Publisher’s version / Version de l'éditeur:

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site

LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

Paper (National Research Council of Canada. Division of Building Research); no.

DBR-P-983, 1981-03

READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE. https://nrc-publications.canada.ca/eng/copyright

NRC Publications Archive Record / Notice des Archives des publications du CNRC : https://nrc-publications.canada.ca/eng/view/object/?id=ab129f2c-b975-4a16-bf09-9409c8b36f47 https://publications-cnrc.canada.ca/fra/voir/objet/?id=ab129f2c-b975-4a16-bf09-9409c8b36f47

NRC Publications Archive

Archives des publications du CNRC

This publication could be one of several versions: author’s original, accepted manuscript or the publisher’s version. / La version de cette publication peut être l’une des suivantes : la version prépublication de l’auteur, la version acceptée du manuscrit ou la version de l’éditeur.

For the publisher’s version, please access the DOI link below./ Pour consulter la version de l’éditeur, utilisez le lien DOI ci-dessous.

https://doi.org/10.4224/40001697

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at

Some overlooked aspects of the severity of compartment fires

Harmathy, T. Z.

National Research

Conseil national

I1$1

Council Canada

de recherches Canada

SOME OVERLOOKED ASPECTS OF THE

SEVERITY OF COMPARTMENT FIRES

ANALYZED

Reprinted from Fire Safety Journal VoL 3, 1980181 p. 261 271

DBR Paper No. 983

Division of Building Research

SO MMAIRE

A cause des courants d l a i r , la ventilation dans les incendies compartiment6s r e e l s e s t g6n6ralement plus intense que dans l e s experiences de combustion classiques. Heureusement, le danger de la propagation des inoendies par destruction de la construction, quelle que soit l a nature de l a charge calori- fique, diminue 'a mesure qulaugmente l a ventilation, de s o r t e que c l e s t une pratique sGre de calculer l a r6sistance au f e u des cloisons des compartiments en slappuyant s u r llhypoth%se de conditions classiques. Toutefois, les incendies ne s e pro- pagent pas gknkralement p a r destruction de l a construction, mais plutst par oonvection des mati'eres volatiles du com- bustible non brG16. Quand il s1agit d e s m e s u r e s 'a prendre pour entraver la propagation dlun incendie, i l peut d t r e neces- s a i r e de tenir compte 6galement de consid6rations non c l a s - siques, comme llutilisation de portes 'a f e r m e t u r e automa- tique, dlinstallations pour m a r t r i s e r llincendie et de

-

t e u r s de flamme,quipourront s e r6v6ler une composante e s - sential des dispositions de s6curit6-incendie.Fire Safety Journal, 3 (1980181) 261

-

271@ Elsevier Sequoia S . A . , Lausanne -Printed in the Netherlands

Some Overlooked Aspects of the Severity of Compartment Fires

T . Z . HARMATHY

National Research Council of Canada, Division of Building Research, Ottawa KIA OR6 (Canada)

SUMMARY

Because o f drafts, the ventilation of real- world compartment fires is usually more intense than that in classic burn experiments. Fortunately, the potential for fires t o spread by structural destruction, irrespective o f the nature o f fire load, decreases with increasing ventilation, so that designing the fire resis- tance o f the compartment boundaries o n the assumption o f classic conditions is a safe practice. Fires, however, d o not usually spread by structural destruction but rather by the convection o f uncombusted fuel volatiles. In deciding on measures for the prevention o f convective fire spread the assumption o f classic conditions is not necessarily a safe practice. Self-closing doors, fire drainage

facilities, and flame deflectors may often prove powerful tools in the provision o f fire safety.

INTRODUCTION

At the turn of the century the prevention of major property losses was regarded as the principal aim of fire safety measures. Because major losses were usually associated with massive structural failures, the structural per- formance of building elements in fire became the centre of interest and the first subject of experimental fire research. As the experi- ments led t o the development of standard fire tests, the question of whether the severity of test fires had any relation t o real-world fires was raised. To answer the question, Ingberg

[ I ] initiated a series of compartment burn experiments that were the forerunners of hundreds, possibly thousands, of studies on fully developed fires.

Ingberg's experiments provided the founda- tion for the concept of fire resistant compart-

mentation. Implicit in that concept are the following assumptions:

(1) Fire spreads by destruction of, or thermal coriduction through, compartment boundaries.

(2) The severity of compartment fires in- creases roughly in proportion t o the specific fire load; SCI also should the ability of the

compartment boundaries t o withstand struc- tural and thermal failure increase.

