Publisher’s version / Version de l'éditeur:

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

Research Report (National Research Council of Canada. Institute for Research in

Construction), 2009-09-01

READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE. https://nrc-publications.canada.ca/eng/copyright

NRC Publications Archive Record / Notice des Archives des publications du CNRC :

https://nrc-publications.canada.ca/eng/view/object/?id=611f4283-1cc2-441d-9a60-15c68d1ca63b https://publications-cnrc.canada.ca/fra/voir/objet/?id=611f4283-1cc2-441d-9a60-15c68d1ca63b

NRC Publications Archive

Archives des publications du CNRC

For the publisher’s version, please access the DOI link below./ Pour consulter la version de l’éditeur, utilisez le lien DOI ci-dessous.

https://doi.org/10.4224/20374391

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at

A Review of Existing Tools and their Applicability to Facility

Maintenance Management

A Review of Existing Tools and their Applicability to Facility

Maintenance Management

Report # RR-285

Neelamkavil, J

September 2009

The material in this document is covered by the provisions of the Copyright Act, by Canadian laws, policies, regulations and international agreements. Such provisions serve to identify the information source and, in specific instances, to prohibit reproduction of materials without written permission. For more information visit http://laws.justice.gc.ca/en/showtdm/cs/C-42

Les renseignements dans ce document sont protégés par la Loi sur le droit d'auteur, par les lois, les politiques et les règlements du Canada et des accords internationaux. Ces dispositions permettent d'identifier la source de l'information et, dans certains cas, d'interdire la copie de documents sans permission écrite. Pour obtenir de plus amples renseignements : http://lois.justice.gc.ca/fr/showtdm/cs/C-42

A Review of Existing Tools and their Applicability

to Facility Maintenance Management

Joseph Neelamkavil

Table of Contents

Summary ... 3

Failure Patterns and Preventions ... 3

Asset Maintenance ... 5

Predictive vs. Condition-based Maintenance ... 7

Condition-based Maintenance – A Strategy for Facility Maintenance ... 9

Facility Maintenance Management Software Tools ... 11

S u m m a r y

Over the past fifty years, the concept of maintenance and the tools/support systems aiding maintenance have changed. The changes are due to a huge increase in the number and variety of assets (plant, equipment and buildings), which must be maintained. More complex designs, new maintenance techniques and changing views on maintenance organization have also contributed to these changes. Maintenance has also responded to changing expectations. It now includes a growing awareness of the extent to which equipment failure affects safety and the environment, a growing awareness of the connection between maintenance and quality, and is subjected to increasing pressure to have a positive effect on the smooth operation of the facility and to also contain costs.

The primary objective of this report is to provide a synopsis of the various computer-based maintenance management software (CMMS) tools that are available in the market today. It will help to facilitate greater understanding of the state of facility maintenance as a

discipline, and will also help to conduct a gap analysis with respect to facility requirements vs. tool’s capabilities. Various forms of maintenance management software (MMS) tools have been available for several years; these tools vary slightly from one developer to another, but the basic purpose and design are similar from one package to another. That is, the fundamental equipment information is stored; Information such as size, date of

purchase, ratings, cost, maintenance cycle, and equipment-specific notes are all maintained. The MMS tool packages can print out work orders when calendar-based preventive maintenance schedules are in effect, and some packages can also store the maintenance results. Some of the modern packages also embed newer concepts of maintenance. But, prior to providing overview of these tool packages, it makes sense to provide brief descriptions on equipment/asset failure patterns, as well as the need for asset maintenance and maintenance management.

F a i l u r e P a t t e r n s a n d P r e v e n t i o n s

Detailed investigation [refer 1] has revealed that all failures fit into one of six conditional probability (or likelihood of occurrence) failure curves, as shown in Figure 1, below. Such failure patterns were summarized based on aircraft maintenance history, as well as US Navy investigations. It was concluded that the majority of failures were not age-related

where the equipment failed because of length of time in use. This also means that time-based preventative maintenance is somewhat irrelevant in many of these cases. 'Age-related use' includes stress fatigue failures (e.g. shafts breaking), corrosion failures (e.g. metal corrosion), wear-out failures (e.g. car tire tread wear) and other such failures where the length of operating time contributes to the eventual failure.

It appears that only about 15% to 20% of maintenance occurs based on age-related factors. One can verify these based on company work orders for the same repair again and again over a period of time. Or one can also confirm this by asking long-serving maintenance planners and operators about what commonly fails on each piece of equipment. The time-based repetitive failures can be addressed by doing preventative maintenance and/or planned replacement maintenance. But non-time related failures cannot be addressed by the renewal-based maintenance strategies, as they require different solutions.

As just mentioned, the time in-service factor has no influence on 77% to 89% of the failures; in addition non-time related failures are somewhat unpredictable. This also means that, for the vast majority of equipment, maintenance needs to be based on non-age related factors, which further infers that repair requisitions can happen randomly. But it is possible to use the changed condition of the equipment to tell when a failure is likely to happen. For example, as a piece of equipment’s operating life progresses, degradation is bound to occur. And it is immaterial what the reasons are for this degradation; the fact is that the item can no longer meets its original function requirements and/or its level of performance falls. By detecting the loss-in-condition of the item one will have advanced warning that

degradation has begun. If this change in performance level is detected in advance, it provides a means to forecast a forthcoming failure.

One can identify a change in equipment condition in many ways. Commonly used procedures include detecting changes in vibration, changes in power usage, changes in operating performance, changes in temperatures, changes in noise levels, changes in chemical composition, and so on. The most important aspect is to detect the signs early enough so that one has time to plan and prepare an organized correction at the least cost. Bear in mind that once the equipment breaks down, one has to spend whatever time, money and resources it takes to get it back in operation.

Source: Mike Sondalini (reference 1)

A s s e t M a i n t e n a n c e

Organizations have now recognized the social and economic implications and impact of facility and asset management. Here, it is very much contextual to provide the evolution of maintenance which can easily be traced through at least three generations [2].

The First Generation spans over the period up to World War II. Prior to this time period, industry was not highly mechanized or automated, and downtime was of little consequence. This also meant that the prevention of equipment failure was not a high priority item. Most equipment was simple to operate and much of it was over-designed, which made it reliable and easy to repair. There was no need for systematic maintenance of any sort beyond simple cleaning and lubrication. The requirement of maintenance skills was not a major concern, either. Such failure-driven maintenance (FDM) was called corrective maintenance or run-to-failure maintenance. It is a reactive management strategy, where corrective maintenance is often dominated by unplanned events, and is carried out only after the occurrence of a function failure, malfunction, or breakdown of equipment. Corrective maintenance action can restore failed equipment by either repairing or replacing the failed component. If the equipment can be repaired easily or is somewhat non-critical, unplanned equipment stoppages will cause only minimal disruption, and the FDM likely will be an

acceptable maintenance strategy. But in today’s economy, this would have a serious impact on production and/or quality of life; urgent corrective maintenance action becomes

necessary to avoid the serious consequences of failure. Note that the impact of urgent and corrective maintenance can result in unpredictable performance in an organization,

evidenced by very high equipment downtime, equipment restoring cost, repair time, penalties associated with the loss of production, and spare parts inventory.

