm or 150 mm thick. The 150-mm-thick foam blocks were used for the backrest and the 100 mm-thick foam blocks for the seat cushion. The wood cribs were made with spruce lumber pieces, each piece measuring 38 mm x 89 mm x 800 mm. The pieces were evenly spaced in rows of six and stacked to heights of 356 mm and 712 mm for the small and large wood cribs, respectively.

Table 2 lists the masses of the wood cribs for each test in which wood cribs were used. Table 3 lists the condition (open or closed) of the doors in the doorway on the 1st and 2nd storey for each test. In each of Tests FS-3 and FS-4, a hollow-core interior door was used to close the doorway at the top of the basement stairwell.

Table 1. Fire load and Basement Ventilation Conditions Number of wood

cribs Ventilation conditions

Test Mock-up sofa mass1 (kg) Small Large Total wood mass (kg) Basement exterior opening2 Doorway at top of basement stairs FS-1 8.88 2 2 148.5 Open (110 s)3 Open FS-2 8.89 0 0 0.0 Open (80 s)3 Open FS-3 8.87 0 0 0.0 Closed Closed FS-4 9.26 2 2 186.9 Open (105 s)3 Closed Notes:

1. One mock-up sofa was used in each of the tests.

2. The panel covering the exterior opening was removed when the temperature at the opening reached 300°C.

3. Time (after ignition) at which the exterior opening was uncovered.

Table 2. Mass of Wood Cribs and Moisture Content (Tests FS-1 and FS-4 only) Large cribs

(kg)

Small cribs (under sofa) (kg)

Test

Wood moisture

content Crib Bh (behind

mock-up sofa)

Crib Bs (beside

mock-up sofa) Crib S Crib N

FS-1 < 6% 50.0 50.1 25.4 24.5

Table 3. Condition (Open or Closed) of Doors in the Doorway on the 1st and 2nd Storeys Test Doorway at top of basement stairs SW Bedroom door SE Bedroom door

First storey exterior door opened (time after ignition, s)

FS-1 Open Open Closed 180 s

FS-2 Open Open Closed 180 s

FS-3 Closed Open Closed Closed all the time

FS-4 Closed Open Closed 180 s

The placement of the fuel package is illustrated in Figure 5. The mock-up sofa was located at the center of the floor area. A photograph of the full fuel package setup is shown in Figure 6.

FIGURE 6. Fuel package for Tests FS-1 and FS-4 (no wood cribs were used in Tests FS-2 and FS-3).

3.2 Instrumentation

Table 4 gives a summary of the instrumentation that was installed at various points on each of the three levels of the test facility. A detailed description of the instrumentation is given in Appendix A.

Table 4. Summary of the Instrumentation

TC SA SD GA FTIR P VL VD

Basement fire room X X X X X

First storey X X X X X X X X

Second storey X X X X X X

Basement exterior opening X X X

First storey exterior door

X

Note:

TC: Thermocouples; SA: Smoke alarms; SD: Smoke density meter; GA: CO, CO2 and O2 gas analyzers;

FTIR: Fourier Transform Infrared Spectrometer; P: Pressure probe; VL: Air velocity probe; VD: Video camera.

3.3 Test Procedure

The mock-up sofa was ignited in accordance with the ASTM 1537 test protocol [3] and data was collected at 5 s intervals throughout each test.

In tests FS-1, FS-2 and FS-4, the non-combustible panel that covered the fire room’s exterior opening during the initial stage of each test was manually removed when the temperature measured at the top-center of the opening reached 300°C. This was done to provide ventilation air necessary for combustion and simulate the fire-induced breakage and complete fall-out of a pane of glass. The exterior opening was left covered in Test FS-3. To simulate occupants evacuating the house, the exterior door on the first storey was opened at 180 s after ignition and left open, except in Test FS-3, where the door was kept closed throughout the test.

The tests were terminated after a prolonged period of declining temperatures was observed in the basement fire room.

4

FIRE DEVELOPMENT AND TEMPERATURES IN THE FIRE ROOM

All inferences about the development of the fire are based on measured temperatures and observations made from the test videos. The test facility was not instrumented for rate of heat release measurements.

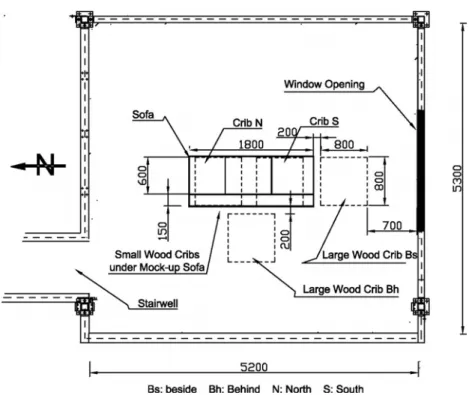

Table 5. Summary of Measurements in the Fire Room

Test Maximum temperature at 2.4 m height (°C) Time1 to reach maximum temperature at 2.4 m height (s) Room section2 Test duration1 (s) FS-1 912 465 SW 1740 FS-2 813 130 SE 690 FS-3 800 115 SE 1410 FS-4 783 130 SW 1875 Notes:

1. Time from ignition.

2. Quadrant in which the vertical thermocouple array measuring the maximum temperature was located - SW: South west, SE: South east.

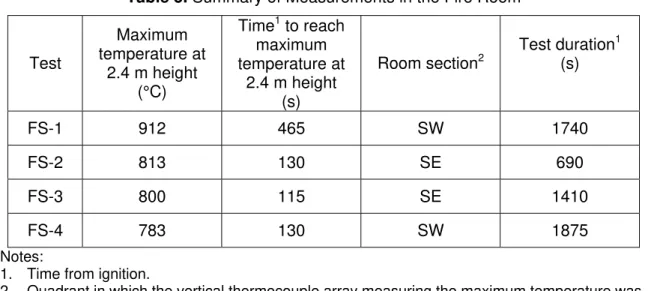

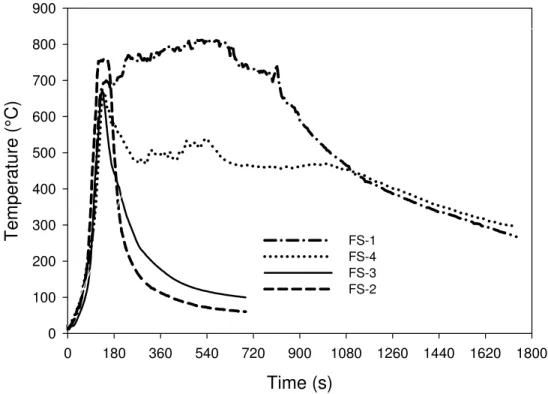

Table 5 shows the maximum temperature measured in the fire room at a height of 2.4 m above the floor for all of the tests. Figure 7 shows the average temperature profiles for the four

quadrants in the fire room at a height of 2.4 m above the floor for all of the tests (see Figure A-1 in Appendix A for thermocouple tree locations). For tests FS-2, FS-3 and FS-4, the maximum temperatures were recorded at this height. Contrary to this trend, a maximum temperature of 1000°C was measured in test FS-1 at a height of 0.4 m in the SW quadrant. This was likely due to radiation incident on the thermocouple at this location due to its close proximity to the flame. The development of the fire from ignition to attainment of the first temperature peak was

consistent for all of the tests indicating the polyurethane foam used for the mock-up sofa dominated the initial fire growth. There was good repeatability of the ignition source and the initial fire development. Following this initial stage, the effects of ventilation and the amount of fuel load became more pronounced in all of the tests.