VENTILATION OF FIRES

Mounting doubts about the validity of the concept prompted research on fully devel- oped fires 1,o resume in the 1950's. The renewed initerest started with Kawagoe's experiments [ 2 ] , continued with the exten- sive work of the British Fire Research Organiza-, tion [ 3

- 51 and that of the National Bureau

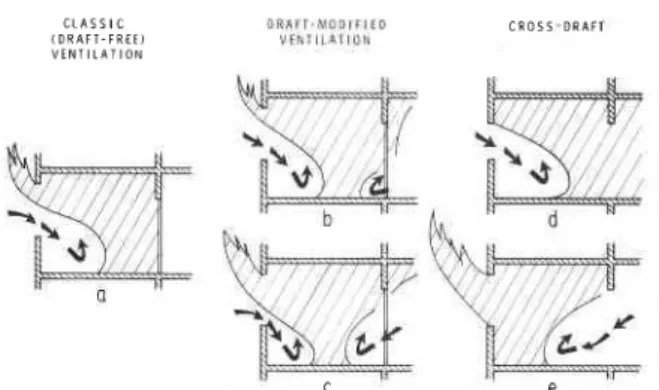

of Standards in the U.S.A. [ 6 ] , and has con- tinued unabated ever since.The new experimental results revealed that the ventilation of fire, in other words the flow rate of air into the fire compartment, is no less important a factor in the severity of fire than the specific fire load. In evaluating the experimental findings, it has always been assumed that the ventilation is a unique characteristic of the compartment on fire, de- termined by the dimensions of the ventilation opening. Th~at assumption is tenable only if the compartment communicates with (receives air from and discharges hot fire gases t o ) a single environment, Fig. l(a). Under such classic conditions the flow rate of air can be expressed approximately as [7] :

U,* = 0 . 1 3 8 ~ ~ ' ~ @ *

-

0.53R (1 where @* is the ventilation parameter,C L A S S I C ~ ~ d r i . h ~ o o t r ~ r o C R O S S . D R A F I i D R A F 1 - F R E E 1 ' J t R ! I I h I I l ' h

V E N T I L A T I O N

Fig. 1. Classic ventilation and draft-modified ventila- tions.

and p a is the density of atmospheric air, A v the area of ventilation opening (window or

door), h the height of the opening, g the

acceleration due t o gravity, and R the rate of

consumption of fuel mass by gasification (usually pyrolysis), often referred t o as "rate

of burning".

x

is a factor, greater than 1,which accounts for the coupling between the streams of air and hot fire gases by the fire plume.

Unfortunately, real-world fires are rarely of the classic type. A compartment on fire almost always has some secondary routes of communication with one or more secondary environments. For example, when its primary communication is with the outside atmo- sphere through a broken window, secondary communications usually develop with other neighbouring spaces through gaps around doors, ducts, service holes, etc. The ventila- tion of the compartment becomes draft-modi- fied, Fig. l ( b ) and (c). Calculations indicate that in heated high-rise buildings, even small areas of secondary communication allow a significant exchange of air and smoke with the secondary environments. If one of these areas is substantial, for example, if a door is left open, cross-draft may develop; the entire window area may be taken up by the in- flowing air and the entire door area by the

departing gases, or vice versa. In a cross-draft

the compartment ventilation may increase by a factor of 5 or more in comparison with that in the classic, draft-free case. In this light, the

flow rate of air determined by the dimensions

of the ventilation opening, that is, by the

ventilation parameter,

a * ,

can be regarded asrepresenting just about the minimum that can occur in real-world fires:

where Ua is the flow rate of air determined by a pressure distribution created by the fire in the compartment and modified by the pres- sure distribution that would exist in the absence of fire.

The form of eqn. (1) applicable t o real- world conditions is as follows:

Ua = 0 . 1 3 8 ~

-

0.53R(4)

where is now a random variable, t o be

referred t o as "ventilation factor", for which,

by virtue of eqn. (3), the lower bound is

a*

@ * < a . (5)

In addition t o the ventilation factor there are some other input variables t o the fire problem that can be specified only on a probabilistic basis. It appears, therefore, that the principal aim of studies of compartment fires is not so much the exact formulation of the fire process as the gaining of insight into the cause-effect relations of the phenomena that make up the process. Even a simple model capable of providing that insight is more valuable than a sophisticated one that is too specific t o the classic conditions.

FIRE SEVERITY PARAMETERS

The term fire severity has different conno- tations for different researchers. Some look upon fire severity as characterizing the fire itself, others as characterizing the destructive potential of fire with respect t o the compart- ment boundaries. The interpretation of fire severity comes naturally from an examination of the dependent variables of the fire process. Their number obviously equals the number of independent equations needed t o describe the process fully. Most can be formulated in two ways: they may describe either momentary conditions or average conditions characteristic of the entire fully-developed period of the fire. It is believed that the nature of the problem does not warrant more realism than is provided by describing average conditions. There are three energy balances: one over the ventilation opening,

f(Ua, R,

&, ?ip,

i,

'fuel', 'compartment') = 0the second over the fuel surface,

f(R,

T,,

'fuel') = 0 (7) and the third over the surface of the compart- mentf(Fg,

4,

T , 'compartment') = 0. (8Another equation can be written for the average rate of evolution of energy from the fuel within the compartment,

a

:Q

= f(Ua, R , 'fuel', 'compartment').

