Publisher’s version / Version de l'éditeur:

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

Internal Report (National Research Council of Canada. Institute for Research in Construction), 1991-03

READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE. https://nrc-publications.canada.ca/eng/copyright

NRC Publications Archive Record / Notice des Archives des publications du CNRC :

https://nrc-publications.canada.ca/eng/view/object/?id=63348dd9-9b2d-4e6a-b88a-1964a9e77172 https://publications-cnrc.canada.ca/fra/voir/objet/?id=63348dd9-9b2d-4e6a-b88a-1964a9e77172

NRC Publications Archive

Archives des publications du CNRC

For the publisher’s version, please access the DOI link below./ Pour consulter la version de l’éditeur, utilisez le lien DOI ci-dessous.

https://doi.org/10.4224/20393375

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at

Heat transfer analysis for fire-exposed concrete slab-beam assemblies Sultan, M. A.; Lie, T. T.; Lin, J.

-

/-Ref

Ser1

TH1'

R4 2 7 1 NaUond Research Condl nattonal1

no.

6 058

~ w n d l Canada de recherches CanadaSul

II

ELBC

- Institute for lnstitut deI 'Flesearch in recherche en

L Construction construction

Heat Transfer Analysis for Fire-Exposed

Concrete Slab-Beam Assemblies

M.A. Sultan, T.T. Lie and J. Lin

Canad3

Internal Report No. 605 Date of issue: March 1991

This is an internal report of the Institute for Research in Construction. Although not intended for general distribution, it may be cited as a reference in other publications

HEAT TRANSFER ANALYSIS FOR FIRE-EXPOSED CONCRETE SLAB-BEAM ASSEMBLIES

by

M.

A. Sultan, T. T. Lie and J.Li

ABSTRACT

A computer program has been developed to catculate the temper- history of a

fire-exposed concrete slab-beam assembly. The procedure used in the calculation is based

on a finite difference method. This program will determine the tempemture history of a

slab-beam assembly made of a single material with known t h d and exposed to any fire for which the tern--time relationship is given. The cases studied,

NOMENCLATURE

specific heat, J/kg°C

coefficient of heat transfer a! fire-unexposed surface, Wh20C

thermal conductivity, W/m°C

max. number of points along y coordinate

max. number of points along x coordinate

point tmpaa-,

Oc

l3zmdhte Greek L e m i n m t mesh width, m emissivity heat of vaporization, J/kg density, kglm3 Stefan-Boltzmann constant, W / d 4 time, hconcentration of moisture, fraction of volume

C con f m n 0 rad W of cxxlcrete convective of the fire

at the point,

m

in rowat the point, n in column

atroomtmpaature radiative

INTRODUCTION

The

structural integrity of building elements exposed to fire is an important factor infire safety. The fire performance of such elements can be determined by testing and, in

many cases, by calculation. One factor requid to calculate the iire performance of

building elements is the temperature history of the elements during exposure to fire.

Methods exist for the calculation of that temperature history for such building elements as

walls, columns and beams.

In this study, a method is described for the calculation of the temperatlve history in

reinfked concrete slab-beam assemblies exposed to heating according to the time-

temperature relationship specified in the

ASTM

E119-83 standardIll.

The resultingtemperam in

the

slab-beam assemblies were calculated using a finite differencetechnique.

The heat iransfer equations that determine the temperature in the assembly were

pmgmmmed for computer processing. The program used can predict the temperature

distribution in the assembly for any given temperature-time relationship of the fire and also

any given dimensions of the slab-beam assembly, if the thermal propdes of the material

of which the assembly is constructed are known. Eight cases, in which the dimensions of

the assembly were varied, were studied The validity of these temperature predictions will

CALCULATION PROCEDURE

The calculation of the tern- disoibution in a slabbeam assembly is canied

out using a finite difference technique. The cross-section of the slab and beam is divided into several elementary regions as shown in Fig. 1. The regions are square inside and mangular at the boundaries. The temperature at the centre of each element is considered to

be representative of the entire element. For a hiangular element, the representative point is located on the hypotenuse.

Since the assembly is symmetrical, only one-half of the assembly section needs to be considered when calculating the temperature dismbution. The cross-seztion of the slag beam assembly is located, as shown in Fig. 1, on a set of x-y coordinate axes. Each representative point of each element is located on

the.^-^

grid In the x-y coordinate system, the representative point of the slab-beam assembly, has the coordinatesx = (n-l)~Q.\r2 and y = ( m - l ) ~ g a . The points n = 1 and m = 1 coincide with the

origin x = 0 and y = 0, m increases in the y direction

and

attains a value m = M at the boundaryFG

and m = MI at the boundary DC, whereas n increases in the x direction and has a value of n = N at the boundary BC and n = N1 at the boundaryDG.

To calculate the temperature history of the concrete slab-beam assembly, a heat transfer equation is written for each elementary region for the time jAr where j = 0, 1,2,

...

and

A7 is the appropriate time increment. Using these equations, the temperature of eachregion can be successively evaluated for any time 7 = (j+l)Az if the temperature at time

T = jAz is known.

