Publisher’s version / Version de l'éditeur:

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

Internal Report (National Research Council of Canada. Division of Building Research), 1958-09-01

READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE.

https://nrc-publications.canada.ca/eng/copyright

NRC Publications Archive Record / Notice des Archives des publications du CNRC :

https://nrc-publications.canada.ca/eng/view/object/?id=a1e06aba-73db-4675-8c6e-f040d1a929bf https://publications-cnrc.canada.ca/fra/voir/objet/?id=a1e06aba-73db-4675-8c6e-f040d1a929bf

NRC Publications Archive

Archives des publications du CNRC

For the publisher’s version, please access the DOI link below./ Pour consulter la version de l’éditeur, utilisez le lien DOI ci-dessous.

https://doi.org/10.4224/20338112

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at

Small-panel method for investigating moisture penetration of brick masonry

NATIONAL RESEARCH COUNCIL O F CANADA D I V I S I O N O F B U I L D I N G RESEARCH

A SMALL-PAMEL ME!L'HOD

FOR

I N V E S T I G A T I H G MOISTURE PEmE!l!EUTION O F B R I C K MASOFRYR e p o r t

No. 160

o f t h e

Division o f Building Research

OTTAWA

Rain p e n e t r a t i o n of

u n i t

masonry h a s been of con- c e r n t o t h e D i v i s i o n e v e r s i n c e it w a s e s t a b l i s h e d i n 1947. A number o f s t u d i e s have a l r e a d y been descrj-bed i n r e p o r t s and p u b l i c a t i o n s . A r a i n p e n e t r a t i o n a p p a r a t u s employinga

p a n e l a b o u t 3$ by4 4

f t i n s i z e w a s d e s i g n e d and adopted f o r a s t a n d a r d t e s t i n t h e l a b o r a t o r y . T e s t p a n e l s f o r t h i s a p p a r a t u s were p u r p o s e l y made a s l a r g e a s p o s s i b l e c o n s i s t e n t w i t h o t h e r r e q u i r e m e n t s so a s t o r e p r e s e n t r e a s o n a b l yan

a c t u a l wall-. I n t h e l a r g e p a n e l a p p a r a t u s t h e p a n e l s a r e normally construc-ted by a b r i c k l a y e r and s o h i s s k i l l and t e c h n i q u e s become one of the f i x e d f a c t o r s i n t h e t e s t . The need f o r a s n l a l l e r l a b o r a t o r y a p p a r a t u si n which

a much l a r g e r number of t e s t s c o u l d be c a r r i e d o u t much more cheaply and r a p i d l y soon beca~ne a p p a r e n t . As m a l l - p a n e l a p p a r a t u s was developed and t r i a l s w i t h it were encouraging. It w a s i n t e n d e d from t h e o u t s e t t h a t i t should be used w i t h p a n e l s c o n s t r u c t e d w i t h r i g i d l y c o n t r o l l e d

t e c h n i q u e s and s o should permit i n v e s t i g a t i o n of f a c t o r s i n t r o d u c e d by t h e b r i c k l a y e r , a s w e l l a s s e r v i n g d i r e c t l y a s a s m a l l - s c a l e v e r s i o n of t h e l a r g e - p a n e l apparatus.

The work w i t h t h e

small

p a n e l s h a s t h u s f a r been most encouraging and o t h e r l a b o r a t o r i e s have e x p r e s s e d i n t e r e s ti n it.

The a p p a r a t u s and t e c h n i q u e s which have been developed a r e now r e p o r t e d t o g e t h e r w i t h some of t h e p r e l i m i n a r y r e s u l t s . I t i s i n t e n d e d t h a t p u b l i c a t i o n oft h i s i n f o r m a t i o n w i l l be made l a t e r , a f t e r f u r t h e r e x p e r i e n c e and r e s u l t s have been o b t a i n e d .

O t t a v r a

September 1958

N.B. Hutcheon

A SMALL-PANEL lE!I'IIOD FOR INVESTIGATING MOISTURE PEXETRAT1ON OF B R I C K MASONRY

by T. R i t c h i e

A method has been developed f o r i n v e s t i g a t i n g t h e i n f l u e n c e o f c e r t a i n f a c t o r s on t h e p e n e t r a t i o n of m o i s t u r e t h r o u g h b r i c k masonry. A s m a l l p a n e l , made of f i v e b r i c k s w i t h m o r t a r j o i n t s , i s c o n s t r u c t e d under c o n t r o l l e d c o n d i t i o n s and s u b j e c t e d t o a r a i n t e s t . I n t h i s t e s t

an

a i r p r e s s u r e d i f f e r e n c e i s maintained a c r o s s t h e panel t o s i m u l a t e wind f o r c e , and a t t h e same time w a t e r i s sprayed on t h e s u r f a c e t o form a c o n t i n u o u s f i l m . The t e s t c o n d i t i o n s t h e r e f o r e r e p r e s e n t heavy wind-driven r a i n . The l e n g t h of time f o r m o i s t u r e t o t r a v e r s e t h e p a n e l and t h e subsequent r a t e of l e a k a g e of m o i s t u r e through i t are measured d u r i n g t h e t e s t .A d e s c r i p t i o n of t h e method of making t h e p a n e l s and of t h e a p p a r a t u s f o r t e s t i n g them i s p r e s e n t e d . The r e s u l t s of some t e s t s , showing t h e i n f l u e n c e of c e r t a i n f a c t o r s on m o i s t u r e p e n e t r a t i o n , a r e given. The a p p a r a t u s has a l s o been u s e d t o s t u d y t h e m o i s t u r e p e n e t r a t i o n

c h a r a c t e r i s t i c s of brickwork removed from t h e w a l l s of

b u i l d i n g s , which h a s been c u t t o s u i t a b l e s i z e

t o

be f i t t e d i n t h e a p p a r a t u s .The r e s u l t s o f some t e s t s i n d i c a t e d t h a t t h e m o i s t u r e p e n e t r a t i o n of t h e p a n e l s depended on s e v e r a l f a c t o r s i n a d d i t i o n t o t h e p r o p e r t i e s of t h e b r i c k s and m o r t a r used. The time i n t e r v a l between p l a c i n g t h e m o r t a r on t h e bottom b r i c k and t h e n e x t b r i c k on t h e m o r t a r a p p a r e n t l y h a s a

c o n s i d e r a b l e i n f l u e n c e on m o i s t u r e t r a n s m i s s i o n o f t h e p a n e l . The flow o r c o n s i s t e n c y o f t h e m o r t a r when it i s p l a c e d a l s o i s of g r e a t importance. The impact of t a p p i n g t h e b r i c k when

it i s

s e t i n t h e m o r t a r a l s owas

foundt o i n f l u e n c e g r e a t l y t h e " t i g h t n e s s 1 ' of t h e panel. T e s t P a n e l s

