Publisher’s version / Version de l'éditeur:

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

Internal Report (National Research Council of Canada. Division of Building Research), 1958-11-01

READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE.

https://nrc-publications.canada.ca/eng/copyright

NRC Publications Archive Record / Notice des Archives des publications du CNRC :

https://nrc-publications.canada.ca/eng/view/object/?id=eefbef92-11f0-4d9f-ae3a-26bbeceb0a1c https://publications-cnrc.canada.ca/fra/voir/objet/?id=eefbef92-11f0-4d9f-ae3a-26bbeceb0a1c

NRC Publications Archive

Archives des publications du CNRC

For the publisher’s version, please access the DOI link below./ Pour consulter la version de l’éditeur, utilisez le lien DOI ci-dessous.

https://doi.org/10.4224/20338063

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at

Small brick panel tests at Halifax: preliminary program on leakage and bond strength

NATIONAL RESEARCH COTJNCIL OF CANADA D I V I S I O N O F B U I L D I N G m S E A R C H

SMALL

BRICK

PANEL T E S T S AT HALIFAXP R E L I M I N A R Y PROGRAM ON LEAKAGE AND BOND STRENGTH

J.I. D a v i s o n and J.D. A t k i n e ANALYZED R e p o r t No.

161

o f t h e D i v i s i o n of B u i l d i n g Research O t t a w a N o v e m b e r1958

PREFACE

Brick masonry r e s e a r c h i s being c a r r i e d out by t h e D i v i s i o n a t i t s A t l a n t i c Regional S t a t i o n i n H a l i f a x a s w e l l a s i n t h e l a b o r a t o r i e s a t Ottawa. S t u d i e s of masonry

performance i n t h e A t l a n t i c Provinces c o n s t i t u t e t h e main r e s e a r c h i n t e r e s t i n t h e H a l i f a x l a b o r a t o r y , while masonry r e s e a r c h i n Ottawa forme only a small p a r t of t h e o v e r - a l l

a c t i v i t y of t h e D i v i s i o n and i s c a r r i e d out w i t h t h e problems of a l l r e g i o n s i n mind.

Unnecessary d u p l i c a t i o n of work on masonry between H a l i f a x and Ottawa i s c a r e f u l l y avoided b u t , o f t e n i n t h e e a r l y s t a g e s of a program such a s t h i s , u s e f u l checking can be done between t h e two l a b o r a t o r i e s . Usef'ul techniques and

i n s t r u m e n t a t i o n developed i n one l a b o r a t o r y may be adopted by t h e o t h e r and t h e same methods and procedures a r e used u n l e s s t h e r e i s good r e a s o n f o r them t o be d i f f e r e n t . R e s u l t s from b o t h l a b o r a t o r i e s can t h e r e f o r e be compared d i r e c t l y .

Much use i s being made a t p r e s e n t i n b o t h l a b o r a t o r i e s of t e s t s on small p a n e l s made from

5

b r i c k s , l a i d up w i t h mortar. A f t e r c u r i n g , t h e s e panels can be t e s t e d f o r leakagecharacteristics and f o r bond s t r e n g t h i n a p p a r a t u s d e v i s e d f o r t h e s e purposes. The work c a r r i e d out w i t h t h e f i r s t

s e r i e s of 25 p a n e l s made a t t h e Halifax l a b o r a t o r y i s now described. The procedures and techniques used a r e g i v e n i n

some d e t a i l , along w i t h t h e t e s t r e s u l t s f o r record purposes, even though some of them may a l s o be covered i n r e p o r t s from t h e Ottawa l a b o r a t o r i e s . A number of r e p o r t s can be expected from b o t h l a b o r a t o r i e s covering work based on t h e small-panel t e s t s , s i n c e , a s w i l l be apparent from this r e p o r t , t h e s e provide an e f f e c t i v e way of a t t a c k i n g i n t h e l a b o r a t o r y many b r i c k masonry problems.

Ottawa,

SMALL B R I C K PANEL TESTS AT HALIFAX

PRELIMINARY PROGRAM ON LEAKAGE AND BOW STRENGTH

J.I. Davison and J.D. Atkins

Following studiels of the p r o p e r t i e s of m o r t a r s and sands used i n t h e a r e a , work i n t h e

DBR

l a b o r a t o r y a t t h e A t l a n t i o Regional S t a t i o n i s now p r o c e e d i n g t o a more d e t a i l e d s t u d y of masonry problems. T h i s program i s c l o s e l y i n t e g r a t e d w i t hmasonry s t u d i e s i n p r o g r e s s i n t h e B u i l d i n g M a t e r l a l a S e c t i o n of t h e D i v i s i o n a t Ottawa b u t w i l l be p r i m a r i l y concerned w i t h

m a t e r i a l s used I n masonry c o n s t r u c t i o n i n t h e A t l a n t i c Provinces. T h i s r e p o r t d e a l s w i t h a p r e l i m i n a r y program which

i n c l u d e d c o n s t r u c t i o n of 2 5 b r i c k p a n e l s and t e s t s f o r l e a k a g e and bond s t r e n g t h . T h i s program provided a n o p p o r t u n i t y f o r f a m i l i a r i z a t i o n w i t h t h e m a t e r i a l s , t e c h n i q u e s , and a p p a r a t u s t o be u s e d i n our masonry s t u d i e s . The r e s u l t s , a s w e l l a s s u p p l y i n g u s e f u l i n f o r m a t i o n , have provided a b a s i s f o r assessment and

a d j u s t m e n t of t e c h n i q u e s and a p p a r a t u s f o r f u.ture worh. MATERIALS

B r i o k s

Three t y p e s of c l a y and s h a l e b r i c k s manufactured i n t h e A t l a n t i c a r e a were used and w i l l 'be d e s i g n a t e d "A" • "Btt # " C n #

and "D1f. The l a s t two a r e t h e same t y p e , ltC" b e i n g a c o r e d and

"D" a s o l i d b r i c k .

B r i c k s were purchased i n l o t s of one hundred. Each b r i c k was t e s t e d f o r i n i t i a l r a t e of a b s o r p t i o n ( I R A ) by t h e s t a n d a r d

C.S.A. and A.S.T.M method (C.S.A. ~82.2-19%). I n t h i s t e s t

a

a d r y b r i c k i s p l a c e d f l a t s i d e down i n

1/8

i n . w a t e r f o r 1 minute and t h e amount of w a t e r absorbed i s measured by weighing. The number of grams of w a t e r absorbed f o r a s u r f a c e a r e a of 30 s q in.i n 1 minute i s t h e i n i t i a l r a t e of a b s o r p t i o n o r a u c t i o n of t h e b r i o k .

S t a n d a r d C.S.A. and A.S.T.M. 24-hour submersion t e s t s and 5-hour b o i l i n g t e s t a were a l s o c a r r i e d o u t on r e p r e s e n t a t i v e

samples of a l l t y p e s of b r i c k s used, and t h e r e s u l t s a r e reoorded i n Table

I.