(9 Finally, there is a simple expression for the duration of fully developed fire:Added t o these equations should be eqn. (4) for the flow rate of air.

In eqns. (6)

-

(10) G, 'fuel', and 'compart- ment' represent the independent or input variables: G is the mass of the fuel (total fire load), 'fuel' stands for the thermodynamic and geometric variables that characterize the fuel, and 'compartment' for the geometric variables or thermal properties that charac- terize the compartment or its lining materials, respectively.It may be added here that the energy balance over the fuel surface, eqn. (7), is not needed if, as in the case of cellulosic ma- terials, the rate of gasification of the fuel, R , can be described by empirical equations.

Ua

,

R ,a,

?;,,

q, and T are the dependent or process variables. Among those yet t o be defined are:?,,

the average temperature of the com- partment gases (average fire temperature) averaged over the compartment volume and temporally over the period of full fire devel- opment,ij, the over-all penetration flux, that is the heat flux penetrating the compartment boundaries, averaged over all compartment boundaries and temporally over the period of full fire development, and

T , the duration of fully developed fire. Of the six process variables, five, U,

,

R,

a , ?;,,andq,

represent values time-averaged over the period of full fire development. Fora,

Tg, andq

this fact is emphasized by the use of a bar over the symbol. As the temporal varia- tion of Ua and R is not very marked, the use of the bar has been dispensed with for simplicity.An examination of the six process variables reveals that only three,

T,,

q,

and T, bear direct relation t o the nature of fire. They will be referred t o as 'fire severity parameters'. Even further, of the three, two, eitherTg

and T , or ij and T , are sufficient t o characterize the fire process. If7,

and 7 are selected, thecharacterization is done from the point of view of the fire itself; whereas if ij and T are chosen, the effect of fire on the compartment boundaries, in other words its destructive potential, is emphasized.

POTENTIAL FOR DESTRUCTIVE AND CONVEC- TIVE SPREAD

As language conveys the idea of the poten- tial of fire for destructive spread by a single expression, fire severity, it has always seemed desirable t o have a single variable t o represent it numerically. Investigations have shown [8] that for reinforced and prestressed compart- ment boundaries, and possibly many other types, a single descriptor, the product formed by the two parameters ij and T, is capable of a more or less unique characterization of the severity of fire, irrespective of the tempera- ture history of the fire gases. The product q7 can be recognized as quantifying the total heat absorption per unit surface area of the boundaries during the period of full fire development. It will be referred t o as over-all heat load and regarded as the measure of the potential of fire for spread by structural destruction*.

It has been recognized for some time that fires rarely spread by structural destruction. The commonest mechanism of spread is the spilling out of the uncombusted products of fuel gasification, carrying flames into the spaces surrounding the compartment on fire. Experiments have indicated that with a fire load of predominantly non-charring plastics, the tendency of fire t o spread by convection of the uncombusted volatiles of fuel is much higher than it is with a fire load of cellulosics.

Irrespective of the nature of the surface lining materials in the surroundings of the fire

*Note that for unprotected steel constructions the over-all heat load is not an adequate measure of the potential of fire for destructive spread.

264

compartment, fuels and conditions conducive As discussed earlier, the flow rate of air in t o massive combustion of fuel volatiles real-world fires depends on a random variable outside the compartment boundaries present (namely, on the ventilation factor, @ ) rather a very real danger from the point of view of than on the dimensions of the ventilation fire spread. A factor has been introduced t o opening, and thereby on the ventilation para- characterize the convective spread potential meter,

a * .

In order t o obtain a full picture of fire [ 7 ] . It is denoted by p and defined as of the nature of fire, therefore, it is necessarythe ratio: to investigate the variation of the process

variables as well as the over-all heat load and the factor of convective spread potential over

rate of heat evolution outside fire compartment a wide interval of the ventilation factor,

a.

I-1=

total rate of heat evolution from fuel Such an investigation was carried out for

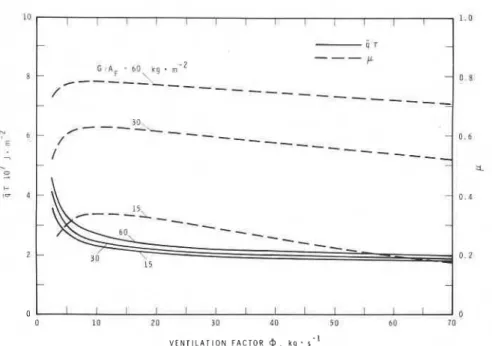

some hypothetical conditions in the cited (11) paper [ 7 ] . In it, the pool material was

