Publisher’s version / Version de l'éditeur: Student Report, 2010-12-20

READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE.

https://nrc-publications.canada.ca/eng/copyright

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

NRC Publications Archive

Archives des publications du CNRC

For the publisher’s version, please access the DOI link below./ Pour consulter la version de l’éditeur, utilisez le lien DOI ci-dessous.

https://doi.org/10.4224/17210709

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at

Development of an ice sheet scheduling package

Smith, Jordan

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

NRC Publications Record / Notice d'Archives des publications de CNRC:

https://nrc-publications.canada.ca/eng/view/object/?id=22b19e8b-8e02-47e0-89c7-9220f2fb32d9 https://publications-cnrc.canada.ca/fra/voir/objet/?id=22b19e8b-8e02-47e0-89c7-9220f2fb32d9

DOCUMENTATION PAGE

REPORT NUMBER SR-2010-26

NRC REPORT NUMBER DATE

December 2010 REPORT SECURITY CLASSIFICATION

Unclassified

DISTRIBUTION Unlimited TITLE

DEVELOPMENT OF AN ICE SHEET SCHEDULING PACKAGE AUTHOR(S)

Jordan Smith

CORPORATE AUTHOR(S)/PERFORMING AGENCY(S)

Institute for Ocean Technology, National Research Council, St. John’s, NL PUBLICATION

SPONSORING AGENCY(S)

IOT PROJECT NUMBER NRC FILE NUMBER

KEY WORDS

Ice Tank, Ice Sheet Scheduler, Software, SEG, SQL server 2005, Python, matplotlib, wxPython, pyODBC, pymssql PAGES ii, 19, App. A FIGS. 4 TABLES SUMMARY

The facilites at the National Research Council of Canada’s Institute for Ocean Tech- nology allow for testing of marine models in ice. Ice properties collected during the creation and testing of each ice sheet are currently stored digitally using outdated architecture. New software and databases are being developed to replace present

systems. Of the components being updated, a program which facilitates the scheduling of ice sheets is of particular focus.

National Research Council Conseil national de recherches Canada Canada Institute for Ocean Institut des technologies

Technology océaniques

DEVELOPMENT OF AN ICE SHEET

SCHEDULING PACKAGE

SR-2010-26 Jordan Smith December 2010

SR-2010-26

EXECUTIVE SUMMARY

Facilities at the National Research Council of Canada’s Institute for Ocean

Technology allow for testing of marine models in ice. Ice properties

col-lected during creation and testing of each ice sheet are currently stored

digitally using outdated architecture. New software and databases are

be-ing developed to replace present systems. In particular, a program which

facilitates the scheduling of ice sheets has been recently developed.

Current ice sheet scheduling tools include empirical equations, data

stor-age systems, and their software. During the months of September to

December 2010 older VMS scheduling routines written for DEC

DATA-TRIEVE were examined and a replacement was written using the modules

matplotlib, wxPython and pyODBC for the Python programming language

along with a Microsoft SQL Server 2005 database.