Around World War II things changed. Wartime requirements increased the demand for assets of all kinds, while the supply of skilled labour dropped sharply, which led to increased automation and mechanization. By the 1950's, machines and equipment of all types became relatively complex, and industries depended on them. As this dependence grew, downtime came into close scrutiny. This led to the idea that failures should be prevented, which in turn led to the concept of preventive (or time-based) maintenance. In the 1950's, it consisted mainly of equipment overhauls that were done at fixed intervals. Around this time, the cost of maintenance started to rise sharply, which led to the growth of maintenance planning and control systems. It also led people to start seeking ways in which they could maximize the life of their assets. To slow down the asset deterioration processes leading to faults, such time-based maintenance (TBM) s carried out by lubricating,

calibrating, refurbishing, and inspecting equipment on a regularly scheduled basis. TBM assumes that the estimated failure behaviour of the equipment (i.e. the mean time between functional failures) is statistically or experientially known for equipment/machinery

degrading in normal usage. TBM also involves minor (sometimes even major) planned shutdowns of systems for overhaul or predetermined repair activities on still functioning equipment. It prevents functional failures by replacing critical components at regular intervals, just shorter than their expected useful lifetime. Although TBM can reduce the probability of system failure or the frequency of unplanned emergency repairs, it cannot eliminate the occurrence of random catastrophic failure. Further, most TBM decisions are made by experienced planners according to the original equipment manufacturer’s recommendations, the reported breakdown history or failure data and the operating experience and judgement of the maintenance staff and/or technicians.

Since the mid-seventies, industry dynamics have gathered even greater momentum that forced even more changes in maintenance management. Downtime affected the productive and functional capability of physical assets, resulting in a reduction of output, increasing

operating costs and even interfering with customer service. By this time, automation had been widely accepted, the growth of which also meant that reliability and availability were key issues in all sectors, including the building construction and health care disciplines. Greater automation meant that frequent failures easily affected the ability to sustain quality of life; as well frequent failures had serious safety or environmental consequences.

Dependence on physical assets grew significantly, and so too their cost to own and operate. To secure the maximum return on the investment that these equipments represented, they must be operating efficiently for as long as their owners want. At the same time, the cost of maintenance itself had been rising in absolute terms and as a proportion of total expenditure. In short, in less than half a century, maintenance as a discipline, became a cost control priority, and moved to the top of the board room agenda. This led to a third generation of maintenance concepts - to what is generally known as predictive and/or condition-based maintenance techniques.

P r e d i c t i v e v s . C o n d i t i o n - b a s e d M a i n t e n a n c e

It makes sense to further elaborate on the essence of third generation maintenance strategies, currently known as predictive and/or condition-based maintenance strategies. These have now found their way to computer-based maintenance management systems (CMMS). In a broad sense, both predictive and condition-based maintenance essentially stand for the same thing. Predictive maintenance comprises methods which attempt to “predict” or diagnose problems in a piece of equipment, based on test results. Predictions are usually based on the trending of results. An example [refer 3] can convey this aspect more clearly.Assume that an insulation test is performed on a 15 kV substation bus. A minimum value of 5,000 Megohms is considered acceptable, and the standard one minute test result indicates a reading of 5,225 Megohms. Such a reading might prompt one to accept the reading and do nothing about it. Further review of Figure 2 can lead one to a totally different conclusion - one that clearly shows that the equipment is seriously deteriorating. The last two readings, taken six months apart, show a drop from approximately 10,500 Megohms to 5,225

Megohms. Assuming the trend will continue, the insulation resistance of this equipment will likely reach zero in a relatively short time. Based on this observation, one can easily

conclude that, while still in service, if the condition of the equipment is checked and action taken, significant savings will be realized.

Figure 2- Insulation Resistance Trending Chart (Source: John Cadick reference 3)

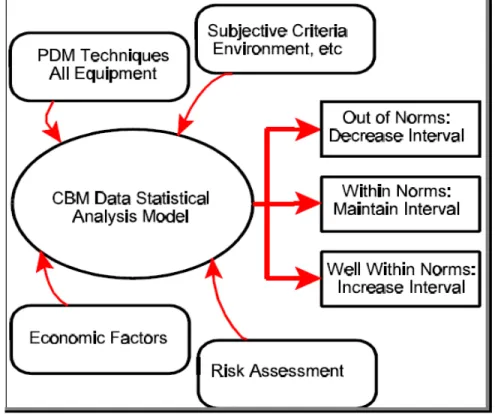

Typically, condition-based maintenance (CBM) adds two factors to the predictive

maintenance model (PDM). First, CBM deals with the entire system as an entity, since it realizes its greatest potential when applied evenly across the entire system. The second factor is the notion of shortening (or extending) maintenance intervals. In early PDM systems, trending techniques were used primarily to confirm maintenance decisions that were previously based on expert opinions. And in such instances, it had minimal effect in reducing the cost of maintenance efforts, whereas trending and statistical analysis are the building blocks of the CBM and as such, because of its systemic approach, CBM can contribute to the decrease of long term maintenance costs. Comparing data absolute values and more importantly, comparing data deviations via statistical analysis provide information never before available. For example, referring to Figure 3 [refer 3], and after entering the needed information into the CBM model as well as performing the required analysis, the results can determine whether the maintenance interval should be increased,

decreased or maintained. And, there is a good possibility that maintenance costs will go down, based on an increased time interval between equipment shutdowns.

Figure 3 CBM Flowchart Model (Source: John Cadick reference 3)

C o n d i t i o n - b a s e d M a i n t e n a n c e – A S t r a t e g y f o r

F a c i l i t y M a i n t e n a n c e

Condition-based monitoring, as a maintenance philosophy, is being quickly embraced by facility managers across the industry, and hence it is worthwhile to elaborate more on this topic. CBM is aimed at immediate detection and diagnosis of off-normal asset operations and the identification of the root causes of this condition, so as to help trigger timely actions. CBM assumes that prognostic parameters, that are indicative of trouble, can be detected and used to quantify the possible failure of equipment before it actually occurs. It is understood that equipment conditions are useful metrics of possible faults and/or potential problems before catastrophic failure or damage to equipment occurs. The trend in

deterioration of critical components can be identified through a trend analysis of the

equipment condition data, while the maintenance decisions depend very much on actual measured abnormalities, faults initiation, and the prediction of the trends in equipment deterioration.

Equipment Monitoring doesn’t have to be expensive; it can be based on inspections, and in such cases, the time periods must be set at a frequency that will let one easily spot the change, well before the impending failure. For example, in Figure 4 [refer 1] it refers to a frequency inspection period that will detect the degrading performance well before the failure. Once the start of a failure is detected, one can prepare for its repair, and/or take necessary steps that make changes in its use, to extend the time before failure. After discovering the potential and cause of failure through condition monitoring, one can now try to remove it, or else it can occur randomly at anytime in future, even after it is repaired.

Source: Mike Sondalini (reference 1)

As already mentioned, careful control of operational parameters can result in extending the component life beyond what is normally expected. The idea is to arrive at a plan to deal with the ‘actual versus intended’ operational environment, with a goal to define strategies in

terms of life cycle and economic management of the facility’s assets. The bottom line is to reduce the number of unplanned asset failures by monitoring the equipments’ condition to predict failures and enabling remedial actions to be taken [refer 4].It is to be noted that, though maintenance is done at the component level, the asset maintenance strategy should take a holistic approach to the entire system; note also that real-time data collection, data mining, systems integration, trending and statistical analysis are the building blocks of any modern CBM strategy.

Many factors need to be evaluated when trying to select and prioritize the various

conditions to monitor - how often, for which components, and leading to what actions. To make the process simple, one may prioritize the assets for which CBM might make sense, based on what could happen when an asset (or component) fails. If the consequences of failure are catastrophic (large loss of production, major safety risk), then CBM might be appropriate. Such criticality assessments are procedures which aim to identify those assets that could have the greatest effect on an operation if they were to fail. Invariably, since the organization is bound to face the problems of certain deterioration and random failure of equipment, decisions based on condition-based fault diagnosis and the prediction of the trend of equipment deterioration will become critical for maintenance planning and control. In addition, increasing the percentage of planned maintenance actions will decrease the quantity and capital investment in spare parts on-hold for emergency repairs [refer 5].

