Publisher’s version / Version de l'éditeur:

Cement and Concrete Research, 12, May 3, pp. 289-299, 1982-05-01

READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE. https://nrc-publications.canada.ca/eng/copyright

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

NRC Publications Archive

Archives des publications du CNRC

This publication could be one of several versions: author’s original, accepted manuscript or the publisher’s version. / La version de cette publication peut être l’une des suivantes : la version prépublication de l’auteur, la version acceptée du manuscrit ou la version de l’éditeur.

For the publisher’s version, please access the DOI link below./ Pour consulter la version de l’éditeur, utilisez le lien DOI ci-dessous.

https://doi.org/10.1016/0008-8846(82)90077-1

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at

Microhardness : fracture studies : high alumina cement systems

Beaudoin, J. J.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site

LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

NRC Publications Record / Notice d'Archives des publications de CNRC:

https://nrc-publications.canada.ca/eng/view/object/?id=0e492d15-3bd2-4b7b-843d-5158b32e6da0

https://publications-cnrc.canada.ca/fra/voir/objet/?id=0e492d15-3bd2-4b7b-843d-5158b32e6da0

National Research

Conseil national

$

Council Canada

de recherche Canada

-~ -

Ser

THl

N21d

,o.

1040

.)

c .

2

!MICROHARDNESS-FRACTURE STUDIES:

HIGH ALUMINA CEMENT S Y S T E M

by J. J. Beaudoin

ANALYZED

Reprinted f r o m

Cement and Concrete R e s e a r c h

Vol. 12, 1982

P O289-299

N*lBLDG.

RES.'

'

L I B R A R Y

82-

O f -

P7

B I B L I O T ~ ~ ~ Q U E

Rech. BS.irn.

CDBR P a p e r No. 1040

D i v i s i o n of Building R e s e a r

ch

P r i c e $1. 25

OTTAWA

NRCC 20377

This publication is being distributed by the Division of Building R e s e a r c h of the National R e s e a r c h Council of Canada. It should not be reproduced in whole o r in p a r t without p e r m i s s i o n of the original publisher. The Di- vision would be glad to b e of a s s i s t a n c e i n obtaining such permission.

Publications of the Division m a y b e obtained by m a i l - ing the a p p r o p r i a t e r e m i t t a n c e (a Bank, E x p r e s s , o r P o s t Office Money O r d e r , o r a cheque, m a d e payable to the R e c e i v e r G e n e r a l of Canada, c r e d i t NRC) t o the National R e s e a r c h Council of Canada. Ottawa. K l A OR6. Stamps a r e not acceptable.

A l i s t of a l l publications of the Division is available and m a y b e obtained f r o m the Publications Section, Division of Building Research, National R e s e a r c h Council of

CEMENT and CONCRETE RESEARCH. Vol. 1 2 , p p . 289-299, 1982. P r i n t e d i n t h e USA.

0 0 0 8 - 8 8 4 6 / 8 2 / 0 3 0 2 8 9 - 1 1 $ 0 3 . 0 0 / 0 Copyright ( c ) 1982 Pergamon P r e s s , L t d .

MICROHARDNESS-FRACTURE STUDIES: H I G H ALUMINA CEMENT SYSTEMS

J

.

J. BeaudoinD i v i s i o n of B u i l d i n g Research, Na t i o n a l Research Council of Canada, Ottawa Canada K1A OR6

(Cormunicated by F.H. Wittmann) (Recevied Oct. 20, 1981)

? i ~ r o h a r d n e s s and f r a c t u r e parameters of s e v e r a l high alumina cement p a s t e systems c o n t a i n i n g v a r y i n g p r o p o r t i o n s of hexagonal and c u b i c

y L - 3 2 3 have been determined u s i n g s i n g l e edge-notched f l e x u r a l foecimens from each system. Specimens were c o n d i t i o n e d and t e s t e d a t

lib p H i n a s p e c i a l l y c o n s t r u c t e d e n v i r o n m e n t a l chamber. Data

demonstrated dependence of the f r a c t u r e p a r a m e t e r s on microhardness

.

E f f e c t of morphology and o t h e r micros t r u c t u r a l f e a t u r e s on f r a c t u r e i nHAC p a s t e is a l s o d i s c u s s e d . Some e v i d e n c e s u p p o r t i n g argument f o r t h e v a l i d i t y of a p p l y i n g l i n e a r - e l a s t i c f r a c t u r e mechanics i n s t u d y i n g f r a c t u r e i n b r i t t l e c e m e n t i t i o u s systems i s p r e s e n t e d .

RESUME

p a r t i r d q C p r o u v e t t e s h encoche pCriphCrique s i m p l e pour e s s a i s de f l e x i o n , on a determind l e s parametres de m i c r o d u r e t g e t de r u p t u r e d e p l u s i e u r s s y s t3mes de p h t e de ciment alumineux c o n t e n a n t d i f f e r e n t e s p r o p o r t i o n s de phases hexagonales e t cubiques. Les Cprouve t t e s o n t Ct6 conditionnCes e t m i s e s h l ' e s s a i 2 11% d ' h u m i d i t g r e l a t i v e dans un c o n t e n a n t s p g c i a l e m e n t c o n s t r u i t

2

c e t ef f e t . Les donnCes o n t montrg que l e s p a r a m e t r e s d e r u p t u r e C t a i e n t f o n c t i o n de l a m i c r o d u r e t e . Onexamine a u s s i l ' e f f e t de l a morphologie e t a u t r e s c a r a c t C r i s t i q u e s de l a m i c r o s t r u c t u r e s u r l a r u p t u r e dans l a p a t e de ciment alumineux. On

prCsente d e s f a i t s venant c o r r o b o r e r l ' a r g u m e n t s e l o n l e q u e l il e s t

v a l a b l e d'employer l a mgcanique de r u p t u r e l i n C a i r e - C l a s t i q u e pour C t u d i e r l a r u p t u r e dans l e s s y s tPmes de l i a n t s f r a g i l e s .