Development followed a traditional design process of gathering

specifica-tions, prototyping, and testing. Developers of the older system were

con-sulted, along with its current users. Documentation and source code were

also reviewed. Specifications were drafted using the collected information,

SR-2010-26 CONTENTS

Contents

1 Tools 3

1.1 Equations . . . 4

1.2 Data and Software Tools . . . 4

2 Design Objectives and Requirements 6 2.1 Original Software System . . . 6

2.2 User Comments on Original VMS System . . . 6

2.3 Technical Specifications . . . 7

3 Development 8 3.1 Gathering Requirements . . . 8

3.2 Package Choice . . . 8

3.3 Design and Prototyping . . . 9

3.4 Implementation . . . 10

4 Suggestions 14 4.1 On Producing Better Models . . . 14

4.2 Expanding the system . . . 15

4.3 Optimizations in Prediction . . . 16

4.4 Optimized Scheduling . . . 16

4.5 Expanding the new Data set . . . 17

References 19

Appendices 20

A Sample code: matplotlib + wxPython A-1

SR-2010-26 CONTENTS

Introduction

Established by the National Research Council (NRC) in 1985, the large

refrigerated model testing tank (the ’Ice Tank’) at the Institute of Ocean

Technology (IOT) has the capability of producing ice covers between 5

and 160 mm (and occasionally thicker). It requires, among other things,

chilling 3.24 million litres of water, then freezing the expansive room in

which the tank is housed to temperatures as cold as -30◦C, followed by

blast reheating the room to condition the ice to appropriate strengths for

testing. These are expensive activities which require significant energy

consumption, specialized staff and finely calibrated equipment; errors in

the freezing process also carry the risk of damaging the tank, testing

car-riages or building structure. As such, it is very important that accurate

estimates of timings, required resources, staff and conditions are available

to tank operators.

Scheduling of ice tank operations is done using a variety of tools

in-cluding, but not limited to, manual analysis of historical data, archival,

an-alytical, and retrieval software systems, empirical equations and

spread-sheet macros. Some of these tools have weaknesses, such as

inaccu-racy, reliance on outdated architecture or programming languages,

SR-2010-26 1 TOOLS

1

Tools

To date (December 2010), over 1100 ice sheets have been grown at IOT.

These have included several types of ice coverings. Different mechanical

manipulations of the final ice product for model testing can simulate

differ-ent natural ice formations including the default level ice testing, pre-sawn

ice, pack ice, ice rubble fields, ’dump-truck’ ridges, thin layered ridges, thick

layered ridges and rafted over rubble. Chemical composition of the

solu-tion from which ice is grown can also be varied, as well as density of the

ice by bubbling air throughout the tank during freezing. This leads to 4

de-fault types of ice: doped model ice (known as ’EGADS ice’, as it contains

Ethylene Glycol, Aliphatic Detergent and Sugar), bubbled model ice (aka

corrected density / CD ice), fresh ice (extremely tough ice) and unseeded

(ice with irregular/natural crystal growth ice is otherwise ’seeded’ with a

water mist at start of freeze to promote uniform vertical crystal growth).

Also, a variety of mechanical testing is done on the sheet to determine

physical properties of the ice; this information is manually recorded onto

paper charts, then transferred to the computer later, though there are

SR-2010-26 1 TOOLS

1.1

Equations

Coupled with research done in late 80’s, in-house experiments and

analy-ses were completed to develop new models for predicting thin ice growth.

These involved analysis of 384 doped ice sheets and 30 freshwater sheets

completed by 1986. (Lozowski, Jones, Hill 1990). This research, coupled

with regression analysis of tempering curves and growth rates yielded a

set of 3 equations for ice growth, and another 3 for ice tempering. (See

appendix) These equations are commonly used for initial estimates and

rough costing or planning. They are indispensable tools for creating

time-lines and provide reasonable accuracy but unfortunately do not take into

account recent developments in ice sheet processes and current

condi-tions. Factors such as minor changes in dopant concentrations, the effect

of bubbling in the commonly used CD ice and other predictable

discrep-ancies change required freezing conditions and require adjustments. For

this reason, equations are not the only tool available and a combination

of tools are usually required to produce final schedules, costing estimates

and determine what staff must be on hand during specified time periods.

1.2

Data and Software Tools

Scheduling software and data systems represent another critical resource.

As tests are completed on an ice sheet a multitude of information about the

sheet is recorded, then analyzed and stored by a software system. The

system which is currently in use is based on VAX/VMS architecture and the

SR-2010-26 1 TOOLS

DEC DATATRIEVE database. Terminal-based FORTRAN and DATARIEVE

procedures are used by several packages in the Ice Analysis, Scheduling,

Bubbler and data collection systems. At time of writing, work is

under-way to move from the VMS system to new architecture. A great deal of

data has been ported to MS SQL Server 2005 databases and new

soft-ware suites to analyze and enter data have been written to interface with

them. The original systems created by Brian Hill, Donald Spencer and

David Molyneux were extensively studied, source code reviewed and

doc-umentation consulted. In addition, meetings with Ice tank staff were held to

determine current use of software and requirements of the new systems.