F a c i l i t y M a i n t e n a n c e M a n a g e m e n t S o f t w a r e

T o o l s

As mentioned earlier, the main purpose of this document is to report on facility maintenance management commercial tools. Yet it seemed appropriate to briefly mention some of the research tools that could evolve as commercial tools, at a later stage. Garcia et al [6] have developed an Intelligent System for Predictive Maintenance. It is a software application that takes into account the information in real-time coming from different sensors and other information sources and tries to detect possible anomalies in the normal behavior expected of the industrial components; this allows for an early diagnosis and the possibility to plan effective maintenance actions. Jay Lee et al [7] developed an E-maintenance system that addresses the needs of predictive intelligence tools to monitor degradation rather than

detecting faults in a networked environment and, ultimately to optimize asset utilization in the facility. Several case studies were introduced to validate these developed technologies and tools. Moore and Starr [8] have reported a system that automatically prioritizes jobs arising from condition-based maintenance using a strategy called Cost-Based Criticality (CBC) which draws together various types of information. CBC weights each incident flagged by condition monitoring alarms with cost information and risk factors, allowing for optimized prioritization of maintenance activities.Trappey et al [9] have tackled engineering asset management functions and processes in a collaborative environment integrated with a service centre with diagnosis and prognosis expertise. The collaborative maintenance chain jointly combines asset operation sites (i.e., maintenance demanders), a service centre (i.e., the system provider and maintenance coordinator), a first tier collaborator (i.e., maintenance providers), and maintenance part suppliers. And, to realize the automation of communication and negotiation among organizations, the multi-agent system (MAS) technique is applied. Ko [10] has presented a web-based RFID building maintenance system that embeds three modules - data management, statistics, and scheduling – in which the users implement maintenance work using tablet PCs attached with portable RFID devices.

Focusing strictly on commercial tools, currently, there are not very many maintenance management tools (MMS packages) that can perform the trending and/or statistical analysis, which is part and parcel of a full implementation of the modern condition-based maintenance program. Recently, some vendors have started incorporating CBM into their computer- based MMS offerings. The simplest packages allow for the manual input of data, such as condition readings for triggering preventive maintenance routines. The more sophisticated MMS software connects online to PLCs or other shop-floor devices for automated data collection. The software then analyzes incoming data to ensure that trends are on target and within user-defined control limits. It tracks the variance from the target, as well as the worst and best readings. When data deviates from the user-established limits, the software comes alive to initiate a work order and/or triggers some other actions.

The rest of this document is devoted to providing an overview of many of the commercial tools that are available in the market today. For more in-depth details of these tools, the reader needs to access the appropriate websites.

Or ga n iz a t ion Tool M a in Fu n ct ion s Spe cia l Fe a t u r e s

Com m e n t s

X ATA Cor p - Burnsville,

MN ( USA) www.xat a.com

Asse t

M a n a ge m e n t

Fleet Asset Managem ent and opt im ize fuel consum pt ion at delivery rout e

V e r ia n Te ch n ologie s-

Charlot t e, NC ( USA) www.verian.com

Asse t M a na ge r - W e b- ba se d a nd de ploya ble via a n in t r a ne t or e x t r a n e t .

Manage t he asset life cycle, from acquisit ion t o disposal. Det erm ine cost of asset ownership as t he syst em t racks acquisit ion cost s,

m aint enance cost s, depreciat ion and disposal cost s

Maint ain asset audit t rail of m ovem ent and ownership. Calculat e depreciat ion using m ult iple m et hods. Procure and m anage asset

m aint enance and repairs wit h built - in work orders. Record part s, labor and depart m ent s associat ed wit h asset m aint enance.

I nt egrat e wit h Verian's Purchase Manager syst em t o order part s for asset s and share dat a wit h ot her syst em s like account ing or I T aut o-discovery t ools. I dent ify opport unit ies t o redeploy asset s inst ead of j ust buying new ones. Plan and budget using asset perform ance and cost dat a. Elim inat e unused asset s t o give t he balance sheet a boost

V e n t yx - I n du s,

M obile D a t a Solu t ions ( M D SI ) - At lant a, GA ( USA) www.vent yx.com Asse t m a n a ge m e n t for pow e r ge n e r a t ion

Vent yx provides asset m anagem ent solut ions for power generat ion, energy delivery and ot her asset - int ensive organizat ions.

Reduce generat ion plant operat ional

cost s; andim prove plant workforce effect iveness. expert ise and solut ion capabilit y in t he indust ry. The Vent yx Asset Managem ent solut ion

int egrat es wit h it s field workforce m anagem ent solut ion. More efficient operat ions im prove abilit y t o m eet environm ent al goals. Meet regulat ory and safet y requirem ent s. St ream line t he supply chain. Operat ions m anagem ent inform at ion syst em s for t he chem ical, power, m arine, pet ro- chem ical, and pulp & paper indust ries. Vent yx has also developed t he Shift Operat ions Managem ent Syst em ( eSOMS) . 48 of t he t op 50 Nort h Am erican power generat ors use Vent yx solut ions

USCS Equ ipm e n t Te ch nology - Brookfield, WI ( USA) www.uscounseling.com Asse t M a n a ge m e n t Soft w a r e

They creat ed t he The r m o Scie nt ific LI FECYCLE

En t e r pr ise Solu t ions por t folio and t he Th e r m o Scie n t ific 3 D M ode l t o help one

m anage asset s t hroughout t heir lifecycle- - from acquisit ion t o disposit ion.

The 3D Model, an int egrat ed services solut ion, capit alizes on available service m et hods, such as m anaged m aint enance, m ult i- vendor direct services, biom edical services and service cont ract s, t o creat e a cust om ized solut ion t hat helps client s im prove product ivit y, reduce t ot al cost of ownership and ensure com pliance.

UN I K Associa t e s- CM M S PEAK I ndust r ia l Solut ion s, pr ovide s

But ler, WI ( USA)

h t t p:/ / w w w .cm m sm a de e a sy .com /

M a in t e n a n ce Soft w a r e

Com put erized Maint enance Managem ent

Syst em s ( CMMS) / Ent erprise Asset Managem ent ( EAM) soft ware solut ions, and consult ing. I ncludes:

Equipm ent Managem ent Prevent ive Maint enance Work Request Syst em Work Order Syst em Labor Managem ent I nvent ory cont rol Requisit ion/ Purchasing Budget ing

Mobile, Bar Code, I nt erface

TM A Syst e m s- Tulsa, OK ( USA) www.t m asyst em s.com CM M S Asse t M a n a ge m e n t Soft w a r e

TMA Solut ions com bines t he funct ionalit y of Asset Managem ent Soft ware wit h

Com put erized Maint enance Managem ent Syst em ( CMMS) providing t he abilit y t o m anage an organizat ion's work- flow process. These feat ures include:

Work Order Managem ent ; Prevent ive Maint enance Managem ent ;

Mat erials/ I nvent ory Managem ent ; Proj ect Managem ent ; Cont ract Managem ent ; Asset Managem ent ; Space Managem ent ( CAFM) ; Fleet Managem ent ; Cust odial Managem ent ; Room I nspect ions; Ut ilit y Managem ent ; Mobile Solut ions

TMA's scalable product set includes: TMA deskt op solut ions, TMA eXpress, TMA

web-based solut ion, WebTMA.

TGX M e dica l Syst e m s - Carm el, I N ( USA)

www.t erragraphix.net

Asse t

M a n a ge m e n t Soft w a r e

TGX Medical Syst em s designs, develops and m arket s soft ware solut ions for m edical asset m anagem ent and t racking. These web- based syst em s work wit h specialized hardware

supplied by m aj or int egrat ors. They are sold t o sm all, m edium and large- sized hospit als and m edical facilit ies.

Provides a baseline for infect ion cont rol, t rack inst rum ent usage t hroughout t heir lifecycle, and report on em ployee product ivit y in a healt hcare facilit y. I t ensures proper st erilizat ion m et hods are being used while m aint aining biological records elect ronically.

Hospit al syst em s

Sym x Cor p - Miam i, FL

( USA)

www.sym xcorp.com

H ospit a l H e a lt h ca r e Ca pit a l

Equ ipm e n t Life Cycle Asse t M a n a ge m e n t

SYMX Corporat ion provides equipm ent life cycle m anagem ent services t o hospit als, int egrat ed healt hcare syst em s and group purchasing organizat ions as well as governm ent ent it ies.