assumed t o exhibit properties similar t o those Once the calculation of the fire severity para- of PMMA, and the fires were assumed t o meters is completed, 1-1 can be calculated from develop in a full-size room identical in dimen-

the spin-off data. sions and lining materials with that used by

Butcher e t al. [12, 131. Three pool sizes were

CHARACTERISTICS OF FIRES OF NON- studied, occupying 25, 50, and 100 per cent

CHARRING FUELS of the floor area, and representing three

specific fire loads (G/AF, where AF is the Non-charring fuels include

all

liquid fuels compartment floor area): 15, 30, and 60 kg and the majority of common plastics. With mP2 in terms of calorifically equivalent mass liquids, the fuel is always present in a pool of wood.configuration in the compartnnent on fire. Figure 2 represents the principal results of There are also a few important non-charring the investigation. It shows, at the three speci- plastics, including polyethylene, polypro- fic fire loads selected, the variation of both pylene, and polystyrene, for which the over-all heat load, qr, and the factor of melting point is lower than the pyrolysis convective spread potential, p, with the venti- temperature. If these plastics are present in a lation factor,

a.

The following conclusions compartment in quantities substantial enough have been drawn:t o survive into the period of full fire develop- (1) The potential of pool fires for spreading ment, they will probably be present also in by the destruction of the compartment the form of a pool on the floor. boundaries, as quantified by the over-all heat

Solids that tend t o retain their original load, qr, is not a strong function of the speci- shape in fire will be consumed in some com- fic fire load. It decreases slightly with in- plex configuration, usually comprising many creasing ventilation. Because of this, and self-viewing surfaces. Any of these configura- because (see eqns. (3) or (5)) the air-flow rate tions will be referred t o as 'pile' in this paper. in real-world fires is higher than that under

Since pile-burning adds greatly to the com- the classic, draft-free condition, use of the plexity of the process, it is understandable value of the over-all heat load pertaining t o that most studies of fully developed fires of the classic condition in assessing structural non-charring fuels have so far been conducted fire safety requirements is expected t o result on pool-like configurations [ 9

-

111.

in a safe design.Explicit forms of eqns. (6)

-

(9), applicable (2) After examination of the factor of t o pool fires of non-charring materials, have convective spread potential, p, it is clear that been presented [ 7 ] . Together with eqns. (4) with increase in fire load an increasing portion and ( l o ) , they constitute a set of simulta- of the fuel energy will be released outside the neous equations from which, by some itera- fire compartment. Thus the danger of storing tive technique, the six process variables U,, R , large amounts of pool-forming materials liesa,

?;,,i ,

and r , can be calculated, and the not so much in the damage that the fire canover-all heat load,

GT,

and the factor of con- cause t o the boundaries of the compartment vective spread potential, p, evaluated. itself, as in the damage it can bring t o the restFig. 2. Over-all heat load and factor of convective spread potential for compartment fires involving non-charring fuel in pool configuration.

of the building. I t is reassuring that, as ventila- tion increases, the threat t o surrounding spaces, as expressed by the factor p, declines slightly. Because of this, and by virtue of eqn. (5), designing spread-preventive measures on the assumption of classic, draft-free condi- tions can be regarded as a safe practice.

Pile-fires differ from pool fires in several ways. A pile acts as a primitive air-entraining and volatile-air pre-mixing device, tending t o produce hotter flames than will a pool. In ad- dition, the fuel surface that sees the flames is larger, so that the rate of production of volatiles by a pile is much larger than that by a pool of the same material and base area. In a series of experiments performed on a non- charring kind of plastic, the author found that the rate of pyrolysis of cross-cribs of material was 3.7

-

5.4 times higher than that of a slab (which is an idealized 'pool') of the same base area. Since the outflow of vast amounts of fire gases further throttles the inflow of fresh air, being unable t o come into contact with sufficient amounts of air within the compart- ment, a greatly increased portion of the pyrolysis products will be forced t o burn out- side the compartment. In the compartment itself, the temperature will remain moderate and the conditions will be conducive t o strong soot formation. It is clear, therefore, that the principal danger in fires involving large quanti-ties of non-charring fuels is the enhanced potential for spread of fire and smoke through the building.

CHARACTERISTICS OF CHARRING FUEL FIRES

Cellulosics and other char-forming fuels cannot normally support fire in a pool configu- ration. In the large majority of experiments with fully-developed fires of cellulosics, piles of wood sticks usually arranged in crib con- figuration were used as fuel.