Time (s)

0 180 360 540 720 900 1080 1260 1440 1620 1800T

e

m

perature (°

C)

0 100 200 300 400 500 600 700 800 900 FS-1 FS-4 FS-3 FS-2Figure 7. Average temperature profiles at 2.4 m height for all of the tests.

Tests FS-1 (full ventilation) and FS-4 (limited ventilation), both of which had the maximum fuel load consisting of the mock-up sofa and four wood cribs, had markedly different fire progression after the initial temperature peak was achieved. This can be attributed to the effect of

ventilation. The first temperature peak signifies the maximum burning rate of the polyurethane foam fuel — the dominant burning fuel during the initial fire development — and in Test FS-1 marks the transition to a wood crib-dominated fire.

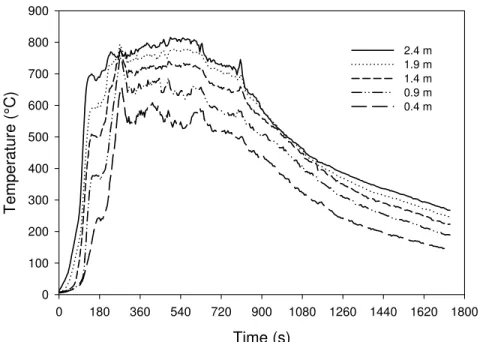

In Test FS-1, which had full ventilation, the fire continued to develop following the first

temperature peak and the average temperature at the 2.4 m height exceeded 600°C for much of the active burning period, indicating a fully-developed post-flashover fire. This assertion is further supported by the fact that an average temperature greater than 500°C was recorded at the lowest point (0.4 m above the floor) as can be seen in Figure 8. The two small wood cribs beneath the mock-up sofa were ignited directly by the flaming droplets of polyurethane foam and the pool fire that formed on the floor beneath the sofa, whereas the large wood cribs were ignited by a combination of the radiant heat from the burning sofa and small wood cribs, and the descending layer of hot gases. The second temperature peak seen in Figure 7 corresponds to the time at which the peak burning rate of the wood cribs was reached.

Time (s) 0 180 360 540 720 900 1080 1260 1440 1620 1800 T e mpe ratur e ( °C) 0 100 200 300 400 500 600 700 800 900 2.4 m 1.9 m 1.4 m 0.9 m 0.4 m

Figure 8. FS-1 temperature stratification (average temperature profiles in 4 quadrants).

In contrast, in Test FS-4, the two large wood cribs did not ignite most likely due to the limited ventilation that was available. Consequently, the maximum temperatures in the room quickly declined to under 600°C following the first temperature peak, after which time much of the polyurethane foam was consumed, and the fire was confined to the two small wood cribs. The average temperature at the 2.4 m height momentarily exceeded 600oC, the temperature criteria for flashover, which indicates that flashover may have occurred. The maximum average

temperature remained around 500°C for a period of time before the final decay phase ensued, while the average temperature at 0.4 m height remained below 300°C for the entire duration of the test, as can be seen in Figure 9. The video recording indicated that a plume of flames vented out of the exterior basement opening at the time when the temperature reached the peak (shortly after the covering panel was removed) for 20 s. After that, only smoke was seen out of the opening during the test.

The omission of wood cribs in Tests FS-2 and FS-3 resulted in significantly shorter active burning periods. The limited ventilation in test FS-3 resulted in a peak average temperature at the 2.4 m height that was lower by about 100°C compared to Test FS-2, which had more ventilation (see Figure 7). Additionally, the oxygen vitiated atmosphere in the fire room in Test FS-3 following the peak temperature resulted in a more gradual fire decay compared to Test FS-2.

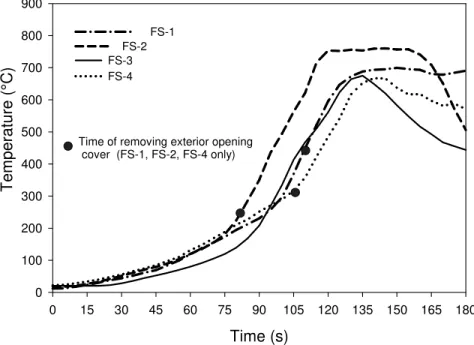

Figure 10 shows the temperature profiles during the initial 180 s in greater detail. Removing the cover on the exterior opening did not appear to have an immediate impact on the rate of

temperature rise in the tests. The faster rate of temperature rise and higher peak temperature obtained in Test FS-2 (mock-up sofa only) during this period is likely due to the absence of additional fuels (wood cribs) that would compete for oxygen in the combustion air with the mock-up sofa.

Figure 9. FS-4 temperature stratification (average temperatures profiles). Time (s) 0 180 360 540 720 900 1080 1260 1440 1620 1800 Tempe ratur e (° C) 0 100 200 300 400 500 600 700 800 900 2.4 m 1.9 m 1.4 m 0.9 m 0.4 m Time (s) 0 15 30 45 60 75 90 105 120 135 150 165 180 0 100 200 300 400 500 600 700 800 900

Time of removing exterior opening cover (FS-1, FS-2, FS-4 only) FS-1 FS-4 FS-3 FS-2 Temperature (°C)

Figure 10. Average temperatures at 2.4 m height for all tests during the initial 180 s.

4.1 Temperature Variation Across the Fire Room at 2.4 m height

Figure 11 to Figure 14 show the variation in temperature at the centre of the four quadrants of the fire room at a height of 2.4 m. The temperatures were fairly uniform during the growth and decay stages of the fire for all of the tests. The highest temperature variation occurred in Test FS-1 during the fully-developed stage of the fire, with a consistently higher temperature in the south west quadrant. This is likely due to the more dynamic airflow resulting from the full fire

involvement of the fuel package and the full ventilation, compared with Test FS-4, in which the two large wood cribs did not ignite and the only ventilation was provided by the exterior opening in the south wall of the fire room.