I n t r o d u c t i o n

High alumina cement (HAC) c o n s i s t s of approximately e q u a l p a r t s of alumina and lime, a b o u t 40% each, w i t h f e r r o u s and f e r r i c o x i d e s and up t o 5% s i l i c a . I t comprises s e v e r a l phases, v i z . , CA, C % , C I 2 A 7 , C2AS, C2S, C2F and C,+AF, b u t the main c e m e n t i t i o u s compounds a r e CA and C12A7

.*

The h y d r a t i o n*In cement chemistry nomenclature: C = CaO, A = A1203, S = S i 0 2 , F = Fe20g, H = H20.

J . J . Beaudoin

Vol. 1 2 , No. 3

p r o d u c t s of CA c o n s i s t of CAH1

,,

,

C2A%, C 3 q and AH3 ( g e l o r c r y s t a l l i n e ) , t h e r e l a t i v e p r o p o r t i o n s depending on t h e hydra t i o n c o n d i t i o n s and c u r i n g p e r i o d . A t lower t e m p e r a t u r e s CAHIO and C 2 q ( b o t h hexagonal p h a s e s ) and AH3 g e l a r e p r e f e r e n t i a l l y formed, and a t h i g h e r t e m p e r a t u r e s a r e c o n v e r t e dt o C3AH6 and g i b b s i t e . Most a t t e m p t s t o e x p l a i n s t r e n g t h g a i n o r l o s s have r e l a t e d t o t h e r e l a t i v e amounts of calcium a l u m i n a t e h y d r a t e i n t h e h y d r a t e d p r o d u c t s . Formation of C 3 q has been a s s o c i a t e d w i t h s t r e n g t h d e c r e a s e , a l t h o u g h under c e r t a i n c o n d i t i o n s i n c r e a s e d s t r e n g t h has been o b t a i n e d ( 1 )

A p p l i c a t i o n s of HAC i n c l u d e s u l p h a t e - r e s i s t a n t cements, b o r e h o l e p l u g g i n g cements

,

f a s t-se t t i n g p a t c h i n g compounds, rock a n c h o r s , g r o u t i n g , c o l d t e m p e r a t u r e c o n c r e t i n g , and r e f r a c t o r i e s . R e c e n t l y , HAC has been used i n s t e a d of CaC12 a s a n a c c e l e r a t o r .I n t h e p a s t decade f i b r e - r e i n f o r c e d cement composites having a v a r i e t y of cement-based m a t r i c e s and o r g a n i c and i n o r g a n i c f i b r e s have proved p a r t i c u - l a r l y u s e f u l i n some r e p a i r a p p l i c a t i o n s . W i t h i n 24 h HAC d e v e l o p s high compressive s t r e n g t h and a p p e a r s t o be a good c a n d i d a t e f o r s u c h a p p l i c a - t i o n s . F i b r e - r e i n f o r c e d cement composites, when compared t o u n r e i n f o r c e d s y s tems, g e n e r a l l y have i n c r e a s e d f l e x u r a l s t r e n g t h and f r a c t u r e toughness, i . e . , r e s i s t a n c e t o c r a c k i n i t i a t i o n and p r o p a g a t i o n . As t h e m a t r i x p l a y s an i m p o r t a n t r o l e i n composite behaviour, knowledge of i t s f r a c t u r e p r o p e r t i e s is n e c e s s a r y f o r u n d e r s t a n d i n g t h a t behaviour. There i s , however, a d e a r t h of i n f o r m a t i o n on f r a c t u r e of non-portland cements and f o r HAC systems t h e r e a p p e a r t o be few p u b l i s h e d d a t a .

The p o s s i b i l i t y of u s i n g m i c r o h a r d n e s s measurements t o p r e d i c t f r a c t u r e mechanics parameters i n non-porous s o l i d s , e.g., soda-lime g l a s s , has been e x p l o r e d w i t h some s u c c e s s (2,3). The o b j e c t i v e of t h e p r e s e n t s t u d y was t o o b t a i n e x p e r i m e n t a l d a t a on t h e f r a c t u r e behaviour of HAC and t o i n v e s t i g a t e t h e p o s s i b l e dependence of s e v e r a l f r a c t u r e mechanics e x p r e s s i o n s ( c r i t i c a l v a l u e s of s t r e s s i n t e n s i t y f a c t o r , s t r a i n energy r e l e a s e r a t e , J - i n t e g r a l , work of f r a c t u r e ) on microhardness.

