Publisher’s version / Version de l'éditeur:

ASTM Bulletin, 226, pp. 48-51, 1957-12

READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE. https://nrc-publications.canada.ca/eng/copyright

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la

première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

NRC Publications Archive

Archives des publications du CNRC

This publication could be one of several versions: author’s original, accepted manuscript or the publisher’s version. / La version de cette publication peut être l’une des suivantes : la version prépublication de l’auteur, la version acceptée du manuscrit ou la version de l’éditeur.

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at

A Reactive aggregate undetected by ASTM tests

Swenson, E. G.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

NRC Publications Record / Notice d'Archives des publications de CNRC:

https://nrc-publications.canada.ca/eng/view/object/?id=4ff39b43-43f4-457f-9041-a8d0c71c45c7

https://publications-cnrc.canada.ca/fra/voir/objet/?id=4ff39b43-43f4-457f-9041-a8d0c71c45c7

N A T I O N A L

R E S E A R C H

C O U N C I L

C A N A D A

D I V I S I O N O F B U I L D I N G R E S E A R C H

Reprinted from ASTM Bulletin No. 226

HIS publication is being distributed by the Division of

TBuilding

Research of the National Research Council as a

contribution towards better building in Canada. It should

not be reproduced in whole or in part, without permission of

the original publisher. The Division would be glad to be of

assistance in obtaining such permission.

Publications of the Division of Building Research may be

obtained by mailing the appropriate remittance, (a Bank,

Express, or Post Office Money Order or a cheque made payable

at par in Ottawa, to the Receiver General of Canada, credit

National Research Council) to the National Research Council,

Ottawa. Stamps are not acceptable.

A

coupon system has been introduced to make payments

for publications relatively simple. Coupons are available in

denominations of 5, 25, and 50 cents, and may be obtained

by making a remittance as indicated above. These coupons

may be used for the purchase of all National Research Council

publications including specifications of the Canadian Govern-

ment Specifications Board.

*

A

Reactive Assresate Undetected

by

ASTM*

Tests

By E. G. S W E N S O N

and map-cracking of concrete has oc- curred a t Kingston, Ont., mainly in structures such as siclc~valks, curbs. floors, ancl foundatiori nalls. T h r problem was brought t o the attention

of the Division of Building Rcscarch by

:L large

Government

construction agcncyancl an invcstigntion 1vn.s begun in 1955. Preliminary laboratory tcsts cstab- lished that a n argillaceous dolomitic limestone coarse aggregate was a rc- sponsible factor. T h e cliaractcristic cracking pattern ancl the conditions unclcr nlhicli esccssive cspansion liacl occurrecl suggested t h a t a ccmcnt- aggregate reaction was involvecl. Ac- corclingly, tlie ASTM tests for sucli reactions merc carried out and samples of the aggrcgates ancl the affected con- cretrs mere esaminccl petrographically

by a rccognizcd authority in this ficld. A t the s:~mc time, estensivc tcsts were carried out on actual concrctc spcci- mcns. Thcrc were tnro rcasons for tak- ing this step: The apparcnt absence of

sonic of tlic usual symptoms of ccnlcnt-

aggregatc reaction, sucli as rcaction rims and gc1 c ~ ~ ~ t l a t i o n s , matlc i t ncccs- sary t o consitlcr other factors such as freezing and thawing. Secondly, the urgency of thc ficld situation made i t ncccssary to t r y out possible rclncclial measures early in tlie invcstigation.

Although further rcscarcli n.ill 11e re- quired to establish tlic esact nature of thc problc~n and to provide n final prac- tical solution, tlie rcsults t o date : I ~ C be-

licvccl to be of unusual significance ancl warrant tlie uliusual step of making preliminary information available a t this time.

I n brief, thc plienomcnoli ~rhicll lias occurred in this case appears to be n.

type of ccment-aggrcgatc reaction n-hicli is not rcvealccl hy recognized ASTM tcsts

:IIICI

whicli eviclc~itly lies outsitle tlie experience of more tlian onc rccog- nizecl authority in this field.General Aspects of t h e Problem One of thc most scverc field cases, where the sources of niaterials, tlie mix design, anel otlicr data were available,

NOTE.-DISCUSSION O F THIS PAPER IS INVITED, either for publication or for the attention of the autllor. Address all co~nlnunications to ASTM Headquarters. 1016 Race St., Philadelphia 3. Pa.