It should be p o i n t e d out t h a t b r i c k s used i n t h i s s t u d y a r e manufaotured and used e x t e n s i v e l y i n t h e A t l a n t i c a r e a and a r e known a s "low I R A b r i c k s g t . It i s noted t h a t "B" b r i c k s d i d have I R A v a l u e s up t o

47.3

gm, b u t87.7

p e r c e n t of "B" b r i c k s t e s t e d had I R A v a l u e s between 1 0 and 20 gm. A l l t h e "A","c"

and"D" b r i c k s t e s t e d had I R A v a l u e s below

7

gm.B r i c k s used in p a n e l s were s e l e c t e d t o f a l l w i t h i n a narrow I R A range. The range of '!Att b r i c k s , f o r example, was

1.8

t o 3.2 gm, "B1' b r i c k s from 11.0 t o

15.5

gm and4.4

t o 19.0 gm, "Ctl b r i c k s from 3.0 t o4.4

gm, and"D"

b r i c k s from 3.2 t o 5.2 gm and 1.0 t o 2.0 gm. Each p a n e l c o n t a i n e d f i v e b r i c k s h a v i n g f i v e d i f f e r e n t IRAta w i t h i n one of t h e above-noted r a n g e s , b u t t h e b r i c k s were s e l e c t e d t o have s i m i l a r v a l u e s i n e a c h panel. A s a n example t h e f o l l o w i n g a r e I R A 1 8 of b r i c k s used i n P a n e l s 1and

4:

Panel 1 Panel

4

Mortar

a

Three m o r t a r s were used i n P a n e l s 1 t o

18:

Type "AN--1 p a r t by volume commercial masonry cement t o3

p a r t s sand;Type "Bt'--1 p a r t b y volume p o r t l a n d cement, 1 p a r t l i m e p u t t y ,

and

6

p a r t a aand; and Type "c*--1 p a r t by volume p o r t l a n d cement, 2 p a r t s lime p u t t y , and9

p a r t a sand.The lime p u t t y was o b t a i n e d from a l o c a l s u p p l i e r , and i t s

d e n s i t y , determined by weighing 1/30 cu f t , was found t o be 81.25 l b p e r ou f t .

The masonry cement used was a commercial product, Itcanada Brandt1, manufactured by Canada Cerrent Co. I t i s b e l i e v e d t o be of t h e p o r t l a n d cement : i n t e r g r o u n d lime s t o n e : a i r - o n t r a i n i n g a g e n t type. " ~ a r i t i m e o rand" p o r t l a n d cement, a p r o d u c t of

Maritime Cement Co. Ltd. was used.

Chezzetcook sand, s o named f o r i t s o r i g i n and o b t a i n e d from a l o o a l s u p p l i e r , was used. P r i o r t o use t h e sand was a i r - d r i e d and then passed t h r o u g h a No.

8

s i e v e . The p o r t i o n r e c o v e r e d conformed i n p a r t i c l e s i z e g r a d i n g t o t h s C.SoA. S p e c i f i o a t i o n f o r Aggregate f o r Masonry Mortar (~82.56-1950) (Fig. 1).I t should be p o i n t e d o u t t h a t l o c a l b r i c k l a y e r s c o n s i d e r Chezzetcook sand t o o c o a r s e f o r masonry m o r t a r and use Lawrenoetown sand, However, a p r e v i o u s s t u d y i n t h e ARS l a b o r a t o r y r e v e a l e d t h a t Lawrencetown aand does n o t f a l l w i t h i n the C.S.A. limit^

because i t c o n t a i n s too g r e a t a percentage of " f i n e s " ,

I n d e t e r m i n i n g amounts of m a t e r i a l s f o r a m o r t a r batch, 1/30 c u f t of dry sand was used a s a b a s i s f o r c a l c u l a t i o n s and t h e r e q u i r e d w e i g h t s of lime p u t t y , p o r t l a n d cement and/or masonry dement t o g i v e t h e corresponding volumes, were calculated.

I n e a c h mortar b a t c h 240 cc of d i s t i l l e d water were used, By experiment it was found t h a t t h i s amount of water w i t h t h e m a t e r i a l s a s measured produced a m o r t a r w i t h a f l o w i n the range

115

t o 120 p e r c e n t which w a s comparable t o the flow of m o r t a r s used i n a c t u a l masonry c o n s t r u c t i o n eWater r e t e n t i v i t y t e s t a were done on a l l m o r t a r s u s i n g

t h e method o u t l i n e d i n A.S.T.M. S p e c i f i c a t i o n

~91-49.

( s e e t able 11,)Lime putty-sand m o r t a r s were used i n P a n e l s

19

t o 22i n c l u s i v e and a r e d e s i g n a t e d a s f o l l o n a : Type " ~ " - - a commercial mix o b t a i n e d l o c a l l y c o n t a i n l n 1 p a r t by volume lime p u t t y and

4

p a r t s Lawrencetown sand; Type C/E1'--1 p a r t lime p u t t y and4

p a r t s Chezzetcook sand p l u s 270 oc w a t e r and mlxed i n t h e l a b o r a t o r y . No w a t e r was added t o Type "D".A l l m o r t a r s were mixed i n a Hobart

N-SO

mixer f o r3

minutes, 2 minutes a t elow speed and 1 minute a t medium. They were l e f t t o s t a n d i n t h e mixing bowl f o r 1 minute b e f o r e using.PANEL

CONSTRUCTIONA l l p a n e l s c o n s i s t e d of f i v e b r i c k s on0 on t h e o t h e r n e c e s s i t a t i n g f o u r m o r t a r j o i n t s each

3/8

i n . t h i c k . The s i z e of p a n e l s was t h e r e f o r e8

i n . by 13l/4

in.P r i o r t o p a n e l c o n s t r u c t i o n t h e s e l e c t e d b r i c k s had been d r i e d a t l l O ° C f o r 72 hours. T h e use of dry b r i c k s e n s u r e d

maximum s u c t i o n on t h e mortar during, p a n e l assembly. Between d r y i n g and a c t u , a l use, a l l b r i c k s were wrapped i n p o l y e t h y l e n e and s t o r e d a t room temperature, Also, b e f o r e s t a r t i n g a p a n e l assembly, r e q u i r e d amounts of m o r t a r i n g r e d i e n t s - - s a n d , p o r t l a n d cement and masonry cement--were weighed and i n d i v i d u a l l y packaged i n paper bags, b o t t l e s , e t c . This w a s n e c e s s a r y s i n c e a new b a t c h of m o r t a r was used f o r e a c h of t h e

four

j o i n t s i n a panel, and t h e work ~ c h e d u l e d i d n o t i n c l u d e t i m e f o r weighing o u t m a t e r i a l s p r i o r t o e a c h mix, When lime p u t t y was t o be used, t h e r e q u i r e df o u r amounts were weighed out and s t o r e d i n covered g l a s s d i s h e s p r i o r t o panel assembly. The f i v e b r i c k s t o be used were then weighed and the panels c o n s t r u c t e d according t o the following time schedule.

Water i s placed i n mixing bowl and lime p u t t y , p o r t l a n d oement o r masonry cement added.

0 min. Stop watch s t a r t e d . S t a r t mixer on slow speed and add

-

add aand gradually.2 min. Stop mixer--change t o medium speed. S t a r t mixer.