Time (s) 0 180 360 540 720 900 1080 1260 1440 1620 1800 Tempe rature (°C) 0 100 200 300 400 500 600 700 800 900 South East North West South West North East Average

Figure 11. Temperature variation at 2.4 m height in Test FS-1 (full fire load and full ventilation).

Time (s) 0 180 360 540 720 900 1080 1260 1440 1620 1800 Temp erat ure (°C ) 0 100 200 300 400 500 600 700 800 900 South East North West South West North East Average

Time (s) 0 180 360 540 720 900 1080 1260 1440 1620 1800 Temperature (°C) 0 100 200 300 400 500 600 700 800 900 South East North West South West North East Average

Figure 13. FS-3 temperature variation at 2.4 m height (sofa only and no ventilation).

Time (s) 0 180 360 540 720 900 1080 1260 1440 1620 1800 Tempe rature (°C) 0 100 200 300 400 500 600 700 800 900 South East North West South West North East Average

Figure 14. FS4 temperature variation at 2.4 m height (full fire load and limited ventilation).

4.2 Comparison with Other Full-Scale Test Data

Figure 15 shows that the rate of fire growth for Test FS-1 agrees well with the test results measured at NIST [4] (formerly the National Bureau of Standards) in fire tests that were

tests, the fire load consisted of household furnishings such as a sofa, an upholstered chair and ottoman, an end table, a bookcase and a coffee table. NIST developed the time-temperature curve shown in Figure 15 by carrying out a polynomial regression of the data from sixteen fire tests. The NIST tests were conducted with higher fire load densities and ventilation rates provided by a 0.76 m wide by 2.03 m high doorway opening and hence the higher peak

temperatures. Similar fire growth rates, with temperatures rising to about 750°C within 180 s of ignition, were also measured at the University of Canterbury [5] in full-scale fire tests using residential living room settings. The Canterbury tests were conducted in an ISO-9705 [6] compatible room and the fire load consisted of a mock-up upholstered sofa and wood cribs stacked to a maximum height of 1.5 m.

Time (s) 0 180 360 540 720 900 1080 1260 1440 1620 1800 Tempera ture (°C) 0 100 200 300 400 500 600 700 800 900 1000 1100 FS-1

NIST experimental curve.

Figure 15. Comparison of FS-1 with data from fire tests in simulated residential basement rooms conducted at NIST.

5 TENABILITY

ANALYSIS

Fires produce heat, narcotic and irritant gases, and smoke that obscures vision. The

temperature and the production of combustion products depend upon the fire characteristics, enclosure geometry and ventilation. The increased temperature and combustion products can, either individually or collectively, create conditions that are potentially untenable for occupants. Tenability analysis involves examination of the production of heat and toxic products of

combustion during the fire tests. It also involves estimation of the potential exposure to heat and toxic smoke and of the potential effects as a result of the exposure. The purpose of tenability analysis is to provide an estimation of the time available for escape — the calculated time interval between the time of ignition and the time after which conditions become untenable for an individual occupant.

There are various endpoints for tenability analysis, such as incapacitation, lethality/fatality, etc. For the FPH project, incapacitation – a state when people lose the physical ability to take effective action to escape from a fire – has been chosen as the endpoint when undertaking the tenability analysis. The time available for escape thus calculated is the interval between the time of ignition and the time after which conditions become incapacitating for an individual occupant.

ISO/TS 13571 and the SFPE Handbook of Fire Protection Engineering provide guidance and methodologies for evaluating the time available for occupants to escape [7, 8]. These

methodologies are used in this report to calculate the time available for escape as an input to the hazard analysis for each fire scenario used in the FPH project. The methodologies include a fractional effective dose (FED) approach to quantify the time at which the accumulated exposure to each fire effluent exceeds a specified threshold criterion for incapacitation. This time then is taken to represent the time available for escape relative to the specified threshold. The calculated time available for escape depends not only on the time-dependent temperatures, concentrations of combustion gas products and density of smoke in the test house, but also on the characteristics of occupants. The age and health of the occupants (such as body weight and height, lung and respiratory system function, blood volume and hemoglobin concentration, skin, vision, etc.) as well as the degree of activity at the time of exposure have an effect on the consequences of exposure to fire effluents and heat. Since the general population has a wide range of susceptibility to fire effluents and heat, the exposure thresholds for incapacitation can change from subpopulation to subpopulation. Thus, each occupant is likely to have a different time available for escape.

This section of the report does not try to debate what criterion should be used as the

incapacitation threshold but rather to present the results of the analysis for 2 typical FED values (e.g. FED = 1 and FED = 0.3). The methodology can be used to estimate the time available for escape associated with other FED values, if required.

The time calculated based on the determination of when the FED = 1 represents the time available for escape for a healthy adult of average susceptibility. The distribution of human responses to the fire effluents is unknown but is assumed to be a logarithmic normal distribution [7]. Under this distribution, the time available for escape calculated at FED =1 also represents statistically the time by which 50% of the general population would have been incapacitated but the conditions would still be tenable for the other 50% of the population.

For a more susceptible person, the threshold can be lower and the time available for escape would be shorter than for an average healthy adult. If FED = 0.3 is used as a criterion to

determine the time available for escape, it would statistically represent the time by which 11% of the population would have been incapacitated but the conditions would still be tenable for the other 89% of the population.

The location of the occupant in the test house has an effect on the time available for escape. The analysis focused on the fire conditions affecting tenability, as measured on the first and second storeys of the test facility, and the impact on any occupant assumed to be present at the time of ignition.

The methodology used does not address quantitatively any interaction between heat, combustion gas products and smoke obscuration. Each component is treated as acting

independently to create incapacitating conditions and the time available for escape is the shortest of the times estimated from consideration of combustion gas products, heat and visual obscuration.

It is necessary to recognize that 2 types of uncertainty exist in the tenability analysis: the uncertainties associated with the experimental data and the uncertainties associated with the equations for FED calculations. Fortunately, with the fast-growing fire used in the FPH project, the resulting uncertainty in the estimated time available for escape is much smaller than the uncertainty in the calculated FED due to their non-linear relationship. More details are provided in the following sections.

5.1 Exposure to Toxic Gases

Exposure to toxic products of combustion from fires has been a major cause of death and injury in many fire incidents. However, understanding the toxic effect of the smoke products and predicting the exposure time necessary to cause incapacitation are complex problems. In regards to the fuel package used in this study, with the combined flaming combustion of polyurethane foam and wood cribs, the primary gas products were carbon monoxide (CO) and carbon dioxide (CO2) in a vitiated oxygen (O2) environment, which are known as asphyxiant

gases. Given the amount of polyurethane foam in the fuel package and the volume of the test house, hydrogen cyanide (HCN) produced from the combustion of polyurethane foam would not reach a concentration of concern to the occupant life safety. A recent literature review by Beyler concluded that exposure to products of flaming combustion of flexible polyurethane foam would result in CO levels in the blood of test animals generally consistent with simple CO exposure, despite the toxicological role of HCN [9]. The fuel package contained no chemical components that would produce acid halides in the combustion gases. In this report, the analysis involves CO and CO2 and oxygen vitiation only.