*

Prcscnted a t the Sixtieth Annual Meetin:: of the Socirty, June 1 6 2 1 , 1057.In Canada, an unusual case of cement-aggregate reaction for which the standard tests were not effective

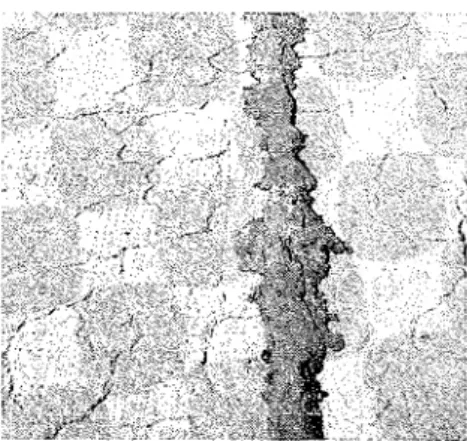

Fig. 1.-Map cracking in sidewalk, show- ing extruded joint filler due to expansion

of concrete.

was sclcctctl for stutly. This was a sidewalk, a scction of which is shown in Fig. 1. Esccssivc cspansion hael closed thc joints, ancl cracking liad oc- currccl within sis months of placing. T h e cracks clcfinctl roi~gliljr IicsagonaI arcas about 2 to 3 in. across ancl cs- tended dcepl~r into the concrete, being clearly distinguisliablc from surface "(;razing,"

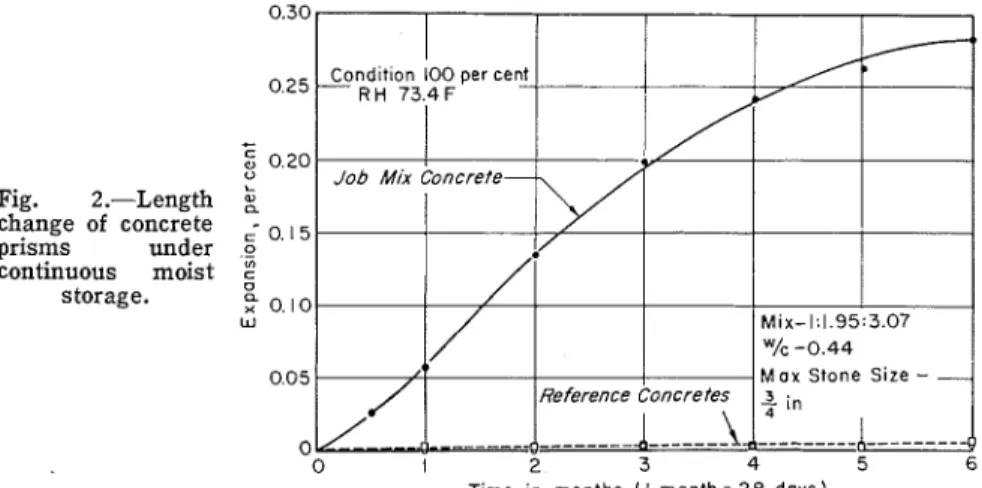

Samples of crushed liliiestone coarse aggregate, sand, a n d cclncnt were ob- tninetl from tlie original sources and concrete prisms were ~i~aclc, using tlic samc ~ n i s proportions tliat had been uscd for tlic job. Tlic prisms Irere kcpt in a curing room colitinuously ancl ~neasurcd pcrioclically for length change. Control prisms !Irere made mitli labora- tory rcfcrcnce materials using the same mi\- prollortions. Figurc 2 shows the rccorcl of cspansion of the tcst spcci- mens, in nrhich cracks bccsmc c l c a r l ~ ~ visible a t about 0.10 per cent cspnnsion.