A new software suite was designed by the IOT software engineering group

with Greg Janes, Wayne Pearson and Michael Sullivan’s leads in primarily

C#, SQL (Structured Query Language) and Python to meet storage and

analysis needs of tank operators. In addition, reporting and scheduling

systems were created using the Python programming language, pyODBC

and pymssql database interface packages, wxPython Graphical User

In-terface (GUI) toolkit, ReportLab PDF library and plotting/math package

matplotlib. These software systems allow for easy entry and retrieval of

historical ice tank data, analysis of results and graphical feedback. The

scheduling tools in particular allow for far more precise results in

SR-2010-26 2 DESIGN OBJECTIVES AND REQUIREMENTS

2

Design Objectives and Requirements

2.1

Original Software System

The primary purpose of the original scheduling software was to facilitate

easy and fast access to historical data. It was structured in such a way as

to be precise without frequent regression analysis of data or reformulation

of equations and to allow operator’s discretion in what data was

consid-ered such as ignoring outliers. The simplest way to do with was to retrieve

data which had been filtered by a user’s required parameters, then plotting

it in the same way tempering curves are plotted. A user could then

pre-form graphical approximation without time-consuming procedural removal

of outliers during a computer’s curve fit or analyze clusters of data to

ob-serve trending. This would allow a user to include newer sheet data for

more accurate estimations, something which the empirical equations do

not allow.

2.2

User Comments on Original VMS System

Users of the current system note that the iterative procedural nature of the

program makes using DATATRIEVE routines time-consuming. Using the

scheduler requires that a user run up to 4 programs consecutively from

the terminal, iterating any time they make a mistake, wish to retrieve more

data or refine their search. Plots which are created are monochrome,

provide little user interaction or analysis of points, require knowledge of

SR-2010-26 2 DESIGN OBJECTIVES AND REQUIREMENTS

DATATRIEVE plotting commands and data returned can be ambiguous or

imprecise.

2.3

Technical Specifications

The new system is centred around a 2005 Microsoft SQL Server Database

and requires any software developed around it be compatible. The new

scheduler software achieves this using the pyODBC package for the Python

scripting language which allows execution of SQL queries and procedures

using Open DataBase Connectivity and Python Database API

Specifica-tion v2.0 interfaces. A Graphical User Interface (GUI) was created using

the wxPython toolkit and plotting/math package matplotlib was used for

SR-2010-26 3 DEVELOPMENT

3

Development

3.1

Gathering Requirements

As per traditional design methodology the first step in developing a new

scheduler was to create a specification that it must satisfy. These were

obtained by analyzing technical constraints such as type and version of

database that must be accessed, the programming language(s) which

were to be used, and chosen deployment MS SQL Server 2005, Python

and Windows XP GUI, respectively. Clients suggested interactive

plot-ting capability, a high degree of user control or filtering and simple, fast

use were important characteristics. In addition, libraries must be free to

work with, highly capable, have a sufficient level of support or

documen-tation and be familiar to other developers. Consuldocumen-tation with developers of

the previous software, available documentation and source code defined

certain functionality which should not be removed, along with details of

software particulars.

3.2

Package Choice

To meet these needs several open source python packages were

cho-sen. In selecting a module for database connectivity there were several

choices, the most promising of which were pyODBC and pymssql. Upon

viewing documentation, online discussions, source code and testing both

packages, pyODBC was chosen. The ODBC module promised continued

SR-2010-26 3 DEVELOPMENT

development, compliance with more standards, more versions, read from

the database easily and supposedly had more features, despite lacking in

several important areas continued support, compliance and possible

fu-ture bug-fixes made it a better choice to support fufu-ture development. The

other module, pymssql on the other hand was implemented much better,

the features it did include were far superior to pyODBC and it worked

with-out problem. Unfortunately it appeared to be reaching the end of it’s

life-time and there were suggestions that it would no longer work if any other

component of the system were to be upgraded, including the database

and other programming libraries. Matplotlib and wxPython were chosen

because of familiarity with the products, ample support, ease of use and

a wide variety of features. Competitor GUI toolkits such as TK were said

to be harder to work with and all alternatives to matplotlib were much less

mature in their development.

3.3

Design and Prototyping

Once a platform for production was chosen the user interface was drafted.