The procedure f o r b r i n g i n g t o g e t h e r t h e b r i c k s and m o r t a r t o make t h e panel

w a s

a d a p t e d from t h a t developed by0.0. Fishburn i n h i s work

a t

t h e United S t a t e s N a t i o n a l Bureau o f Standards ( p r i v a t e correspondence) on bond s t r e n g t h between b r i c k and m o r t a r , u s i n g c r o s s e d - b r i c k c o u p l e t s .The p a n e l s a r e c o n s t r u c t e d of f i v e b r i c k s , l a i d one above t h e o t h e r w i t h a m o r t a r j o i n t between. Although p a n e l s could be c o n s t r u c t e d t o c o n t a i n v e r t i c a l j o i n t s t h i s would complicate t h e method of b u i l d i n g them. For

t h i s r e a s o n t h e p a n e l s s t u d i e d have c o n t a i n e d o n l y h o r i z o n t a l m o r t a r j o i n t s .

The b r i c k s t o be used i n t h e p a n e l s a r e t e s t e d f o r t h e p r o p e r t y o f i n . i t i a 1 r a t e of a b s o r p t i o n and t h e n a r e d r i e d t h o r o u g h l y b e f o r e b e i n g b u i l t i n t o t h e panel.

The m o r t a r i s mixed i n a n i n d i v i d u a l b a t c h f o r each of t h e f o u r m o r t a r j o i n t s i n t h e p a n e l . The w a t e r , cementing m a t e r i a l s and sand a r e mixed i n a Hobart mixer ( t y p e N - 5 0 ) ; t h e amount of w a t e r i s predetermined t o g i v e a r e q u i r e d f l o w t o t h e m o r t a r . The w a t e r i s p l a c e d i n t h e bowl f i r s t t h e n t h e cementing m a t e r i a l s a r e added. The mixer i s s t a r t e d s i m u l t a n e o u s l y w i t h a stop-watch t o r e c o r d t h e time o f

mixing. A f t e r t h e mixer

i s

s t a r t e d t h e sand i s added t o t h e bowl g r a d u a l l y s o t h a t i s h a s been a l l addedi n a p p r o x i -

mately t h e f i r s t 20 seconds of mixing. The f i r s t -hvo minutes of mixing a r e done a t low s p e e d , t h e n t h e machine i s stopped and switched t o medium speed. Before t h i si s

done, m o r t a r on t h e s i d e s o f t h e bowl i s s c r a p e d down w i t h a r u b b e rs c r a p e r t a k i n g about 1 0 seconds, t h e n t h e mixing

i s

resumed f o r 50 seconds. The t o t a l mixing time i u t h r e e m i n u t e s , t h e f i r s t two minutes a t low s p e e d , and t h e l a s t a t medium speed.The m o r t a r i s allowed t o s t a n d i n t h e bowl f o r one minute a f t e r mixing and t h e n i s p l a c e d i n a m e t a l mould on t h e b r i c k t o f o r m t h e j o i n t . The mould r i s e s 3/8-inch above t h e s u r f a c e of t h e b r i c k . A s l i g h t s h o u l d e r on t h e s i d e s of t h e mould r e s t s on t h e b r i c k s u r f a c e s o t h a t t h e s i d e s o f t h e mould a r e i n s e t about 1/8-inch from t h e f a c e of t h e b r i c k . A f t e r s t a n d i n g , t h e m o r t a r i s q u i c k l y dashed i n t o t h e mould from a small scoop s o t h a t i n a f e w seconds t h e m o r t a r i s heaped above t h e t o p of t h e mould. A s t r a i g h t m e t a l edge i s moved a c r o s s t h e t o p s u r f a c e s of t h e mould

t o

s c r a p e o f f t h e m o r t a r a t a h e i g h t of 3/8-in. above t h e b r i c k s u r f a c e . The mould i s t h e n l i f t e d from t h e b r i c k , l e a v i n g t h e bed of m o r t a r .A c e r t a i n time a f t e r t h e m o r t a r comes i n c o n t a c t w i t h t h e b r i c k , t h e n e x t b r i c k i s p l a c e d on t h e m o r t a r bed. The l e n g t h o f t i m e t h e m o r t a r bed remains on t h e b r i c k b e f o r e t h e n e x t b r i c k i s p l a c e d on it h a s a n i m p o r t a n t i n f l u e n c e on t h e r e s i s t a n c e of t h e w a l l t o m o i s t u r e p e n e t r a t i o n , a s w i l l be shown.

The second b r i c k i s p l a c e d on t h e m o r t a r bed d i r e c t l y o v e r t h e b r i c k below, and immediately a t a p p i n g d e v i c e i s p l a c e d on it. T h i s i s a s m a l l hammer r a i s e d a c e r t a i n d i s t a n c e and dropped t o d e l i v e r a n impact t o t h e b r i c k , bedding it i n t h e mortax.

Tihen t h e f i r s t m o r t a r j o i n t i s completed and t h e b r i c k s e t i n i t , t h e mould i s c l c a n e d and p l a c e d on t h e upper b r i c k , and tlie n . m e procedure i s follorn?ed i n l a y i n g a n o t h e r b r i c k , w i t h a f r e , : h l y mixed b a t c h of mortar.

The

f o l l o w i n g schedule h a s been used i n p r e p a r i n g p a n e l s when t h e time f a c t o r between p l a c i n g t h e mortar i n c o n t a c t w i t h t h e b r i c k and p l a c i n g t h e n e x t b r i c k on them o r t a r

was

45

seconds. The w a t e r , cementing m a t e r i a l s and sand a r e proportioned beforehand f o r t h e f o u r b a t c h e sr e q u i r e d . Time

-

0 min. 2 min.3

min. 4 min. ProcedureS t a r t mixer, slow speed, and add sand t o bowl i n f i r s t 2 0 seconds ( w a t e r and cementing m a t e r i a l placed i n bowl b e f o r e mixer s t a r t e d ) .

Stop mixer, s w i t c h t o medium speed,

s c r a p e down mortar i n t o bowl,

start

mixer. Stop mixer, a l l o w mortar t o s t a n d i nbowl.

P l a c e m o r t a r i n form, s c r a p e o f f e x c e s s , remove form from b r i c k .

4

min. 45 s e c . Place b r i c k on mortar and t a p w i t h hammer. Clean and d r y t h e mixer bowl and b l a d e , t h e mortar mould and o t h e r equipment; prepare f o r second mix.9

min. S t a r t second mix.DIix

a s above.1 2 min. Stop mixer, a l l o w mortar t o s t a n d .