-

3

min. Stop mixer. Let mortar s t a n d 1 minute i n mixing bowl.4

min. Place mortar i n mortar form on brick--screed off--remove formo

5

112 min. Place second b r i c k on mortar bed. Place drop hammer on b r i c k and give one drop. Remove hammer. Clean mixer and mortar form and prepare f o r n e x t mix.9

min. S t a r t second mix--same a s f i r s t mix. 12 min. Stop mixer. Seoond mix complete.1 3 min. Place mortar i n form--screed o f f and remove form.

4

1/2 min. Place t h i r d b r i c k on mortar and t a p a s before. Clean u t e n s i l s and prepare f o r nextniixo

18

min. S t a r t t h i r d mix.2 1 min. Third mix completed.

22 min. Plaoe mortar i n form, e t c .

23 1/2 min. Place f o u r t h b r i c k on mortar, t a p and prepare f o r n e x t mix.

27

min. S t a r t f o u r t hmix.

30 min. Fourth mix completed.31

min. Place mortar i n form, e t c .32 1/2 min. P l a c e f i f t h b r i c k on mortar, tap, e t c .

m i Place t h r e e b r i c k s on t o p of panel a s dead weight t o remain t h e r e during c u r i n g period.

Thickness of mortar j o i n t s was c o n t r o l l e d by u s i n g a s p e c i a l l y b u i l t mortar frame which was p l a c e d on t h e b r i c k t o be used and then f i l l e d w i t h mortar. (Mortar frame and s t a n d a r d drop hammer a r e shown i n Fig. 1 2 ) . Excess mortar was screeded w i t h a s t e e l s t r a i g h t - e d g e t r o w e l o r s p a t u l a . The mortar frame was t h e n c a r e f u l l y l i f t e d o f f l e a v i n g a mortar bed

3/8

in. t h i c k on t h e b r i o k . A f t e r t h e n e x t b r i c k was s e t i n p l a c e on t h i s mortar bed i t waa given one t a p w i t h t h e s t a n d a r d d r o p hammer,i.e

.,

a weight of 2 l b was dropped on t h e b r i c k from a h e i g h t of1 1/2 i n .

When t h e p a n e l s were completed t h e y were weighed. The g a i n i n weight i n d i a a t e s t h e amount of mortar used. They were t h e n wrapped w i t h polyethylene and t h r e e b r i c k s were p l a c e d on t o p f o r dead weight a s i n d i o a t e d i n t h e time schedule.

A l l p a n e l s were assembled a t room temperature, t h e range being

73'

t o8S0F.

R e l a t i v e humidity v a r i e d from 12 t o44

p e r cent.MOISTURE

CONTENT

OF MORTARIn

a o n j u n c t i o n w i t h p a n e l assembly, mortar moisture o o n t e n t d e t e r m i n a t i o n s b e f o r e and a f t e r 3-min c o n t a c t w i t hb r i o k s were c a r r i e d out. A p a i r of b r i c k s f o r t h i s purpose had been s e l e c t e d f o r e a c h p a n e l , t h o s e chosen h a v i n g I R A 1 8 a s c l o s e a s p o s s i b l e t o t h e average I R A of t h e f i v e b r i c k s used i n t h a t panel.

A sample of mortar was taken from t h e mixing bowl a t t h e end o f t h e p a n e l assembly ( f o u r t h mix), and the m o i s t u r e c o n t e n t of t h i s sample was determined w i t h a Cenco m o i s t u r e balanae.

Some of t h e same m o r t a r was then p l a c e d on one of t h e b r i c k s u s i n g t h e mortar frame a s d u r i n g p a n e l assembly. Excess m o r t a r was screeded o f f , t h e frame removed, and t h e second b r i c k p l a c e d on t h e mortar and given a t a p w i t h t h e s t a n d a r d hammer. Aftep

3

minutes the b r i c k s were s e p a r a t e d and a m o i s t u r e c o n t e n t d e t e r m i n a t i o n was done on a sample from t h e mortar j o i n t a g a i n u s i n g t h e Cenco m o i s t u r e balance.The v a l u e s o b t a i n e d were a percentage of the t o t a l weight of t h e sample r a t h e r t h a n of t h e d r y weight. T h i s wa a

s a t i s f a c t o r y s i n o e a comparison of m o i s t u r e c o n t e n t s o n l y was requiped.

CURING

A f t e r 2 4 hours the polyethylene wrapping was removed from the p a n e l s and r e p l a c e d by a s t r i p of the same m a t e r i a l w i t h which t h e top, bottom, and ends of the p a n e l s were wrapped,

l e a v i n g t h e f r o n t and back exposed t o a i r . A f t e r

7

days t h i s covering was removed and t h e t o p , bottom, and ends were c o a t e d with a commercial c a u l k i n g compound,"La

sto-Fderictl, a product of the Tremao Company* P a n e l s N O S . 1 t o 22, e x c e p t i n g Nos*9

and 11, were t r e a t e d i n t h i s manner. Another commercial oaulking compound," 3 ~ " ,

waa used on Panels Nos.9

and 11. The procedure was simply t o c o a t d e s i g n a t e d a r e a s of t h e panel w i t h t h e c a u l k i n gcompound, t h e n t o plaoe a s t r i p of polyethylene over t h i s smoothing i t i n t o p l a c e w i t h s l i g h t p r e s s u r e . For c o a t i n g P a n e l s Nos. 23, 24, and 25 a n o t h e r Tremco product, tlRoofclad't, was used. For

Panel Noa 23 a c o a t i n g of "Roof c l a d H was a p p l i e d and t h e n t h e polyethylene s t r i p a s mentioned. A f t e r the i n i t i a l c o a t of

t l ~ o o f a l a d " had been a p p l i e d t o Panel No. 24, a s t r i p of processed o o t t o n was a p p l i e d , t h e n a n o t h e r c o a t of l'Roofclad't, and f i n a l l y t h e polyethylene s t r i p , A s i m i l a r procedure was followed f o r Panel No. 25, s u b s t i t u t i n g a g l a s s mat f a b r i o f o r t h e processed cotton.

The purpose of t h i s t r e a t m e n t was t o waterproof t h e t o p , bottom, and ends of the panel, e n s u r i n g t h a t any leakage would pass through t h e f a c e . The p o l y e t h y l e n e f l a s h i n g s t r i p s were u s e f u l i n d i v e r t i n g water from t h e f a c e and back of t h e p a n e l s t o d r a i n s d u r i n g leakage t e s t s .

The t h r e e b r i c k s were t h e n r e p l a c e d on t h e t o p of t h e p a n e l which was l e f t f o r a n o t h e r

7

days. Duration of t h e c u r i n g p e r i o d , t h e r e f o r e , was14

days.Tern e r a t u r e range d u r i n g t h e c u r i n g p e r i o d s of the 25 a n e l s was 920 t o 88OF and r e l a t i v e humidity ranged from 12 t o

c9

p e r cent.LEAKAGE

TESTS ApparatusThe a p p a r a t u s was s u p p l i e d by t h e

DBR

masonry l a b o r a t o r y a t Ottawa and was modelled a f t e r the l a r g e p a n e l leakage a p p a r a t u s being used t h e r e .The a p p a r a t u s , shown i n Figs. 2 and 10, c o n s i s t s of t h r e e main p a r t s :

(1) A c o n s t a n t - l e v e l w a t e r supply w i t h a connection t o a s p r a y tube i n s i d e an a i r - p r e s s u r e chamber.