I t ut ilizes t he SYMX ATLAS ( Asset Tracking Locat ion Account abilit y Syst em ) t o enable RFI D dat a access, m anagem ent and int egrat ion. The SYMX ATLAS uses act ive RFI D t o deliver real-t im e locareal-t ion and process aureal-t om areal-t ion for healt hcare organizat ions and it s pat ient s, clinicians, st aff and equipm ent . I n em ploying Microsoft BizTalk Server 2006 R2, ATLAS delivers t he " Connect ed Ent erprise," so cust om ers can connect real- t im e business processes and com m and int elligent RFI D dat a, giving hospit als a com pet it ive business

advant age in t erm s of asset t racking, equipm ent m anagem ent , pat ient safet y and increasingly effect ive st aff perform ance.

Hospit als RFI D is used for real- t im e

locat ion info.

Sym ology Lt d - Caddingt on, Bedfordshire ( UK) www.sym ology.co.uk I n fr a st r u ct u r e Asse t M a n a ge m e n t

I nfrast ruct ure Asset Managem ent Solut ions: Sym ology develops and supplies a range of int egrat ed solut ions for t he m anagem ent of infrast ruct ure asset s, including highways, land and propert y, bridges and st ruct ures, public light ing, and dist ribut ion net works.

St reet - works and highway asset

m anagem ent

St Cr oix Syst e m s I n c - Wat ert own, MA ( USA)

www.st croixsyst em s.co m

Asse t

M a n a ge m e n t Soft w a r e

CMMS applicat ion in healt hcare and is t he core of St . Croix's asset m anagem ent solut ion. Com put erized facilit y and equipm ent

m anagem ent soft ware and services designed t o int egrat e funct ions of asset m anagem ent , asset logist ics, safet y m anagem ent , and capit al planning for healt hcare providers.

Aut om at e t he core funct ions of Work Order Managem ent , Workforce Managem ent , Prevent ive Maint enance, I nvent ory Managem ent , Cont ract Managem ent , Regulat ory Com pliance and Report ing; Track and m anage t he condit ion and perform ance of facilit ies and equipm ent , including prevent ive m aint enance according t o m anufact urer, JCAHO and ot her regulat ory st andards;

Real- t im e dat a driven report ing;

Manage t he int ake of service request s via a web- enabled request and dispat ch solut ion t hat aut o- creat es work orders and escalat es unt il request s processed and closed;

Drive workforce efficiencies wit h Mobile Asset

Manager designed for port able PCs and PDAs.

Sour ce At la n t ic-

Cam bridge Massachuset t s

www.sourceat lant ic.com

H e a lt h ca r e Equ ipm e n t Soft w a r e

Source At lant ic soft ware m edical equipm ent m anagem ent , new facilit y const ruct ion

planning. At lant ic soft ware coordinat es capit al planning, forecast ing, budget ing, purchasing. Source At lant ic soft ware asset m aint enance m edical equipm ent , furnit ure.

Healt hcare

Soft Sols Gr ou p Lt d -

Wrent horpe, Wakefield ( UK)

www.im pact xp.com

Fa cilit ie s M a in t e n a nce Soft w a r e

Supplier for Com put erized Maint enance Managem ent Syst em s ( CMMS) and facilit ies m anagem ent soft ware. Claim s:

- Ext ended Asset Life t hrough im proved m aint enance and reliabilit y

- I ncreased product ion from im proved equipm ent availabilit y and bet t er planning - Lower m aint enance cost s from bet t er planning and cont rol of ext ernal cost s

- I ncreased qualit y by reducing scrap rat es and breakdowns

- Quick, low cost im plem ent at ion

Focuses on m any indust ries including

healt hcare, oil & gas, m anufact uring, et c. SM Globa l I n c- Cary, NC ( USA) www.sm global.com CM M S M a in t e n a nce Soft w a r e

CMMS Soft ware for Windows: Plant

m aint enance; facilit y & building m aint enance; ut ilit y m aint enance ( e.g. wat er/ sewage/ power) ; aircraft or vehicle fleet m aint enance; ent erprise asset m anagem ent ; hot el &

rest aurant m aint enance; general equipm ent m aint enance

Mult iple indust ries

Se lt e k Solu t ion s -

St ockwood,

Worcest ershire ( UK) www.m aint enance-soft ware.co.uk

Pr e v e n t ive M a in t e n a nce Soft w a r e

Provides wit h t he inform at ion t o cont rol resources by priorit izing and allocat ing

planned m aint enance work, t racking m achine and/ or t ool repairs and m aint aining invent ory

Manufact uring

levels. I t allows one t o:

Track m achines and ot her equipm ent ; Track t ools, e.g. m ould t ools, foundry pat t erns, press t ools; Schedule m achine planned m aint enance based on dat es or hours run; Schedule t ool planned m aint enance based on dat es or cycles run; Flag planned m aint enance work due for m achines and t ools; Priorit ize planned

m aint enance work load; I ssue a t ask and kit list for each due planned m aint enance; Track int ernal and ext ernal repairs; Flag open m achine or t ool repairs; Record m achine and t ool cost hist ories; Cont rol m achine and/ or t ool part s invent ory.

RD M I M a int e n a n ce Solut ions - Nort h York,

ON ( Canada) www.rdm i.com

CM M S Soft w a r e Offers Com put erized Maint enance Managem ent

Syst em ( CMMS) solut ions t o m anufact uring, service and governm ent agencies.

Maint enance of Crit ical Asset s ( MoCA for Windows) is com plet e Crit ical Asset Maint enance Syst em ( CAMS) designed for sm all, m edium and ent erprise level

organizat ions. I t is t he only CMMS which allows Facilit y, Building, Equipm ent , Fleet and Asset m aint enance wit h m ult iple service cat egories and m ult iple work order num bers in one package. Prim arily m anufact uring Canadian – Toront o based Pr e co Ele ct r on ics - Boise, I D ( USA) www.preco.com V e h icle

Com m u n ica t ion Tr a ck in g

Syst e m s

Rugged pulsed radar collision avoidance syst em s enabling heavy equipm ent operat ors t o navigat e blind spot s around t heir vehicles

(PreView™) .

Wireless inform at ion collect ion, t ransm ission, and analysis syst em for t racking fleet and

Heavy equipm ent indust ry

equipm ent accessory act ivit y ( PreCise™) .

Safet y Alert Syst em (SAS™) com bining act ive blind spot det ect ion sensors wit h passive backup alarm s and safet y light ing.

PM X pe r t Soft w a r e -

Saskat oon, ( Canada) www.pm xpert .com

Pr e v e n t ive M a in t e n a nce Soft w a r e

Pr e ve n t ive M a in t e n a n ce Soft w a r e .

Generat es scheduled em ergency and work orders, view cost ent ries and reviews, and t rack t he service hist ory on equipm ent .

General equipm ent Canadian- Saskat oon based PM S Syst e m s Cor p -

Sant a Monica, CA ( USA) www.asset sm art .com

Asse t

Opt im iz a t ion M a n a ge m e n t Tr a ck in g Soft w a r e

Provider of int egrat ed, ent erprise- wide asset m anagem ent soft ware, which addresses various phases of asset m anagem ent and handles all cat egories of equipm ent .

SM ART/ PEM S ( Pr ope r t y a n d Equ ipm e n t M a n a ge m e n t Syst e m ) delivers asset

m anagem ent across t he ent erprise. The applicat ion offers com prehensive t racking and m anagem ent of t he com pany and governm ent propert y, t o reduce asset downt im e,

m aint enance and m anagem ent cost s and increase asset ut ilizat ion and redeploym ent .