Several rough sketches were created to test layout, look and feel, as well

as functionality. Once particulars were determined a graphical interface

was prototyped. To support the interface a backend for processing user

var-SR-2010-26 3 DEVELOPMENT

end appeared in the GUI, and interface events such as button presses

and user selections triggered appropriate responses and updates from the

backend.

3.4

Implementation

Development of the scheduler was centred around ease of use. The

pre-vious software was very time-consuming and tricky for current users who

are unfamiliar to DATATRIEVE commands or used to a Graphical User

In-terface. As such, attempts were made to make it possible to navigate using

a mouse exclusively, but also allow users to navigate with the keyboard.

Because of this there are many SpinControls in the interface.

(SpinCon-trols are text boxes which allow keyboard entry of numbers, but also allow

increasing or decreasing the value by clicking on up and down arrows next

to the the form). Certain portions of the previous system were merged in

this design, making the interface less cluttered and faster to use. Where it

once required entering answers to a series of questions before displaying

output, a user can now click on a few controls and see results instantly.

When the program is run, the first thing it does before loading any large

modules, is produce a ’splash screen’ image (Fig. 1) from a few lines of

stored code and display it to the user to let them know the program is

in-deed running and has not ’frozen’.

SR-2010-26 3 DEVELOPMENT

Figure 1: Result of importing splash.py

Figure 2: Blank fields of GUI on initalization

This is done to prevent multiple attempts at initialization in the event of

a slow loading process. On top of this image the main GUI is loaded as

a separate application. (Fig.2) On startup the GUI contains many blank

SR-2010-26 3 DEVELOPMENT

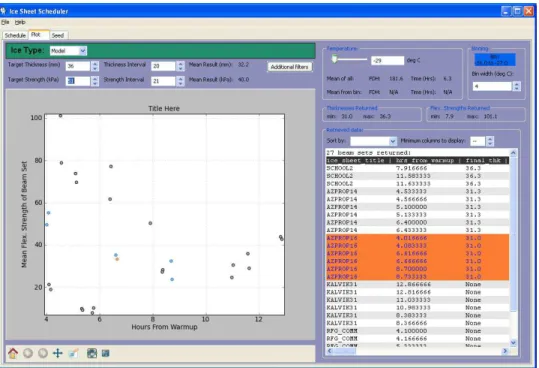

Figure 3: Demonstrations of various graphical feedback

As data is entered it triggers color changes, as when choosing ice type

the background of the control turns white for bubbled, blue for fresh, etc.

When choosing temperature, cold temperatures turn a display blue while

warm turn it orange. This reminds a user of what action they have taken,

or whether they have set a particular parameter. Also, as each filtering

pa-rameter is set, new filters are applied to the query sent to the database and

a reload of the plot is triggered as well as the tabular display of returned

data. Other changes occur when a user interacts with the plot area. The

toolbar at the bottom of the plot allows a user to ’zoom in’ on portions of

clustered data, move the section around or return the plot to it’s initial

SR-2010-26 3 DEVELOPMENT

Figure 4: Distribution of values within a test at a single location

dition. If a user moves their cursor over a data point the group of related

points (those tests within the same ice sheet) are highlighted, as well as

text which gives particular details of that sheet. This aids in identifying

individual tempering curves, mentally sorting large clusters of data and

matching details to ambiguous points so users may apply more

appropri-ate filters. In addition, if a user right-clicks on a point, a menu is displayed

(Fig. 4) showing membership details of that point and giving the option of

breaking the point into it’s constituent parts. The ’point details’ option of

the menu launches a box plot and scatter plot of the beam strengths which

have been averaged to create a single point on the main plot. This is very

useful in identifying outliers and finding the source of problems within a

SR-2010-26 4 SUGGESTIONS

4

Suggestions

Tank operators have become very familiar with the original software

sys-tems and data handled by them. As such they have offered several

sug-gestions on how the scheduling process could be improved, along with the

software which facilitates it. Current development is an opportune time to

act on these suggestions and implement them in a functional system. In

addition to these suggestions, various other things were noted during the

development process by developers which may help in future

advance-ment of the software.