A similar tcst n-:~s carried out using the s:~mc luaterials but with comb in:^-

tions of tlic local limcstonc cruslictl aggregate with a rcfcrcncc snntl and :i

rcfcrcnce linlcstonc crusliccl aggregate

with tlic local sand. Tllc rcsults of thc tcsts produced d a t a similar to tliosc in Fig. 2 and sho~vcd that the local cruslied limestone coarse aggregate was responsible for tlic abnormal ex- p:~nsion of tlie concrctc anel t h a t t h e s:~ntl coniponcnt apparently did not play

a significant rolc, a t least in tlic ex- tremely rapid cspansion occurring in t h e first 12 months.

Pctrograpliic csan1in:~tion of spcci-

lucns of 1,oth lal~oratoqr ancl field con- crctos which hael rxpantlccl cscessively ~.rvcalccl unmist:tknblc cvidcnce of cc- ~nent-aggregate reaction involving the crushecl liillcstonc particles, many of which cshibitcd darkcned rcaction rims. T h c csact nature of tlic rcaction and the constitue~it actu:tlly responsible merc not clctectccl. The abscnce of signifi- cttnt amounts of gel deposits nf:ts con- sidered significant. Petrographic es- amination of the clolomitic limcstonc ~cvcalecl th a t thc constituents could be regnrclecl a s not normally reactive with high-alkali cemcnts. Physically this material was considered satisfactory. I t was foilnd that about 2 per cent of thc sand colisisted of materials knolvn to bc rcactive mith Iiigh-alkali cements. This quantity mas not regardcd as eviclcncc tliat the sand ns a ~vliole was clclctcriously rractivc.

A survey of concretc work eshibiting tlic cliaractcristic niap-cracking in the affected area indicatccl t h a t this prob- lem lins occurred principally under con- ditions of dampness or xvctting and clrying, a n d included elements protected from tlie ~vcathcr as well a s exposccl

sections. Since the largc clacks ex- t~ncled most of the distance tlirough the clclllclits csamincd, i t appeared tliat a diffcrcntial movcmcnt hael occurred in such a may t h a t the inner p:wt espalided a t a relatively uniform rate under a continuo~~sly moist cnv~ronmcnt, ~vhilc tlic cspansion in the outer p a r t lind I~ccn

E. G. S W E N S O N , associate research offi- cer, Materials Section, Division of Building Research, National Research Council of Canada, former assistant professor in chem- istry at the University of Saskachewan, i s

currently i n charge of cement a n d concrete research and the author of several papers in this field.

Fig. 2.-Length change of concrete prisms under continuous moist storage. T i m e i n m o n t h s ( I m o n t h = 2 8 d a y s )

interrupted by periods of drying, thus leading to progressive deepening of the cracks which had begun a t the exposed side.

The field survey revealed that this problem has existed to some degree for many years in this area. Limited but reliable records have established that the particular limestone quarry which supplied the coarse aggregate for the cases investigated has not been the only source of aggregates for concretes which have subsequently developcd map-cracking.

Materials Selected for Study

The limestone coarse aggregates ancl the sands used in the main laboratory

TABLE I.-AGGREGATES USED I N TESTS.

I I A . . .

.

. . / Crusher-run, used in pre- Designation Description Limestones I I B . . . . . . KC .... . . K G . . . . . . OC. . .study are designated and described in TABLE II.-ALIIALI CONTENTS OF Table

I.

The limestone sanlules I a . CR~LIRNTS TrSED I N TESTS.liminary tests

Roek saxnples, laboratory crushed

Crusher-run,,

24- to 30-ft greenish" layer Reference, outside source

CS. . . LS. . . AS. . . .. R R . . . . . . K R . . . . . . - -. . - - - . -

KB. KC and KG mere a11 iron1 the -

-Sands Land-mined; used on job Lake sand; locally used Reference, unreaetive Alkali-reactive refcreiicc Conrow-reactive reference

'

Tentative Method of Test for Potential lteactivity of Aggregates (Chemical Method) (C 289 - 54 T ) 1955 Book of ASTnI Stand- ards, Part 3, p. 1206.B and M-two high-alkali cements R-low-alkali ceinent

KB-sample of the reactive limestone KG-highly absorptive greenish layer CS-local land-mined sand

RR-alkali-reactive reference sand OC-unreactive reference linlestonc The pozzolan is California calcined shalc. The boldface numbcrs in parentheses

refer to the list of references appended to this

quarry which had been the source of

limestone used on the jobs which gave Dcsig-

rise to thc original inquiries. The KG llatio"

sample 1vas from a 6-ft 'fgrcenisl~J'

stratum a t about the 24- to 30-ft level -

in the quarry which was reported to be B . . . .

excluded from the stone used for con- ,

crete, due to its inferior quality. The absorption of this material was about

3 per cent as compared with about 0.7 UI-I..

per cent for the other samples. The KI;;:

OC reference limestone and AS rcfcr- -

paper.