I n d e n t a t i o n F r a c t u r e

T h i s s e c t i o n i s i n c l u d e d t o p r o v i d e a b a s i s f o r t h e e x p e c t a t i o n of a dependence of f r a c t u r e p r o p e r t i e s on microhardness. The p r i n c i p l e s and a p p l i c a t i o n s of i n d e n t a t i o n f r a c t u r e have been reviewed, p r i n c i p a l l y by Lawn and Wilshaw ( 4 ) and o n l y a few s a l i e n t p o i n t s w i l l be d i s c u s s e d . The c a r d i n a l f e a t u r e s of Lawn and Wilshaw's approach, upon which f r a c t u r e mechan- ics a n a l y s i s was based, a r e :

(1) t h e s h a r p p o i n t of t h e i n d e n t o r produces a n i n e l a s t i c d e f o r m a t i o n zone; ( 2 ) a deformation-induced f l a w suddenly d e v e l o p s i n t o a s m a l l c r a c k ( c a l l e d median v e n t ) on a p l a n e of symmetry c o n t a i n i n g t h e c o n t a c t a x i s ; ( 3 ) i n c r e a s e d l o a d c a u s e s f u r t h e r s t a b l e growth of t h e median v e n t ;

(4)

on u n l o a d i n g t h e median v e n t d o e s n o t c o m p l e t e l y c l o s e and l a t e r a l v e n t s begin t o develop. F i g u r e 1 i l l u s t r a t e s v e n t c r a c k f o r m a t i o n under a s h a r p i n d e n t o r ( 4 ) . C a l c u l a t i o n s approximating t h e s t r e s s f i e l d b e n e a t h t h e i n d e n t o r by a Boussinesq e l a s t i c f i e l d ( e x c l u d i n g t h e small d i s t u r b e d zone b e n e a t h t h e i n d e n t o r ) where t h e d e p t h of t h e median v e n t , c , i s much g r e a t e r t h a n t h e d e p t h of t h e d i s t u r b e d zone r e s u l t i n t h e f o l l o w i n g e x p r e s s i o n f o r s t r a i n energy r e l e a s e r a t e :G = (1-v2) [ ( ~ - ~ v ) ~ / u T ~ ] ( a / f i 2 ) (HIE) P/c

Vol. 1 2 , No. 3

MICROHARDNESS, FRACTURE, ALUMINATE CEMENT

FIG. 1

Schematic of Lawn's model of v e n t c r a c k f o r m a t i o n under p o i n t i n d e n t a t i o n . Dark r e g i o n is i n e l a s t i c d e f o r m a t i o n zone ( 2 )

of e l a s t i c i t y , H is m i c r o h a r d n e s s , P i s a p p l i e d l o a d and a and 0 a r e

d i m e n s i o n l e s s g e o m e t r i c a l f a c t o r s .

The r a t i o P / c h a s been found t o be c o n s t a n t . For many porous c e m e n t i t i o u s m a t e r i a l s E and H a r e e m p i r i c a l l y r e l a t e d by a n e x p r e s s i o n of t h e form E = kHn (k and n a r e c o n s t a n t s ) ( 5 ) . Thus, i t might be e x p e c t e d from e q . (1) t h a t G would b e r e l a t e d t o m i c r o h a r d n e s s through a power law r e l a t i o n . I t i s assumed t h a t t h e c r a c k is i d e a l l y Hookean and t h a t l i n e a r e l a s t i c i t y t h e o r y a p p l i e s , and, t h e r e f o r e , l i n e a r e l a s t i c f r a c t u r e mechanics (LEFM)

.

A p p l i c a t i o n of F r a c t u r e Mechanics t o Cement P a s t e Sys tems The m a j o r i t y of f r a c t u r e mechanics s t u d i e s of cement p a s t e s y s t e m s , u s u a l l y p o r t l a n d cement p a s t e , have been conducted i n t h e l a s t decade (6). D a t a a r e o f t e n c o n f l i c t i n g , and t h e r e i s d i s a g r e e m e n t c o n c e r n i n g t h e a p p l i c a - b i l i t y of LEFM and t h e r e l a t i v e m e r i t s of e x p r e s s i o n s d e s c r i b i n g f r a c t u r e behaviour. There

i s

a l s o d i s a g r e e m e n t c o n c e r n i n g t h e c r a c k p r o p a g a t i n g mechanism i n c e m e n t i t i o u s m a t e r i a l s . The b a s i c i s s u e is one of b r i t t l e n e s s v e r s u s d u c t i l i t y i n t h e c r a c k t i p zone. There a r e two major s c h o o l s of thought. One assumes a n i d e a l l y s h a r p c r a c k i n which f r a c t u r e p r o c e e d s by p r o g r e s s i v e r u p t u r e of c o h e s i v e bonds a c r o s s a s e p a r a t i o n p l a n e , c r e a t i n g new s u r f a c e a r e a i n a r e v e r s i b l e manner. The o t h e r s c h o o l p o s t u l a t e s t h a t t h e macroscopic " p l a s t i c - z o n e " c o n c e p t d e s c r i b i n g t h e c r a c k t i p r e g i o n of some metals and polymersis

a p p l i c a b l e t o ceramic m a t e r i a l s on a m i c r o s c a l e . The c o n t r o v e r s y remains u n r e s o l v e d . There a p p e a r s t o be, however, a u n i v e r s a l concensus t h a t , whatever t h e e x t e n t of t h e v a l i d i t y of LEFM t o b r i t t l e f r a c - t u r e , t h e i n f o r m a t i o n g a t h e r e d h a s been v a l u a b l e i n b o t h c h a r a c t e r i z i n g m a t e r i a l s and p r o v i d i n g i n p u t t o t h e d e s i g n p r o c e s s .Some c r i t i c s have s u g g e s t e d t h a t f r a c t u r e terms c a l c u l a t e d u s i n g maximum l o a d v a l u e s ( o b t a i n e d from l o a d - d e f l e c t i o n c u r v e s ) a r e e s s e n t i a l l y i n d i c a t o r s of r e s i s t a n c e t o c r a c k " i n i t i a t i o n " and d o n o t n e c e s s a r i l y a s s e s s r e s i s t a n c e t o c r a c k "propagation." The t o t a l work of f r a c t u r e , however, determined by i n t e g r a t i o n of b o t h a s c e n d i n g and d e s c e n d i n g b r a n c h e s of l o a d - d e f l e c t i o n t r a c e , r e f l e c t s r e s i s t a n c e t o b o t h c r a c k i n i t i a t i o n and p r o p a g a t i o n . I n t e g r a t i o n of a r e a s u n d e r t h e a s c e n d i n g b r a n c h only r e f l e c t s r e s i s t a n c e t o c r a c k i n i t i a t i o n . E x p e r i m e n t a l M a t e r i a l s