It was among the most important dis- coveries of fire science that a t low ventilation the rate of consumption of the mass of wood piles is roughly proportional t o the rate of inflow of air, whereas at higher ventilations it

is proportional t o the surface area of the fuel [14]. The extent of the two regimes, com- monly referred t o as ventilation-controlled and fuel-surgace-controlled regimes, respec- tively, and the point of transition between them, was determined from a plot of some 250 experimental data reproduced in Fig. 3

[15]. In it, A f is the free surface area of the fuel. Note that with cellulosic fuel @

>>

R , so that by virtue of eqn. (4) it was permissible to use the ventilation factor instead of the flow rate of air in plotting the data.266 lo-1, , , , , , , , , 1 R 0 0236 0 R

-

0 0062 A,. .

--

.A e . , ti rn x-

<-

m - V E N T l L A T l O N FUEL S U R F A C EFig. 3. Correlation of experimental data concerning rate of consumption of cellulosic fuel in fully-devel- oped compartment fires.

The fact that the value of the rate of con- sumption of fuel need not be derived by the solution of six simultaneous equations, but is obtained directly from Fig. 3, translates into the claim that the rate of consumption of fuel is not coupled with any of the other process variables except air-flow rate. Since, with non- charring plastics, the rate of consumption of fuel can never be decoupled from the other process variables, the feasibility of such de- coupling for cellulosics must be attributed t o the fact that they are char-forming materials. Indeed, it has been proved by specially devised tests [16] that the char that covers the surface of cellulosics and char-forming materials in general is instrumental in the unique coupling of R and

U,.

The air-flow feeds the oxidation of char, which, in turn,provides the heat that drives the pyrolysis. In

brief, these fuels have a built-in heat supply mechanism for pyrolysis, and therefore their rate of consumption by pyrolysis depends t o a much lesser extent on the thermal condi- tions prevailing in the compartment than it does for non-charring fuels.

At low ventilations the inflowing air is capable of feeding the oxidation of char only in the vicinity of the ventilation opening

[15]. A zone of intense pyrolysis develops there and will slowly move away from the opening as time goes on. The migration of the zone of intense pyrolysis is illustrated in

Fig. 4. Illustration of zonal pyrolysis in ventilation- controlled fires of cellulosics (see text).

Fig. 4; curves 1 , 2, and 3 represent tempera- tures during an experimental burn in the inside of a wood crib a t 0.38, 0.75, and 1.13 m from the ventilation opening, respectively. In the experiment, the crib covered the entire

floor area of a small-scale compartment, 1 m

X 1 m X 1.5 m deep.

The extent of the zone of intense pyrolysis is roughly proportional t o the rate of inflow of air. If the air-flow rate is large in compari- son with the amount of fuel present, the zone will extend t o the entire compartment. Under such a condition the rate of consumption of fuel by pyrolysis is maximum. As the rate of pyrolysis is controlled by the oxidizing surface char, and that surface cannot further be extended by the extension of the zone, the rate of consumption of fuel will no longer respond t o further increase in air supply. This is why at higher ventilations the fire process becomes fuel-surface-controlled.

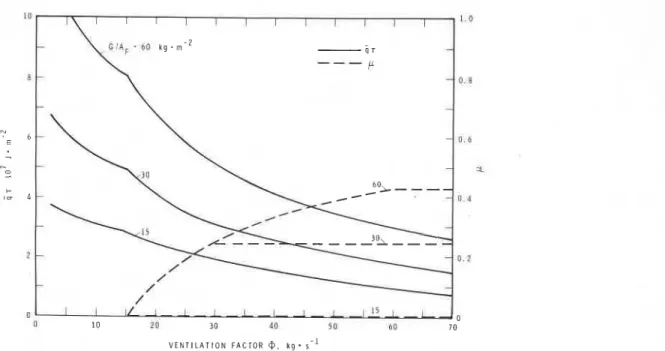

Explicit forms of eqns. (6), (8), and (9) have been presented in several publications, among them refs. 7 and 15. These, together with eqns. (4) and ( l o ) , and those shown in Fig. 3, now represent the set of equations for describing the process. Again, a compre- hensive investigation was undertaken t o gain insight into the characteristics of fires of cellulosics. The fires were assumed, again, t o reproduce the conditions described in the

experiments of Butcher et al. [12,13] with

respect t o both compartment characteristics and fire loads, 15, 30, and 60 kg m-2. The principal results of the investigation are given in Fig. 5, which illustrates the variation of

I I I/ I I 1 I I I J 1 15 I

D I

0 10 20 30 6 0 I 0 6 0 70

V E N T I L A T I O N F A C T O R 0 , k g ' s - '

Fig. 5. Over-all heat load and factor of convective spread potential for compartment fires involving cellulosic fuel.

over-all heat load,

q7,

and of the factor of convective spread potential, y , with the venti- lation factor, a . It may be added that the results of these studies were checked against more than 20 experimental data reported by Butcher et al. [12, 131 and found to be of satisfactory accuracy.The following conclusions may be drawn : (1) With cellulosic materials the potential for fire to spread by destruction, as judged from over-all heat load, ijr, is, as a rule, higher than with non-charring plastics and depends strongly on the fire load. It decreases substan- tially with increasing ventilation (that is, with increasing values of a ) . This fact (in the light of eqns. (3) and (5)) again permits the conclu- sion that it is safe practice to design the fire resistance of compartment boundaries on the assumption that air-flow rate is as it would be under classic ventilation conditions.