1 3 min. P l a c e mortar i n form a s above.

1 3 min. 45 s e c . P l a c e b r i c k on m o r t a r and t a p . P r e p a r e f o r t h i r d mix a s above.

18 min. S t a r t t h i r d mix.

2 1 min. Stop mixer, a l l o w mortar t o s t a n d . 22 min. P l a c e m o r t a r i n form

a s

above.22 min. 45 s e c . Place b r i c k on mortar and t a p . Prepare f o r f o u r t h mix.

27 min. S t a r t f o u r t h mix.

30 min. Stop mixer, a l l o w mortar t o s t a n d .

3 1 min. P l a c e mortar i n form

as

p r e v i o u s l y . 3 1 min.45

sec. P l a c e b r i c k on mortar and t a p .A f t e r t h e y a r e made, t h e p a n e l s a r e s t o r e d a n d l o a d e d w i t h

3

b r i c k s ; t h i s l o a d i s a p p l i e d u n t i l t h e t e s t i s made. So t h a t t h e m o r t a r s u r f a c e s a t t h e s i d e s of t h e p a n e lw i l l

b e l e v e l w i t h t h e b r i c k s , t o a l l o w t h e p a n e l t o be w e l l s e a l e d i n t h e t e s t a p p a r a t u s , wet m o r t a r i s a p p l i e d w i t h a s o f t b r u s h t o t h e j o i n t s a t t h e s i d e s t o b r i n g them f l u s h . The m o r t a r j o i n t s o f t h e f r o n t and back f a c e s o f t h e p a n e l , however, a r e l e f t as formed i n t h e mould and a r e n o t t o o l e d o r o t h e r w i s e t r e a t e d . The p a n e l s a r e c o n s t r u c t e d , s t o r e d and t e s t e d i n a l a b o r a t o r y of c o n t r o l l e d t e m p e r a t u r e and h u m i d i t y(73"l?,

50%

R . H . ) . A f t e r a p a n e l i s made, i t i s covered on a l l s u r f a c e s by p l a s t i c s h e e t i n g f o r 24 h o u r s . T h i s c o v e r i n g i s t h e n removed from t h e f a c e and back o f t h e p a n e l , b u t n o t from t h e s i d e and t o p s u r f a c e s , and t h e f a c e and back a r e exposed t o l a b o r a t o r y a i r u n t i l t h e p a n e li s t e s t e d .

For p a n e l s made of l i m e m o r t a r , however, o n l y t h e t o p and s i d es u r -

f a c e s a r e c o v e r e d ; t h e f a c e and back of t h e p a n e l a r e l e f t exposed t o t h e a i r immediately a f t e r it i s c o n s t r u c t e d .Before t h e t e s t , t h e edges o f t h e p a n e l a r e s e a l e d w i t h

a

p l a s t i c a d h e s i v e ("Lasto-Meric", made by Tremco Manufacturing Company, T o r o n t o ) , and t h i s i s c o v e r e d w i t ha

s h e e t o f 10-mil p o l y e t h y l e n e p l a s t i c which e x t e n d s a b o u tan

i n c h from t h e p a n e l f a c e s . ' A t th.e bottom o f t h e p a n e li t

a c t s a s a d e f l e c t o r f o r m o i s t u r e , l e a d i n g it away from t h e f a c e s o f t h e p a n e l .The t e s t i s u s u a l l y made 1 4 d a y s a f t e r c o ~ z s t r u c t i o n o f t h e p a n e l and

i t

lasts f o r24

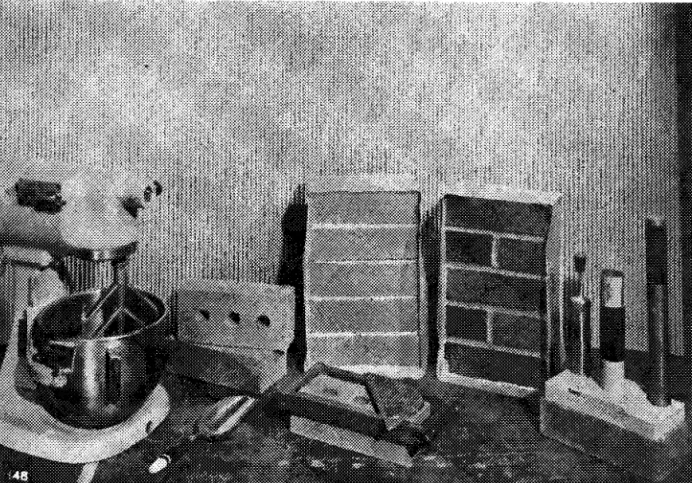

h o u r s .The equipment u s e d i n making t h e p a n e l s i s shown i n Fig. 1.

The

mechanical m i x e r on t h e l e f t i s u s e d t o p r e - p a r e t h e m o r t a r ; t h e mould f o r forming t h e m o r t a r j o i n t i s shown i n t h e c e n t r e , f i t t e d o v e ra

b r i c k . The s c o o p i su s e d t o d a s h t h e m o r t a r i n t o t h e mould; t h e m o r t a r i s s c r a p e d o f f w i t h t h e m e t a l s t r a i g h t - e d g e shorvn on t o p o f t h e mould. The t a p p i n g d e v i c e i s sllorm on t h e right, p l a c e d o v e r

a

b r i c k . It c o n s i s t s o f a wooden b a s e t o whichi s a t t a c h e d

a

m e t a l p l a t e and t u b e . Two d r o p p i n g hammers have been u s e d , a s shown, one weighing 2 I b and t h e o t h e r4

I b .'Phese a r e p l a c e d i n t h e t u b e a n d dropped t h r o u g h a d i s t a n c e o f

13

i n c h e s . A completed p a n e l w i t h p l a s t i c s e a l i n garound t h e edges i s shorm behind t h e mould; b e s i d e it i s a p a n e l c u t from brickwork removed from t h e w a l l o f

a

b u i l d i n g , s i m i l a r l y p r e p a r e d f o r t e s t .Qparatus

f o r liloisture P e n e t r a t j - o n --.-Tests

The p a n e l i s f i t t e d i n a n a p p a r a t u s designed t o

s p r a y w a t e r on one s u r f a c e o:f t h e panel t o f o r m a continuous f i l m and a t t h e same time t o a p p l y ai.r p r e s s u r e a g a i n s t t h e w e t t e d s u r f a c e . A c o n d i t i o n of t e s t simula.ti.ng heavy

wind-driven r a i n i s t h u s produced. T h e method of t e s t was a d a p t e d from t h a t developed a t t h e 1JnLt;ed S - t a t e s N a t i o n a l Bureau of S t a n d a r d s for t e s t i n g i a r p e p:mels of b r i c k masonry (1).