4.1

On Producing Better Models

It may be possible to flag outlying data as new data is entered into the

sys-tem and have a computer perform regression analysis to produce better

equations, automatically presenting more accurate results while

remov-ing errors caused by manual approximations. Alternatively, as many more

sheets have been completed since the inception of the original systems

and models of ice growth, more precise modern models could be created.

Also, due to the nature of the sheets being completed at the time, the

orig-inal system did not discriminate between different ice types and different

uses; variations in chemical and physical composition were not taken into

account and it is known to greatly affect current models and equations.

SR-2010-26 4 SUGGESTIONS

4.2

Expanding the System

Other data may be available in physical records, that is not kept in our

database. This includes the results of concentration testing done

period-ically to determine dopant and contamination levels or when refilling the

tank with new solution. There is evidence that the effect on initial

freez-ing is minimal, but these dopants do affect other parts of the ice sheet

creation cycle and model testing. In addition to EGADS there are

particu-lar density test results which are invaluable in calibration which are rarely

recorded and have not been kept as part of ice tank archives. Users also

suggested allowing a comment field for each sheet summary to review the

overall quality of the sheet and mark anomalies or fixes. Also related to

ex-pansion is a comment that particular test results, such as friction, are not

necessarily tied to a particular sheet, for example testing of experimental

new hull coatings which are not applied to models - it would be of benefit

if a parallel, rather than integrated system were to handle this. Also, given

the relative cheap cost of modern storage, it would be of benefit to begin

storing images taken in association with an ice sheet, such as those

an-alyzed to determine ice covering concentrations in pack ice testing which

are usually given to students for analysis, then lost.

SR-2010-26 4 SUGGESTIONS

Sections of the freeze cycle which occur during the large temperature

changes of initial cooling and warmup have traditionally been accounted

for with straight line approximation when in fact they demonstrate

New-tonian cooling/heating curves or could be calculated though integrals of

curves from temperature records. It is possible that this was originally

done as blast heating modifies the curve to a more linear result, though

times of heating are recorded and division of the curves is possible if

re-quired. This modification would not only increase accuracy of prediction,

but allow for cost savings: curves could be extrapolated to test time to

minimize the amount of costly blast heat required to temper ice quickly.

4.4

Optimized Scheduling

It has also been suggested that a scheduling tool might include capabilities

for planning multiple sheets in the same session. It may be possible to, for

example, outline the specifics of project’s individual sheets, then use this

information to plan all relevant tests within the project, bearing in mind

per-sonnel schedules, overtime requirements and other preferences. It would

also be possible to print monthly schedules (perhaps as pdf output with

ReportLab and other packages) or calendar entries for Outlook, Google

Calendar or Rainlendar.

SR-2010-26 4 SUGGESTIONS

4.5

Expanding the New Data Set

It would be very beneficial to add more of the available data to the database

as parsers for such material have already been written and storage is

read-ily available. Currently, certain features are restricted to approximately 200

of the most recent sheets (of the some 1100 completed). Any analysis

for generating new equations or improving scheduling or current

predic-tive capabilities are lacking with the current data set. The modern

collec-tion, though containing newer data and more raw data than before,

cov-ers fewer sheets than 1988’s data set. In particular, the database table

tblIceSheet should be completed, and filling of key matched data spaces

found in tblBeam, tblThickness and tblDensity would be invaluable. Doing

this would require little more effort than requesting archived text files from

Computer systems and running parsers on archived files. Small changes

to parsers could be made in similar way to original development viewing

FORTRAN source to determine format and appending parser

dictionar-ies. This data would allow users to view data in finer resolution when

scheduling and doing other activities (currently this capability is limited to

the aforementioned range). The extra data would also be valuable in model

development. Another important set of data would be the run information

SR-2010-26 4 SUGGESTIONS

reports such as tank diagrams. It would provide a reference for ice

proper-ties which are currently dissociated from testing. This would allow a client

to see the condition of the ice in the location and time window of the test,

which is an important connection when analyzing model test results.