(2) With cellulosic fuel, the potential for convective spread, as judged from the values of p , is much lower than that for non-charring plastics. It increases with increase

in

both fire load and ventilation. Unfortunately, because of the latter finding, the value of y calculated for the classic ventilation condition is not suitable for the design of spread-preventive measures. It is recommended that design considerations be based on a value of the ventilation factor representing an agreed-upon multiple of the ventilation parameter.To the author's knowledge no char-forming plastics have ever been used as principal fuel in compartment burn experiments. Based, however, on the remarkable similarities be- tween cellulosics and char-forming plastics, with regard t o the effect of ventilation on rate of consumption of fuel by pyrolysis [15], one may hypothesize that all major conclu- sions drawn for fires of cellulosics are ap- plicable t o fires of char-forming plastics as well.

DESIGN FOR FIRE RESISTANCE

Fire resistance is the capability of compart- ment boundaries to withstand the spread of fire by destruction. Because the potential of fire for destructive spread is measured by the over-all heat load, the product q7 is clear- ly the basic input information in fire resis- tance design.

It is natural to think, however, that in determining the fire resistance requirements, the heat loads on the individual compartment boundaries, rather than the over-all heat load, are of interest to the designer.

Numerical studies supported by theoretical considerations [S] suggest that the heat loads on the individual compartment boundaries, the products

qi7,

can be derived from the over-all heat load as follows:where

G,

the over-all thermal inertia for the compartment, isSubscript i (= 1 , 2 , 3 ,

. .

.) refers to the various surface materials as well as the boundaries formed by them ; k , p,

and c are thermal con- ductivity, density, and specific heat, respecti- vely, without subscript denoting values characteristic of the compartment as a whole; the Ai's are surface areas of the individual boundary elements, and A, is the total surface area of the compartment.The purpose of the fire resistance design is to ascertain, either by test or by calcula- tion, that all boundaries of a compartment, when exposed t o an appropriate heat load derived from an analysis of the expected fire under the classic (that is, most adverse) condi- tion, will yield satisfactory performances. An indication of satisfactory performance is that the temperature of a key component of the compartment boundary examined (for example, a steel bar in a reinforced concrete construction) remains below a critical level.

If the satisfactory performance is t o be examined by a numerical heat flow study, the procedure is as simple as specifying a constant rate heat penetration, qi, for a period T , as

boundary condition, in such a way as t o have their product, Qir, amount t o the specified heat load.

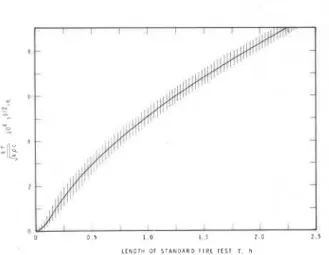

If the satisfactory performance of the construction is t o be determined by standard fire resistance test, the question that will arise is how the heat load imposed on the construc- tion in a standard test is related t o the dura- tion of the testing time (assuming that the testing time is equal t o the time of satisfac- tory performance). That relation is now available from a series of numerical studies t o be reported elsewhere. It has been found that a more or less unique relation exists between the heat load, Qir, and the length of standard fire test, provided that the heat load is nor- malized by dividing it by the thermal inertia

of the construction material,

JG.

Byvirtue of eqn. (12) the i subscripts have been omitted in plotting that relation in Fig. 6.

L E N G T H O F S T A N D A R D F I R E T E S T T h

Fig. 6 . Heat load imposed on constructions in standard fire tests.

It is clear from eqn. (12) and Fig. 6 that the fire resistance requirements for all bound- aries of a compartment can be determined from information on the over-all heat load and the over-all thermal inertia.

The following is a numerical example illustrating the procedure t o be followed in determining the fire resistance requirement. Analysis of the data yielded by a full-scale compartment burn test [12] provided the following values for the three fire severity parameters [15] :

The over-all thermal inertia for the com-

partment was calculated as = 1080 J

s- v 2 m- 2 K- 1

The over-all heat load is:

and the normalized value of the over-all heat load is:

Entering this value in Fig. 6 along the or- dinate axis, the value of the fire resistance (i.e., the time of satisfactory performance in standard fire test) is read along the abscissa as 1.05 h.

It may be added that the case used in the example related t o a fairly severe, ventilation-

controlled fire of cellulosics. In three out of four fires occurring in residential and office buildings, fuel-surface-controlled conditions prevail. The over-all heat load is normally lower, and the required exposure time in standard fire test rarely much higher than 30 min.