The SFPE Handbook of Fire Protection Engineering contains information on the tenability limits for incapacitation or death after a 5-min exposure [8], as shown in Table 6, which indicates the test results that need to be analyzed. In the following sections, tenability due to each

asphyxiant gas is first analyzed independently; the interaction between asphyxiant gases is then considered.

Table 7 shows the maximum CO and CO2 concentrations and the minimum O2 concentrations.

In Tests FS-1 and FS-2, the CO2/CO ratio was decreased from over a hundred to 10 in 3

minutes, indicating a quick transition from a well-ventilated flaming fire to an under-ventilated fire.

Table 6. Tenability Limits for Incapacitation or Death after 5-min exposure [8]

Asphyxiant Incapacitation Death

CO 6000 – 8000 ppm (0.6 – 0.8%) 12,000 – 16,000 ppm (1.2 – 1.6%) Low O2 10 – 13% < 5% CO2 7 – 8% > 10%

Table 7. Maximum CO and CO2 Concentrations and Minimum O2 Concentration (%) Location \ Test FS-1 FS-2 FS-3* FS-4 CO 0.62 @ 300 s 0.34 @ 205 s 0.03 0.08 @ 760 s CO2 9.4 @ 450 s 2.4 @ 230 s 0.9 1.0 @ 1200 s 2nd storey 1.5 m high O2 10.8 @ 430 s 17.7 @ 200 s 19.5 19.5 @1200 s CO 0.61 @ 305 s 0.22 @ 300 s 0.03 0.08 @ 760 s CO2 9.5 @ 460 s 2.1 @ 320 s 1.0 1.2 @ 1200 s 2nd storey 0.9 m high O2 10.9 @ 430 s 18.5 @ 320 s 19.6 19.6 @1200 s CO 0.57 @ 285 s 0.28 @ 200 s 0.03 0.06 @ 760 s CO2 9.1 @ 420 s 2.6 @ 200 s 1.1 0.95 @1200 s 1st storey 1.5 m high O2 11.0 @ 420 s 17.6 @ 200 s 19.4 19.8 @1200 s CO 0.58 @ 285 s 0.29 @ 215 s 0.04 0.06 @ 840 s CO2 9.3 @ 435 s 2.1 @ 215 s 1.3 0.95 @1200 s 1st storey 0.9 m high O2 10.9 @ 430 s 18.5 @ 215 s 19.4 19.9 @1200 s Notes:

All concentrations listed are before fire suppression.

*For FS-3, all peak concentrations occurred near the end of the test (~1400 s).

5.1.1 Exposure to O2 Vitiation

Fires consume oxygen and create a low oxygen atmosphere. Past human experiments in an oxygen-depleted atmosphere indicated that most people could tolerate a 15% O2 atmosphere

[8]. Healthy individuals could also tolerate a 12% O2 level for a short period (<5 min) [10].

When oxygen diminished to below 10%, however, unconsciousness could occur rapidly. For healthy adults, the following equation was derived from the experiments with human [8] and can be used to predict the time, (minute), to loss of consciousness due to lack of oxygen alone. 2 ,O in

t

(1) 2 ,exp[8.13 0.54(20.9 %

)]

in Ot

=

−

−

2O

With the changing O2 concentration, the fractional effective dose approach has to be used in the

analysis. The incapacitation dose for oxygen vitiation can be expressed by (20.9 - %O2) × .

The fractional effective dose is the accumulation of the ratio of the actual exposure dose (20.9 - %O

2

,O

in

t

2) ×Δt and the incapacitation dose at each discrete increment of time:

∑

∑

=

−

Δ

−

⋅

−

Δ

⋅

−

=

2 1 2 2)]

%

9

.

20

(

54

.

0

13

.

8

exp[

)

%

9

.

20

(

)

%

9

.

20

(

2 2 1 2 , 2 , t t t t inO O inO

t

t

O

t

O

F

(2)where Δt (minute) is the discrete increment of time, i.e. the time interval for data sampling. Table 8 shows the calculated times for the fractional effective dose reaching 0.3 and 1.0 for exposure to O2 vitiation alone. For Test FS-1, the O2 vitiation alone would cause incapacitation

after 640 s (in the corridor on the second storey) and 840 s (on the first storey) using = 0.3

2

,O

in

F

as a criterion. The maximum = 0.4. For Tests FS-2, FS-3 and FS-4, the minimum O

2

,O

in

F

2concentrations were 17.6 to 19.9%, which were well above 15% and would not contribute to incapacitation.

5.1.2 Exposure to CO2

CO2 is not toxic at concentrations of up to 5%. Above 7%, CO2 becomes an asphyxiant gas; the

danger of loss of consciousness of an exposed person increases. Loss of consciousness could occur in approximately 2 minutes at 10% CO2, for example. The following equation can be used

to predict the time, (minute), to loss of consciousness due to the CO

2 ,CO in

t

2 asphyxiant effect [8]: 2 ,exp(6.1623 0.5189 %

2)

in COt

=

−

⋅

CO

(3)Similarly, with the changing CO2 concentration, the fractional effective dose approach has to be

used. The incapacitation dose for CO2 exposure can be expressed by %CO2 × above

which loss of consciousness would occur for people of average susceptibility. At each discrete increment of time, the increment of the fractional effective dose was calculated as the actual exposure dose (CO

2

,CO

in

t

2 concentration × time increment) divided by the incapacitation dose. The

fractional effective dose was the accumulation of this ratio of each time increment:

2 2 1 2 2 2 , , 1 2 2 % % exp(6.1623 0.5189 % ) t t in CO in CO t t CO t t F CO t CO ⋅ Δ Δ = = ⋅ −

∑

∑

⋅ (4)Table 8 shows the calculated times for the fractional effective dose reaching 0.3 and 1.0 for exposure to CO2 alone. For Test FS-1, CO2 alone would be able to cause incapacitation, after

555 s in the corridor on the second storey and 615 s on the first storey using =1 as a criterion, and after 380 s in the open spaces on both storeys using = 0.3. For Tests FS-2, FS-3 and FS-4, the maximum CO

2 ,CO in

F

2 ,CO inF

2 concentrations on the first and second storeys were 1 to 3%,

which is below the toxic level and CO2 would not contribute to incapacitation.