SM ART/ M M S ( M a in t e n a n ce M a n a ge m e n t Syst e m ) is a generalized m aint enance and

repair m anagem ent syst em for plant

m aint enance, com put ers and m anufact uring equipm ent .

Opt im ize equipm ent resources by planning, scheduling and t racking service request s and equipm ent m aint enance across t he organizat ion

St andardize m aint enance processes across

Mult iple indust ries and Governm ent

organizat ion; I m prove speed and access t o inform at ion for m aint enance planning and service request s via t he SMART/ WEB int erface;

Provide real- t im e m aint enance inform at ion from a single applicat ion int erface; I ncrease visibilit y and availabilit y of real- t im e m aint enance inform at ion by int egrat ing all m aint enance and work- in- progress dat a int o a single dat a

reposit ory.

OPS Syst e m s I n c- Rio

Rancho, NM ( USA) www.opssys.com

M a in t e n a nce D a t a Soft w a r e

Com put erized m aint enance m anagem ent

program t hat assist s in m aint enance operat ions. The Calendar displays all t he scheduled work, com plet ed work, overdue work, and skipped work for a 52- week period.

Wat er and wast ewat er indust ry N e x a n t I nc – Ut ilit y -San Francisco, CA ( USA) www.nexant .com Pe t r oche m ica l Soft w a r e

Assess t he value of energy asset s by enabling com panies t o m ake inform ed decisions wit h speed and reliabilit y. Nexant provides a proven suit e of soft ware product s, ranging from

net work congest ion analysis and unit

com m it m ent t o generat ion asset valuat ion and port folio analysis.

Soft ware is inst alled bot h as advanced energy m anagem ent syst em ( EMS) applicat ions and as st andalone packages.

Power

generat ion and energy

conservat ion

150 ut ilit ies worldwide

N e t Sim plicit y –

Aust in, TX ( USA)

www.net sim plicit y.com

Asse t

M a n a ge m e n t Soft w a r e

Provides a visual floor- plan of your com pany’s asset s showing you what your com pany owns, where it is and what it is wort h.

Cat egorize and invent ory asset s; Check resources in and out ; Track usage and depreciat ion; Replace t racking wit h Excel® spreadsheet s; Meet indust ry com pliance regulat ions.

M Pu lse Eugene, OR ( USA) www.m pulsecm m s.com M a in t e n a n ce Soft w a r e D e sk t op M a in t e n a n ce Tools – used t o

m anage t he ent ire MPulse Syst em : MPulse Gold, WorkFlow R, WorkFlow M, or WorkFlow W.

MPulse Gold: I nt egrat ed asset m aint enance m anagem ent suit e. CMMS syst em includes advanced user int erface, browser- based request ing syst em , asset m anagem ent , work order generat ion & m anagem ent , ext ensive prevent ive m aint enance ( PM) scheduling & m anagem ent , invent ory ordering, cont rol & m anagem ent , m anagem ent t racking & report ing, et c.

On lin e M a in t e na n ce Tools – used by drop in

users t o get inform at ion such as work hist ory, pickup work assignm ent s, com plet e work

orders, subm it request for work, check st at us of work t hat is in t he queue.

H a ndh e ld M a in t e n a nce Tools - used t o

creat e a paperless environm ent .

product ion, educat ion, and governm ent indust ries Market s several soft ware product s M icr on ics GPS

Pert h ( Aust ralia)

www.m icronicsgps.com Fie ld Asse t M a n a ge m e n t Soft w a r e , GPS M obile M a pping, W e a r a ble Lon g Ra n ge D GPS

Global Posit ioning Syst em and t he Free t o Air Different ial Beacon locat ed at Cape Shanke Vict oria, t o achieve sub- m et re accuracy in t he capt ure of road defect localit y dat a.

Linked t o t he Geographical I nform at ion Syst em st ored in a lap- t op com put er, loaded wit h an asset m anagem ent soft ware package, which also enables t he assignm ent of at t ribut es t o each unique point recorded.

GPS and GI S syst em s t o ident ify defect locat ions

M icr om a in Cor p

Aust in, TX ( USA) www.m icrom ain.com CM M S Pr e v e n t ive M a in t e n a nce Asse t Soft w a r e , Fa cilit y M a n a ge m e n t , Ca pit a l Pla n n in g M a in t e n a nce a nd Fa cilit y M a n a ge m e n t Soft w a r e : M icr oM a in M a in t e n a n ce M a n a ge m e n t

soft ware for aut om at ed work orders, prevent ive m aint enance scheduling, asset hist ories,

invent ory and budget cont rol, fleet

m anagem ent , purchase orders, and m ore. I t includes risk assessm ent for biom ed/ clinical engineering depart m ent s in hospit als and ot her healt hcare set t ings. Plant asset m anagem ent , MRO, and equipm ent m aint enance are also sim plified wit h MicroMain m aint enance m anagem ent soft ware. I t s Fa cilit y

M a n a ge m e n t soft ware includes basic

funct ionalit y such as:

Linking dat a t o facilit y drawings; using dat a-enabled drawings t o search for asset s; t racking em ployee & occupancy dat a; t racking building and propert y inform at ion; ensuring cont inuit y &safet y; using m ark- up t ools for FM proj ect collaborat ion; viewing inspect ion and m aint enance hist ories

Mult iple indust ries including hospit als, product ion, educat ion. et c. Facilit y m anagem ent and asset m anagem ent included

M a in t sm a r t

Lodi, CA ( USA)

www.m aint sm art .com

CM M S

M a in t e n a nce Soft w a r e

Reliabilit y Analysis, Decision Support and Maint enance Program Opt im izat ion. Chance of Failure of An Equipm ent I t em During a Specified Tim e Period? Work Orders Managem ent and Analysis. Equipm ent Down Tim e Managem ent and Analysis. I nvent ory and Purchasing Managem ent and Analysis. Prevent ive Maint enance Managem ent and Analysis. I nvent ory Tree View - Drag and Drop Part s Requisit ions. Det erm ine t he " Cost t o Own" a Equipm ent .. Securit y and Access Cont rol. Mat ch Personnel Skills t o Tasks.

Mult iple indust ries M a in t e n a nce Ex pe r t s ( M EX) Annerley, Brisbane ( Aust ralia) www.m ex.com .au

CM M S Soft w a r e Com put erisedMaint enanceManagem ent Syst em

Com prehensive work order, prevent at ive

m aint enance, asset m anagem ent and invent ory cont rol syst em . Product s include Fleet MEX, MEX

Ops, FuelMEX and MEX Mobile

Mult iple indust ries

4,500 users worldwide

Ka k a r i Syst e m s Lt d

Edm ont on, Albert a ( Canada)

www.kakari.com

CM M S Soft w a r e Kakari offers a variet y of soft ware applicat ions,

including I GOR® , t he com put erized

m aint enance m anagem ent soft ware ( CMMS) , ESTI MATOR, est im at ing soft ware for bot h general and pipe const ruct ion, and Task Tracker, a j anit orial m anagem ent syst em .

Mult iple indust ries Canadian – Albert a based. I TH EC Lissieu ( France) www.it hec.com M a in t e n a nce M a n a ge m e n t Soft w a r e

I THEC I nt ernat ional specializes in m aint enance m anagem ent syst em s and in soft ware for t he t ransport indust ry

t ransport indust ry

I n t e lliTr a ck

Hunt Valley , MD ( USA) www.int ellit rack.net

W a r e h ou se M a n a ge m e n t Asse t Tr a ck in g, Or de r Fu fillm e n t , Ba r code , RFI D

I nt elliTrack provides invent ory m anagem ent

soft ware. Wit h innovat ive barcode and RFI D

t echnology, one not only elim inat e t he m anual processes t hat are wast ing precious m an hours, one can also reduce account ing errors and im prove cust om er service.

Manufact uring, hospit als, educat ion, hospit als, et c.