MEASURES FOR PREVENTING CONVECTIVE SPREAD

It has been emphasized throughout this paper that the potential of fires t o spread by the destruction of compartment boundaries is only one aspect of safety design. The prin- cipal problem t o be dealt with is usually the danger of fire spread by the dispersion of uncombusted gaseous products of pyrolysis in the spaces surrounding the fire compart- ment. This danger is especially acute where fire load consists mainly of non-charring plastics.

Although the degree of the threat of convective fire spread can be characterized quantitatively by the factor p , there is no established method, as yet, of using its value in fire safety design. In most cases, however, commonsense considerations will suffice.

It is self-evident that the danger of fire spread is more severe if uncombusted volatiles have a means of entering the inside of a building, for example, by a corridor, than if

they leave through windows t o the outside atmosphere. In high-rise buildings there is an increased danger that the volatiles will enter the corridors because the pressure drop in the lower storeys during the winter heating season is directed away from the outside shell of the building t o the major shafts. Consequently, equipping the lower storeys of high-rise buildings with self-closing doors, preferably sliding doors that open and close with ease irrespective of pressure conditions, may prove t o be the best possible investment in fire safety.

If the fire load is higher than usual and consists mainly of plastics, the use of fire drainage in the corridors may prove benefi- cial. Figure 7 shows a section of a corridor equipped with fire drainage facilities. The cor- ridor is divided into a number of imaginary cells, 1 , by retractable fold-up drop curtains,

2, made from thin metal sheets. If flames

Fig. 7 . Typical corridor in a building equipped with fire drainage system. 1, corridor cell; 2, fold-up drop curtain; 3, curtain grooves; 4 , access gates; 5, drainage duct.

penetrate one of the cells, they activate drop curtains on either side of the penetration. The curtains slide down in grooves, 3, but stop a certain distance from the floor t o allow for controlled ventilation of the fire. Shortly afterwards, the flames will trigger the opening of an access gate, 4, which will connect the cell containing the fire with a drainage duct,

5, running along the entire height of the building and opening into the atmosphere above the roof level. If properly designed, the fire drainage system will perform a threefold function: it will draw air into the corridor cell at a rate that ensures relatively low heat load on the cell; it will keep the pressure in the cell below the level of the neighbouring spaces and thus hinder the spread of flames and smoke; and it will remove the flames and smoke from the cell in a safe and organized manner. Further details of the design of fire drainage facilities are available [17].

In the upper storeys of high-rise buildings the pressure distribution favours movement of uncombusted fire gases towards the outside atmosphere, so that the use of self-closing doors and fire drainage may not be justified. Naturally, even if the uncombusted gases are discharged towards the outside atmosphere, for example, through windows, there remains a potential danger of convective fire spread. The heat from the issuing flames can break the windows of the compartment above and set its contents on fire. To lessen such danger of vertical fire spread along the building facade the use of flame deflectors has been suggested [17]. These are light metal panels

270

The problem of designing compartment boundaries for fire resistance has been examined, and a graph presented that makes it possible t o translate the expected destruc- tive potential of real-world fires into time of exposure in standard fire resistance tests. Self- closing compartment doors, fire drainage facilities in corridors, and flame deflectors above windows may prove t o be powerful tools in counteracting the spread of fire by convection.

NOMENCLATURE Fig. 8. Flame deflectors in operation.

A Surface area of fuel

mounted vertically above the windows (Fig. A F Area of floor of compartment

8) that fall down t o assume a horizontal posi- A i Area of i-th compartment boundary

tion when activated by flames, thus shielding A, Total surface area of compartment

the compartment above from the flames and A, Area of ventilation opening

c Specific heat characteristic of materials

radiated heat. I

of compartment as a whole

c i Specific heat of material forming i-th

CONCLUSION compartment boundary surface

'compartment' Geometric variables or thermal The flow rate of air in real-world compart- properties that characterize the compart- ment fires is usually draft-modified and higher ment or its surface forming materials than the classic flow rate derived from the di- 'fuel' Thermodynamic and geometric variables mensions of the ventilation opening. On this that characterize the fuel

account, the nature of fire cannot be realisti- g Acceleration due to gravity cally evaluated without extending studies of G Total mass of fuel

the process variables over a sufficiently large h Height of ventilation opening interval of the possible ventilation conditions. i = 1 , 2 , 3,

...