4.6

Conclusions

This development proved to be a significant undertaking requiring more

time than initially thought. Also, as the scheduler is being updated

any-way, it would have been beneficial to concurrently update the models and

algorithms used to predict required freezing and tempering times. As the

current scheduler stands, though the result is useable, there is significant

room for refinement. Further work should be done on the system before

it is deployed as accuracy and reliability is important. As well, results

re-turned from the new system have not been verified to agree with the older

system and caution should be taken when interpreting them. Choices

made with regards to packages and platforms appear to be reasonable,

with the exception of pyODBC (the database connectivity module) and

new developments in this packages should be monitored. As with using

any new module, one must weigh the current condition of the code base,

documentation and future support before one chooses to develop using

that tool.

SR-2010-26 REFERENCES

References

[1] B. T. Hill, “Procedures for scheduling ice sheets,” Tech. Rep.

LM-2007-03, National Research Council Institute For Ocean Technology, April

2007.

[2] B. T. Hill, “Vms ice analysis procedures and preparation of ice sheet

summaries,” Tech. Rep. LM-2006-05, National Research Council

Insti-tute For Ocean Technology, March 2006.

[3] E. P. Lozowski, S.J.Jones, and B. T. Hill, “Labratory measurements of

growth in thin ice and flooded ice,” Cold Regions Science and

Technol-ogy, vol. 20, pp. 25–37, May 2006.

[4] B. T. Hill, “Environmental modeling - ice,” Tech. Rep.

42-8595-S/GM-4, National Research Council Institute For Ocean Technology, January

2008.

[5] J. Smart, R. Roebling, V. Zeitlin, R. Dunn, and et al, wxWidgets 2.8.11:

A portable C++ and Python GUI toolkit. wxWidgets team, 2.8.11 ed.,

February 2010.

[6] D. Dale, M. Droettboom, E. Firing, and J. Hunter, Matplotlib

SR-2010-26

Appendices

SR-2010-26 A SAMPLE CODE: MATPLOTLIB + WXPYTHON

A

Sample code: matplotlib + wxPython

1 from __future__ import print_function 2 ” ” ”

3 Produces a box ( and w h i s k e r ) p l o t i n a s e p a r a t e d i a l o g so←֓ t h a t a user can 4 analyze a p l o t p o i n t i n g r e a t e r d e t a i l . 5 6 Author : 7 Jordan Smith 8 Date : 9 W i n t e r 2010 10 F u t u r e :

11 I f data i s n o t k e p t i n database , suggest where i t ←֓ might be a v a i l a b l e .

12 13 ” ” ”

14

15 import random # used f o r demo o n l y

16 import wx

17 import pyodbc

18 import matplotlib

19 matplotlib . use ('WXAgg') # r e q u i r e d f o r i n i t a l i z a t i o n

20 # wxAgg backend r e q u i r e d f o r m a t p l o t l i b i n wxPython .

21 from matplotlib . backends . backend_wxagg import \ 22 FigureCanvasWxAgg , \

23 NavigationToolbar2WxAgg

24 from matplotlib . figure import Figure 25 from matplotlib . pyplot import boxplot 26 from pprint import pprint

27

28 class BoxPlotDialog ( wx . Frame ) :

29

30 def __init__ ( self , BeamId , parent=None , title=" point ←֓ detail ") :

SR-2010-26 A SAMPLE CODE: MATPLOTLIB + WXPYTHON

33 self . figure = Figure ( )

34 self . canvas = FigureCanvasWxAgg ( parent=self ,

35 id=wx . ID_ANY ,

36 figure=self .←֓

figure ) 37

38 # box and w h i s k e r p l o t

39 # s u b p l o t ( numRows , numCols , plotNum )

40 self . axes = self . figure . add_subplot ( 1 2 1 ) 41 # s e l f . axes . s e t a x i s b g c o l o r ( ' b l a c k ' )

42 self . axes . set_title ('Distribution', size =12)

43 self . axes . set_ylabel ('Flex. Strength of Beam (kPa←֓ )')

44

45 # p l o t o f i n d i v i d u a l p o i n t s

46 self . axes2 = self . figure . add_subplot ( 1 2 2 ) 47 self . axes2 . set_xticks ( [ 0 ] )

48 self . axes2 . set_xlabel ('X = flagged as outlier') 49 self . axes2 . set_title ('Individual', size =12) 50

51

52 # add some c o n t r o l s and c o n t e n t

53 self . draw_plot ( BeamId )