Tentative Method of Tcst for Potential Alkali Reactivity of Cement-Aggregate Combinations (C 227 - 52 T ) , 1955 Book of ASTBI Standards, Pnrt 3, p. 47.

B-cemcnt, KB-l~mcstonc, and CS-sand are combinations commonly used in af- fected area

OC-limestone and AS-sand arc unre- active reference materials

source East Canada East Canada west Canada U.S.

E:::

Alkali Content, per cent Total N a N/

II.0/

as NazOTABLE 111.-DATA FROikI QUICII CI-IEMICAL TEST FOR POTENTIAL

ALIIALI-REACTIVITY. R", Aggregate n~illimolcs lnillimoles

per liter

1

1

per litcrence sand have both had satisfactory performance records and mere used in control specimens for purposes of com- parison. KB ... IIG

...

OC . . . CS . . . AS . . . RR . . . December1957

A S T M B U L L E T I N

Alkali contents of thc nornlal port- land ccnlents used in these studies are givcn in Table

11.

Crnle~lt I3 was ob- tained from the principal source of sup- ply for the affected area.19.1 8 . 3 6 . 5 10.4 9 . 7 98.3

Tests for Cement-Aggregate Reaction

160.3 323.3 48.6 53.6 70.3 63.1 Chemical T e s f

The results of thc Quick chemic:~l test, ASTM il1ethod C 289 - 54 T,' for the IIB and KG limestones, the local CS sand, and for selected reference ma- terials are given in Table 111. Thc data indicate that these local materials are not deleteriously reactive to high-alkali cement. Reference to experiences with the Quick chemical method shol~,, 1101~-

ever, t h a t a dolomitic limcstonc can effect an extraneous reduction in alka- linity and, in some cases, may also give a fictitiously low silica release (1,2).2 In view of thc results of later tests with concrete prisms, which showed that the expansive reaction produced by the limestonc coarse aggregate was influ- enced markedly by the alkali content of the cement, the

R,

and S, values for this material cannot be accepted as re- liable.I t has been suggcstcd that, for cases of this kind, the test may be performed on the acid insoluble fraction, but this procedurc may yiclcl spurious values for silica release (2). Work in this dircc- tion is in pro; ~ I P S S . *

Mortar Bar Test

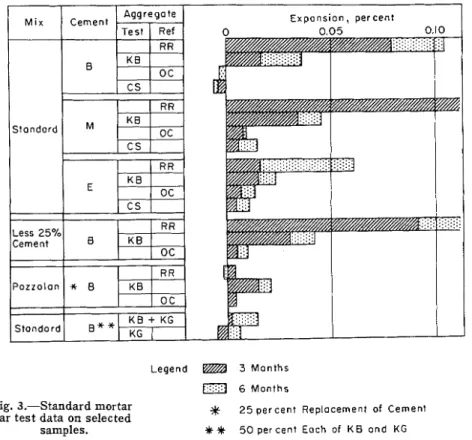

The standard proccclure for this test (ASTM Mcthod C 227 - 52 T),3 was followed escept that duplicate 5-in. bars were used. Various cornhinations of ag- gregates, ccmcnts. and pozzolans were tested, and some typical data are shown in Fig. 3. A representative sanlple of the limestone. IZB, sho\ved more than normal expansion with the high-alkali cements but not sufficient to be classi- fied as deleteriously alkali-reactive. Expansion mas nlarkedly reduced ~ v i t h the use of a low-alkali cenlent or by re- placing 25 per cent of the cement with a California calcined shale. The ap- parent nonreactivity of the highly ab- sorptive K G material (24-30

ft

layer) was consistcnt with later results for the concrete beams tests. The CS sand used in the field case was shown to be nonreactive in this test.The failure of the mortar bar test t o reveal deleterious alkali reactivity in the limestone in question, despite the influence of cement alkalis later sho~vn in the concrete prism tests, may be due to one of several possible factors (4), among thcm thc possibility that more than one type of reaction is involved. A study of this ancl other aspccts of this case is contemplated.