The c o m p o s i t i o n of t h e HAC was a s f o l l o w s : A1203 = 40.02%; Fe203 = 17.71%; CaO = 37.26%; Si02 = 3.46%; MgO = 0.91%; SO3 = 0.08%; Na20 = 0.08%; K20 = 0.08%. B l a i n e f i n e n e s s was 394 &/kg.

V o l . 1 2 , No. 3

J

.

J.

BeaudoinE i g h t s e r i e s of samples were prepared. Each c o n s i s t e d of a s e t of samples f o r t h e f o l l o w i n g waterlcement r a t i o s : 0.25, 0.30, 0.35, 0.40, 0.45 and 0.50. Mixes were c a s t i n moulds 1.2 x 7.5 x 20 cm t h a t were f i t t e d w i t h m e t a l shims 0.6 x 0.025 cm t h i c k ( r u n n i n g t h e l e n g t h of t h e mould) t o p r o v i d e a p r e c a s t c r a c k i n t h e specimen. The samples were removed a f t e r 3 d a y s a t 100% RH and sawn a t 0.127 cm i n t e r v a l s a l o n g t h e i r l e n g t h t o produce t h e f i n a l t e s t specimens. Thus, t h e t e s t p i e c e was a beam 1.2 cm deep x 0.127 cm t h i c k x 7.5 cm long w i t h a mid-span n o t c h 0.025 cm wide x 0.6 cm deep. A l l

beam samples were s t o r e d a t 11% RH f o r a minimum of 14 d a y s p r i o r t o t e s t i n g o r p r e t r e a t m e n t . * Various t r e a t m e n t s a r e summarized i n Table I. T h e i r o b j e c t i v e was t o produce systems having v a r i e d amounts of hexagonal and c u b i c phases.

The systems were c h a r a c t e r i z e d u s i n g a d i f f e r e n t i a l s c a n n i n g c a l o r i m e t e r (DSC). Within e a c h s e r i e s t h e r a t i o of peak h e i g h t s a t approximately 300 and 140 t o 155OC was k e p t constant.** Endothermic peaks a t 300 and 140 t o 155OC r e p r e s e n t t h e thermal decomposition of c u b i c and hexagonal p h a s e s ,

r e s p e c t i v e l y . I n s e r i e s 1 t o 5 t h e peak a t 140 t o 155'C d e c r e a s e d w i t h l e n g t h of h e a t t r e a t m e n t a t 80°C due t o d e h y d r a t i o n of CAHL0.

Technique DSC

D i f f e r e n t i a l thermograms of t h e samples were o b t a i n e d by DSC s u p p l i e d a s a module t o Du Pont 900 thermal a n a l y s i s system. T h i s u n i t u t i l i z e s chromel- cons t a n t a n thermocouples f o r d i f f e r e n t i a l t e m p e r a t u r e measurement. The r e f e r e n c e m a t e r i a l was i g n i t e d cr-A1203 and t h e h e a t i n g r a t e 20°C

min-l .

The d i f f e r e n t i a l temperature was r e g i s t e r e d a t a s e n s i t i v i t y of 0.02 mV in.'l. Thermograms were o b t a i n e d i n a i r , and i n e a c h e x p e r i m e n t 20 mg of t h e sample was s u b j e c t e d t o a n a l y s i s .Microhardness

Hardness was measured w i t h a L e i t z m i n i l o a d t e s t e r i n a c o n d i t i o n e d box (11% RH) f r e e of C02 u s i n g t h e Vickers pyramid i n d e n t o r . F i v e d e t e r m i n a t i o n s were performed on t h e s u r f a c e of e a c h sample.

F r a c t u r e T e s t i n g

An e n v i r o n m e n t a l chamber (Fig. 2) was mounted on t h e cross-head of an I n s t r o n t e s t i n g machine (10,000 kg c a p a c i t y ) . Notched beam specimens c o n d i t i o n e d t o 11% RH were simply supported i n i t and loaded a t t h e mid- p o i n t . The mid-span d e f l e c t i o n was measured u s i n g an LVDT w i t h a r e a d o u t a c c u r a t e t o 0.0001 mm. The cross-head s p e e d was 0.005 mm/min. Load- d e f l e c t i o n c u r v e s were o b t a i n e d from t h e I n s t r o n c h a r t r e c o r d s ; t h e maximum l o a d s were g e n e r a l l y l e s s t h a n 1 kg ( t h e s t i f f n e s s of t h e I n s t r o n machine is extremely l a r g e r e l a t i v e t o t h e f l e x u r a l s t i f f n e s s of t h e t e s t p i e c e s ) .

* S t r e n g t h and f r a c t u r e of hydrated cements a r e humidity dependent. The 11% RH c o n d i t i o n minimizes t h e r i s k of c a r b o n a t i o n , f u r t h e r h y d r a t i o n , e x c e s s volume change and i s a c o n v e n i e n t r e f e r e n c e s t a t e .