RFI D, et c

I n t e gr ys – Asse t point CM M S a nd Asset Po in t ' s p r im ar y m ain t en an ce Mult iple Crit ical plant

Greenville, SC ( USA) www.asset point .com

EAM Asse t M a n a ge m e n t

i m p r ov em en t t oo ls ar e:

T a b W a r e EFx is an En t er p r ise Asset

Man ag em en t / co m p u t er ized Mai n t en an ce Man ag em en t Sy st em ( EAM/ CMMS)

ap p l i cat i on accessed u ser s t o m an ag e $ i n cr it ical p lan t an d f aci l it y asset s w or ld w id e. Asset Poi n t i s r ecog n i zed b y i n d u st r y

an aly st s as o n e o f t h e t o p su p p l i er s o f EAM so l u t io n s. Mai n t en an ce con su lt i n g , t ech n o l o g y , su p p o r t an d t r ai n in g o p er at i o n t h at f ocu ses on i m p r ov i n g m ai n t en an ce p r og r am s, sy st em s an d p r oced u r es t o r ed u ce m ai n t en an ce cost an d i m p r ov e p r od u ct i on u p t i m e. Asset Po in t ’s r oot s ar e i n m ain t en an ce m an ag em en t , b eg i n n in g at Fl u or Cor p or at i on i n t h e l at e 1 9 7 0 ’s.

indust ries and facilit y asset s Gr a n d Ra vin e Soft w a r e – M a in t sca pe Ot t awa, ON ( Canada) www.m aint scape.com CM M S M a in t e n a nce Soft w a r e

General purpose Com put erized Maint enance Managem ent Syst em ( CMMS) for plant and facilit y m aint enance.

Canadian –

Ot t awa based.

GP Solu t ion s

Balt im ore, MD ( USA) www.gpsonline.com

CM M S

M a in t e n a nce Soft w a r e

Give users web browser- based access. Support rem ot e users wit h port able bar code readers or PDA devices. Add problem report ing capabilit ies t o com pany or cust om er web sit e. Generat e rem ot e m onit oring report ing t o m anagem ent via web delivered cont ent

Mult iple indust ries

FSC

Thunder Bay, Ont ario www.4sit e.com

CM M S

M a in t e n a nce Soft w a r e

Asset m aint enance, invent ory m anagem ent , m aint enance m anagem ent

Power, m anufact uring, healt hcare Canadian – Thunder bay based Fou r Rive r s Soft w a r e Syst e m s I n c

Pit t sburgh, PA ( USA)

CM M S Four Rivers Soft ware Syst em s, I nc. delivers

m aint enance m anagem ent soft ware ( EAM/ CMMS) solut ions t o t he healt hcare indust ry.

healt hcare over 1,300 healt hcare

facilit ies nat ionwide

www.frsoft .com FKW Oklahom a Cit y, OK ( USA) www.fkw.com M a in t e n a n ce M a n a ge m e n t Soft w a r e

The Recurring Work Program ( RWP) m odule encom passes Prevent ive Maint enance ( t im e-based) and Predict ive Maint enance ( condit ion-based) requirem ent s. RWP provides m anagers wit h an aut om at ed scheduling and t racking program for all recurring act ivit ies. Prevent ive Maint enance refers t o periodic act ivit ies. Predict ive Maint enance m anages equipm ent m aint enance based upon condit ions rat her t han t im e.

TM2 Facilit ies can include such diverse facilit ies as archit ect ural display s, t ennis court s, roads, sidewalks, curbs, flag poles, ant enna syst em s, t raffic light s, et c. Creat e Facilit y records for buildings, infrast ruct ure com ponent s, or any physical ent it y. I dent ify t enant s or owners for each Facilit y record and t rack space allocat ion and ut ilizat ion. Show ut ilit y usage and ut ilit y reim bursem ent fact ors down t o t he t enant and room level. Maint ain organizat ion codes and m ailing list s. Maint ain const ruct ion dat a down t o t he “ room ” level; i.e., what ceilings or walls in what room s cont ain asbest os. Maint ain crit ical real propert y dat a, including: Map Codes, Work Zones, Condit ion Codes, Disposal Dat a, Area Availabilit y/ Usage, Track lease dat es, et c.

FD S Adva n ce d Syst e m s Lt d

Knaphill Woking, Surrey ( Uk)

www.fdslt d.co.uk

uses Qube Global soft ware:

Fa cilit ie s M a n a ge m e n t Soft w a r e

Qube Global Soft ware is one of t he m ost significant suppliers of propert y and facilit ies m anagem ent soft ware.

Provide a responsive facilit ies help desk. Manage planned and react ive m aint enance. Keep cont rol of cont ract ors. Opt im ize use of space. Provide web- based facilit ies inform at ion

Most indust ries are covered

Wit h over 800 cust om ers in 52 count ries

h t t p:/ / w w w .qube glo ba l.com /

t o cust om ers. Ensure a safe working

environm ent . Quot e and invoice client s. Provide workforce wit h m obile dat a t ools.

Ex pr e ss Te ch n ology I n c Fairhope, AL ( USA) h t t p:/ / w w w .e x pr e sst e ch n ology.com / M a in t e n a nce Soft w a r e

ExpressMaint enance is a m aint enance ( PM) soft ware designed for rugged m ult i- user environm ent s.

m anufact urers, schools, fleet s, inst it ut ions, plant s, ut ilit ies, t ransport ers, et c. m any large and sm all com panies in 30 different count ries EQ2

Burlingt on, VT ( USA) www.eq2.com

H ospit a l Equ ipm e n t M a n a ge m e n t Soft w a r e

EQ2 Soft ware for hospit al equipm ent m anagem ent of capit al asset s. CMMS

m aint enance soft ware for clinical inst rum ent s, beds, HVAC, gas and elect rical syst em s,

elevat or m aint enance. EQ2 CMMS Soft ware for scheduled and rout ine m aint enance.

For each pat ient adm it t ed t o a healt hcare inst it ut ion, t here are hundreds of equipm ent it em s required t o successfully deliver efficient , high qualit y care t o t he pat ient . These

equipm ent asset s com prise or support t he delivery of bot h crit ical and non- crit ical pat ient care in t he m odern environm ent of care. EQ2 support s t he equipm ent m anagem ent

professionals who m aint ain t hese crit ical equipm ent asset s wit h soft ware and service solut ions.

Hospit als

En gin e e r e d Soft w a r e I n c

Bellev ille, MI ( USA)

h t t p:/ / w w w .e ngin e e r e dsoft w a r e .com /

M a in t e n a n ce Opt im iz a t ion

Reliabilit y & Maint enance Analyst :

The soft ware consist s of t wo m odules; a life dat a analysis m odule and a m aint enance opt im izat ion m odule. Dat a is ent ered wit h t he specialized dat a ent ry grid which allows billions of dat a point s. This ent ry grid is linked t o a Microsoft ® Access™ dat abase. All graphics can be cust om ized wit h easy t o use dialog t abs. Life

dat a analysis m odule is capable of est im at ing t he dist ribut ion param et ers for t he Weibull dist ribut ion, norm al dist ribut ion, lognorm al dist ribut ion, and exponent ial dist ribut ion.

e M a in t

Medford, NJ ( USA) www.em aint .com

En t e r pr ise s - Asse t

M a n a ge m e n t Soft w a r e

Est a blish e d in 1 9 8 6 , eMaint was am ong t he

first providers of CMMS ( Com put erized

Maint enance Managem ent ) syst em s t o em brace t he power of t he I nt ernet Mult iple indust ries Appears t o be a good t ool ED L Syst e m s

Wit ham , Essex ( UK) www.easy- fm .co.uk

Fa cilit ie s M a n a ge m e n t Soft w a r e ( CM M S)

Planned m aint enance asset survey Planned m aint enance scheduling and opt im isat ion

Dat a loading

Measured Building Surveys for Asset Maint enance Plan

Topographical surveying/ GI S int erface Checking exist ing sit e and building plans for accuracy/ cont ent

Am ending/ developing Aut oCAD drawings Linking drawings wit h Asset Managem ent dat abases Ea gle Te ch n ology I n c Mequon, WI ( USA) www.eaglecm m s.com CM M S M a in t e n a nce M a n a ge m e n t Soft w a r e

ProTeus is a full- feat ured fa cilit y m a in t e na nce

soft w a r e solut ion. ProTeus can seam lessly

int erface wit h int elligent Building Aut om at ion Syst em . Link cont inuous com m issioning and t he LEED process.