5.1.3 Exposure to CO

CO is known to be the most important toxicant for the asphyxiant effect of the fire gases. The lowest CO concentration in air that has been reported to cause human death is 5,000 ppm for a 5 min exposure [11]. The asphyxiant effect of CO is due to its affinity with the hemoglobin in human blood to form carboxyhemoglobin (COHb), which reduces the transport of oxygen in the blood to various parts of the body. When COHb in the blood increases to a threshold

concentration, loss of consciousness or death may occur. The time for the toxic effect to occur depends on the uptake rate of CO into the blood of a victim and the threshold COHb

concentration for that victim.

The CO uptake rate is determined by the difference between the CO concentration inhaled and that already in the body, and varies with the breathing rate, the degree of activity, the lung function, the body size, the blood volume and hemoglobin concentration of the victim and the exposure duration. The complexity of the CO uptake is described in the theoretical

Coburn-Forster-Kane (CFK) equation, which takes account of a wide range of variables to predict the COHb concentration [12]. For high-concentration and short-duration exposures such as the fire scenarios used in the FPH tests, one can use a simpler equation that was derived from human exposure experiments with healthy adults [8, 13]:

-5 1.036

%

COHb

=

3.317 10 [

×

CO

]

RMV t

⋅

(5)where [CO] is the inhaled carbon monoxide concentration in parts per million, RMV (respiratory minute volume) is the volume of air breathed in litres per minute, and t is the exposure duration in minutes. This equation gives equally good predictions as the CFK equation for average healthy adults. Since the CO concentration in the experiments varied with time, %COHb was calculated as a summation of the CO uptake at each discrete time step:

0 -5 1.036

%

3.317 10 [

]

t tCOHb

=

∑

×

CO

RMV

⋅Δ

t

(6)For an average adult, the normal breathing rate is 20 L/min with light activity. However, the breathing rate is affected by the presence of CO2 in a fire situation. In the concentration range

of 2 to 6%, CO2 can stimulate breathing. A CO2-induced hyperventilation factor, VCO2, for

breathing can be estimated using [7, 8]:

2 2

%

exp(

)

5

CO

VCO

=

(7)The hyperventilation increases the uptake rate of other toxic gases, such as CO, from the fire. This effect should be considered when the CO2 concentration is above 2%. The presence of

5% CO2 could triple the normal breathing rate, for example. Considering the CO2-induced

hyperventilation in a fire situation, the breathing rate would be

2

%

20 exp(

)

5

CO

RMV

=

⋅

(8)For the same individual, the CO uptake rate changes if the breathing rate changes, which also depends on the degree of activity of that individual. The CO uptake rate varies from person to person for a given smoke atmosphere and small children take up CO more rapidly than adults. The COHb incapacitating concentration at which loss of consciousness may occur is in the range of 25-40% depending on the degree of activity of the occupant among other variables [8, 14]. The threshold of 40% is more appropriate for those at rest and 30% for those engaged in light activity [8]. Certain susceptible populations may be incapacitated at lower COHb

concentrations.

With the rate of CO uptake and the likely incapacitating concentration of COHb, time to incapacitation due to CO exposure can be predicted. For those engaged in light activity,

fractional effective dose for incapacitation due to the CO uptake can be expressed as the COHb concentration in the blood divided by the incapacitating COHb concentration

0 5 1.036 2 ,

%

%

2.2113 10

[

]

exp(

)

30

5

t in CO tCO

COHb

F

=

=

×

−∑

CO

Δ ⋅

t

(9)Alternatively, the fractional effective dose for incapacitation due to CO can also be calculated using the approach given in ISO TS 13571 for short exposure to CO at high concentrations [7]:

2 2 , 1

%

[

]

exp(

)

35000

5

t in CO tCO

CO

t

F

=

∑

⋅ Δ

(10)where the incapacitation dose is 35000 ppm⋅min, which is consistent with the tenability limits of 6000 to 8000 ppm for incapacitation for 5-min exposure given in the SFPE Handbook of Fire Protection Engineering [8]. For the FPH tests, the difference between the incapacitation times predicted using these two equations is relatively small.

The time to incapacitation determined using = 1.0 as a criterion represents the time available for escape for healthy adults of average susceptibility. For more susceptible people, the exposure thresholds could be lower. The CO uptake and the COHb increase are known to be faster in small children than in adults [

CO in

F

,

15]. Therefore, the incapacitation time for small children or a more susceptible subpopulation would be shorter than for average healthy adults. These can be addressed, to a certain degree, by using Fin, CO =0.3 as a criterion to determine

the incapacitation time. Table 8 shows the calculated times for the fractional effective dose reaching 0.3 and 1.0. Calculation for the CO fractional effective dose was done with and without the CO2 hyperventilation factor exp(%CO2/5).

For Test FS-1, the CO concentration peaked at 5 min. On both the first and second storeys, if setting =0.3 as a criterion, CO would cause incapacitation after 315 s without considering the CO

CO in

F

,

2-induced hyperventilation and after 250-260 s with the contribution of hyperventilation.

The incapacitation time would be 320-325 s (with hyperventilation) on both storeys if setting

F

in,CO=1.0 as a criterion.For Test FS-2, the maximum fractional effective dose of CO was close to 0.3 on the first storey near the end of the test. On the second storey, the maximum fractional effective dose of CO with the CO2-induced hyperventilation was 0.35; the time to reach =0.3 was 440 s. This

indicates that flaming combustion of the polyurethane foam alone would be sufficient to cause incapacitation of the more susceptible subpopulation.

CO in

F

,

For Test FS-3 with the basement door and exterior opening closed, the maximum fractional effective dose of CO was less than 0.15 on the upper storeys and was less likely to cause incapacitation for the majority of the population.

For Test FS-4 with the basement door closed and the basement exterior opening open, the maximum fractional effective dose of CO was 0.3-0.5 on the upper storeys. The time to

reach =0.3 was 1100-1800 s depending on which storey an occupant would be on and

whether the effect of hyperventilation is considered. The calculation for Tests FS-3 and FS-4 showed that closing the door to the basement could reduce the amount of combustion products spreading to the upper storeys and thereby reduce the potential for incapacitation of occupants.

CO in

F

Table 8. Time (in seconds) to the Specified Fractional Effective Dose for Exposure to O2

Vitiation, CO2 and CO

Test FS-1 Test FS-2 Test FS-3 Test FS-4

FED = 0.3 FED = 1.0 FED = 0.3 FED = 0.3 FED = 0.3

CO alone – 1st storey 315 1210 n.r. (FED < 0.20) n.r. (FED < 0.12) 1800 (FED < 0.31) CO with CO2 hyperventilation – 1st storey 250 320 > 700 (FED < 0.3) n.r. (FED < 0.15) 1550 (FED < 0.36) Low O2 hypoxia – 1st storey 840 n.r.