Although the maisture movement is not taken into account in the present model,

emporntion of moisture is considered in the heat balance for each element Concrete

contains 3-6% moisture by volume.

Equations for Fire-Exposed Boundaries

With fire exposure considered only from below, the beam is exposed to fire on two

sides FG and

DG

and the slab is exposed tofm

only on one sideDC,

as shown in Fig. 1.It is assumed that the fire teapmhm follows the smdard teapmhm-time relation

according to that specified in

ASTM

E119-83 [I] as shown in Eg. 2, although thecalculation pmxdure is valid for any other temperatumtime relation. Several analytical

expressions that approximately describe the

ASTM

relation exist [2,3]. The followingexpression was used in this study:

Tf

=To

+

750[1- exp (-3.79553&+

1 7 0 . 4 1 6where Tf and

To

are the fire and ambient temperature in degrees celsius and .r is the time,after the start of the fire, in hours.

Equations for the Boundary CD (Slab) -The heat transmitted by radiation

from the fire to a surface element PMlsl) (see Fig. 3(a)) during the periodjA~ < r <

(j+l)A.r per unit length of the slab can be written as:

From the region PWlslp heat is transferred by conduction to the two neighbouring

The sensible heat &sorbed from the fire by an element P(M1,n) is:

J y][Tj+l Tj

]

[ ( ~ ~ ~ ~ j ~ ~ ~ )

P W'W q ( ~ 1 . n (u1.n)-

(M1.n) (4)The mk- concentration

dwlp1

in that element Can be d-edfor

'iM1,)

< 100°C as:(5)

The temperature of an element

PWla)

can k. beved by solving Eqs. (2)-(6). Thetemperature for an element

Pwl,)

at a time T = (j+l)Az is given by the expression:Equations for the Boundary DG (Beam)

-

The temperature rise in anelement

PcmN1)

can be derived h r n the heat balance for the element (see Fig. 3@)) in asimilar fashion to that demibed above.

The temperature for an element

PcmN1)

at a time T = (i+l)A~ is given by theAlso, the moisture

on

+msl) can befor Tidl) < 100°C as:

Equations for the Boundary

FG

(Beam)-

The temperature of an element Pm) can be obtained h m the heat balance for the element (see Fig. 3(c)) as discussed above.Also, the moisture concentration

#m)

can be obtainedfor TfM,) < 100°C as:

and for T!Ma) 2 100°C as:

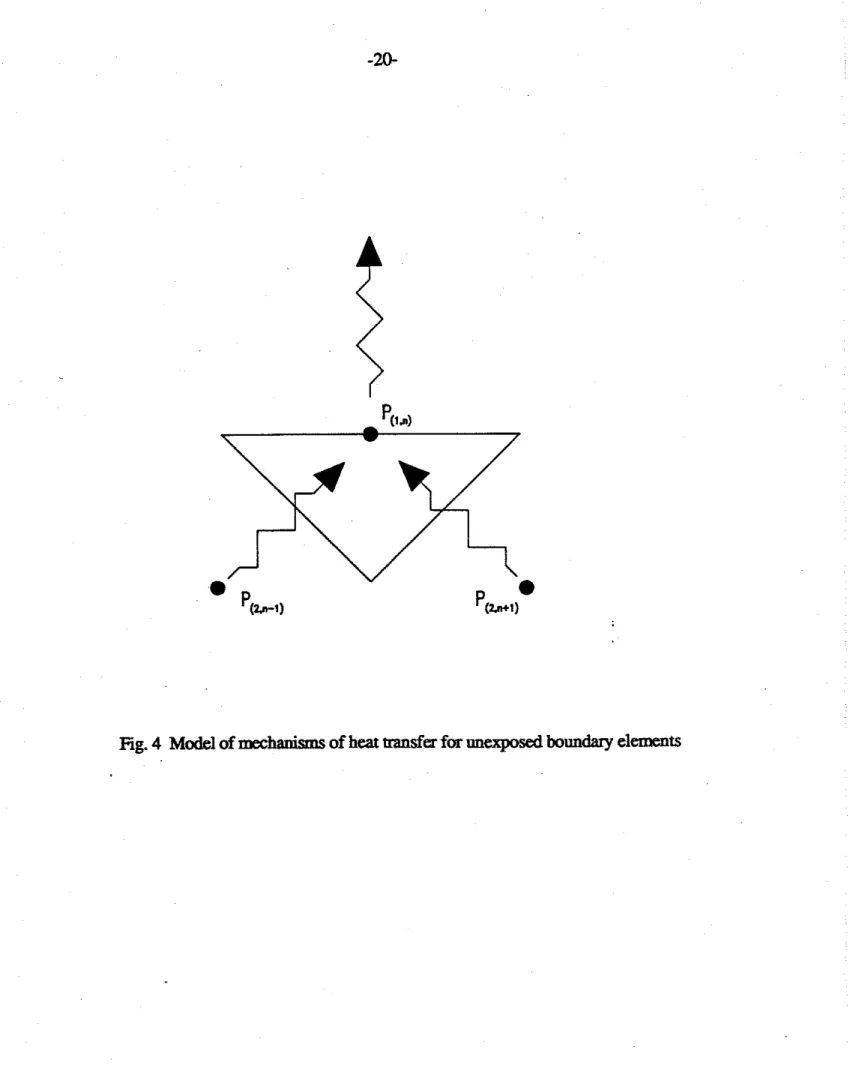

Equations for Unexposed Boundaries

Equations for the Boundary AB (Slab)