Mast er PM Scheduler ( Mult i- Cycle) ; Building Aut om at ion Alarm Syst em I nt erface; Aut om at ed Work Order Generat ion; PM I m plem ent at ion Library; Tenant Service Request ; Mobile

Capabilit ies; Barcode Syst em ; Over 120 Report s and Graphs.

ProTeus has capabilit ies for a ir por t

m a in t e na nce m anagem ent solut ion.

Mult iple indust ries. Airport and Healt hcare – m ain focus 3,000 cust om ers 29

• Scheduling and tracking of work to aut horized cont ract ors

• Track m aintenance activities by individual. asset and locat ion

• Track costs associated with all activities • Building Autom ation System (BAS)

I nt erface. D PSI Greensboro, NC ( USA) www.dpsi- cm m s.com M a in t e n a nce M a n a ge m e n t Soft w a r e ( CM M S)

iMaint is an ent erprise asset m anagem ent ( EAM) syst em t hat cont rol and m onit or all m aint enance act ivit ies, from an individual sit e t o a global ent erprise. Maint enance t racking; cost - effect ive invent ory cont rol; in- dept h report ing and analysis; Windows or Web- based client int erface; choice of dat abase, and choice of host indust rial plant s, facilit ies, vehicle fleet s DPSI has 3200 facilit ies in 80% of Fort une 500 D e lin e a - H CI Syst e m s

Port land, ME ( USA) www.hcisyst em s.com

CM M S Soft w a r e 4t ell™ Solut ions, LLC ( form erly HCI

Solut ions, LLC) develops inform at ion t echnology and soft ware product s for sust ainable governance of facilit ies,

infrast ruct ure and buildings. Opt im ize t heir capit al and operat ing lifecycle budget s Manage t heir facilit y governance processes ; Keep t heir environm ent al com m it m ent s; Com ply wit h regulat ions and report ing requirem ent s; I nform st akeholders t hrough sust ainabilit y report ing

Governm ent , schools, hospit als, et c. D a t a Tr a k I n c Friendswood, TX ( USA) h t t p:/ / w w w .da t a -t r a k .com / CM M S -M a in t e n a n ce M a n a ge m e n t Soft w a r e

Dat a- Trak, I nc. develops and support s soft ware for asset m aint enance and m anagem ent for sm all t o m id- sized m aint enance organizat ions wit h em phasis on low ent ry cost and ease of use.

Mult iple indust ries

Cybe r M e t r ics Cor p

Scot t sdale, AZ ( USA)

M a in t e n a n ce M a n a ge m e n t

Founded in 1988, CyberMet rics Corporat ion is a developer and supplier of supply chain, and

Mult iple indust ries

Fort une 1000 cust om ers

www.cyberm et rics.com Soft w a r e facilit ies m aint enance m anagem ent soft ware solut ions.

Creat e Work Orders & PM's; Receive Service Request s and Em ail Not ificat ions; Est ablish and Require Maint enance Procedures and

Com pliance; Predict Prevent at ive Maint enance Labor Requirem ent s; Track Maint enance Hist ory & Cost s; Cust om izable Program Messages, Field Labels and Report s; PDA Com pat ible; Facilit y-wide Service Request I ssuance via t he I nt ernet wit h Web Service Request Module.

COGZ Soft w a r e Woodbury, CT ( USA) www.cogz.com CM M S M a in t e n a nce M a n a ge m e n t

COGZ prevent ive m aint enance program scheduling is aut om at ion for t he m aint enance

m anagem ent operat ion. COGZ CMMS can be

used in com put erized m aint enance environm ent t hat requires prevent ive m aint enance program s. COGZ CMMS Soft ware can be ut ilized as m aint enance

soft ware, including: building m aint enance

soft ware, facilit y m aint enance soft ware, fleet

m aint enance soft ware, plant m aint enance

soft ware, vehicle m aint enance soft ware, educat ional facilit y m aint enance soft ware, heavy equipm ent m aint enance soft ware, elect r ical prevent ive m aint enance soft ware, hospit al CMMS soft ware, hot el m aint enance soft ware, et c.

Mult iple indust ries

Ch a se Soft w a r e Syst e m s

Om aha, NE ( USA)

CM M S

M a in t e n a n ce

Chase is a Com put erized Maint enance Managem ent Syst em ( CMMS) t hat links

m at erial and labor cost s t o Equipm ent ( Asset s) , and includes a Prevent at ive Maint enance ( PM) m odule. The Chase Syst em helps t he facilit y t o t rack cost s as well as budget .

• Asset Managem ent • I nventory Managem ent • MSDS Managem ent • Work Order Processing • Preventative Maintenance • Warranty Tracking

Ch a m ps Soft w a r e I n c

Cryst al River, FL ( USA) www.cham psinc.com

W e b CM M S M a in t e n a n ce

CHAMPS soft ware solut ions help opt im ize aspect of m aint enance, im prove equipm ent reliabilit y, personnel product ivit y and ensure m at erial availabilit y. CHAMPS CMMS / EAM m odules include:

Maint enance, I nvent ory, Purchasing, A/ P Lockout / Tagout , Correct ive Act ion, Scheduling, Calibrat ion, Proj ect Tracking

CAE Con su lt a n t s I n c Yonkers, NY ( USA) www.m unicipalnet s.com En t e r pr ise Fa cilit ie s Pla n t W e b M a in t e n a n ce Soft w a r e Pr e ve n t a t ive M a in t e n a n ce

Prevent ive m aint enance, facilit y m aint enance, m unicipal infrast ruct ure, et c.

Calendar allows schedule work ahead of t im e; I nvent ory feat ure and part s m anagem ent ; I SO com pliance built in. Take procedures, phot os and video anywhere wit hout loading t he

dat abase. Open your lapt op and click and t he server will send all you need t o do t he repair over t he I nt ernet . Maint enance index and flagging helps t he personnel spot t rouble when t hey fill out each work request .

Be n de r En gin e e r in g

Los Alam it os, CA ( USA) www.m aint st ar.com

CM M S

M a in t e n a n ce Soft w a r e

Asset Repair Hist ory; Prevent ive Maint enance ( PM) ;

Work Request and Work Order Creat ion; Asset Tracking and Replacem ent ; Screen and Report Cust om izat ion; Work Cost Hist ory including Labor, Equipm ent and Mat erials; Act ivit y Based Planning

Maint enance and Product ivit y Cost s; Labor Resource and Scheduling; I nt erface wit h

Microsoft Proj ect ; I nvent ory Cont rol linked wit h Work Orders; Purchasing Cont rol linked wit h I nvent ory; Bar Code and Palm Pilot capabilit y ; Web and E- m ail Work Request and Approval Process; GI S, Aut o Cad, and Digit al I m aging I nt egrat ion; Depreciat ion Tracking

Replacem ent Cost Analysis; Replacem ent Cost ; Proj ect ion m et hods; Budget ing; Cust om Report Writ er. Mult iple indust ries Very com prehensiv e BD R Syst e m s I n c

Downingt on, PA ( USA) www.bdrsyst em s.com

CM M S

M a in t e n a n ce Soft w a r e

I ncludes t he CPRO 2000 and CPRO 2000 PLUS I SO Professional Calibrat ion syst em s, t he MPRO 2000 and MPRO 2000 PLUS Prevent ive

Maint enance syst em s, PURCHASI NG PRO 2000 Procurem ent , Vendor Rat ing/ Managem ent syst em , FLEET 2000 Vehicle Maint enance syst em , and t he PROPERTY 2000 Asset Managem ent syst em .