The panel i s mounted i: a frame c u ~ i s t r u c t e d of s t e e l c h a m e l members ( 4 - by l F - i n . ) a s shobvn i n F i g , 2.

The

panel i s s e p a r a t e d from t h eframe

at

t h e s i d e s and t o p by a s h e e t of foamed p1ast:ic:5/4-.in.

. t h i c k , and a t t h e bottom by a t h i n s h e e t of sponge r u b b e r about 1/8-in. t h i c k . One of t h e s i d e members cell b e rnoved l a t e r a l l y by two screws, b r i n g i n g t h e sponge pl..asi;i.c :;rlugly a g a i n s t t h e s i d e s of t h e p a n e l . !This s i d e nernber i s t h e n s e c u r e d t o t h e base of t h e frame by a 'ba3:t. %no t o p of t h e framei s

connected by b o l t s t o -the s i d e members, and can t h u s be t i g h t e n e d a g a i n s t t h e sponge plas't.:'j.c laid on t o p of t h e p a n e l . The p a n e l i s t h e r e f o r e finn1.y h e l di n t h e frame

and s e a l e d a t t h e edges b y t h e spo.rii~e p:l.as-tic which t a k e s up any s l i p a t unevenness i n t h e f ? d { ; ~ : s of' t h e p a n e l .The t e s t panel and frame f u m onc w a l l o f a n a i r p r e s s u r e chamber a l s o cons-t-ructed o C s teczl channel members

( 4 -

by 1 6 - i n . ) . The edges o f t h o chamher a r e f i t t e d w i t h sponge p l a s t i c which p r a v i d e s ;an e f f e c t i v e :?eaI. when t h e frame i s f a s t e n e d t o t h e chamber by thr P o l ' t s provided.The a i r p r e s s u r e chambcr i s shown i n Fig. 2. The frame and chamber a r e moved i n t o p o s i t i o n f a c i n g one a n o t h e r and t h e b o l t s of t h e frame a r c fitted i n t o t h e s l o t s on

t h e chamber. By t i g h t e n i n g t1he f o u r n u t s , t h e two p a r t s a r e s e a l e d t o g e t h e r . The o t h c r w a l l o f -the p r e s s u r e chamber i s made of c l e a r plas t i c mat;ori.aI.. W s e c t i o n a l drawing of t h e frame and p r e s s u r c chamber i s shown in Fig. 3 .

The w a t e r s p r a y t u b e

i s

a l e n g t h of b r a s s p i p e , w i t h h o l e s d r i l l e d a l o n gi t s .I.er@th, spaced 3/8-in. a p a r t .

The s i z e of h o l e i s t h a t o b t a i n e d

f r m

a Mo.76

d r i l l . A flow of w a t e r about 6 0 0 m l p e r minu-be i s maintained through t h e h o l e s , from a c o n s t a n t - l e v e l w a t e r supply.The w a t e r s p r a y t u b e i s i l e l d 3.n p l a c e by a p i e c e of m e t a l a t t a c h e d t o it which f i t s between .the p l a s t i c and t h e t o p b r i c k of t h e p a n e l .

The s p r a y w a t e r e n t e r s %he t o p o f t h e p r e s s u r e chamber and p a s s e s through a rubtier tube t o t h e s p r a y pipe. The w a t e r p a s s e s down t h e f a c e of the panel, and on r e a c h i n g

t h e p l a s t i c s h e e t i s d e f l e c t e d away from t h e f a c e and f a l l s i n t o t h e bot-Com o f t h e p r e s s u r e chamber. A d r a i n t u b e

l e a d i n g f r o m t h e b a s e o f t h e chamber c a r r i e s t h e w a t e r away. An a i r b l o c k i s f i t t e d i n t h e d r a i n t u b e t o m a i n t a i n t h e p r e s s u r e

i n

t h e chamber.The w a l l of t h e p r e s s u r e chamber i s made o f

a

c l e a r p l a s t i c s h e e t a b o u t $ - i n c h t h i c k h a v i n g two d r i l l e d a c c e s s h o l e s . A t %he s t a r t of t h e t e s t a small b r u s h i s i n s e r t e d t h r o u g h t h e a c c e s s h o l e s i n t h e window t o s p r e a d t h e s t r e a m s of w a t e r o v e r t h e o n t i r e s u r f a c e o f t h e p a n e l . Normally w i t h some p a n e l si t

t a k e s c o n s i d e r a b l ~ t i m e f o r t h e small s t r e a m s o f w a t c r t o s p r e a d o v e r t h e s u r f a c e t o e s t a b l i s ha

c o n t i n u o u s f i l m . I n t h e t e s t , t h i s i s dono by t h e b r u s h i m m e d i a t e l y a f t e r t h e vfater spray i s s t a r t e d . The h o l e s a r e t h e n s e a l e d w i t h n t b b e r s t o p p e r s a s shown i n F i g . 2 , and t h e a i r p r e s s u r e i s a p p l i e d . The c o n s t u n t - l e v e l w a t e r s u p p l y t o t h e s p r a y t u b e i s shown i n F i g . 4. \ $ l a t e r i s b r o u y h t from t h o t a p t o t h e i n v e r t e d b o t t l e . Two t u b e s l e a d f r o m t h e s t o p p e r o f t h e b o t t l e . The l a r g e one i sa

d r a i n t u b e t o t h e s i n k ; t h e o t h e r i s t h e w a t e r s u p p l y t u b e t o t h e p r e s s u r w chamber. Water i s s u p p l i e d t o t h e b o t t l e a t a r a t e e x c e e d i n 6 t h e f l o wi n

t h e s p r a y t u b e , a n d t h e excess is d r a i n e d t h r o u g h t h e l a r g e t u b e . A c o n s t a n t l e v e l i s t h e r e f o r e m a i n t a i n e d above t h e s p r a y t u b e . A s shown i n P i g . 4 , t h e w a t e r e n t e r s t h e t o p of t h e p r e s s u r e chamber, p a s s e s by r u b b e r t u b e t o t h e s p r a y p i p e (as i n d i c a t e d by t h e w h i t e c o r d ) , a n d t h e n down t h e f a c e of t h e p a n e l . It i s d e f l e c t e d by t h e p l a s t i c s h e e t a t t h e b a s e of t h e p a n e l i n t o t h e d r a i na t

t h e bottom o f t h e p r e s s u r e chamber. Compressed a i r from t h e l a b o r a t o r y s u p p l y i s u s e d f o r t h e a i r p r o s s u r e chamber. The flovr o f a i r t o t h echamber i s r e g u l a t e d by t h e v a l v e shown i n P i p . 2 , a t t a c h e d t o t h e s i d e o f the chamber ( M i n n e a p o l i s Honeyviell No.