( 2 ) An a i r - p r e s s u r e chamber f i t t e d w i t h a n a i r - p r e s s u r e r e g u l a t i n g valve and n manometer,,

( 3 )

A frame f o r h o l d i n g t h e p a n o l t o be t e s t o d , T h i s frame i s s e a l e d a g a i n s t t h o a i r - p r e s s u r e chamberby f o u r b o l t s and s e p a r a t e d from i t by sponge p l a s t i c . The frame f o r h o l d i n g tha p a n e l h a s t h r e e p a r t s , one s i d e and t h e base which a r e s t a t i o n a r y , a v e r t i c a l member which can be a t t a c h e d t o the base and a g a i n o t which p r e s s u r e can be a p p l i e d by two screws, and a h o r i z o n t a l t o p member which can be a t t a c h e d t o t h e two u p r i g h t members by wing n u t s . The b r i c k p a n e l t o be t e s t e d was p l a c e d on t h e base of the frame on a t h i n s t r i p of foamed p l a s t i c c u t t o f i t t h e l e n g t h and w i d t h of a b r i c k , and was s e p a r a t e d from t h e f i x e d s i d e by a t h i c k s t r i p of the same m a t e r i a l . Another s t r i p of p l a s t i c was p l a c e d between the p a n e l and t h e movable s i d e of t h e frame. By t i g h t e n i n g t h e wing n u t s on t h e v e r t i c a l member, t h e p a n e l was s e a l e d on t h e

s i d e s by t h e p l a s t i c . A p i e c e of t h i c k foamed p l a s t i c was t h e n p l a c e d on t o p of t h e p a n e l and t h e t o p of t h e frame put i n p l a c e over t h e p l a s t i c . Bg t i g h t e n i n g t h e wing n u t s a g a i n s t t h e frame, t h e t o p of the p a n e l was s e a l e d by t h e p l a s t i c ,

The s p r a y t u b e connected t o t h e w a t e r r e s e r v o i r was t h e n p u t i n p l a o e by i n s e r t i n g a p r o j e c t i n g m e t a l p l a t e between t h e t o p of t h e panol and tho p o l y e t h y l e n e f l a s h i n g s t r i p . The tube was t h u s h e l d i n p o s i t i o n s l i g h t l y below t h e t o p of t h e panel.

The frame h o l d i n g the p a n e l now was moved i n t o p o s i t i o n a g a i n s t t h e a i r - p r e s s u r e chamber and s e a l e d t o i t by t i g h t e n i n g t h e b o l t s ,

T e s t

-

Having t e s t e d f o r and c o r r e c t e d any a i r l e a k s i n t h e s e t up, a l l was r e a d y f o r t h e a c t u a l t e s t d u r i n g which a f i l m o f w a t e r was maintained on t h e f a c e of t h e p a n e l by a l l o w i n g t h e water

from t h e c o n s t a n t - l e v e l water supply t o flow t h r o u g h t h e s p r a y tube

A t t h e s t a r t of t h e t e s t t h e f r o n t of t h e p a n e l was "wettedn by a brush i n t r o d u c e d through two h o l e s i n t h e f r o n t of t h e a i r - p r e s s u r e chamber. This o p e r a t i o n took p l a c e d u r i n g a 1-min i n t e r v a l between s t a r t i n g t h e s p r a y and t u r n i n g on t h e a i r p r e s s u r e and was designed t o e n s u r e a c o n t i n u o u s f i l m of water r u n n i n g down t h e p a n e l f r o n t r a t h e r t h a n s t r e a k s of water.

The r e s e r v o i r , s p r a y tube, e t c . , were designed t o produce a s p r a y of approximately 600 cc of w a t e r p e r minute. A i r p r e s s u r e was a p p l i e d t o m a i n t a i n a manometer r e a d i n g of 2 i n . of water.

C o n d i t i o n s c r e a t e d by t h e s p r a y and a i r p r e s s u r e i n t h e chamber a r e c o n s i d e r e d e q u i v a l e n t t o a 50 rnph wind-driven r a i n storm. T h s w a t e r l e v e l i n t h e r e s e r v o i r was m a i n t a i ~ l o d through a

c o n n e c t i o n w i t h t h e l a b o r a t o r y w a t e r supply, e x c e s s w a t e r be i n g d r a i n e d t h r o u g h a n overflow tube.

The t e s t p e r i o d was 2 4 houre. Water which l e a k e d through t h e p a n e l was d i v e r t e d by t h e p o l y e t h y l e n e f l a s h i n g s t r i p t o a c o n t a i n e r f o r measurement. Water remaining i n t h e a i r - p r e s s u r e chamber was removed t h r o u g h a d r a i n i n t h e bottom of t h e chamber,, Records

P r i o r t o s t a r t i n g t h e l e a k a g e t e s t , panola were weighed, t h e change i n w e i g h t b e i n g due t o t h e a d d i t i o n of t h e c a u l k i n g compound and p o l y e t h y l e n e f l a s h i n g s t r i p . A t t h e end of t h e l e a k a g e t e s t p a n e l s were a g a i n weighed, t h e d i f f e r e n c e between t h e s o two weighing8 ( T a b l e 111) g i v i n g t h e w e i g h t of w a t e r absorbed d u r i n g t h e t e s t .

Temperature and r e l a t i v e humidity maxima and minima were a l s o r e c o r d e d d u r i n g t h e 24-hour p e r i o d of t h e l e a k a g e t e s t . For t h e 2 5 p a n e l s t e s t e d t e m p e r a t u r e from

6k0

t o 80°F and r e l a t i v e humidity from13

t o53

p e r a e n t .A t l e a s t once d u r i n g e a c h l e a k a g e t e s t a check vras t a k e n on t h e r a t e of s p r a y and t h e r e s u l t recorded.

A t t h e s t a r t of t h e leakage t e s t a n o t a t i o n w a s made a s t o whether or n o t t h e r e was immediate leakage. A "yes" meant t h a t t h e r e were drops of water v i s i b l e on t h e back of t h e p a n e l n o t merely damp s p o t s . I n a t l e a s t one i n s t a n c e ( p a n e l No. 2 2 ) t h e r e was immediate l e a k a g e ( w a t e r v i s i b l e a s such on t h e back of t h e p a n e l ) b u t n o t enough leakage o c c u r r e d t o g i v e a measurable amount of w a t e r u n t i l t h e second hour of t h e t e s t .