**This was achieved by p r e - s e l e c t i n g t r e a t m e n t times from t h e r e s u l t s of time s e q u e n t i a l DSC r u n s , i . e . , t r e a t m e n t times f o r samples were i n c r e a s e d i n c r e m e n t a l l y u n t i l t h e d e s i r e d DSC peak r a t i o was a t t a i n e d .

Vol. 1 2 , No. 3 293 MICROHARDNESS, FRACTURE, ALUMINATE CEMENT

TABLE I D e s c r i p t i o n of Sample Treatments f o r F r a c t u r e S t u d i e s S e r i e s Treatment 100% RH, 3 d; 11% RH, 21°C 100% RH, 3 d; 11% RH, 21°C; vacuum 3 h, 80°C; 11% RH 100% RH, 3 d; 11% RH, 21°C; vacuum 6 h, 80°C; 11%

RH

100% RH, 3 d ; 11% RH, 21°C; vacuum 24 h, 80°C; 11% RH 100% RH, 3 d ; 11% RH, 21°C; vacuum 21 d, 80°C; 11% RH 100% RH, 3 d; 11% RH, 21°C; 100% RH, 80°C; 11%RH

100% RH, 3 d; 11%RH,

21°C; 100% RH, 80°C; 11%RH

100% RH, 3 d; 11% RH, 2 1 ' ~ ; a u t o c l a v e d , 216OC; 11% RH Very l i t t l e c u b i c phase Mostly hexagonal i n o r d e r 1 2 3 4 5Cubic and hexagonal approximately e q u a l Approx. 80% c u b i c 20% hexagonal Mostly c u b i c

*For s e r i e s 6 and 7 t h e times a t 100% RH, 80°C, v a r i e d w i t h water/cement r a t i o from a b o u t 1 0 t o 25 min. S e r i e s 7 was

t r e a t e d f o r l o n g e r p e r i o d s .

**Approximations made by e s t i m a t i n g DSC peak h e i g h t s a t 300°C

'allowing i s a d e s c r i p t i o n of the e x p r e s s i o n s d e f i n i n g t h e c o n d i t i o n s of i r a c t u r e and t h e i r method of d e t e r m i n a t i o n from l o a d - d e f l e c t i o n curves: 1 Kc: S t r e s s i n t e n s i t y f a c t o r , K, has been d e s c r i b e d a s a s i n g l e -

parameter d e s c r i p t i o n of t h e s t r e s s and d i s p l a c e m e n t f i e l d s i n t h e r e g i o n of t h e c r a c k t i p . The c r i t i o a l s t r e s s i n t e n s i t y f a c t o r , Kc, i s t h e v a l u e of K f o r u n s t a b l e f r a c t u r e .

For mid-point l o a d i n g of s i n g l e e d g e n o t c h e d f l e x u r a l specimens ( 7 ) Kc = Y 312 (pmaxt%/(b.d2)

where

Y = 1.93

-

3.07 a / d+

14.53 (a/d12-

25.11 ( a ~ d ) ~+

25.8 ( a / d ) 4 Pmax = maximum l o a d ; t = l e n g t h of beam; a = l e n g t h of notch;2 9 4 J . J . Beaudoin Vol. 1 2 , No. 3 FIG. 2 F r a c t u r e - t e s t i n g a r r a n g e m e n t showing e n v i r o n m e n t a l chamber mounted on cross-head of I n s t r o n machine ( 2 ) Gc: S t r a i n e n e r g y r e l e a s e r a t e , G , i s a m a t e r i a l c o n s t a n t d e p e n d i n g on t h e p h y s i c a l p r o c e s s e s o c c u r r i n g a t t h e c r a c k t i p and i s e q u a l t o t w i c e t h e f r a c t u r e s u r f a c e e n e r g y p e r u n i t a r e a . C r i t i c a l s t r a i n e n e r g y r e l e a s e r a t e i s d e s i g n a t e d Gc. The dependence of c o m p l i a n c e ( r a t i o of c e n t r e - s p a n d e f l e c t i o n t o l o a d ) on c r a c k l e n g t h was d e t e r m i n e d a t e a c h w a t e r l c e m e n t r a t i o f o r e v e r y s e r i e s . For a g i v e n c r a c k l e n g t h s a m p l e s w e r e l o a d e d t o a b o u t 70% of t h e maximum d u r i n g e a c h l o a d i n g c y c l e . A f t e r a compliance d e t e r m i n a t i o n t h e c r a c k was e x t e n d e d u s i n g a saw and t h e c o m p l i a n c e f o r t h e new c r a c k was d e t e r m i n e d . Gc was c a l c u l a t e d a c c o r d i n g t o t h e f o l l o w i n g e x p r e s s i o n :

Gc =

PL,

( d ~ / d a ) 12b wherePmax = maximum l o a d ; C = compliance; a = c r a c k l e n g t h ;

b = beam w i d t h .

(3) Jc: J i s a p a t h i n d e p e n d e n t l i n e i n t e g r a l d e s c r i b i n g t h e c r a c k t i p s t r e s s - s t r a i n f i e l d i n t e n s i t y u n d e r e l a s t i c - p l a s t i c c o n d i t i o n s . For e l a s t i c b o d i e s t h e c r i t i c a l v a l u e of J - i n t e g r a l e q u a l s Gc, i . e . ,

Jc = Gc.