356529, Biranual Loading I k e s s u r e R e ~ u l a t o r ) . The a i r e n t e r s t h e s i d e v i a l 1 o f t h e charnbcr b e n e a t h t h e r e g u l a t o r v a l v e . A manometer i s mounted on t o p of t h e p r e s s u r e chamber a s shown i n F i g . 2.

I n t h e t e s t s made s o f a r , t h e a i r p r e s s u r e d i f f e r e n c e a c r o s s t h e p a n e l

i s m a i n t a i n e d

a t two i n c h o s o f w a t e r , which i s a p p r o x i m a t e l y e q u i v a l e n t t o t h e p r e s s u r e o f a 50-mphwind blo~.rln(; n{;ains& a w a l l . A r e c o r d i s made o f t h e t i m e t a k e n f o r dampness t o a p p e a r on t h e back of t h e p a n e l

and of t h e r z t e a t v~llich 1ecika;:e ~rrat-er comes o f f t h e back s u r f a c e

of

t h e p a n e l . T h e t c s t s a r c u s u a l l y c o n t i n u e d f o r 2 4 h o u r s .R e s u l t s of T e s t s

F i r s t t e s t s mere made of n i n e p a n e l s i n which one t y p e o f m o r t a r a n d t h r e e t y p e s o f b r i c k s were u s e d , w i t h each combination r e p r e s e n t e d by t h r e e p a n e l s .

The m o r t a r was composed of one p a r t by volume o f p o r t l a n d cement, t h r e e p a r t s of s a n d , and o n e - h a l f p a r t of

a

c l a y p l a s t i c i z e r mixed w i t h w a t e r t o a f l o w o f a b o u t 115 p e r c e n t . The sand w a s a n a t u r a l sand o f p a r t i c l e - s i z e g r a d i n g which conformed t o t h e r e q u i r e m e n t s o f C . S . A . andA.S.T.M.

s p e c i f i c a t i o n s . I n t h e s e and s u b s e q u e n t t e s t sa

l / 3 0 - c u b i c f o o t volume o f compacted, a i r - d r y sand was u s e d f o r t h e m o r t a r b a t c h e s ( s u c h a volume i s o b t a i n e d from t h e s t a n d a r d mould used i n A.S.T.M. s o i l t e s t s ) . The amounts o f cementing m a t e r i a l s f o r t h e m o r t a r s were t h e n c a l c u l a t e d on t h e b a s i s of t h e volume of s a n d .The t h r e e t y p e s o f b r i c k s v a r i e d g r e a t l y i n i n i t i a l r a t e o f a b s o r p t i o n o r s u c t i o n . Those of t h e f i r s t t y p e were between 1 and

3

gm/rnin/30 s q i n . of bedding a r e a ( b ys t a n d a r d t e s t of d e t e r m i n i n g t h e w e i g h t i n c r e a s e i n grams when t h e dry b r i c k i s p l a c e d f o r one minute i n w a t e r t o a d e p t h of 1/8 i n c h ) . m e i n i t i a l r a t e o f a b s o r p t i o n o f t h e second t y p e w a s between 1 6 and 18 ,gn/min/30 s q i n . , w h i l e t h a t o f t h e t h i r d t y p e w a s 7 1 t o 73 gm.

The p a n e l s were t e s t e d 2 8 days a f t e r c o n s t r u c t i o n , r a t h e r t h a n a t 1 4 d a y s , t h e a g e of l a t e r p a n e l s when t e s t e d . The r e s i s t a n c e of t h e p a n e l s t o m o i s t u r e p e n e t r a t i o n d i f f e r e d g r e a t l y , a p p a r e n t l y l a r g e l y because of t h e t y p e o f b r i c k u s e d . A 1 1 t h r e e p a n e l s o f t h e b r i c k o f low i n i t i a l r a t e

of

a b s o r p t i o n were h i g h l y r e s i s t a n t t o m o i s t u r e p e n e t r a t i o n . Although some damp s p o t s a p p e a r e d i n t h e m o r t a r j o i n t sd u r i n g t h e t e s t t h e r e was no f r e e w a t e r coming o f f t h e backs

of

t h e p a n e l s . O f t h e t h r e e p a n e l s of t h e b r i c k of moderate i n i t i a l r a t e of a b s o r p t i o n two l e a k e d a t a sliat r a t e w h i l e t h e t h i r d l e a k e d a t a c o n s i d e r a b l y h i g h e r r a t e . The l e a k a g e o f t h e p a n e l s o f t h e h i g h - s u c t i o n b r i c k was a l s o inconsistent, two o f t h e pmels h a v i n ga

h i g h r a t e of leaka{;e and t h e t h i r d a r e l a t i v e l y low r a t e .It w a s i n d i c a t e d from t h e s e t e s t s t h a t t h e t y p e of b r i c k used w i t h t h i s p a r t i c u l a r m o r t a r g r e a t l y i n f l ~ ~ e n c e d t h e r e s i s t a n c e o f t h e pnt::Ls t o m o i s t u r e p e n e t r a t i o n . !The i n c o n s i s t e n c i e s i n t h e r e s u l t s f o r t h e b r i c k s of moderate and h i g h i n i t i a l r a t e s o f a b s o r p t i o r ! , however, were v e r y n o t i c e a b l e . Those were b e l i e v e d clue i r ? some p a r t 'to the v a r i a b l e t i m e f a c t o r bc!tv~een placiri;: 'thc m o r t a r on 'the

I n t h e s e f i r s t t e s t s , t h e m o r t a r was p l a c e d i n t h e form. a s soon a s p o s s i b l e a f t e r t h e mixer w a s stopped and t h e second b r i c k was p l a c e d on t h e m o r t a r bed and tapped a t a s e t time a f t e r t h e mixer was stopped ( r a t h e r t h a n at. t h e s e t time a f t e r t h e m o r t a r came i n c o n t a c t w i t h t h e f i r s t b r i c k ) . T h i s procedure probably i n t r o d u c e d a v a r i a t i o n i n t h e time of c o n t a c t between t h e m o r t a r and t h e bottom b r i c k b e f o r e

t h e n e x t briclr was l a i d which cou1.d i n f l u e n c e t h e bond between t h e b r i c k and m o r t a r and t h u s a f f e c t t h e m o i s t u r e p e n e t r a t i o n of t h e p a n e l s .

Three a d d i t i o n a l p a n e l s w e r e c o n s t r u c t e d of t h e b r i c k of h i g h i n i t i a l r a t e of a b s o r p t i o n , and t h e same mortar. The time fact-or betwt?cn p l a c i n g t h e mortal- on t h e b r i c k and t h e n s e t t i n g t h e n e x t b r i c k on i t was c a r e f u l l y c o n t r o l l e d . When t h e s e p a n e l s w e r e t e s t e d i t was found t h a t t h e r a t e s of l e a k a g e were v e r y c o n s i s t e n t .