Of the six process variables that charac- k Thermal conductivity characteristic of terize a fire, three are of paramount impor- materials of compartment as a whole tance and are referred t o as fire severity para- ki Thermal conductivity of material for-

meters. Two of these three can further be

-

ming i-th compartment boundary surface combined in a single descriptor, named over- q-

Over-all penetration fluxall heat load, which, alone, is suitable for q i Heat flux penetrating the ith compart-

quantifying the potential of fire to spread by ment boundary

destruction. Another descriptor can be devel-

a

Average rate of evolution of heat from oped for quantifying the potential of fire t o fuel within compartmentspread by convection. R Rate of consumption of fuel by gasifica- Numerical studies of pool fires of a non- tion (pyrolysis)

charring plastic fuel indicate that the princi-

T,

Average temperature of compartment pal danger presented by such fires is not so gases .much the structural damage the fires can U , Flow rate of air under real-world condi-

cause, as the high likelihood of their spreading tion

through the building. Other numerical studies

u,*

Flow rate of air under classic condition on fires of cellulosics have revealed that their p Factor of potential for convective firepotential for structural destruction is high, spread

although they present a lesser danger from the p Density characteristic of compartment point of view of spread by convection. materials as a whole

p i Density of material forming i-th com-

partment boundary surface

p a Density of atmospheric air T Duration of fully developed fire

@ Ventilation factor * Ventilation parameter

x

Factor accounting for coupling between streams ofair

and hot fire gasesRERERENCES

1 S. H. Ingberg, NFPA Q., 2 2 (1928) 43.

2 K. Kawagoe, Fire behaviour in rooms, R e p t . No.

2 7 , Building Research Institute, Japan, 1958.

3 C. T. Webster, H. Wraight and P. H. Thomas,

The burning of fires in rooms, Part I, Small scale

tests with cribs and high ventilation, Fire

Research Note No. 3 8 9 , JFRO, England, 1959.

4 D. L. Simms, D. Hird and H. G. H. Wraight, The

temperature and duration of fires, Part I, Some experiments with models with restricted ventila- tion, Fire Research Note N o . 4 1 2 , JFRO, England, 1960.

5 A. J. M. Heselden, Some fires in a single compart- ment with independent variation of fuel surface

area and thickness, Fire Research Note N o . 469,

JFRO, England, 1961.

6 D. Gross and A. F. Robertson, Experimental fires

in enclosures, 1 0 t h S y m p . (Int.) o n Combustion. The Combustion Institute, Pittsburgh, PA, 1965, p. 931.

7 T. Z. Harmathy, Fire Mater., 3 (1979) 49. 8 T. Z. Harmathy, Fire Mater., 4 (1980) 71.

9 V. Babrauskas and V. G. Wickstrom, Combust.

Flame, 3 4 (1979) 195.

1 0 J. G. Quintiere, B. J. McCaffrey and K. D. Braven,

Experimental and theoretical analyses of quasi- steady small-scale enclosure fires, 17th S y m p .

(Int.) o n C o m bustion. The Combustion Institute,

Pittsburgh, PA, 1978, p. 1125.

11 M. L. Bullen and P. H. Thomas, Compartment

fires with non-cellulosic fuels, 1 7 t h S y m p . (Int.)

o n Combustion. The Combustion Institute,

Pittsburgh, PA, 1978, p. 1139.

1 2 E. G. Butcher, T. B. Chitty and L. A. Ashton, The

temperatures attained by steel in building fires,

Fire Res. Tech. Paper N o . 1 5 , JFRO, England,

1958.

1 3 E. G. Butcher, G. K. Bedford and P. J. Fardell, Further experiments on temperatures reached by steel in buildings, S y m p . N o . 2 , JFRO, Her Majesty's Stationery Office, London, 1968. 1 4 P. H. Thomas, A. J. M. Heselden and M. Law,

Fully developed compartment fires; two kinds of behaviour, Fire Res. Tech. Paper N o . 1 8 , JFRO, England, 1967.

1 5 T. Z. Harmathy, Fire Technol., 8 (1972) 196,

326.

1 6 T. Z. Harmathy, Combust. Flame, 31 (1978) 259.

17 T. Z. ~ a r m a t h ~ , Fire Technol., 1 2 (1976) 95,

221.

This paper is a contribution from the Divi- sion of Building Research, National Research Council of Canada, and is published with the approval of the Director of the Division.

This publication is being distributed by the Division of Building R e s e a r c h of the National R e s e a r c h C o a ~ c i l of Canada. I t should not be reproduced in whole o r in p a r t without p e r m i s s i o n of the original publisher. The Di- vision would be glad to be of a s s i s t a n c e in obtaining s u c h p e r m i s s i o n .

Publications of the Division m a y be obtained by m a i l - ing the a p p r o p r i a t e r e m i t t a n c e (a Bank, E x p r e s s , o r P o s t Office Money O r d e r , o r a cheque, m a d e payable t o the R e c e i v e r G e n e r a l of Canada, c r e d i t NRC) to the National R e s e a r c h Council of Canada. Ottawa. KIA OR6. Stamps a r e not acceptable.

A l i s t of allpublications of the Division i s available and m a y be obtained f r o m the Publications Section, Division of Building R e s e a r c h , National R e s e a r c h Council of Canada, Ottawa. JUAOR6.