(FED<0.33) n.r. (FED < 0.007) n.r. (FED < 0.015) n.r. (FED < 0.015) CO alone – 2nd storey 315 1070 n.r. (FED < 0.26) n.r. (FED < 0.12) 1260 (FED < 0.44) CO with CO2 hyperventilation –2nd storey 260 325 440 (FED < 0.35) n.r. (FED < 0.14) 1100 (FED < 0.53) Low O2 hypoxia – 2nd storey 640 n.r.

(FED<0.40) n.r. (FED < 0.007) n.r. (FED < 0.02) n.r. (FED < 0.017) High CO2 hypercapnia – 1st storey 380 615 n.r. (FED < 0.04) n.r. (FED < 0.08) n.r. (FED < 0.10) High CO2 hypercapnia – 2nd storey 380 555 n.r. (FED < 0.04) n.r. (FED < 0.07) n.r. (FED < 0.10) Note:

Based on concentrations at 1.5 m height; n.r.: not reached.

5.1.4 Interaction of CO, CO2 and O2 Vitiation

Interactions between asphyxiant gases and their combined effect are not well understood. The asphyxiant effect of CO2 is generally treated as being independent of other asphyxiant gases;

the effect of O2 vitiation (low oxygen hypoxia) is generally treated as being additive with the

asphyxiant effect of CO [8]. The asphyxiant effect of the smoke gases is determined by

or ( ), whichever is larger (with including the effect of CO

2 ,CO in

F

2 , ,CO inO inF

F

+

F

inCO , 2-induced hyperventilation).Table 9 shows examples of this treatment. The calculation shows that the O2 vitiation did not

add much to the asphyxiant effect at the time when CO was capable of producing

incapacitation. CO was the most important toxicant for the asphyxiant effect of the smoke gases; increased CO uptake by CO2-induced hyperventilation was the most important

interaction. Therefore, the exposure to CO with CO2-induced hyperventilation determined the

incapacitation time for the asphyxiant gases analyzed.

Table 9. FED due to CO, CO2, O2 vitiation at Specified Time for Test FS-1

1st storey SW quadrant 1.5 m height 2nd storey corridor 1.5 m height Time 250 s 320 s 260 s 325 s CO 0.14 0.31 0.14 0.32 CO × CO2 hyperventilation 0.30 1.02 0.30 1.02 Low O2hypoxia 0.006 0.03 0.006 0.03

CO × CO2 hyperventilation + low O2 hypoxia 0.306 1.05 0.306 1.05

A recent paper by Gann includes an analysis of incapacitation by exposure to CO alone for a susceptible subpopulation such as people with coronary artery disease or small children; incapacitation could occur at an FED range of 0.14-0.21 (CO alone) [16]. As shown in Table 9, when the FED due to CO exposure with CO2 hyperventilation reached 0.3, the FED due to CO

exposure alone already reached this range. This shows consistency in the estimation of time to incapacitation.

For exposure to the asphyxiant gases, each calculation for estimating incapacitation in this section was associated with a particular position where the concentrations were measured — each calculated time applies to an occupant who would stay at that particular location. In real fire situations, the occupant might move through different locations during egress. Therefore, the time to incapacitation would be in-between the times calculated for different locations.

5.2 Exposure to Heat

Convected heat is the most important source of heat exposure for occupants in the first and second storeys. Table 10 shows the maximum temperature during each test. The

temperatures at the 1.4 m height from the floor were used for the analysis of convected heat exposure.

Table 10. Maximum Temperatures (°C)

Test FS-1 FS-2 FS-3 FS-4 Bedroom SE 1.9 m 36 9 6 17 Bedroom SE 1.4 m 34 9 6 17 Bedroom SE 0.9 m 34 9 6 17 Bedroom SW 1.9 m 135 40 14 30 Bedroom SW 1.4 m 124 35 13 29 Bedroom SW 0.9 m 115 30 12 28 2nd storey corridor 1.9 m 190 65 17 35 2nd storey corridor 1.4 m 170 55 17 34 1st storey 1.9 m 290 110 20 40 1st storey 1.4 m 250 80 18 37

The rate of convected heat transfer from hot gases to the skin depends on temperature, ventilation, humidity of the enclosure and clothing over the skin [8]. The tolerable time of

exposure to convected heat is 15 min for dry air of 100°C or saturated air of 80°C. For hot air at temperatures above 120°C and with water vapour of less than 10%, pain and skin burns would be likely to occur in minutes; assuming unclothed or lightly clothed subjects, the time to

incapacitation due to exposure to convected heat, t in,conv (minutes), can be estimated for a

constant temperature T (°C) using [7, 8]:

(11)

7 3.4 , 5 10

in conv

t = × T−

Since the temperatures in the FPH experiments were changing, the exposure was estimated using the fractional effective dose analogy at each discrete increment of time, Δt (minutes):

3.4 7 ,

5 10

in convt

T

t

t

Δ

=

Δ

×

(12)When the temperature is increasing or stable, the fractional effective dose for the convected heat exposure can be calculated using the following equation:

2 2 1 1 3.4 , 7 ,

5 10

t t in heat t in conv tt

T

F

t

Δ

t

=

=

×

∑

∑

Δ

(13)The calculated time to incapacitation due to the convected heat exposure is given in Table 11. For Test FS-1, the convective heat exposure alone would produce incapacitation, but the time depended on the location of the occupants. For occupants in the corridor on the second storey, the incapacitation time would be after 330 s and 440 s for Fin,heat= 0.3 and Fin, heat= 1,

respectively. For occupants in the open bedroom, the incapacitation time would be after 470 s and 710 s for Fin,heat= 0.3 and Fin, heat= 1, respectively. Heat exposure would not contribute to

incapacitation in the closed bedroom (Fin, heat<0.04). For occupants on the first storey, the

incapacitation time would be after 245-260 s for Fin,heat= 0.3 and 290-315 s for Fin,heat= 1.

Each calculation was associated with a particular position where the temperature was

measured; in other words, each calculated time applies to an occupant who would stay at the location of a particular thermocouple tree. In real fire situations, the occupant might move through different locations during egress. Therefore, the time to incapacitation would be in-between the times calculated for different locations.

Radiant heat is important when the hot smoke layer is over 200°C, which corresponds to the threshold radiant heat flux of 2.5 kW⋅m-2

for the second degree burning of skin [17]. Only in Test FS-1, the hot smoke layer was over 200°C; however, the calculation indicated that the convected heat exposure would result in incapacitation before the radiant heat began to play a major role on the first and second storeys.

For Tests FS-2, FS-3 and FS-4, based on the temperature measurements and calculation, heat exposure was not a safety concern to occupants on the first and second storeys.