T h i s c a l c u l a t i o n r e q u i r e s load-def lec t i o n c u r v e s f o r b o t h n o t c h e d and u n n o t c h e d samples.

where

An = a r e a u n d e r l o a d - d e f l e c t i o n c u r v e u p t o maximum l o a d , P,, f o r n o t c h e d sample;

Vol.

12,

No. 3MICROHARDNESS, FRACTURE, ALUMINATE CEMENT

Au = a r e a u n d e r l o a d - d e f l e c t i o n c u r v e of t h e unnotched sample up

t o t h e maximum l o a d , P,,, which was determined f o r t h e

n o t c h e d sample;

b = specimen width.

( 4 ) Work of f r a c t u r e , yT: T h i s term i s d e t e r m i n e d by d i v i d i n g t h e a r e a u n d e r t h e t o t a l l o a d - d e f l e c t i o n c u r v e by t h e a r e a of t h e uncracked beam l i g a m e n t ( b . { d - a ) ) . y~ r e p r e s e n t s t h e work of f r a c t u r e f o r c r a c k i n i t i a t i o n and p r o p a g a t i o n . The a r e a u n d e r t h e a s c e n d i n g p o r t i o n of t h e l o a d - d e f l e c t i o n c u r v e c a n a l s o be d e t e r m i n e d , and when t h i s a r e a i s d i v i d e d by t h e uncracked l i g a m e n t a r e a a n e s t i m a t e of t h e work of f r a c t u r e f o r c r a c k i n i t i a t i o n , y

i,

i s o b t a i n e d . FIG. 3 P l o t of s t r e s s i n t e n s i t y f a c t o r ,E

Kc v e r s u s microhardness f o r2

20 v a r i o u s HAC p r e p a r a t i o n s + 5 V) V) u, E VI 20 30 40 50 60 70 80 90 !OOMICROHARDNESS. H x lo-', MPa

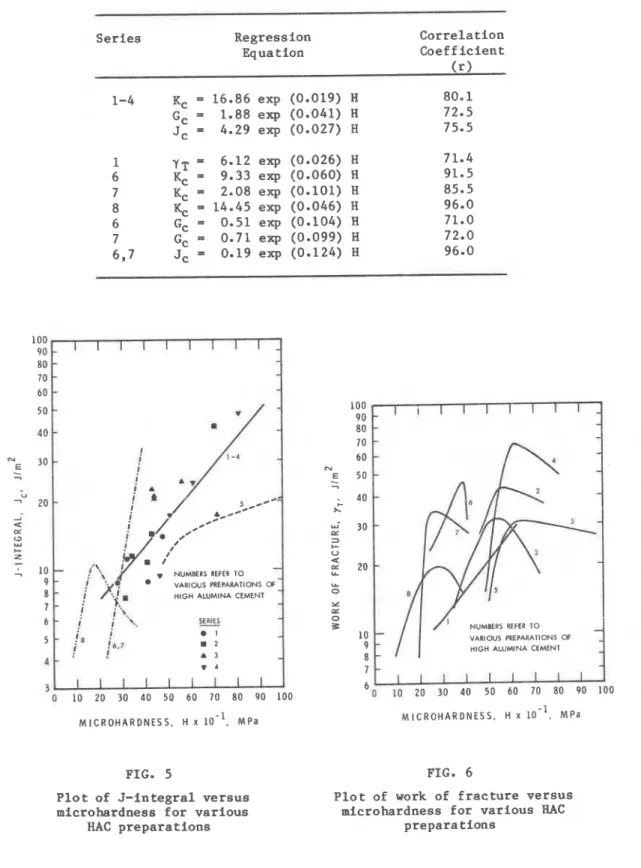

O b s e r v a t i o n s Dependence of F r a c t u r e Terms on Microhardness

F r a c t u r e t e r m s , K c , G c , J C a n d y T , a r e p l o t t e d a g a i n s t

m i c r o h a r d n e s s , H, f o r s e r i e s 1-8 p r e p a r a t i o n s ( F i g s . 3-6). There is a l i n e a r dependence of l o g a r i t h a s on m i c r o h a r d n e s s f o r many of t h e terms; some depen- dences a r e non-linear. R e g r e s s i o n a n a l y s i s f o r t h e l i n e a r c u r v e s i s presen- t e d i n T a b l e 11, and c a n g e n e r a l l y be d e s c r i b e d a s f o l l o w s : semi-log p l o t s of Kc, Gc and Jc v e r s u s H f o r s e r i e s 1 t o 4 a r e l i n e a r , and v a l u e s of

t h e s e terms i n c r e a s e w i t h microhardness. One c u r v e f o r e a c h f r a c t u r e term

f i t s t h e d a t a f o r s e r i e s 1 t o 4. A semi-log p l o t of y, v e r s u s H f o r s e r i e s 1 i s a l s o l i n e a r . A l l o t h e r l o g y v e r s u s H c u r v e s ( s e g i e s 2 t o 8 ) a r e non- l i n e a r and i n c r e a s e t o a maximum v a l u e , t h e n d e c r e a s e a s H i n c r e a s e s . The l o g

(

K c,

J c,

Gc, yT) v e r s u s H c u r v e s f o r s e r i e s 5 a r e n o n - l i n e a r andg e n e r a l l y i n c r e a s e t o a maximum v a l u e a s H i n c r e a s e s ; f o r yT and Gc they

s u b s e q u e n t l y d e c r e a s e w i t h i n c r e a s i n g H. The c u r v e , l o g K, v e r s u s H f o r

s e r i e s 8, i s l i n e a r and l o g

K,

i n c r e a s e s w i t h H. Log ( J c , Gc, Y ~ )f o r system 8 i n c r e a s e s , however, t o a maximum and t h e n d e c r e a s e s a s h a r d n e s s

i n c r e a s e s . Log ( K ~ , Gc, Jc) v e r s u s H c u r v e s f o r s e r i e s 6 and 7 a r e

a l s o l i n e a r and e a c h c u r v e has a g r e a t e r s l o p e t h a n t h e c u r v e f o r s e r i e s 1 t o 4.