-

At this boundary, the heat istransferred to the ambient air by radiation and convection mechanisms. The temperatwe rise in an element P(la) can be beemined as discussed previously h m the heat balance for the element (see Fig. 4).

where

h is the convective heat uansfer c d k i e n t at the unexposed surface 141, and

?he moisture concentration can be defined

for

~ i ~ ~ )

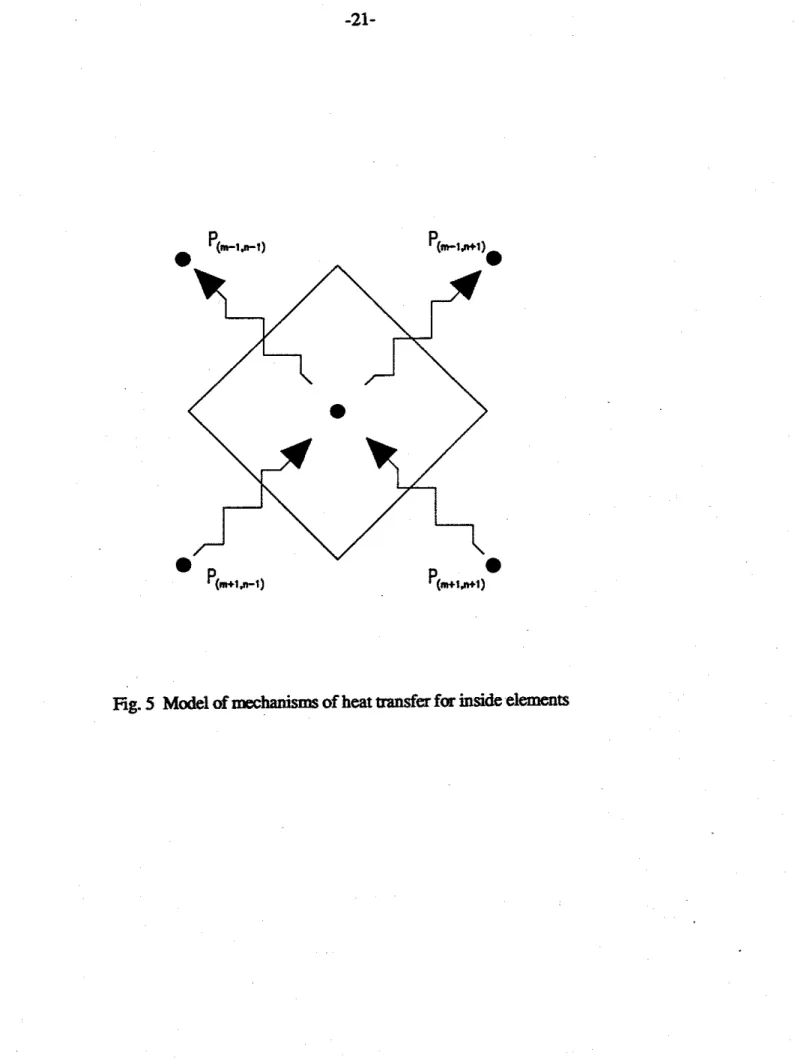

l)< 100°C as:Equations for Elements Inside the Slab and Beam

The temperature in the interior of the slab and beam can be calculated from a heat balance for the inside elementary regions, as shown in

Fig.

5. For an element P(m,n), theAlso, the moistme concentration can be debdefined

for

T

i

,

)

c100°C

as:Auxiliary Equations

There is no heat transfer across the line of symmetry AEF. The temperatures along

this line are obtained by equating the ternpemttms of symmetrical points. Thus along line

AEF:

The line BC has been chosen far enough from the beam so that heat is transferred

only vertically across the slab. The temperatures along line BC are also obtained by

Stability Criterion

In

order to ensun that any envr inthe

solution at a specified time is not amplified insubsequent calculations, a stabiity criterion has to be satisfied which, for a selected value

of

g,

limits the maximum of thetime

stepAT.

Following the method described inReference [5], the stability criteria along all boundaries and

inside

the slab-beam assemblyare presented in Appendix A. It was found that the stability criterion along the fneexposed

bo-es is most restrictive arnd is given by:

where the maximum value of the coefficient of heat hansfer during exposure to the standard

tire is approximately 3 x 106 ~ / m ~ h O c

[a.

With the aid of equations (1-22). it is possible to calculate the temperature

distribution inside the c o n a t e slab-beam assembly and along its boundaries. Initially,

only the temperatures at the t = 0 level, which are usually equal to xuom temperature, are

known. Starting with these temperatures and knowing

the

fire temperature, Tf, thetemperatrue history of the concrete slab-beam assembly can be detemked for any specified

time. In this study, the concrete temperature was calculated for 4 hours.