M i x Cement Aggregate Exoansion. Dercent Standord C S I K B

+

KG tondord B **

KGI

Legend 3 MonthsF-7

6 MonthsFig. 3.-Standard mortar $# 25 percent Replacement of Cement bar test data on selected

samples.

* *

50 per cent Each of K B ond KGConrow Test

I11 this test (ASTM Method C 342 - 55 T),4 mortar bars made wit11 the ICB and KG limestones and the CS sitrid gave negative results with the 13 ancl

E

ce- ments. The CS sand in combination with the M cement produced an ex- pansion of the bars approaching the 0.2 per cent limit at 12 months. On the basis of other tests with concrete beams, it was concluded, ho~vcvcr, that the CS sand clid not contribute signifi- cantly to the rapid rate and high de- gree of expansion observed for the concretes, a t least in thc first year. Tllc apparent unsoundness of the CS sand cannot be ignored, ho~vever, as a 110s- siblc contril~ution to later stages of de- terioration of concretes in the affected area.Tests with Concrete Prisms Influence of Exposure Conditions

Concrete beams were subjected to certain exposures to determine those conditions which promoted the abnor- mal expansion observed in the field cases. The most pertinent conditions mere :

(a) Continuous exposure to 100 per cent relative humidity and 73.4 F ;

Tentative Method of Test for Potential Volume Change of Cement-Aggregate Com- binations (C 342 - 55 T), 1955 Book of ASTM Standards. Part 3. p. 1244.

B and UII-high-alkali cements

E, UM, and UL-low-alkali cements KC-reactive limestone

OC-reference limestone LS-local sand

(b) Outside csposure to weather, beginning in early sumriicr;

( c ) Freczing-and-thawing cycling con- sisting of 6 lir freezing to 10 F and G hr thawing at rooln temperature (56 cycles in 28 days); and

(d) UTetting-drying cycling; 6 lir wet- ting a t room temperature ancl 6 hr dry- ing a t 130 & 3 F ; this was a modifica- tion of the Scholer method (3) and cur- rently under study in this laboratory (56 cycles in 28 clays).

For the nlises used in this series, the sands were scparatccl into six fr:tctioris and reblenclecl to conform to ASTM grading requirements. Equal parts of

to

+

in. and$

toi

in. stone sizes were used. All aggregates were in a labora- tory-dry state when incorporatecl in thc concrete. The beams were 3 by 4 by 16 in., with measuring studs counter- sunk a t each end. Measurement of length was made to the nearest 0.0001 in. with a special comparator.Figure 4 shows a set of curves typical of several series of tests carried out si- n~ultancously. The mix in this case was 1 :2$:2+, water celllent ratio = 0.47, entrained air = 5 per cent, and slump 2 in. The B-I(I3-CS (cement- stone-sand), prisnls nlade \\-it11 mate- rials from sources used on the job in- vestigated, are shown to espand ex- cessively undcr all four conditions. Since the refcrencc

concretes,

B-OC-AS, showed no significant volume change under any of these conditions, only the data points for one condition are shown in Fig. 4. Abnormal expansions similar50

(TP238)

A S T M B U L L E T I N

to those for thc B-ICE-CS samples shotvn nrcrc, ol~taincd for a B-KB-CS nlis containiiig no entrained air, and a iVI-ID-CS mix ~vith another high alkali cement, M, sometimes used in the af- fected arca. Wetting-drying cycling ancl exposure

to

high humidities in- variably produced greater cspansions than frcezing-thawing ancl outside ex- posure. Conditioning at 100 per cent relative humidity and 100 F produced more rapid initial expansion than any of the above methods of exposure. Expan- sions in the duplicate sanlplcs were in very close agreement until cracking be- gan to be visible at about 0.08 per cent expansion. Beanls made with the greenish KG liniestone as coarse ag- gregate showed only a slight tendency to expand after 9 months of outside ex- posure. This is in agreement with the mortar bar test on this material. The presence of this material in varying amounts in the coarse aggregates used in field concrete may be a factor in the marked differences in the severity of this problem observed in the affected area.The results of these exposure tests as ~vell as evidence from field cases indi- cated that abnormal expansion occurred as a result of some internal reaction ~vl~icll mas influenced primarily by mois- ture and temperature conditions. Influence of Materials