Records of l e a k a g e were k e p t a s follovrs: Amount of l e a k a g e d u r i n g t h e f i r s t 2 1/27 rnin of t h e t e s t and a f t e r t h a t l e a k a g e r a t e p e r minute a t

3 ,

5 ,

7,

10,15,

20, 2 5 , 30,45

and60

mine

Timing d u r i n g the f i r s t hour of t h e t e s t was done w i t h a s t o p watch. The l e a k a g e r a t e p e r minute a t any g i v e n time was e s t a b l i s h e d by measwing t h e l e a k a g e f o r 1 minute. Forexample, t h e r a t e of l e a k a g e a t

3

m i n u t e s was o b t a i n e d by measuring t h e w a t e r c o l l e c t e d i n t h e c o n t a i n e r a t t h e bottom of t h e backof the p a n e l from 2 1/2 min t o

3

1/2 m i n , l e a k a g e r a t e a t5

rnin

I n a d d i t i o n t o t h e water c o l l e c t e d f o r leakage r a t e s d u r i n g t h e f i r s t hour, t h e r e m ~ i n i r l g water which passed through t h e p a n e l d u r i n g t h a t p e r i o d was c o l l e c t e d ; and t h u s , by adding t o t a l s f o r water c o l l e c t e d , t o t a l leakage d u r i n g t h e f i r s t hour was r e c o r d e d * The amount; of leakago was recorded. t h e r e a f t e r

f o r each hour. Water was a l s o co1.lected o v e r n i h t , and by adding a l l t h e t o t a l s a f i g u r e f o r t o t a l leakage f o r 2

f+

h o u r s waso b t a i n e d , T o t a l leakage f i g u r e s f o r p a n e l s t h a t 1.eaked badly a r e n o t complete because t h e Commissionaire w a s f o r c o d t o empty t h e c o n t a i n e r d u r i n g the n i g h t i n o r d e r t o prevent a n overflow. Leakage r e s u l t s a r e found i n T a b l e s I V and V while m o i s t u r e c o n t e n t l o s s e s a r e r e c o r d e d i n Table V I .

P a n e l s 1 t o

6

Panels assembled w i t h Type "A" bricks--IRA

1.3

t o 3.2 gm-- and m o r t a r s "A" 8 "B", and"c"

d i d n o t l e a k d u r i n g t h e 24-hour t e s t .A s t u d y of t h e i n c r e a s e i n weight of t h e s e p a n e l s d u r i n g t h e

leakage t e s t i n d i c a t e s t h a t t h e amount of water absorbed i n c r e a s e d w i t h t h e lime c o n t e n t of the mortar used f o r t h e p a n e l * I n view

of t h e low s u c t i o n of t h e b r i c k s and the i n c r e a s e of water w i t h i n c r e a s i n g lime c o n t e n t of mortar,

it

i s assumed t h a t t h e w a t e r was absorbed by t h e m o r t a r r a t h e r than by the b r i c k n e Moisture c o n t e n t d e t e r m i n a t i o n s on m o r t a r s b e f o r e and a f t o r a 3-minutec o n t a c t w i t h Type "A" b r i c k s r e v e a l a l o s s of from 0.9 t o 1.9 p e r c e n t . S i n c e t h e r e was no l e a k a g e f o r t h e s e p a n e l s , the drop i n moisture c o n t e n t of m o r t a r s p r i o r t o the p l a c i n g of the second b r i o k was obviously not d e t r i m e n t a l t o t h e bonding o f thoso m o r t a r s and Type "Aff b r i c k under t h e c o n d i t i o n s of t h i s e x p e r i - ment.

P a n e l s 7 t o 1 2

A l l s i x p a n e l s c o n s t r u c t e d w i t h Type "B" bricks--IRA 11.0 t o

15.5

gm--showed immediate leakage. I n e a c h c a s e f i r s t l e a k s were observed a t t h e i n t e r f a c e between t h e t o p of t h e mortar bed and t h e bottom of t h e b r i c k r e s t i n g upon it. Also, i n oach c a s e t h e leakage r a t e reached a maximum d u r i n g t h e f i r s t ten minutes of t h e t e s t and a t t h e end of twenty-four hours had dropped t o a comparatively small amount ( F i g .3 ) .

Panels9

and 1 2 u s i n g mortar"C" had l e s s t o t a l leakage t h a n the o t h e r f o u r p a n e l s maclo w i t h m o r t a r s having lower lime c o n t e n t s . Moisture c o n t e n t l o s s e s of from 4.7 t o

6.6

p e r c e n t were r e c o r d e d f o r m o r t a r s a f t e r the 3-minute c o n t a c t w i t h Type"B"

b r i c k s . The p a t t e r n was s i m i l a r t o leakage r e s u l t s i n t h a t t h e r e was l e s s m o i s t u r e l o s s f o r Type"C" m o r t a r which c o n t a i n e d t h e h i g h e s t percentage of lime, t h e analogy being t h a t l o s s of m o i s t u r e from the m o r t a r had a

d e t r i m e n t a l e f f e c t on t h e r e s u l t i n g bond between Type "B" b r i c k s and t h e v a r i o u s m o r t a r s , v a r y i n g w i t h t h e l i m o c o n t e n t of t h e mortars.

A s i g n i f i c a n t i n c r e a s e i n t h e amount of water absorbed d u r i n g t h e leakage t e s t over t h e p r e v i o u s p a n e l s was noted. There was no p a t t e r n r e l a t i n g the amount of w a t e r t o t h e lime c o n t e n t of the mortars. 0bviou.sly t h e a d d i t i o n a l w a t e r was absorbed by t h e b r i c k s * T h i s could be a d e s i r a b l e f e a t u r e . I f

s i m i l a r w a l l s of Types "Att and "Btt b r i c k s each developed a s m a l l l e a k which l a t e r stopped, Type "B" b r i c k s , by a b s o r b i n g t h e w a t e r , would p r e v e n t damage t o i n t e r i o r w a l l s while Type "A" b r i c k s

being of v e r y low s u c t i o n would permit r e a d y passage of water through a c r a c k t o the i n t e r i o r .

P a n e l s

13

t o18

Panels

13

and16,

Types "C1' and "D" b r i c k and Type ''A"m o r t a r , d i d not l e a k . P a n e l

14.

d i d n o t a c t u a l l y l e a k ; s e v e r a l "wet" s p o t s appeared on the m o r t a r J o i n t s ear1.y i n t h e t e s t b u t l a t e r d r i e d up. P a n e l 17, a d u p l i c a t e of Panel14

u s i n g Type'ID" i n s t e a d of Type

"c"

b r i c k ( s o l i d i n s t e a d of c o r e d ) , showedimmediate l e a k a g e and l e a k e d badly d u r i n g t h e e a r l y p a r t of t h e t e a t . However, t h e l e a k a g e t a p e r e d off and had stopped by t h e end of t h e t e s t . P a n e l s

15

and18

b o t h showed inurjediate leakage. I n e a c h c a s e t h e l e a k was on t h e r i g h t s i d e of one J o i n t only and a t t h e i n t e r f a c e betwesn t h e bottom of t h e t o p b r i c k and t h e t o p of t h e m o r t a r bed belovr. Leakage was a l i g h t and e v e n t u a l l y d r i e d up. Moisture c o n t e n t l o s s e s of m o r t a r s i n c o n t a c t w i t hTypes "C" and

"D"

b r i c k s were r e l a t i v e l y low a t 1.0 t o2.6

p e r c e n t . The amount of w a t e r absorbed by t h e s e p a n e l s d u r i n g t h e leakage t e s t s was a l s o low r e f l e c t i n g t h e low s u c t i o n r a t e s of t h e b r i c k s .P a n e l s

19

t o 22These p a n e l s of Type "B" b r i c k and Types "D" and "E"

m o r t a r s ( l i m e p u t t y : s a n d ) a l l l e a k e d p r o f u s e l y , but t h e leakage p a t t e r n w a s v e r y d i f f e r e n t from t h a t e n c o u n t e r e d i n t h e o t h e r l e a k y panels. Panels

19

and 22 showed immediate l e a k a g e , and ther a t e i n c r e a s e d a s t h e t e s t progressed. I t should be n o t e d t h a t while t h e r e was l i q u i d water v i s i b l e on the back of P a n e l 22 a s

soon a s the t e s t s began, no w a t e r r a n o f f i n t o t h e measuring

v e s s e l u n t i l t h e second hour of t h e t e s t . This i s a good example of t h e w a t e r - r e t a i n i n g c a p a c i t y of lime m o r t a r s .