To demonstrate the capability of the computer program and also to generate

information on the temperature history in concrete slabs-beam assemblies exposed

m

fue,eight different assemblies were studied.

Details

on their dimensions are presented inTable 1. Both the slabs and beams were considered to consist of siliceous aggregate

concrete. The physical properties, such

as

thermal capacity and thermalconductivity,

usedin this study, are presented in Appendix B.

The computer program developed was used to generate informarion on the

temperature dismbutions in the m-te slabbeams assemblies. Details on such

tern- distributions for different fire durations (30-240 Minutes, at 30 minute

intervals)

are

pmented in AppendixC.

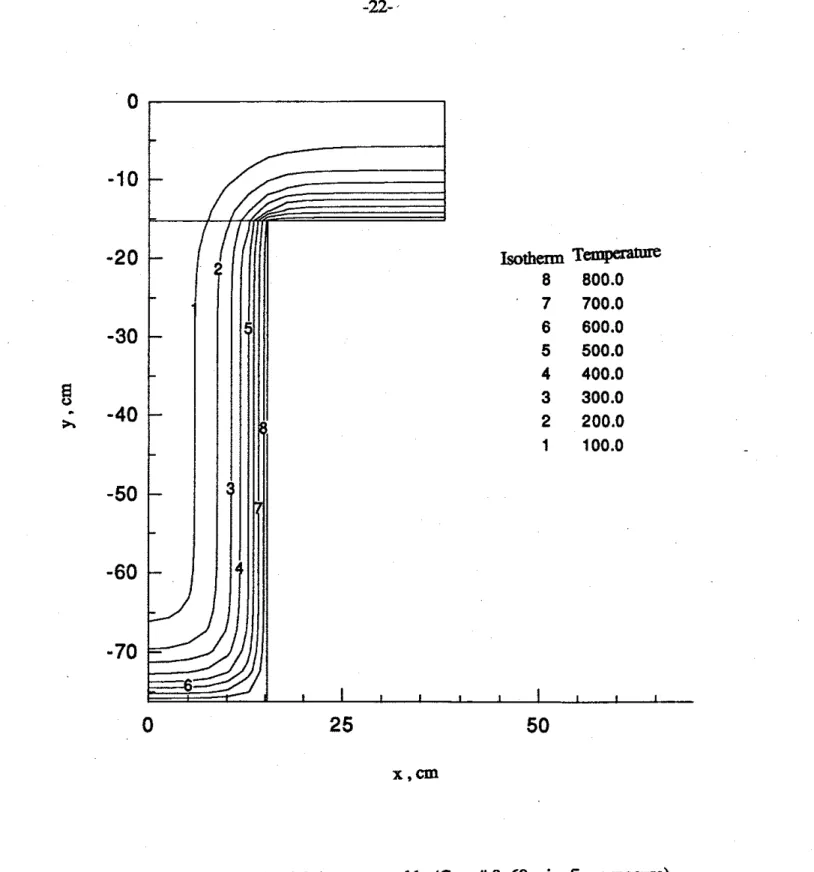

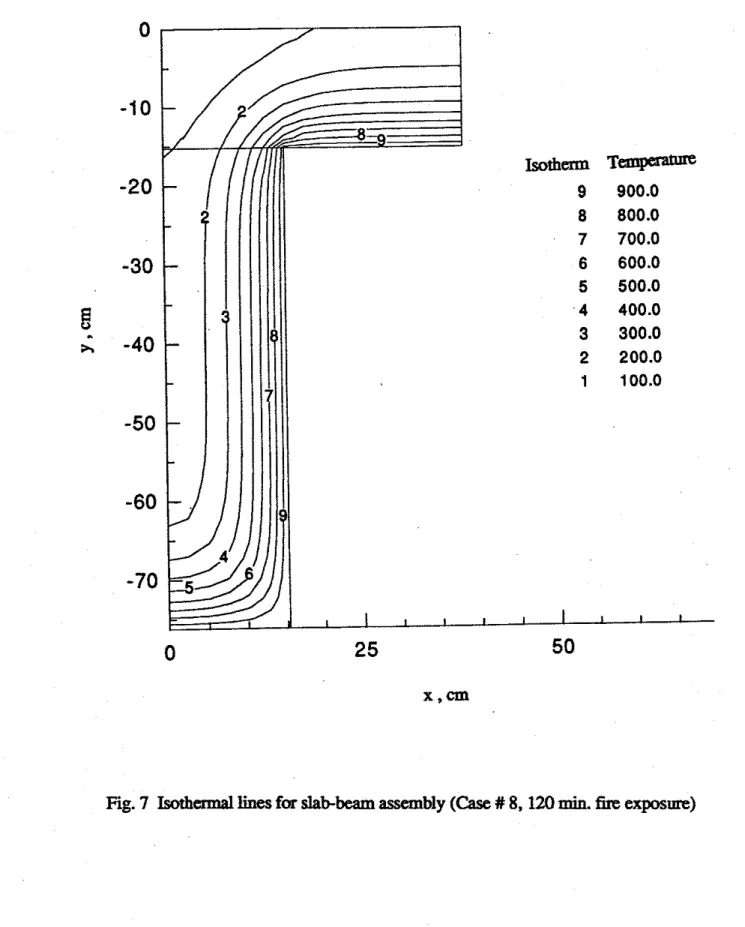

For

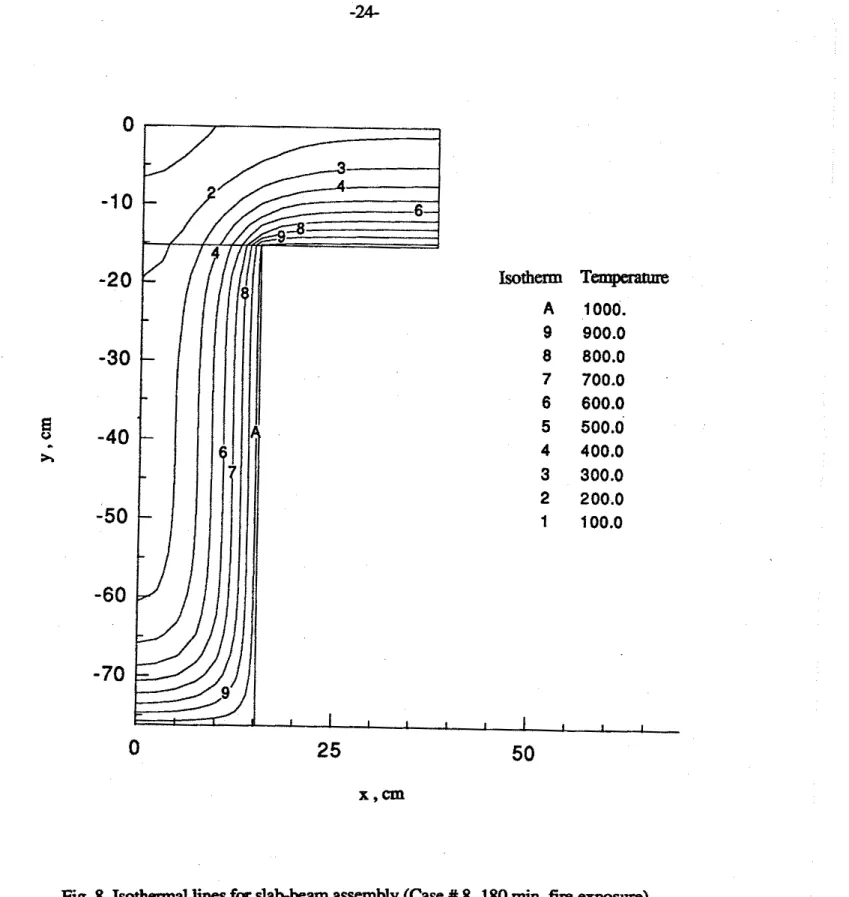

illusmtion purpses, Figs. 6,7 and 8 show the isothennal lines predicted forTABLE 1

Dimensions for cases studied

Case#