54 self . toolbar = NavigationToolbar2WxAgg ( self .←֓ canvas )

55 self . vertical . Add ( item=self . canvas ,

56 proportion =10 ,

57 flag=wx . ALL| wx . EXPAND ,

58 border=5 )

59 self . vertical . Add ( self . toolbar , 0 , wx . ALL| wx . ←֓ EXPAND| wx . ALIGN_BOTTOM , 5 )

60 self . SetSizer ( self . vertical ) 61 self . Layout ( )

62 self . Centre ( ) 63 self . Show ( True ) 64

65

66 def draw_plot ( self , BeamId ) :

67 data = self . get_flex_data ( BeamId ) 68

SR-2010-26 A SAMPLE CODE: MATPLOTLIB + WXPYTHON

69 # s t r e n g t h s from non−o u t l i e r down beams

70 flex_strengths = [ each ['FlexuralStrength_kPa'] ←֓

for each in data if \

71 ( each ['Outlier'] == False and ←֓

each ['Down'] == True ) ] 72

73 # s t r e n g t h s from o u t l i e r down beams

74 outliers = [ each ['FlexuralStrength_kPa'] for each←֓

in data if \

75 ( each ['Outlier'] == True and each ['←֓ Down'] == True ) ]

76

77 self . axes . boxplot ( flex_strengths ) 78 # t i m e i r r e l e v a n t w i t h i n t e s t . : x=1

79 self . axes2 . scatter ( [ 1 ] * len ( flex_strengths ) , ←֓ flex_strengths , marker="v")

80 if outliers :

81 self . axes2 . scatter ( [ 1 ] * len ( outliers ) , ←֓ outliers ,

82 marker="x", edgecolors='r'←֓

) 83

84 def get_flex_data ( self , BeamId ) :

85 ” ” ”

86 S i m i l a r c o n t e n t and workings as ←֓

D a t a b a s e I n t e r f a c e c l a s s o f p r o t o t y p e ,

87 connects t o and f e t c h e s data from database .

88 ” ” ”

89 # e s t a b l i s h c o n n e c t i o n :

90 # t a k e s c o n n e c t i o n s t r i n g s o r named keywords o r ←֓ both

91 self . cnxn = pyodbc . connect (” ” ”

92 d r i v e r ={SQL Server } ;

93 T r u s t e d C o n n e c t i o n =yes ” ” ” , 94 server=" Karfe ",

95 database=" IceAnalysis ") 96 self . cursor = self . cnxn . cursor ( )

SR-2010-26 A SAMPLE CODE: MATPLOTLIB + WXPYTHON 99 vwBeamMeasurementSI . F l e x u r a l S t r e n g t h / 1 0 0 0 . 0 AS ←֓ F l e x u r a l S t r e n g t h k P a , 100 vwBeamMeasurementSI . O u t l i e r , 101 vwBeamMeasurementSI . Down 102 FROM vwBeamMeasurementSI

103 WHERE BeamId = ? ” ” ” # ? used f o r p a r a m e t e r i z a t i o n

104 self . cursor . execute ( query , BeamId )

105 table_as_list_of_dict = self . cursor_as_dict ( ) 106 pprint ( table_as_list_of_dict )

107 return table_as_list_of_dict

108

109 def cursor_as_dict ( self ) :

110 ” ” ”

111 See g e t f l e x d a t a .

112 Format r e t u r n e d on execute i s awkward ;

113 a l i s t o f d i c t s i s e a s i e r t o handle .

114 ” ” ”

115 a_list = [ ]

116 for each in self . cursor :

117 a_dict = {}

118 for thing in each . cursor_description :

119 a_dict [ thing [ 0 ] ] = each . __getattribute__ (←֓ thing [ 0 ] )

120 a_list . append ( a_dict )

121 return a_list

122

123 if __name__ == " __main__ ": 124

125 app = wx . App ( redirect=False )

126 sample_data = [ random . randrange ( 1 0 0 ) for x in xrange←֓ ( 1 0 ) ]

127 print( sample_data )

128 BoxPlotDialog ( BeamId =2191 , parent=None , title=" point ←֓ detail ")

129 app . MainLoop ( )