Panels 20 and 2 1 d i d not show immediate leakage, merely damp j o i n t s , but began t o l e a k w i t h i n f i f t e e n minutes w i t h

i n c r e a s i n g leakage a 8 t h e t e s t progressed ( ~ i g .

4).

Thus, w i t h t h e s e p a n e l s t h e t r e n d was r e v e r s e d and leakage i n c r e a s e d r a t h e r t h a n d e c r e a s e d a s t h e t e s t progressed. Also, w i t h t h e s e p a n e l s water seemed t o be permeating t h e m o r t a r beds r a t h e r t h a n coming through a t t h e i n t e r f a c e between b r i c k and mortar a s before. Moisture c o n t e n t l o s s e s of mortars a f t e r t h e 3-minute c o n t a c t w i t h b r i c k s was h i g h a t8.9

t o 10.5 p e r c e n t . I t must be noted, however, t h a t t h e s e m o r t a r s contained a l o t of water having very h i g h flow v a l u e s of 132 t o158

p e r c e n t , while t h e b r i c k s had h i g h e r s u c t i o n s a t14.4

and 19.0 gm. The p a n e l s absorbed a l o tof water ( f o u r t o f i v e times more than P a n e l s

13

t o18)

d u r i n gt e s t s , a r e s u l t of h i g h e r s u c t i o n of t h e b r i c k s and w a t e r - r e t a i n i n g c a p a o i t y of the lime.

P a n e l s 23 t o 2 5

These p a n e l s were d u p l i c a t e s of Panel

1 7

f o r b r i c k s andmortar. Briok s u c t i o n was s l i g h t l y lower a t 1.0 t o 2.0 gm

compared w i t h

3.2

t o5.1

@;me Proczedure was a l t e r e di n

t h a t d u r i n g p a n e l assembly b r i c k s were g i v e n two t a p s w i t h t h e s t a n d a r d drop hammer. None of t h e s e p a n e l s leaked. The a d d i t i o n a l t a p t h u s proved effecztivs i n improving bond. Loss of moisture from m o r t a r s d u r i n g 3-minute c o n t a c t w i t h b r i c k s was 0.4 t o1.8

p e r c e n t , and t h e amount of water absorbed by p a n e l s d u r i n g t h e t e s t was very low.A second purpose of t h e s e p a n e l s was t o a s s e s s t h e r e l a t i v e

merits of " ~ o o f oladtt and " L a a t o - ~ e r i c " a c s o n l i n g compounds f o r t h e purposes of t h e t e s t s . ttRoofclad" was used i n t h r e e d i f f e r e n t ways:

1. ItFtoof c l a d n and polyethylene

.

2 " ~ o o f c l a d t @ , c o t t o n and polyethylene.

3.

' ' ~ o o f c l a d t t , g l a s s mat f a b r i c and polyethylone.tlRoofcladlt was e a s y t o a p p l y and i t d i d t h e job e f f e c t i v e l y . Method

3

was most s a t i s f a c t o r y i n t h a t polyethylene seemed t o b i n d b e t t e r w i t h t h e g l a s s mat f a b r i c t h a n w i t h t h e m a t e r i a l s used i n t h e o t h e r two methodso l l ~ o o f c l a d t ' w a s d i r t y t o work w i t h , however, p a r t i c u l a r l y when the p a n e l s were s t r i p p e d f o r l a t e r bond s t r e n g t h t e s t s * ttLazto-?,larictt was much b e t t e r t o work w i t h i n t h i s r e s p e c t . BOND STRENGTH TESTSBond s t r e n g t h t e s t s were c a r r i e d out on a l l p a n e l s u s i n g t h e bending a p p a r a t u s (Fig. 11) designed and assembled a t t h e

D i v i s i o n of B u i l d i n g Research. R e s u l t s obtained were i n c o n s i s t e n t w i t h v a l u e s obtained u s i n g the direct

-

tension machines a t t h e DBRand t h e Nova S c o t i a Technical College, a n d were not c o n s i d e r e d r e a l i s t i c , Since bond s t r e n g t h t e s t s proved h e l p f u l i n s t u d y i n g

leakage and gave u s o f u l conlparativo v a l u e s , a b r i e f account w i l l

be i n c l u d e d d e s p i t e apparent i n a c c u m t e r e s u l t s ,

A l l p a n e l s were s t o r e d a t room temperature betweon leakage and bond strene;th t e s t s . The age of the p a n e l s a t t h e time of t h e l a t t e r t e s t s ranged from

36

t o 125 d a y s o Before bond s t r e n g t h t e s t s were done, t h e p o l y e t h l o n e f l a s h i n g was removed and c a u l k i n g compound ( l ' L a s t o - ~ e r i c r ' e t c .3

was scrapod from t h e j o i n t s .The machine used measured bond s t r e n g t h by means of a

bending s t r e s s . There were two frames f o r h o l d i n g t h o b r i c k s , e a c h w i t h two screws per s i d e . One of t h e s e frames was f a s t e n e d t o a plywood b a s e o The bottom b r i c k of a p a n e l was p l a c e d i n t h i s frame and s e c u r e d by t i g h t e n i n g t h e f o u r screwso The second frame was t h e n lowered over t h e p a n e l and, by u s i n g wooden s p a c e r s r e s t i n g on t h e lower frame, i t was p l a c e d o p p o s i t e the c e n t r e l i n e of the second b r i c k from t h e bottom of t h e p a n e l and s e c u r e d by t i g h t e n i n g t h e screws. Tho wooden s p a c e r s were t h e n removed. Two 1- by 2-in. hardwood s h a f t s o r l e v e r s which had been counter- balanced were then l a i d a l o n g t h e f l a n g e s a t t h e ends of tho t o p frame s o t h a t t h e h o l e s i n t h e i r o u t e r ends were 2 4 i n . from t h e c e n t r e of t h e m o r t a r bond a r e a of t h e p a n e l b e i n g t e s t e d . To a s s i s t i n t h i s a guide l i n e had been dravm through t h e c e n t r e of t h e t o p b r i c k and t h i s was l i n e d up w i t h t h e 24-in. marks on t h e s h a f t s .