It was fouricl that the separate sam- plings of limestone, IU, IIB, and KC, each considered to be representative of the stone used for concrete from this quarry, produced marked differences in degree of expansion, suggesting vari- ability in the quarry material. Beams nlacle with varying proportions of the highly absorptive KG and the I<C limestone sample sl~o~vecl decreased ex- pansion with increasing amounts of ICG. These tests were carried out at 100 per cent relative huiniclity and 73.4 F. This property of the ICG material was noted previously.

0 3 6 9 12

Time In m o n t h s ( I m o n t h = 28 days1

Fig. 4.-Effect of exposure conditions on degree of expansion of concrete prisms.

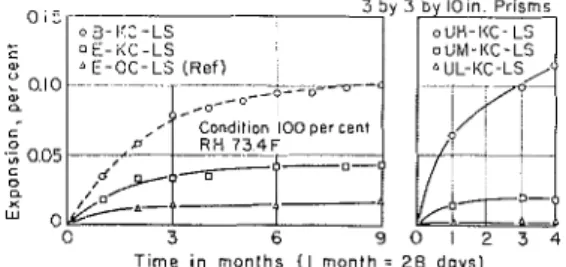

Concrete beams made with the K C limestonesample a n d cements~vithvary- ing alkali contents (Table 11), ancl condi- tioned a t 100 per cent relative humidity ancl 73.4

F,

produced clifferences in ex- pansion~vhich indicatecl t h a t the reaction of t h e limestone producing this ex- pansion was sharply influenced by t h e alkali colltents of t h e cements. Typical data are s h o ~ i ~ n in Fig. 5. The reason for the difference in rate and degree of expansion between t h e concretes con- taining the two lligh-alkali cements B and UII, was n o t determined. T h eUH cement is t h e Inore finely ground, ancl i t is t o be noted also t h a t the rela- tive anlouilts of sodium and a potassium oxide present in each cement are mark- edly different (Table 11).

A number of adlnistures were used t o determine their effectiveness in reducing abnormal espansion with tlie higli- alkali cement B. A 25 per cent replace- ment of ceinellt by weight with cal- cined shale mas most effective. Fly ash was less effective, and i t mas found t h a t the mere recluction of the cenlent content by 25 per cent with no acldition reduced the expansion nearly as much as the fly ash. A finely divided, non- pozzolanic silt reduced the expansion by about the same amount. Addition of 1 per cent lithium chloride lmd about t h e same effect. These results, after 8 t o 11 months, seemed t o indicate t h a t pozzolanic or chemical admixtures of the type usually found to be effective in controlling cement-aggregate reaction have less beneficial influence than usual in this case.

Summary

I n the course of a Canadian investiga- tion, a dolomitic limestone coarse ag- gregate has been found t h a t produces excessive espansion and cracking in con- mete. This phenon~enon was repro- duced in the laboratory ~ v i t h concrete prisms subjected t o highly llumid con- ditions or t o a tiretting-and-drjring test. Abnormal expansion was usually ob- tained in a few weeks. T h e rate and degree of espansion were found t o in- crease with increasing alkali content of the cement. Pozzolans and chenlical admixtures, ~vllicll are usually effective in controlling alkali-aggregate reaction, sl~o~vecl somewhat lilnitecl beneficial influence in this case.

Despite the observed influence of ce- ment alkalis, the results of the ASThlI Tcsth~Iethod C 289 o n the limestone were negative. The limitations of this test when applied to dolomitic linlestones were, however, recognized. The re- sults of the ASTM mortar bar test were also negative b u t indicated some nlkali- reactivity in the limestone. The nega- tive results of the ASTM Conrow test

1957

Time i n m o n t h s ( l m o n t h = 28 days)

:~pparently elinlinatecl the possibility of a cement-aggregate reaction of t h e type for which this method mas developed. Expert petrographic evaluation, not given in detail here, indicated t h a t some type of cement-aggregate reaction mas involved b u t t h e exact nature of the reaction mas not established. The constituents of t h e limestone were re- garded a s not ilorlnally deleteriously reactive with high-alkali cements.