1 2 3 4 5 6 7 8 Beam Height (mm) 406.4 609.6 406.4 609.6 406.4 609.6 406.4 609.6 Slab width (mm) 101.6 101.6 152.4 152.4 101.6 101.6 152.4 152.4 Height (mm) 101.6 101.6 101.6 101.6 152.4 152.4 152.4 152.4 Width (mrn) 381.0 381.0 381.0 38 1 .O 381.0 381.0 381.0 381.0REFERENCES

"Standard Methods of Fire Tcsts of Building Conshuctions and Materials", American

Society for Testing and Materials, Philadelphia, PA, Designation El 19-83.

Lie, T.T.,

Fire

and Buildings, Applied Science Publishers Ltd, London, 1972.Williams-Leir. G., "Analysis Equivalents of Standard F i Temperature Curves",

Fire Technology, Vol. 9, No. 2, pp. 132-136, 1973.

Holman, J.P.. "Heat Transfer", McGraw Hill Book Company, New Yo*,

5th edition, 1981.

Dusinberre, G.M.,

Heat

Transfer Calculations by F i t e Differences, InternationalTextbook Co., Scranton. PA, 1961.

Lie, T.T.

and

Lin, T.D.."Fue

Performance of Reinforced Concrete Columns",Fie

Safety: Science and Engineering,

ASTM

STP 882. pp. 176-205,1985.Lie,

T.T.

and Allen, D.E., "CaIculations of the Fire Resistance of ReinforcedConcrete Columns", Technical Paper 378, NRCC 12747, Division of Building

Research, National Research Council of Canada, Ottawa, 1972.