Prim arily m anufact uring and fleet m aint enace Ash com Te ch n ologie s

Ann Arbor, MI ( USA) www.ashcom t ech.com

CM M S

M a in t e n a n ce Soft w a r e

Provides an array of indust rial product s in t he areas of a com put erized m aint enance

m anagem ent syst em ( CMMS) , docum ent m anagem ent soft ware, and aut om at ed invoice

Mult iple indust ries

Many

inst allat ions

processing soft ware.

API M a in t e n a n ce Syst e m s A/ S

Albert slund ( Denm ark) DK

www.apipro.com

M a in t e n a nce m a n a ge m e n t

API Maint enance Syst em s develops, m arket s and support s m aint enance m anagem ent soft ware.

m ult iple Over 600

inst allat ions world- wide

Am e r ica n Qu a lit y Syst e m s ( AQS)

Mont icello, I N ( USA)

Ca libr a t ion , M a in t e n a n ce M a n a ge m e n t Soft w a r e CM M S

CyberMet rics Corporat ion is a developer and supplier of supply chain, and facilit ies

m aint enance m anagem ent soft ware solut ions. Reduce Maint enance Cost s, Opt im ize I nvent ory & Purchasing, I m plem ent St andards &

Com pliance, St ore & Ret rieve Records, I m prove Maint enance Managem ent Program Reliabilit y, Scalable t o m eet fut ure needs.

m ult iple

Am e r ica n Biom e dica l Gr ou p I n c ( ABGI ) Oklahom a Cit y, OK ( USA) www.abgi.net H ospit a l M a in t e n a n ce M a n a ge m e n t Cost Con t a in m e n t Soft w a r e

Am e r ica n Biom e dica l Gr ou p, I nc. specializes

in asset int egrat ion and m anagem ent .

Healt hcare

AM Pr odu ct s I n c

Boca Rat on, FL ( USA)

www.at t r.com

M M S

M a in t e n a n ce Soft w a r e

MMS allows m aint enance engineers t o ensure QA com pliance by providing a t raceable hist ory of all m aint enance work. Com ply wit h dom est ic and int ernat ional st andards. Allows asset m anagem ent . Dat a base accept s unlim it ed num ber of equipm ent or part s.

Aim s - Ph oe n ix D a t a Syst e m s I n c

Sout hfield, MI ( USA)

www.goaim s.com

M a in t e n a nce M a n a ge m e n t Soft w a r e ( M M S)

Medical Equipm ent Maint enance Managem ent Soft ware ( MMS) for Hospit als and Healt hcare clinical engineering.

Healt hcare

Net Facilit ies, I nc. Long Beach, CA 90803 h t t p:/ / ne t fa cilit ie s.co m / Fa cilit y M a in t e n a nce M a n a ge m e n t Soft w a r e

Tot al Work Order Managem ent ; Service Aut opilot Work Orders; Tot al Asset Tracking; Prevent ive Maint enance Aut opilot ; Work Flow Dist ribut ion; Vendor Collaborat ion; Dashboard View; Work Order Pooling Assignm ent s; Report

m ult iple Facilit y m gnt , school m gnt ,

propert y m gnt . over 300

Cent er; I nvent ory Managem ent Syst em ; Budget Tracking; Role Based Users ( unlim it ed) ; Cust om Perm ission Levels; Guided Set - up

facilit ies and m any syst em users. Propert yTrak LLC Overland Park, KS 66210 h t t p:/ / w w w .pr ope r t y t r a k .com / fa cilit ie s m a n a ge m e n t soft w a r e

Propert yTrak im plem ent s web- based Com put erized Maint enance Managem ent Syst em ( CMMS) solut ions t hat deliver facilit ies m anagem ent aut om at ion. Adding prevent ive m aint enance feat ure t o

Propert yTrak increases it s pract ical usabilit y by enabling facilit y m anagers t o schedule regular m aint enance act ivit ies on expensive and m ission crit ical asset s. I t allow s facilit y m anagers t o record in advance and in det ail all m at erials, t ools and act ivit ies associat ed wit h specific prevent ive m aint enance t asks. Also, Propert yTrak Equipm ent t racking lays t he ground work for ent erprise asset m anagem ent .

eWorkOrders

http://www.eworkorders.com/

CM M S eWorkOrders is a web based CMMS t hat allows

individuals from different organizat ions – m unicipalit ies, real est at e owners, propert y m anagers, building engineers, t enant s, service providers, I T support and vendors – t o work t oget her in real- t im e while request ing and delivering services. Schedules prevent at ive m aint enance or recurring t asks. Tracking asset s

such as vehicles, equipm ent , buildings,

com put ers, and infrast ruct ure. Tracks t im e and m at erials. Provides st andardized report s and queries. Sm art group. Meredit h, NH 03253 Smartware Group Fa cilit y M a in t e n a nce Soft w a r e

For m aint enance operat ions. Bigfoot soft ware is about scheduling, m anaging, analyzing, and report ing on all aspect s of m aint enance,

including prevent ive m aint enance, work orders, m aint enance request s, invent ory, and predict ive m aint enance. Equipm ent Asset Managem ent , Prevent ive Maint . Managem ent ; Work Orders Managem ent ; Predict ive Maint enance Analysis and Report ing;

Mult iple 6,000 users - large and

sm all, m ult i-sit e and single- sit e

Mainst ream Soft ware Twinsburg, OH 44087 ht t p: / / www.m ainst ream s.com / En t e r pr ise fa cilit y a nd m a in t e na nce m a n a ge m e n t

Facilit y m anagem ent , asset m anagem ent , work order m anagem ent , et c.

Mult iple m ore t han

10,000 end users Spr ock e t Layt on, UT 84041 h t t p:/ / w w w .spr ock e t cm m s.com /

CM M S Sprocket CMMS is a web- based, facilit y and

asset m anagem ent soft ware applicat ion.

Sprocket GPS provides fleet and asset m anagem ent soft ware t o const ruct ion indust ries. I t enhances t he abilit y t o t rack, m onit or and evaluat e asset effect iveness wit h m apping and cust om not ificat ions for

m aint enance alert s. Benefit s: Obt ain inform at ion regarding runt im e hours of equipm ent ; Not ify m aint enance personnel of equipm ent t hat requires servicing; Knowledge of asset locat ion and hist ory; Account abilit y by m em bers using rem ot e asset s; Up t o t he m inut es st at us of driver; Em ail not ificat ions on ent er and exit of defined locat ions for t im e st am ping; Billing for cust om ers receiving service.

Advent Net , I nc.

Pleasant on, CA 94588, USA

h t t p:/ / m a n a ge e ngine .a dv e n t n e t .com /

Facilit ies Desk is a com put er aided facilit ies and m aint enance m anagem ent soft ware . I t

facilit at es in m anaging and m aint aining t he propert y , space , people and asset of an organizat ion effect ively. This facilit ies and m aint enance m anagem ent applicat ion provides all t hat you need t o have for int egrat ed

workplace m anagem ent and general service adm inist rat ion. This CMMS t ool offers seam less m aint enance and workorder m anagem ent , real-t im e dareal-t a sharing of all real-t he m ainreal-t enance & facilit ies' act ivit ies and reduct ion in facilit ies cost run.

m ult iple Large variet y of soft ware

Perm anent Solut ion I ndust ries, I nc Alexandria VA, 22314 h t t p:/ / w w w .psiw e bw a r e .com / Fa cilit y m a in t e na nce a n d j a n it or ia l se r vice s

Fa cilit y Asse t M a n a ge m e n t Soft w a r e ( FAM S® ) helps you docum ent im port ant work

t hroughout t he day - from Prevent ive Maint enance, t o Proj ect Work, t o Em ployee Managem ent , t o Service Request s or Com plaint s, and provides t he st ruct ure and organizat ion t hat helps achieve your t asks.