Decrease i n Leakage Rate

I n t h e s e f i r s t t e s t s and i n l a t e r o n e s , it was observed t h a t t h e r a t e of l e a k a g e of m o i s t u r e through t h e p a n e l s d e c r e a s e d v e r y n o t i c e a b l y d u r i n g t h e t e s t , par- t i c u l a r l y i n t h e f i r s t h o u r o r s o . Some examples which i l l u s t r a t e t h i s a r e shown i n P i g ,

5

i n which th.e r a t e of l e a k a g e i s p l o t t e d a g a i n s t L h e 'time l a p s e s i n c e t h e s t a r t of t h e t e s t .A t f r e q u e n t i n t e r v a l s d u r i n g t h e t e s t s w a t e r which l e a k e d through t h e p a n e l and came o f f t h e back was c o l l e c t e d o v e r a p e r i o d of one minute, and t h e l e a k a c e r a t e s o f t h e p a n e l s a t p a r t i c u l a r t i m e s durin(:. t h e t e s t s a r e expressed on t h e g r a p h s i n m i l l i l i t r e s p e r minute.

Flow of t h e Mortar

S e v e r a l p a n e l s were b u i l t t o i n v e s t f g a t e t h e i n f l u e n c e

o f

m o r t a r f l o w , t a p p i n g impact and t h e time f a c t o r on m o i s t u r e p e n e t r a t i o n .For t h e s e p a n e l s a s t i f f mud b r i c k w i t h 3 c o r e - h o l e s was used. The i n i t i a l r a t e of a b s o r p t i o n of t h e b r i c k

v a r i e d from a b o u t 8 t o

35

gm/n1in/30 sq i n . For t h e p a n e l s , however, b r i c k s were s e l e c t e d t o be i n t h e range 11 t o 1 4grams. Each panel c o n t a i n e d one b r i c k of t h e f a l l o w i n g i n i t i a l r a t e of a b s o r p t i o n : 11, 1 2 , and 14 grams, and t w o b r i c k s of 1 3 grams. Although t h e i n i t i a l r a t e of a b s o r p t i o n of t h e b r i c k s i n a p a n e l v a r i e d t h e r e f o r e , i t was o v e r a s m a l l range and each panel c o n t a i n e d t h e same number of b r i c k s of t h e same a b s o r p t i o n r a t e .

The m o r t a r s u s e d were composed of a n a t u r a l s a n d , a s d e s c r i b e d p r e v i o u s l y , mixed w i t h masonry cement o r l i m e p a s t e . The amount of sand i n each b a t c h was 1/30-cubic f o o t .

C o n s i d e r a b l e d i f f i c u l t y w a s e x p e r i e n c e d i n o b t a i n i n g c o n s i s t e n t f l o w v a l u e s f o r t h e m o r t a r mixes used. (I'he

flow i s measured i n t h e s t a n d a r d method by moulding a

t r u n c a t e d cone of t h e f r e s h m o r t a r on a , c i r c u l a r m e t a l p l a t e which i s dropped t h r o u g h a d i s t a n c e o f 7 i n c h ,

2 5

t i m e s i n1 5

s e c o n d s ; t h i s c a u s e s t h e m o r t a r t o s p r e a d depending on i t s c o n s i s t e n c y . The i n c r e a s ei n d i a m e t e r

o f t h e b a s e of t h e cone of m o r t a r , e x p r e s s e d as a p e r c e n t a g e of t h eo r i g i n a l d i a m e t e r , i s termed t h e flow of t h e m o r t a r .

The

h i g h e r t h i s v a l u e i s , t h e more f l u i d i s t h em o r t a r ) ,

I n p r e p a r i n g t h e m o r t a r , t h e s a n d and cementing

m a t e r i a l s wore c a r e f u l l y weighed t o g i v e t h e r e q u i r e d volumes f o r t h e b a t c h a n d t h e w a t e r w a s c a r e f u l l y measured i n a

g r a d u a t e d c y l i n d e r . Even a f t e r t h e c o n t r o l l e d s c h e d u l e o f mixing t h e same amounts o f i n g r e d i e n t s f o r each b a t c h t h e r e s u l t i n g flow v a l u e s o f t e n v a r i e d w i d e l y ,

For one o f t h e masonry cements u s e d in p r e p a r i n g m o r t a r

i t

was found t h a t t h e f l o w o f s u c c e s s i v e mixes v a r i e d between 1 1 0 and 1 2 0 p e r c e n t . m e v a r i a b i l i t y o f f l o w o f t h e m o r t a rwas

r e d u c e d , however, t o a r a n g e betwoen 110 and 1 1 5p e r c e n t when t h e masonry cement and sand were p a s s e d t h r o u g h

a

r i f f l e t o o b t a i n i d e n t i c a l samples f m m t h e same bag ofcement and from t h e s a n d , I n t h e p r e v i o u s c a s e t h e cement h a d been t a k e n d i r e c t l y from t h e bag.

The impor-tiance of t h e f l o w o r c o n s i s t e n c y o f t h e m o r t a r

was

o b s e r v e di n

comparing t h e m o i s t u r e p e n e t r a t i o nc h a r a c t e r i s t i c s o f two s e t s o f p a n e l s , each of t h e same b r i c k and m o r t a r , and c o n s t r u c t e d , aged and t e s t e d i n t h e same way, t h e o n l y d i f f e r e n c e b e i n g i n t h e f l o w of t h e m o r t a r a s u s e d .