Allen, D.E. and Lie, T.T.. 'Further Studies of the Fire Resistance of Reinfurced

Concrete Columns". Technical Paper 416. NRCC 14047. Division of Building

Research, National Research Council of Canada,

Ottawa,

1974.Hamathy, T.Z. and Allen, L.W., "Thermal Propexties of Selected Masonry Unit

Isotherm TempeadMe 8 800.0 7 700.0 6 600.0 5 500.0 4 400.0 3 300.0 2 200.0 1 100.0

APPENDIX A

STABILlTY CRITERION

To ensure that any error that may exist in the solution at

a

specif~ed time is notamplified in subsequent calculations, the stability criterion for a selected value of and

AT

is satisfied for all boundaries and inside the slab-beam assembly itself using the method described in Reference [5] as discussed below.Stability Criterion along Boundary CD (Slab)

The sum of the coeacients of

gWla)

in Equation (7) should be positive, thusStability Criterion along Boundary DG (Beam)

S i y , the sum of all the coefficients of in Equation (8) should be

positive, hence

-A2-

The sum of all the coefficients of

TjW)

in Equation (11) should be positive,therefme

Stability Criterion along Boundary AB (Slab)

The sum of all the coefficients of $la) in Equation (14) should be positive, thus

Stability Criterion for Inside the Slab and Beam

The sum of all the wdficients of

$ma)

in Equation (16) should be positiveIf A6 is assumed to be 17.% x 10-3 m, then the calculated values for

AT

for- A 3

TABLE A.l

To achieve the stability criterion for the numerical calculations at given as presented in Table A.l, the smallest value of

AT

(3.56 x 10-3 hr),was

used in the calmlatiom.AT

hr 21.0 x 10-3 3.56 x 10-3 3.56 x 3.56 x 10-3 55.9 x 10-3 Boundary AB 0DG

FG Inside l'cccJhn3y

1.8 x106

1.8 x106

1.8 x106

1.8 x 105 1 . 8 ~ 1 0 6k,

W b T 1.3 0.72 0.72 0.72 0.72 ~ r n ~CmzhOc 1.4 x 16 3.0 x106

3.0 x 106 3.0 x106

-

('kaJ-

~hn%Oc 3.5 x 104-

-

-

-

A6 m 17.96 x 10-3 17.96 x 10-3 17.96 x 10-3 17.96 x 10-3 17.96 x 10-3APPENDIX B

MATERIALS PROPERTIES AND PHYSICAL CONSTANTS

The values of the materials p p a i e s and physical constants used in this study are

given below. With the exception of those for the t h d conductivity of m a t e , the

values are approximate [7,8]. Forth- conductivity, the values assumed to be valid for

concrete made with pure quartz aggregate wae replaced by the values obtained by

Harmathy and Allen [9] from tests on conacte with predominantly siliceous aggregate.

Instead of tabulated values, approximate equations are used in this study to describe the

relationship between the properties and temjxxauues.

CONCRETE PROPERTIES

Thermal Capacity of Concrete

for

400°C

<T

5500°C

for T > 600°C

pccc = 2.7 x

106

J1m3°CThermal Conductivity of Concrete

for O°C

IT

S 800°C k = -0.00062ST+

1.5 W/m°C forT

> 800°C Water Properties T h d wty p&,,, = 4.2 x106

Jlm3OCHeat of vapization

Physical Constants

a

= Stefan-Bolt~nann constant: 5.67 x 104 W/dK4Ef = emissivity of fire: 1 = anissivity of concrete: 0.9

APPENDIX C

CASES STUDIED

In the slab/beam assembly, the slab was considered to be fire exposed from below

and the beam

b m

below and from the two sides.The computer pro- with input data such as slab thickness, beam width, beam

height and duration of the fm exposure, was used to generate information on the time history for 8 cases. Each case was also studied at 8 different times of exposure from 30 to 240 minutes, at 30 minute intervaIs.

A

B

23

m rcl.:

0s O r a>

SJZi d. 16P

sz

Crcl0

8

Y +fv m l R l l

%$

?-

" 2 aa f3

51

e

3 E:

" "-

":

-

..

f,.

P1-

=

.r:-;-:-:

-1

- * - - -- -- . * ---

. . "

- .

\99*-? 5 ,$ &

.

; E 5 1 , j f E Z 2X ~ S G ~ S :

O \ m - m b -1;

ll II I1 II I1 118 %

" - 1 5 E 5 12 - - : : = :

B

; - I : : : q

m 5 E Z ;51

5

" 3 qg f - j z ~ z 3 ~

,g

~B.la

.!I

P? 3 E S i ,&,"Was

z.-.i5

i 3 ,.g

g ~ a , ~

a s t = , - : : L4. . . . - . -

g&zz

wmmcgaE E

u ~ x - I E- . . " -

2;I

I : ? : : :.

a 5 1 .I3 5 5 5 1 D . . " "= : = :

.

3 E gL~-:-5-;-:-:-:-f-:-;~i~:-:-5-f--- " .

- , , ~ ~ i : " ' " " ' : " " ' " - - -- . . . . - - . " . .

' O C f P . , " - - . . . . * . " - -E - ~ : ; ~ ~ ~ : : : : : : : = : : : ~ ; Q P I

- " - - - . . - - - - ^ - . ^ . . . - . . - - . . ; r 2 : r x : r : r : r a t ~ : - ( z E z 5 ; : e : : : : : : ~ , - - -- - - . . - - - : I

- - - -

: " : " - - . : : - - - * " " - * " ., = = = - - -

- - - -

z - - - . . - .. . " " " " " *

.I"

- " .