A h y d r a u l i c jack w i t h mounted proving r i n g was t h e n p l a c e d on the plywood base between t h e hardwood s h a f t s , tho c r o s s b a r from t h e proving r i n g being a l i e n e d a t r i g h t a n g l e s t o them and p a r a l l e l t o t h e l e n g t h of t h e p a n e l f a s t e n e d i n t h e frame, The two m e t a l connecting r o d s which hang from t h e c r o s s b a r on t h e proving r i n g were t h e n l i f t e d i n t o tho s l o t s i n t h e end of t h e hardwood. beams and s e c u r e d by p i n s i n s e r t e d through h o l e s i n t h e c o n n e c t i n g r o d s and s h a f t s . Before f o r c e was a p p l i e d w i t h t h e jack, t h e d i a l

r e a d i n g was notod. The proving r i n g had p r e v i o u s l y been c a l i b r a t e d a g a i n s t t h e a x i a l - s t r e s s machine a t tho DBR i n Ottawa. The jacking p r o c e s s was t h e n s t a r t e d . The dead n e e d l e on t h e d i a l , used a s a n

i n d i c a t o r t o r e c o r d maximum r e a d i n g s , was of no h e l p s i n c e most r e a d i n g s exceeded one d i a l r e v o l u t i o n . During t h e ns t e s t a , t h e r e - f o r e , one o p e r a t o r a p p l i e d f o r c e g r a d u a l l y while t h e o t h e r c a r e f u l l y watched t h e d i a l i n o r d e r t o r e c o r d t h e r e a d i n g when t h e j o i n t

f r a c t u r e d . The number of s c a l e d i v i s i o n s o b t a i n e d by s u b t r a c t i n g t h e two r e a d i n g s was t r a n s l a t e d t o pounds by c o n s u l t i n g t h e c a l i - b r a t i o n curve

C a l o u l a t i o n s

S t r e s s was o b t a i n e d from t h e bending e q u a t i o n

The bending moment M i s t h e p r o d u c t of the l o a d i n pounds ( P ) a p p l i e d a t the ends of t h o hardwood s h a f t s t i m e s t h e l e n g t h of t h e s h a f t s ( 2 4 in.). Thus M

=

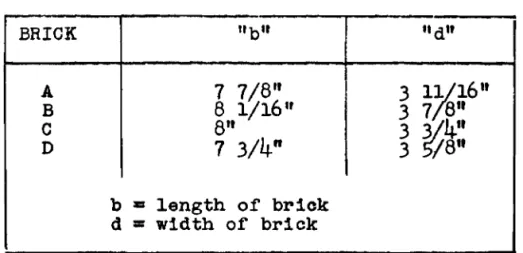

2 4 ~ i n . l b . The b r e a d t h , b i s t h e l e n g t h of t h e mortar c o n t a c t a r e a and d t h e depth, i s t h e w i d t h of t h e c o n t a c t a r e a . Average v a l u e s of b and d f o r e a c h of t h e f o u r t y p e s of b r i c k s o b t a i n e d by measurement a r e found i n TableV I I . Average v a l u e s f o r s t r e s s f o r v a r i o u s b r i c k and mortar combinations a r e found i n Table V I I I .

R e s u l t s

P a n e l s 1 t o

6

P a n e l s were

113

t o 1 2 5 days o l d a t time of t e s t . High bond s t r e n g t h v a l u e s were o b t a i n e d w i t h t h e bending machine, v a l u e s r a n g i n g from 102.5 t o 225a8 p s i . Average v a l u e s f o r t h e t h r e e m o r t a r s were a s f o l l o w s :Type "A'' Mortar

-

162.9 p s i Type"B"

Mortar-

15

Type "C" Mortar

-

13

Many j o i n t s f r a c t u r e d t h r o u g h t h e m o r t a r bed, t h e remaining b r e a k s being w e l l d i v i d e d between t o p b r i c k and m o r t a r bed and

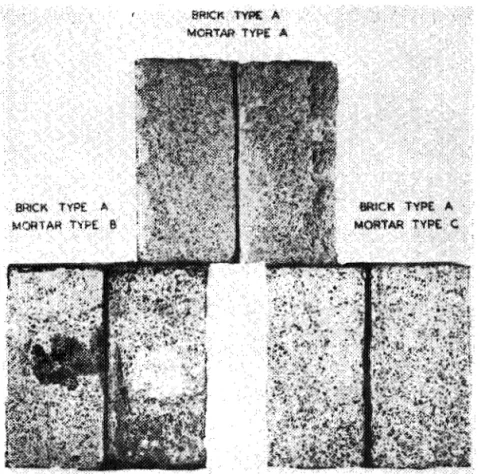

bottom b r i c k a n d mortar bed. There was good e x t e n t of bond i n a l l c a s e s . T y p i c a l examples of e a c h mortar t y p e a r e shown i n Fig.

I n c o n t r a s t t o bending machine r e s u l t s , two s e c t i o n s of P a n e l

5

gave v a l u e s of16.6

and5.1

p s i when t e s t e d on t h e T i n i u s - Olsen direct-tension machine a t t h eDBR.

P a n e l s

7

t o 1 2The age of t h e p a n e l s a t t h e time of t e s t ranged from 103 t o 111 days. Much lower bond s t r e n g t h v a l u e s were obtainod.

Average r e s u l t s f o r t h e t h r e e typr3s of m o r t a r were a s f o l l o w a : Type "A" Mortar

-

31.8

p s iType

"B"

Mortar-

19.3

p s i Type "C" Mortar-

33.7

p s iI n a l l c a s e s the t o p b r i c k l i f t e d o f f t h e mortar bed and t h e e x t e n t of bond was poor. The p a t h of the l e a k could be t r a c e d along t h e mortar bed i n many i n s t a n c e s , by n o t i n g the r u s t s t a i n s l e f t behind by t h e water, I n s e v e r a l of t h e s e leaky j o i n t s t h e r e was a r e a l channel j u s t next t o t h e mortar whlch had been packed

i n t o t h e end of t h e j o i n t during fabrication, Com a r i s o n of r e s u l t s f o r t h e t h r e e mortars can be seen i n F i g ,

8

.

Panels 1 3 t o

15

Panels had been aged from 92 t o 97 days a t the time of the t e s t . Bond s t r e n g t h values were b e t t e n than those f o r Panels

6

t o 12 and average r e s u l t s were a s follows: Type "A" Mortar-

25.4

p s i Type"B"

Mortar-

1.5

p s i Type"c"

Mortar-

53.7 p s iA l l breaks occurred a t o r near the t o p of t h e mortar bed. I n most c a s e s mortar key i n c o r e s broke o f f i n the upper b r i c k . There was good e x t e n t of bond i n a l l cases. A t y p i c a l example c a n be seen i n Fig. 7. A l e a k channel was found

i n

one of the j o i n t s i n Panel15.

I t was l o c a t e d j u s t i n s i d e t h e mortar packed i n t o the end J o i n t and was s i m i l a r t o one foundi n previous panels.

Values of

33.3

and43.3

p s i were obtained f o r two j o i n t s of Panel13

t e s t e d on the direct-tension machine a t the NovaS c o t i a Technical College compared w i t h 96.0 and 94.7 p s i obtained f o r the o t h e r two j o i n t s on t h e bending apparatus.