The p a n e l s were c o n s t r u c t e d of l i m e :sand m o r t a r , The l i m e

was

o b t a i n e d by s l a k i n g a q u i c k l i m e t o p u t t y which w a s s t o r e d f o r s e v e r a l weeks b e f o r e u s e . The p a n e l s were t e s t e d 1 4 d a y s a f t e r t h e y were made. I n c o n s t r u c t i n g t h r e e o f t h e p a n e l s t h e m o r t a r w a s u s e d a t a r e l ' a t i v e l ylow

f l o w , a v e r a g i n g 110 p e r c e n t ; i n t h e o t h e r t h r e e p a n e l s t h e m o r t a rwas

u s e d a t a n a v e r a g e flow of 1 2 8 p e r c e n t , I n b o t h c a s e s , however, t h e r e w a s a v a r i a t i o n i n f l o w from b a t c h t o b a t c h o f a s much as f5

p e r c e n t from t h e a v e r a g e .I n

t h e c o n . s t r u c t i o n of t h e p a n e l s t h e t i m e i n t e r v a l between p l a c i n g t h e m o r t a r on t h e b r i c k and t h e , n e x t b r i c k on t h e m o r t a r was 45 s e c o n d s ,The p a n e l s o f t h e lovr-flow m o r t a r allowed moisture t o p e n e t r a t e immediately a f t e r t h e start of t h e t e s t . Those of high-flow m o r t a r showed g r e a t e r r e s i s t a n c e , a l t h o u g h

dampness appeared on t h e back of t h e p a n e l s i n

13,

3 and 25 minutes a f t e r t h e s t a r t of t h e t e s t . The r a t e of leakage of moisture through t h e p a n e l s was much g r e a t e r f o r t h o s e of t h e low-flow mortar, a s shown i n T a b l e I i n which t h e p a n e l s a r e compared on t h e b a s i s o f t h e maximum r a t e of moisture p e n e t r a t i o n measured during t h e t e s t ( m l of w a t e r p e r minute coming o f f t h e back of t h e p a n e l ) .TABLE I

LEAKAGE

RATES

FOR PANELS OF LOW-PLOWAND

HIGH-FLOW MOHTARPanel Average Plow Maximum

Hate

o f LeakageNumber of Mortar ( $ ) (ml/min from, back of p a n e l )

S i m i l a r r e s u l t s were obtained with panels c o n s t r u c t e d of

a

masonry cemen-t mortar, t h e leakage of t h e panel being a p p r e c i a b l y g r e a t e r w i t h t h e low-flow mortar.I t i s evident from t h e s e t e s t r e s u l t s t h a t the flow of t h e m o r t a r a s used i n panel c o n s t r u c t i o n h a s an a p p r e c i a b l e i n f l u e n c e on t h e moisture p e n e t r a t i o n of t h e p a n e l s . A t

t h e same time t h e flow of m o r t a r i s a p r o p e r t y which a p p a r e n t l y can vary widely from b a t c h t o b a t c h and i s d i f f i c u l t t o

c o n t r o l w i t h i n c l o s e

l i m i t s .

Time

F a c t o rSeveral panels were c o n s t r u c t e d of a masonry cement mortar used w i t h t h e b r i c k s d e s c r i b e d p r e v i o u s l y ( i n i t i a l r a t e of a b s o r p t i o n 11 t o 14 gm/min). I n t h e s e p a n e l s t h e m o r t a r flow was r e l a t i v e l y h i g h , averaging 127 p e r c e n t , b u t w i t h v a r i a t i o n from b a t c h t o b a t c h a s noted before. One s e t of panels was c o n s t r u c t e d w i t h

a

time f a c t o r of45

seconds between p l a c i n g t h e m o r t a r on t h e b r i c k and p l a c i n g t h e n e x t b r i c k on t h e mortar. Another s e twas

c o n s t r u c t e d w i t h a time f a c t o r of 1+ minutes. The panels were s t o r e d under t h e same c o n d i t i o n s f o r

1 4

days b e f o r e being t e s t e d .It was found t h a t t h e a v e r a g e maximum r a t e of l e a k a g e of m o i s t u r e t h r o u g h t h o p a n e l s was t w i c e as g r e a t f o r t h e p a n e l s c o n s t r u c t e d w i t h t h e 12-minute t i m e f a c t o r a s f o r t h o s e of t h e 45-second t i m e f a c t o r . Although few t e s t s have been made t o i n v e s t i g a t e t h e i n f l u e n c e of t h i s f a c t o r on m o i s t u r e p e n e t r a t i o n ,

it

i s now b e l i e v e d t o be of c o n s i d e r a b l e i m p o r t a n c e . Tapping Impact I n t h e f i r s t t e s t when t h e b r i c k w a s p l a c e d on t h e bed o f m o r t a r it w a s s t r u c k by a 2 - l b hammer f a l l i n g t h r o u g h 1$ i n c h e s . A l a t e r s e r i e s of t e s t s was made u s i n ga

hammer t w i c e t h i s w e i g h t t o d e t e r m i n e t h ei n -

f l u e n c e of t h e s t r e n g t h of t a p on t h e m o i s t u r e p e n e t r a t i o nof

t h e p a n e l .l n b o f h c a s e s t h e hammer

w a s dropped t h r o u g ha

d i s t a n c e of 1$ i n c h e s . S i x p a n e l s were c o n s t r u c t e d o f t h e 1ime:sand m o r t a r d e s c r i b e d p r e v i o u s l y , mixed t oa

r e l a t i v e l y low flow ( a v e r a g e a b o u t 110 p e r c e n t ) . I n c o n s t r u c t i n g t h r e e o f t h e p a n e l s , t h e b r i c k s were t a p p e d w i t h t h e 2 - l bhammer; i n t h e o t h e r t h r e e t h e 4 - l b hammer w a s used. I n Table I1 t h e p a n e l s a r e compared

on

t h e b a s i s of t h e maximum r a t e o f m o i s t u r e p e n e t r a t i o n measured d u r i n g t h e 24-hr t e s t . The r a t e of m o i s t u r e p e n e t r a t i o n i s e x p r e s s e d a s m l p e r minute.TABLE I1

LEAICAGE RATES FOR P A N E L S CONSmUCTED BY L I G H T AND HSAVY IXQACTS ON rPHE BRICKS

P a n e l Average Flow Hammer Weight IYIaximum Rate of

Number of Mortar ( f a l l i n g t h r o u g h Leakage (ml/min

($1

1s

i n c h e s ) from back o f p a n e l )The f l o w of t h e m o r t a r u s e d i n t h e p a n e l s which were c o n s t r u c t e d w i t h t h e h e a v i e r t a p was s l i g h t l y l e s s t h a n t h a t of t h e o t h e r s , a s shown i n t h e t a b l e . The d i f f e r e n c e be-tween t h e r e s u l t s , however, would have been even g r e a t e r had t h e f l o w s b e e n i d e n t i c a l , s i n c e , a s shown