"-

= : - - - " " -

z f : z - -- -. *- .* .- -" -- --e- " 51

n r : a : r : q : g g q g ; r : x - - - - - - - = I : ;-- -- ~ 2 z z = ~ ~ E ~ z z = : 2 = = 2 ~ 2 ~ 5 i

: ~ X ; C ' X : O D 1 1 : : ~ : " : : :- - -

- -

-

a - l . . " " "

2 9-

- .- -

* "-

: : s : s = : - .-

:

:

$ 1

..

" "- -

. . 2 = = -. . . - . . . .

" - - - * . , - - - . " - . f- " - .

L P : .LE-z-z-=-z~=-:i-:-2-:-2-:-- ---x-:-i-:-e-r~. - "- .

~ -" ' 2 ' * < i . ; ; ; ' i i p - . " ' ? - l - ? - - " - O - . ? . q . . ? - q z = x : z z : z = "" " .

-

-

-:p

Y X1

V K 9 .-

0-:-:-:-1-=..

-

-

I-.

. .

^ - - ?

z z 2 : : : z 1 . 1 ~ 2 5 ' : 5;i

- - . . , - . . . .

II If II II II II- . . - - * . -

L ^-: - I i

z ::j

S-

:: 2-

..

! - - * - - e-

..

" " Z P : : D- 1

E . 2 I 3 5 1. - . " . " -

: : ; = = L-: - I l

2 5 f * - - - . - . ,. "

-

- " " : ' z g'-1:

5 2 f 5 51 z = ? i z = = z . I 5 3i j

2 , : z z ; g ; g-

'.I?

2 I ? L " r-:-:-z--.--.-=----.-z-z-z-zd-i-?" .

.

-

-

-

- -

" "-

-

e m- . . . . *

- - - - - - - - - - - - -= . . . - . " - " " " ' " i E . : : a r- - - - . . .

. . - . -

. * . . . .

- 5 5 : - ?- - -

z . . " . - - - . * " o e - * . . ":.I:

I P Z ; 2 r-

: :'

:'

=

=

: =- . . - -

- * - ":

1

- . . " e m ? t i ; ; P ~ t ~ E E L P i h ; : ' :: * . " - - " " " " - - " e - " " - * - - . ; . l z z 2 z : : : : : ' : : ' : z : z 2 :=

2 5 1 3 3-

: ? : 5 ; 3 9 2 ; ~ 5 ; 3 5 5 3 - " 2 z z : L 0 r . l z E z ? " t t - - - - - -- _ I c e r 2 z z r t : $ 5 E E F z t q l- - - - . . -

- . , e m - - - - = r ; $ s ; f i 3 ; l i 4 f E t 5 1 f .L~-I-D-:-=-:-=-~-- - - m e " - - - . - 5 - I - ~ - i - ~ z - s - 2 - = - i i C C e - ~ i .. . . . - - - . . - -

-

9 f = . ' - - . . - - : ' ? ? 9 : 7 1 1 ? : t ? : : I :. . . - . . -

? W =:zzz.;Ei~EI12s:1-IB

-

X?

-

-

".,

$

'Ei

;

CI)-

.r:1:T5r1yZ-:-

-1- -

-

-

: " - - - " -:.I::

r 5 S Ef l

-

-

-

-

- ". . " " " - - =

- - -

- 1 :

r 5 1 E E (- : : ; : : = :

" .

-1:

: 5 S g 5 1 " " . . - - " -" , . " . , " - "

. . - -

" " " " " . . " . . - -f .

24

V) Ir 0-5

0 %>

3%

.a a~2

0

1

S"0

0 0> 2

Y KP m t l l B l l

3 %

3-8

9.

z-:-:-=-:-z. . " " "

GI

" -11

3 3:

:

-

-

:

* -9‘9'9 : - 1 5 Ea

- - " - ^ - " . .

- . - - - . . -

. . . . - - . - *

f f l a e g g

d e - m II II II I1 II II U:

" "-

r

-

:: t 2 ? :-

-

X 7 ^ ? = = : z : s z LL. . - . . . . - - -

-1:

3 5;I

: r : : : : 2 - - - e . . -2 - 1 :-

-

3 . 5 as

" -. . - - " . - .

. I D : : :.I:

r

g l ; s 3 s ; i z 7 - 2 5 2 1 - - - - * --= -= : -= -= -= :

.I"

"

""I

l ~ ~ h 3 ; i - 1 2 5 2 f _ZL:-F-Z-:-:-:--'- _ - - - - . - - E-E-E-:-:-:-:-E-E-‘-Z-i.-~-2-:-1-= - - - - . - + - - - - - * * *=I

2 . -Z t Z ?- a : . . . - - - . . - : = " 0 0 . z I I L ' t t t " t ~ " ~ ~ r 2 : " -g

? - ~ 2 ~. . " - "

f ' ~ : : Q.