Table 11. Time (in seconds) to the Specified Fractional Effective Dose for Exposure to Convected Heat

Test FS-1 Test FS-2 Test FS-3 Test FS-4

Fractional Effective Dose

FED = 0.3 FED = 1.0 FED = 0.3 FED = 0.3 FED = 0.3

1st storey SE quadrant 245 290 n.r. (FED <0.12) n.r. (FED <0.008) n.r. (FED <0.079) 1st storey SW quadrant 245 290 n.r. (FED <0.12 n.r. (FED <0.008) n.r. (FED <0.074) 1st storey NE quadrant 260 315 n.r. (FED <0.13) n.r. (FED <0.007) n.r. (FED <0.065) 1st storey NW quadrant 255 305 n.r. (FED <0.12) n.r. (FED <0.007) n.r. (FED <0.066) 2nd storey corridor 330 440 n.r. (FED <0.05) n.r. (FED <0.006) n.r. (FED <0.062) 2nd storey open

bedroom

470 710 n.r. (FED <0.015) n.r. (FED <0.002) n.r. (FED <0.035) 2nd storey closed

bedroom

n.r. (FED <0.04) n.r. (FED<0.0004) n.r. (FED <0.0001) n.r. (FED <0.0077) Notes:

Based on temperatures at 1.4 m height. n.r.: not reached.

5.3 Visual Obscuration by Smoke

Visual obscuration by the optically dense smoke tended to be the first hazard for occupants, which could impede and even totally prevent evacuation. Although visual obscuration would not directly cause incapacitation, it would cause delays in movement by the occupants and thus prolong exposure of occupants to other hazards. In this report, the smoke obscuration is expressed as the optical density per meter (OD in m-1):

⎟

⎠

⎞

⎜

⎝

⎛

=

I

I

L

OD

0 10log

1

(14) where I0 is the intensity of the incident light, I is the intensity of the light transmitted through thepath length, L (m), of the smoke. The optical density is related to the extinction coefficient (k in m-1) by OD = k/2.303. Table 12 shows the maximum optical density of smoke measured during each test. The times to reach various optical density levels at different locations for this series of the tests are listed in Table 13.

Table 12. Maximum Optical Density of Smoke, OD (m-1)

FS-1 FS-2 FS-3 FS-4

2nd storey 1.5 m 3.0 @ 215 s 3.1 @ 180 s 0.57 @ 1400 s 0.52 @ 700 s

2nd storey 0.9 m 2.8 @ 225 s 1.9 @ 190 s 0.54 @ 1400 s 0.54 @ 800 s

1st storey 1.5 m 4.5 @ 195 s 1.8 @ 150 s 0.52 @ 1400 s 0.40 @ 700 s

1st storey 0.9 m 4.5 @ 225 s 1.3 @ 190 s 0.52 @ 1400 s 0.32 @ 800 s

Table 13. Time (in seconds) to the Specified Smoke Optical Density

Test FS-1 Test FS-2 Test FS-3 Test FS-4

OD (m-1) = 0.25 0.50 1.0 2.0 0.25 0.50 1.0 2.0 0.25 0.50 0.25 0.50 1st storey SW quadrant at 1.5 m height 110 130 155 180 115 130 145 n.r. 260 880 520 n.r. 1st storey SW quadrant at 0.9 m height 140 165 185 200 140 165 180 n.r. 360 800 650 n.r. 2nd storey corridor at 1.5 m height 130 140 165 190 125 140 155 165 170 950 300 660 2nd storey corridor at 0.9 m height 140 160 180 195 145 155 180 n.r. 220 1050 330 660 Note: n.r.: not reached.

Studies by Jin indicated that the optical density of smoke and visibility through smoke were related (the visibility is proportional to the reciprocal of the OD for non-irritating smoke, for example) [18]. Various threshold OD values related to the loss of visibility have been suggested for small buildings with occupants familiar with the egress route. The limiting OD value was suggested to be 0.5 m-1 for non-irritating smoke and 0.2 m-1 for irritating smoke [8, 18]. A limiting OD value of 0.5 m-1 was also set by Babrauskas using results of full-scale burns of upholstered chairs and mattresses [14,19]. A recent home smoke alarm study used an OD of 0.25 m-1 as the tenability limit for smoke obscuration [20]. In ISO 13571[7], the minimum visible brightness difference between an object and a background is used to estimate the smoke obscuration limit at which occupants cannot see their hands in front of their faces (a distance of 0.5 m or less). It is estimated that occupants cannot see their hands in front of their faces and

become disoriented at an optical density of 3.4 m-1. For an occupant whose vision is less precise, this can happen at an optical density of 2 m-1 or less.

In addition to the optical density measurement, video records were also analyzed for visual obscuration. The video images became completely obscure when the optical density was approaching 2 m-1. Note that there were at least 2 halogen lamps (2 x 500 Watts) providing lighting in the view direction of each video camera on the first and second storey. This lighting condition was much better than that in a real house.

In this report, therefore, a tenability limit of optical density is set at ODLimit = 2 m-1, recognizing

that this limit could be lower for people with less precise vision. The time to untenable smoke obscuration is the moment when the optical density reaches this limit. Times to reach other smoke levels are also provided for discussion.

For Tests FS-1 and FS-2, the times to reach various optical density levels of interest were very similar, which suggested that the combustion of polyurethane foam produced sufficient smoke for conditions to reach the smoke obscuration limit. In Test FS-2, the peak OD value (1.8 m-1) for the first storey was very close to the ODLimit (2 m-1). Both the optical density measurements

and video records indicate that complete visual obscuration would occur around 3 minutes in Tests FS-1 and FS-2 (the video images for the first and second storeys became completely obscure at 180-200 s for both tests).

With the basement door closed in Tests FS-3 and FS-4, the maximum smoke optical density was significantly reduced. The optical density did not reach the tenability limit in either test. The video images of Test FS-4 confirmed that neither the first storey nor the second storey became completely obscure. Two out of 3 camera views from Test FS-3 also indicated that the first and second storeys did not become completely obscure; however, one camera view from the west wall on the first storey became completely dark at approximately 10 minutes. In Test FS-3, there was a positive pressure built-up in the fire room (with a peak value of 135 Pa) during the first 2 minutes. Since the fire room was completely closed, the overpressure might have created leakages to release the pressure, through which smoke leaked into the first storey in addition to through the undercut of the door to basement. This explained the localized smoke obscuration recorded by the third camera in Test FS-3. The non-combustible “sub-floor” was re-sealed before Test FS-4.

Psychological effects of smoke on occupants may accelerate the loss of visibility [18]. Possible reduction of time to untenable smoke level due to psychological effect is not addressed in this report.

5.4 Summary of Estimation of Time to Incapacitation

Tenability was analyzed independently for the gas exposure, heat exposure and smoke

obscuration to estimate the time available for escape, using incapacitation as the endpoint. The combined effect as a result of simultaneous exposure to the asphyxiants, heat and smoke obscuration is not well understood. Table 14 summarizes the estimated times to the onset of untenable conditions, where each value is the shortest time among each set of values from Table 8, Table 11 and Table 13.