This brief paper is intended t o pro- vicle for the benefit of those concerned with the use of t h e standard tests for alkali-aggregate reaction a record of this Canadian esperience with a n appar- ently unusual case of cement-aggregate reaction for n-hich the standard tests were not effective. T h e prism test herein recorded can be comincnded in vien- of the assistance nlhicll i t has given in t h e stucly of the case under revie~v. iirorli is continuing o n the problem, and more detailed reports on t h e case in cluestion mill be published in due course.

The author wishes to recorcl his ap- preciation of expert a s s i s t ~ n c e received flsom the U. S. Bureau of Reclamation, IT'. I-I. Price, chief of laboratories, ancl especially for t h e help given b y R. C. iCIielenz and D . Ranlaley of t h e Bureau's Petrographic Laboratory. Valuable ns- sistance has also been given by other U. S. experts t o whom the author's thanks are also recorded. Much assist- ance was naturally received from the staffs of the various Canadian agencies involvecl with t h e problem n o ~ v 11nc1er stucly and from mauy of those inter- ested in t h e problem in the Kingston area. This paper is a contribution of the Division of Building Research of the National Research Council of Canada and is published with the np- proval of the director.

(1) R. C. Mielenz, I<. T. G~.cenc, and 6.

J. Bellton, "Chemical Test for Reac- tivity of Aggregatcs with Cement Al- lialis; Chcmical Proccsses in Cement- Aggregate Reaction," Proceedings,

Am. Concrete Inst., Vol. 44, pp. 193- 221 (1948).

Fig. 5.-Influence of alkali con- tent of cements on expansion of

concrete prisms.

( 2 ) R. C. Alieleriz, and E. J. Benton, "Evaluation of tlle Quicli Chemical Test for Alkali Reactivity of Concrete Aggregate (ASTM Method C 289 - 54 T)," copy of a paper submitted to the Iligh.r.r,ay Rcsearch Board for pub-

lication.

(3) C. H. Scholer, "A Wetting and Drying Test for Predicting Ccmcnt-Aggregate Reaction," ~ r o c k d i n g s , A;: Soc. Testing 3iIats., Vol. 49, p. 942 (1949).

(4) E . G. Sn-erison, "Ccment-Aggregate Reaction in Concrete of a Canadian Bridec." <> , Proceedinas. Am. Soc. Test- ing ~ a t s . , 1'01. 57 f1957).

DISCUSSION

MR. BRYANT MAT HER^.-I sllould like t o complinlent t h e author on a very excellent job of tying field performance ~vitll laboratory investigations. I be- lieve t h a t it is through studies of t h i s sort t h a t we can best learn tlie extent and scope of these problems.

I would say, however, that we have llad some previous indications of cement- aggregate reaction apparently involving cloloinitic limestone, p:rrticularly some cases in Southern a n d Central I n ~ l i a n a , ~ in Ohio, and in Virginia. All of these involved clolon~itic limestone and nat- ural sand. Unforlunately none of them have been investigated to the ex- tent t h a t the author h a s investigated the Kingston problem a n d therefore have n o t received much publicity or adequate documentation. I suspect t h a t had they been more tliorougl~ly investigated they mould have proved rather similar t o this Kingston situ- ation. I hope t h a t t h e author's pre- sentation of these d a t a ~vill inspire people in tlie United States who have heard of these other cases t o investigate them more thoroughly, ancl inspire others t o pin down some of the poorly known cases of concrete deterioration t h a t m a y provide still further esainples.

Corps of Engineers, Concrete Div., U. S. Waterways Esperiment Station, Jackson. Miss.

R. W. Gilmore, "Railway Colicrete De- terioratlon, P ~ o c e e d i n g s , Am. Concrete Inst., V:?. 45, p. 731 (1952); Iiatharine Mether, Crushed Limestone Aggregates for Concrete," Transactions, Am. Inst. Mining and Metallurgical Engrs., ilfi?zi7~u E~zgineer-

ing, Oct. 1953. p. 1022.