J . J . Beaudoin Vol. 1 2 , No. 3 I I I t r J . . I I 1 1 -1 : ; i'd

-

7 . . N E 30-

U C ) - 2 0 - C 4 (LHIGH ALUMINA CEMENT

.

I m 2 A 3 v 4 1 . 1 ~ [ I I I I I 0 10 20 30 40 5 0 60 70 80 90 100 FIG.4

P l o t of s t r a i n energy r e l e a s e r a t e v e r s u s microhardness f o r v a r i o u s KAC p r e p a r a t i o n s MICROHARONESS. H x l o - ' , MPa D i s c u s s i o nI n t h i s s t u d y f r a c t u r e terms ( K c Gc, J,) f o r HAC systems a r e dependent: on microhardness, i n agreement w i t h measurement of i n d e n t a t i o n f r a c t u r e of non-porous ceramic bodies. Hydrated

HAC

s y s tems c o n t a i n i n g m i x t u r e s of hexagonal p h a s e s and c u b i c p h a s e s had l a r g e r i n c r e a s e s i n t h e s e f r a c t u r e terms f o r an e q u i v a l e n t microhardness change than t h e s y s tems c o n s i s t i n g mainly of hexagonal p h a s e s alone.A p o s s i b l e e x p l a n a t i o n of t h i s behaviour i s t h a t t h e d e n s e r c u b i c phase ( d e n s i t y of C AH6 = 2.52; CAH = 1.75) o c c u r s a s f i n e l y d i s p e r s e d i n c l u s i o n s t h a t modify t i e s t r e s s f i e l d i n t h e m a t e r i a l and a c t a s c r a c k a r r e s t o r s . The ( K c G,, J,) v e r s u s microhardness c u r v e s f o r t h e mixed morphology p r e p a r a t i o n s c r o s s t h e c u r v e s f o r p r e p a r a t i o n s c o n s i s t i n g mainly of hexagonal phases. A t lower m i c r o h a r d n e s s v a l u e s mixed morphology systems have lower f r a c t u r e v a l u e s , p o s s i b l y owing t o t h e r e l a t i v e e a s e of c r a c k i n i t i a t i o n and p r o p a g a t i o n through weak a r e a s a t p o i n t s of i n t e r p a r t i c l e c o n t a c t .

The r a t e of change of Kc w i t h h a r d n e s s f o r t h e p r e p a r a t i o n c o n t a i n i n g mainly c u b i c phase i s a l s o g r e a t e r t h a n t h e mainly hexagonal systems. Gc and Jc f o r t h e c u b i c m a t e r i a l i n c r e a s e w i t h h a r d n e s s i n t h e same manner a s do the mixed morphology systems, b u t d e c r e a s e a t h i g h e r microhardness v a l u e s . The d e c r e a s e may be due t o pore-crack, i n t e r a c t i o n . F r a c t u r e toughness may be dependent on c r a c k - a r r e s t i n g p r o p e r t i e s of p o r e s a s w e l l a s on t o t a l p o r o s i t y (8). Values of Kc f o r some porous c e r a m i c s , e.g., b e r y l l i u m , i n c r e a s e t o a maximum and t h e n d e c r e a s e a s s t r e n g t h i n c r e a s e s ( 9 ) .

Vol. 1 2 , No. 3 297 MICROHARDNESS, FRACTURE, ALUMINATE CEMENT

TABLE I1 R e g r e s s i o n A n a l y s i s of Fracture-Microhardness Data S e r i e s R e g r e s s i o n C o r r e l a t i o n E q u a t i o n C o e f f i c i e n t ( r ) 1-4 K, = 16.86 exp (0.019) H G, = 1.88 exp (0.041)

H

J, = 4.29 exp (0.027) H 1 y~ = 6.12 exp (0.026)H

6 K, =9.33

exp (0.060)H

7 K, = 2.08 exp (0.101)H

8K,

= 14.45 exp (0.046)H

6 Gc = 0.51 exp (0.104) H 7 Gc = 0.71 exp (0.099)H

6,7 J, = 0.19 exp (0.124) H 100 9 0 - I II

'

I I' -

80-

70-

60-

50-

00-

7 ! I . U-

20-

i i 1. I i a a C3 Y,-

Z-

.