The uncertainty in the calculation of the FED is estimated to be ±25% for the heat exposure and ±40% for the CO exposure (with CO2 induced hyperventilation) [7]. With the fast-growing fire

used in the FPH project, the resulting uncertainty in the estimated time is much smaller than the uncertainty in the calculated FED due to the non-linear relationship. Table 14 lists the

uncertainty in the estimated time for Test FS-1.

Table 14. Summary of Estimation of Time to Specified FED and OD (in seconds)

OD = 2 m-1 FED = 0.3 FED = 1

Test 1st storey 2nd storey 1st storey 2nd storey 1st storey 2nd storey

FS-1 180 190 245±15 260±15 290±20 325±30

FS-2 175* 165 >700 440 not reached not reached

FS-3 not reached not reached not reached not reached not reached not reached

FS-4 not reached not reached 1550 1100 not reached not reached

Notes:

Values determined using the measurements at 1.5 m height (for gas concentrations and OD) or 1.4 m height (for temperatures);

* Time for smoke obscuration determined by video record.

Smoke obscuration was the first hazard to occur. Although smoke obscuration would not directly cause incapacitation, it could impede evacuation and prolong exposure of occupants to other hazards. With the doorway to the basement left open in Tests FS-1 and FS-2, the time to reach various optical density levels of interest was very similar, which suggested that the combustion of polyurethane foam was mainly responsible for reaching the smoke obscuration limit. With the basement door closed in Tests FS-3 and FS-4, the maximum OD value was significantly reduced and the tenability limit ODLimit = 2 m-1 was not reached. It must be pointed

out that people with less precise vision could become disoriented at a lower optical density. Because of the variation in susceptibility to heat and/or gas exposure, the time to untenable conditions was not a single value. The times corresponding to FED = 0.3 and FED = 1 in Table 14 represent this variation to a certain extent. There was also a slight variation of the

corresponding time on the 2 different storeys for each FED in Table 14. In Test FS-1, the first storey became untenable earlier than the second storey. For Tests FS-2 and FS-4, the second storey reached FED=0.3 first. The conditions on the first and second storey during Test FS-3 did not reach what would be considered untenable conditions associated with FED = 0.3 or 1. It should be pointed out that in Test FS-1, the heat exposure and the CO exposure (with

hyperventilation) would almost simultaneously cause incapacitation on the first storey. Closing the door to the basement fire room prolonged the time available for escape.

For the closed bedroom, only heat exposure could be estimated. Judged from the temperature measurements and the heat exposure calculation, during all tests, the conditions in the closed bedroom on the second storey would not reach what would be considered untenable conditions associated with FED = 0.3 or 1. Assuming occupants were initially in the closed bedroom in Test FS-1, if the occupants tried to open the bedroom door to escape through the normal

routes, they would be exposed to much severer conditions than staying in the closed room. The time remaining for egress would depend on when the bedroom door was opened, among other variables.

The analysis so far addressed a potential exposure that started at the time of ignition, which applies to occupants in the open spaces of the house. Further analysis has also been

conducted for exposure starting at times later than ignition. This further analysis is important for those occupants who were initially in the closed bedroom but then tried to open the bedroom door to escape through the normal routes.

for occupants of average susceptibility (FED=1) Onset of exposure (s) 0 200 400 600 800 1000 1200 1400 1600 T im e r em ai ni ng t o i nc apac it at ion ( s ) 0 200 400 600 800 1000 CO uptake -1st storey CO uptake -2nd storey Convected heat - 1st storey Convected heat - 2nd storey

for more susceptible occupants (FED=0.3) Onset of exposure (s) 0 200 400 600 800 1000 1200 1400 1600 T im e re m a ini n g t o i n c a pa c itat ion ( s ) 0 50 100 150 200 250 300 350 400 CO uptake -1st storey CO uptake -2nd storey Convected heat - 1st storey Convected heat - 2nd storey

Figure 16. Time remaining to incapacitation versus onset of exposure in Test FS-1 (ignition at time zero).

Figure 16 shows the time remaining to incapacitation calculated from the convected heat and hyperventilated CO exposure in Test FS-1 for people of average susceptibility (FED=1) and for more susceptible occupants (FED=0.3) as a function of onset of exposure. The CO uptake curve has a minimum, which marks the transition from a polyurethane foam-dominated fire to a wood crib-dominated fire. Compared to the polyurethane foam, the wood crib dominated stage

had more efficient combustion. Again, this calculation was associated with particular positions where the concentrations or temperatures were measured (each calculated time applies to an occupant who would stay at that particular location). The actual time to incapacitation would be in between the times calculated for different locations since the occupant would move through different locations during egress. The time remaining to incapacitation tended to be dictated by the gas exposure if occupants tried to open and leave the bedroom in the early part of the test, but the convected heat would become more severe as time advanced. It would be likely for the occupants to be incapacitated in the egress route if leaving the closed bedroom about 300 s after the ignition, since the convected heat would block the safe passage on the first storey. Occupants would have a better chance for survival if remaining in the closed bedroom.

5.5 Smoke Alarm Activation Times

Table 15 shows the time of activation of all of the smoke alarms installed in the test facility. The ionization smoke alarm was not installed in the basement fire room in order to avoid dealing with radioactive materials in the cleanup of debris after the fire tests. The photoelectric smoke alarms in the fire room took about 30 s to activate consistently whereas similar smoke alarms in the bedroom with an open door on the second storey took 100 s longer to activate. The smoke alarms in the closed bedroom took even longer to activate. This highlights the importance of having the smoke alarms wired to activate simultaneously when one of them detects smoke. Interconnecting the smoke alarms would shorten the detection and alarm time and allow more time for evacuation.

New smoke alarms were installed for each test. In some cases, the smoke alarms on the first storey activated earlier in Tests FS-3 and FS-4 (closed doorway to basement) than in Tests FS-1 and FS-2 (open doorway to basement). This could be due to the variation in the sensitivity of the smoke alarms used. The overpressure created in Tests FS-3 and FS-4 might also have an effect by pushing the smoke through the undercut of the door to the smoke-alarm location on the first storey.

Table 15. Smoke Detector Activation Times (in seconds) after Ignition Location Basement Bottom of stairs 1st Storey Top of stairs 2nd Storey Top of stairs 2nd Storey SW bedroom Door open 2nd Storey SE bedroom Door closed Smoke alarm type I P I P I P I P I P Test FS-1 - 30 50 75 105 125 125 130 190 255 Test FS-2 - 30 70 70 110 115 125 125 480 260 Test FS-3 - 40 55 55 105 125 145 140 NA NA Test FS-4 - 30 50 50 175 195 235 250 790 995 Notes