b e f o r e , i n c r e a s e d f l o w r e s u l t s i n g r e a t e r r e s i s t a n c e t o m o i s t u r e p e n e t r a t i o n . I t i s e v i d e n t from t h e r e s u l t s o f t h e s e t e s t s t h a t t h e amount o f i m p a c t g i v e n t o t h e b r i c k s e t on a bed of m o r t a r c a n i n f l u e n c e c o n s i d e r a b l y t h e m o i s t u r e pene- t r a t i o n q u a l i t i e s o f tlie pan.el. C o n c l u s i o n A method o f i n v e s t i g a t i n g some o f t h e f a c t o r s which i n f l u e n c e m o i s t u r e p e n e t r a t i o n p r o p e r t i e s o f b r i c k masonry, u s i n g small p a n e l s s u b j e c t e d t o c o n d i t i o n s s i m i l a r t o a heavy w i n d - d r i v e n r a i n , h a s b e e n d e s c r i b e d . R e s u l t s o f t e s t s i n d i c a t e t h a t t h e m o i s t u r e pone- t r a t i o n o f t h e t e s t p a n e l s depended on t h e t y p e o f b r i c k a n d m o r t a r u s e d . t o a c o n s i d e r a b l e e x t e n t on t h e f l o w o f t h e m o r t a r , on t l i e t i m e i n t e r v a l between p l a c i n g m o r t a r on b r i c k , t h e n b r i c k on m o r t a r and on t h e t a p p i n g i m p a c t i m p a r t e d t o t h e b r i c k when i t i s p l a c e d i n - m o r t a r , I n c o n s i s t e n c i e s i n r e s u l t s were f r e q u e n t l y n o t e d , a n d

it

w a s i n d i c a t e d t h a t v e r y c a r e f u l c o n t m l o f t h e f a c t o r s d e s c r i b e d p r e v i o u s l y i s r e q u i r e d t o minimize t h e s e i n c o n s i s t e n t r e s u l t s . I t was o b s e r v e d t h a t t h e i n i t i a l p e n e t r a t i o n o f m o i s t u r e o c c u r r e d between t h e t o p s u r f a c e o f t h e m o r t a r j o i n t a n d t h e b r i c k . Some p a n e l s were b r o k e n a f t e r t h e t e s t t o examine t h e e x t e n t o f bond between b r i c k a n d m o r t a r . F o r t h e p a n e l s which l e a k e d t h e e x t e n t o f bondw a s

v e r y i n c o m p l e t e w i t h many a r e a s o f t h e b r i c k a p p a r e n t l yunbonded t o t h e m o r t a r . By d a s h i n g t h e m o r t a r a g a i n s t t h e t o p s u r f a c e o f t h e b r i c k a f a i r l y complete e x t e n t o f bond i s o b t a i n e d , b u t t h e t o p i n t e r f a c e between m o r t a r a n d b r i c k may have many unbonded a r e a s dependint;; or, t h e m a t e r i a l s u s e d , and on o t h e r f a c t o r s .

I t w a s o b s e r v e d d u r i n g t e s t s o f p a n e l s t h a t were permeable t h a t t h e r a t e o f m o i s t u r e p e n e t r a t i o n o f t h e

p a n e l s d e c r e a s e d v e r y markedly d u r i n g t h e t e s t , p a r t i c u l a r l y i n t h e f i r s t h o u r o r s o . This may have been due t o s w e l l i n g o f t h e m o r t a r a s

i t

became damp which r e d u c e d t h e s i z e o f o p e n i n g s , t o p l u g g i n g o f some o f t h e moist!.~re p a t h s by p a r t i c l e s o f m a t e r i a l moving w i t h t h e w a t e r o r t o some o t h e r c a u s e . One p a n e l w a s d r i e d a f t e r t h e t e s t , and t h e t e s t was r e p e a t e d . The maximum l e a k a g e r a t e and t h e c u r v e of d e c r e a s e i n r a t e o f l e a k a g e d u r i n g t h e second t e s tI n normal b r i c k l a y i n g o p e r a t i o n s t h e t i m e which e l a p s e s behveen t h e m o r t a r coming i n c o n t a c t w i t h t h e b r i c k t o form t h e m o r t a r bed and t h e p l a c i n g o f t h e n e x t b r i c k i n it may v a r y c o n s i d e r a b l y . Some o b s e r v a t i o n s made l o c a l l y have i n d i c a t e d t h a t t h i s time i n t e r v a l mag be as s h o r t a s 1 5 s e c o n d s o r a s l o n g a s 60 s e c o n d s , s i n c e

i t

i s common p r a c t i c e f o r t h e b r i c k l a y e r t o s p r e a d o u t t h e m o r t a r bed i n advance f o r f o u r b r i c k s . These o b s e r v a t i o n s were made on o n l y a few jobs and t h e t i m e r a n g e may be g r e a t e r t h a n t h i s u n d e r o t h e r c o n d i t i o n s . The t e s t s d e s c r i b e dp r e v i o u s l y have shown t h a t t h e t i m e f a c t o r i s of c o n s i d e r a b l e importance i n t h e l e a k a g e c h a r a c t e r i s t i c s of t h e p a n e l .

!l?he b r i c k l a y e r may t a p t h e b r i c k s i n t o t h e m o r t a r bed. T e s t s were made t o i n v e s t i g a t e t h e i n f l u e n c e o f t h e t a p p i n g i m p a c t on m o i s t u r e p e n e t r a t i o n . T t

was

found t h a t t h e impact c a n a f f e c t g r e a t l y t h e r e s i s t a n c e t o m o i s t u r e p e n e t r a t i o n .The f l o w of t h e mor-liar was a l s o found t o be a n i m p o r t a n t i n f l u e n c e on t h e m o i s t u r e p e n e t r a t i o n p r o p e r t i e s

o f

t h e brickwork and i n a d d i t i o n , was found t o be a m o r t a r p r o p e r t y d i f f i c u l t t o c o n t r o l a t a c e r t a i n v a l u e .The d e g r e e t o which t h e s e f a c t o r s i n f l u e n c e m o i s t u r e p e n e t r a t i o n w i l l undoubtedly v a r y w i t h t h e materials b e i % used. The method of t e s t , and t h e t e s t a p p a r a t u s d e s c r i b e d a p p e a r u s e f u l i n i n v e s $ i g a t i n g f a c t o r s i n v o l v e d i n t h e problem o f m o i s t u r e p e n e t r a t i o n of b r i c k m a s m r y , and f ' u r t h e r s t u d i e s a r e b e i n g made u s i n g t h e method. Reference F i s h b u r n , C . C . , D. W a t s t e i n and D.C. P a r s o n s , Water p e r m e a b i l i t y of masonrx w a l l s , U . S . Department o f Commerce, Repor$ BMS

7 ,

1938.Figure 1. Equipment used

to

p r e p a r e %as$panels.

F5gnre 2, Erame f o r %est wall, and a i r pressure chamber.

I N L E T F O R S P R A Y WATER T E E L CHANNEL R U B B E R SEALANT C L E A R P L A S T I S H E E T I/: R U B B E R S T O P P E R S I N A C C E S S H O L E POLY ETHYL TO D R A I N FIGURE 3

SECTION OF AIR PRESSURE CHAMBER AND FRAME.

Figure 4. A p p a r a t u s for moisture penetration

-bests.

0 2 0 3 0 4 0 5 0 4 6 8