NUMBERS REFER TO H l G H ALUMINA CEMENT ' t I 2 4-

a 3-

. 4 3 1 I f l I I I I I 0 10 20 30 40 50 60 70 80 90 100 VARIOUS PREPARATIONS OF HlGH ALUMINA CEMENTM I C R O H A R D N E S S , H x lo-', M P a M I C R O H A R D N E S S , H x lo-', MPa

FIG. 5 FIG. 6

P l o t of J - i n t e g r a l v e r s u s P l o t of work of f r a c t u r e v e r s u s microhardness f o r v a r i o u s m i c r o h a r d n e s s f o r v a r i o u s HAC

Vol. 1 2 , No. 3 3.5. Beaudoin

1 -1

HIGH ALUMINA CEMENT PREPARATIONS

-

-

SERIES-

1 m 2-

A 3 v 4 0 5-

0 6 A 7 V 8-

-

REGRESSION LINE Jc= 5.07 + 0.70 G, FIG. 7 P l o t of J - i n t e g r a l v e r s u s s t r a i n energy r e l e a s e r a t e f o r v a r i o u s HAC p r e p a r a t i o n s S T R A I N E N E R G Y R E L E A S E R A T E , G c . J l m 2I t i s a p p a r e n t t h a t i n cement s y s terns micros t r u c t u r a l f e a t u r e s , e.g., p o r o s i t y , pore s t r u c t u r e , d e n s i t y , c r y s t a l l i n i t y and morphology, may a f f e c t

t h e dependence of t h e f r a c t u r e terms on microhardness. Two p i e c e s of e v i d e n c e s u p p o r t t h e a p p l i c a t i o n of l i n e a r f r a c t u r e mechanics and t h e bond r u p t u r e p r o c e s s f o r t h e m a t e r i a l s s t u d i e d .

(1) Measured v a l u e s of G, f o r c e r a m i c m a t e r i a l s and f o r t h e HAC systems s t u d i e d approach v a l u e s of 2-y w i t h i n a f a c t o r of two o r t h r e e ( s e e T a b l e 111). Gc is s e v e r a l o r d e r s of magnitude i n e x c e s s of 2y f o r m e t a l l i c and polymeric m a t e r i a l s , which f r a c t u r e a c c o r d i n g t o a p l a s t i c c r a c k - t i p s e p a r a t i o n p r o c e s s . ( 2 ) I d e a l l y , i f l i n e a r e l a s t i c p r o c e s s e s a r e i n v o l v e d i n f r a c t u r e , Jc = Gc. F i g u r e 7 i s a p l o t of Jc v e r s u s Gc f o r t h e HAC s y s t e m s . The d a t a p o i n t s a r e p o s i t i o n e d a b o u t t h e " l i n e of e q u a l i t y . " R e g r e s s i o n a n a l y s i s g i v e s a l i n e , Jc = 5.07

+

0.700 Gc w i t h c o r r e l a t i o n c o e f f i c i e n t = 79.3%. TABLE 111 R a t i o of ~ , / y f o r V a r i o u s M a t e r i a l s Reference M a t e r i a l s HAC S e r i e s * - - - - *Values f o r e a c h s e r i e s a r e a v e r a g e v a l u e s f o r v a r i o u s w/c p r e p a r a t i o n sVol. 12, No. 3

MICROHARDNESS, FRACTURE, ALUMINATE CEMENT

Conclusions

1. There i s a r e l a t i o n between f r a c t u r e b e h a v i o u r of high alumina cement systems and microhardness. T h i s means t h a t i t may be p o s s i b l e t o e s t i m a t e t h e v a l u e s of t h e f r a c t u r e terms from microhardness measurements.

2. The r e l a t i o n between t h e f r a c t u r e terms and microhardness i s dependent on t h e morphology of t h e h y d r a t i o n p r o d u c t s .

3. Mixed morphology (hexagonal and c u b i c p h a s e s ) systems have g r e a t e r

f r a c t u r e toughness than systems c o n t a i n i n g mainly hexagonal phases e x c e p t a t low v a l u e s of microhardness.

4. Non-linear r e l a t i o n s between l o g a r i t h n s of work of f r a c t u r e and micro- hardness a r e o b t a i n e d f o r most systems. N o n - l i n e a r i t y may r e s u l t from energy d i s s i p a t i o n p r o c e s s e s due t o pore-crack i n t e r a c t i o n .

5. Approximate e q u i v a l e n c e of J - i n t e g r a l and s t r a i n energy r e l e a s e r a t e s u p p o r t s t h e assump t i o n t h a t l i n e a r e l a s t i c f r a c t u r e mechanics i s a p p l i c - a b l e high alumina cement p a s t e s y s terns.

References

1. V.S. Ramachandran and R.F. Feldman. Cem. Concr. Res.

3,

729 (1973)- 2.B.

Lawn and E.R. F u l l e r . J. Mats. Sci.,10,

2016 (1975).3.

B.

Lawn and M. Swain. J. Mats. Sci.,10,

113 (1975). 4.B.

Lawn and R. Wilshaw. J. Mats. S c i . , 1 0 , 1 0 4 9 (1975).5.

J.J. Beaudoin and R.F. Feldman. Cem. Concr. Res.5,

103 (1975).6. S. Mindess. Mats. Res. Ser. ( 2 ) , U n i v e r s i t y of B r i t i s h Columbia, p. 95 (1981).

7.

B.

Gross and J. Srawley. ASTM STP 410, 1 3 (1966).8. R.W. Rich. I n T r e a t i s e on M a t e r i a l s S c i e n c e and Technology, Vol. 11, Acad. P r e s s , Chapt. 4, 1977, p. 200, (ed. by R.K. MacCrone).

9. R.E. Cooper. Atomic Weapons Research E s t a b l i s h m e n t , Report 017/72, U . K . , Atom. Ener. Auth. 40, (1972)

Acknowledgement

The a u t h o r a c k n w l e d g e s t h e s k i l f u l a s s i s t a n c e of J. Wood i n c o n d u c t i n g t h e e x p e r i m e n t a l work.

T h i s paper is a c o n t r i b u t i o n from t h e D i v i s i o n of B u i l d i n g Research, N a t i o n a l Research Council of Canada, and i s p u b l i s h e d w i t h t h e a p p r o v a l of