' ~ 5. " - : : : : : : : : : : $ : - . : : I

" " . . - - . . . . - . ' " ' ~ ' " ' : " h ~ ~ ~ 3 $ ~ ~ ~ ~ ~ i i i f i f ~ ~ ~ ~ : : : f E- z i i i I I I I i i i i i i I j i ~ i l i

: : = = * . . . . -

- - -

- : 2 t x r r ; ; ~ 5 5 ; ~ ; ; ; ; ; ; $ $ ~ : : : ; i-1

-

= ~ ~ 2 z E t 5 f f f f I E E E E I E ~ ~ ~ ! ~ ~ 5 ~ ~ ~ . f ) . - S ; ;-

~ f f l ~-

=- -

: : i ; 3 i i f ~ ; ; ~ : : E 5 : ~ : ; .L:-:-:-Z-~-::-~~~-::-:-::-:-~-~-~-:-X-:-:-=-=-.:-~-:-~-~-~-:-OJ - _ _ l l l _ _ - _ - - l _ l - _ _ . _ ^ - ^ I - - - - - ~ - -V AP

-

X;

" s3

-

g

3

2

3 X ,.-

-

-

..

-

I D .. ?-

?.r:-:-=-:--

" "-

:-:1-

z s E ; 3 $ %-

" . a:-Is

r , : 21

- "= " -

- " : D : t " " " a ? . z" - 1 %

5:

5:

5 1 0 " " " . * " = z 2 : = : e sf

; - / : : : : ; i l rh.

-

=

2 - 1 :

5 :..

-

:-

: I13

0 e m " - - .-- -- -- --

P

- " " " : : ; LU : - l i i : i /$

Z .- - ' 3 2 ? i - " " " &- 1

5-

- - - -

--

- - : : s t$ 1

" " z- 1

5 ; 5 9 1 " " o " " -- -- -- -- -- -- :- - . . - - . -

:.I;

-

i 5 5~i

= = = = = ? '-

- - -

- . - - .

- 1 :

2 Pii

.,

" " " " " 1. "

. "

- 1

=

:. " - " - "

f : ; : : : . *-

- . . . . " " - - " " " " " " "

- 1 s 3 5 a : zi~-~-~-z-.-.---.-.-.---.-.-.-.-:-:-:-~-:-:-z-z-- x = = g -" . . " " - * . - . -

- - - - = . . z : : . . . = = : . = z : I : : z P l . . " - . - - - - - L P t X L : : i % : : : : : : : = : z S - _ " " " _ . ~ . * - * * * * . * - . * - . . - . * - - -- -

~ ~' - 1 3 f " s r "

" " - : = : : : :- . - .

- - . - - - . . . - - -

g Q = .O -O- O- O. I' P l i i D : : P O 5I

^ - - ^ " D " . - " I " ^ L . - - - * . - - . - . - - - . 3 ' ~ : ' : 2 4 : : : I : ~ ~ e O : : ? : ~ z z : : : ~ : ~ P 2 s - ~ 5 ~ " : : : : : : g z : : : : : : E ~ s : = = : : : : ? : ; ~- - - - . -

z . ^ . - " . ' - - - - . . - . - - - " . - " . - - - - : = , ~ r r : r : : o ~ : : : : : : : ~ : : : ~ : ~ ~ : :-

-

-

. . " - - " " " " - - " - " " " " m " - . . D : - / i f g ~ ~ ~ i i V " " " " . . . ' . " " ..,

" - D z z Z : : 2 2 Z 2 : : 2 X :. .

, " 2 S I z = : t : = - . . z c .-

-* " - - - . . " . - - . - . " - - - o- - - - " .

. . . .L=-:-^-=-I:-P-:-:-l-C-i-:-:-:-:,--:-=-:-:-z-O-:-.-P-.-?-z-li - - - I " " _ _ _ _ - - - . _ . _ . - - - - - - " " - - - . - l * l l . . . 1 . 1 1 1 , . 1 , 1 1 1 1 . , . , ? " ? 0 - : ~ ~ : ' " ? " " ~ : " : q : : ~ - ? : : 7 :, . - .

" . - - - - . - " - - - - " - " * - * " - -:::*:jp

- . ' z 3 C t 2 : E L I E l t ~ : : I ~ E : : I I I I . Y A4

'.I!

2 5 1'

-

- -

-

-

"-

?-

-

-

I p.- . . . . - - - -

" ? . . - " " -

- - - - . - =

.I"

'

'

"'"I

- * - . = - .

. . . -

- - - - . - $.

- - . - - . .

2 5 5 3 1 o - = : = p : " "-

: : : 3 3 : 1= - I "

-

- -

*-

-

.

E i 5 5 5 1. . - - . ? . .

e : : = - - :. I n

. . - - - . . -

1 E ::..

tL5-P,a_:-

:-..-i.-i.-.i_ i.-i-: -i.-i.- ::-:-:-:-i-:~;:-::-3-:-- - - - I : I : : = I : z : I : : = : z z z I : : z z z - = : - m- e- -. z : - : - - - * - - - * . . E P $ $ F ; E n z a g n - -