Panels

16

t o18

The age of the p a n e l s a t the time of the t e s t was

86

t o91

days. Bond s t r e n g t h values were h i g h e r t h a n f o r Panels13

t o

15.

The r e v e r s o had been a n t i c i p a t e d s i n o e Panels13

t o15

were assembled w i t h cored b r i c k , and i t had been thought t h a t mortar keys formed i n core a might give h i g h w bond s t r e n g t h values when t e s t e d with the bending apparatus. Average r e s u l t s f o r t h e v a r i o u s mortars were a s follovrs:Type "A" Mortar

-

1 Type "B'' Mortar-

Type "C" Elortar

-

62.5

p s iMost f r a c t u r e s occurred a t t h e t o p of the mortar bed, and t h e e x t e n t of bond was g e n e r a l l y good (Fig.

7 ) .

A bad l e a k had occurred i n Panel 17, and t h e t y p i c a l l e a k channel d e s c r i b e d p r e v i o u s l y was discovered j u s t i n s i d e the mortar packed i n the end j o i n t ( ~ i g .8).

Other examples of l e a k y p a n e l s can bo seen i n Fig.9.

Two bond s t r e n g t h v a l u e s of

65.8

and4+.5

p s i were o b t a i n e d on t h e direct-tension machine a t t h e Nova S c o t i a T e c h n i c a l College while v a l u e s f o r the o t h e r two j o i n t s t e s t e d on t h e bending maahine were96.6

and 172.7 p s i .P a n e l s

19

t o 22The age of t h e p a n e l s a t t h e time of t h e t e s t was

77

t o85

days. There was v e r y l i t t l e bond i n t h e j o i n t s of P a n e l s1 9

and 20 and no v a l u e s could be o b t a i n e d a s most j o i n t s broke d u r i n g t h e s e t t i n g - u p procedure Three v a l u e s r a n g i n g from6.0

t o13.1

p s i , however, were o b t a i n e d f o r Panel 21n Tho f o u r t h j o i n t broke d u r i n g t h e s e t t i n g up. Panel 22 was saved f o r l a t e r t e s t i n g .

The m o r t a r i n P a n e l s

19

and 20 appeared t o be mostly sand; t h e r e was v e r y l i t t l e bonding. There was some bond i n Panel 21, b u t mortar crumbled r e a d i l y and appeared t o be mostly sand.P a n e l s 2 3 t o 25

he a g e s of t h e p a n e l s a t t h e time of t h e t e s t were

36

and 37 days. Average bond s t r e n g t h was 92.2 p s i.

Two j o i n t sof Panel 2 4 gave v a l u e s of

42.4

and 33.2 p s i on t h e d i r e c t - t e n s i o n machine a t Ottawa compared w i t h bending machine v a l u e s of 1 1 7 0 7 and96.6

p s i f o r t h e o t h e r two j o i n t s . A v a l u e of78.3

p s i wae o b t a i n e d f o r one j o i n t of P a n e l 2 5 on t h e d3rect-tension machine a t the Nova S c o t i a Technical C o l l e g e , compared w i t h 113.0,89.5,

and86.0

p s i on t h e bending machine. These t h r e e p a n e l s were d u p l i c a t e s of Panel1 7

w i t h t h e e x c e p t i o n t h a t d u r i n g f a b r i c a t i o n b r i c k s were g i v e n two t a p s of t h e s t a n d a r d drop hammer i n s t e a d of one when placed on t h e m o r t a r bed. E x t e n t of bond was much b e t t e r t h a n f o r Panel17,

and t h e r e was no l e a k c h a n n e l a si n

Panel

17.

A comparison of r e s u l t s can be seenin

F i g ,8.

CONCLUSIONS

The combination of leakage t e s t , m o i s t u r e l o s s , and bond s t r e n g t h r e s u l t s i n d i c a t e s t h a t f o r t h e c o n d i t i o n s of t h i s s t u d y b r i c k s having very low s u c t i o n w i l l combine s a t i s f a c t o r i l y w i t h the t h r e e m o r t a r s used t o produce leak-proof p a n e l s having good bond. However, a s the s u c t i o n of t h e b r i c k s i n c r e a s e d , r e s u l t s o b t a i n e d w i t h t h e t h r e e m o r t a r s under s i m i l a r c o n d i t i o n s de t e r i o - r a t e d b o t h w i t h r e s p e c t t o l e a k a g e and bondo

The low s u c t i o n of Typo "htt b r i c k s , e s t a b l i s h e d by I R A

d e t e r m i n a t i o n s , was f u r t h e r demonstrated by low m o i s t u r e l o s s from mortar a f t e r 3-minute c o n t a c t w i t h b r i c k s and by t h e s m a l l amount of water absorbed by t h e p a n e l s d u r i n g t h e l e a k a g e t e s t a o

The h i g h e r s u c t i o n of Type "B" b r i c k s r e s u l t e d i n a l o s s of m o i s t u r e from t h e mortar bed t o t h e bottom b r i c k i n q u a n t i t i e s which proved d e t r i m e n t a l f o r good bonding when t h e t o p b r i c k was

s e t i n p l a c e . The h i g h e r s u c t i o n of t h i s type of b r i c k was

i l l u s t r a t e d by g r e a t e r l o s s of m o i s t u r e from mortar d u r i n g 3-minute c o n t a c t w i t h b r i c k s and by t h e l a r g e r amounts of w a t e r absorbed by p a n e l s d u r i n g t h e leakage t e s t s . Notably, w i t h t h e l e a k y p a n e l s leakage r a t e s were l o w e s t f o r p a n e l s made w i t h high-lime c o n t e n t mortars. k r e a s o n a b l e explana t i o n could be t h a t h i g h e r water r e t e n t i v i t y of t h i s mortar p e r m i t t e d b e t t e r bonding.

A d d i t i o n a l r e s u l t s a r e needed t o s u b s t a n t i a t e t h i s from the bond s t r e n g t h a s p e c t .

R o s u l t s f o r Types "C" and "Dl' b r i c k s which had s l i g h t l y h i e r s u c t i o n than Type

P

"A" b u t c o n s i d e r a b l y lower than Type"B

s u b s t a n t l a t e t h e abovo c o n c l u s i o n s w i t h leakage and bond s t r e n g t h r e s u l t s t h a t f a l l between those o b t s i n e d f o r Type " A "and Type "B" b r i c k s ,

I n

g e n e r a l , r e s u l t s empha s i z e t h e importance of m o i s t u r e l o s s from t h e mortar a f t e r i t i s p l a c e d on a b r i c k and p r i o r t o t h e p l a c i n g of t h e second b r i c k , a s a s i g n i f i c a n t f a c t o r i nu l t i m a t e bonding of t h e mortar and t h e second b r i c k . A subsequent study of moisture l o s s h a s been c a r r i o d out.

A b e t t e r bond betwoen Type "B" b r i c k s and mortar might be o b t a i n e d by s h o r t o n i n g t h e time f o r placj.ng t h e second b r i c k on the mortar bed. R e s u l t s f o r t h e l a s t t h r e e p a n e l s a l s o

i n d i c a t e t h e b e n e f i c i a l e f f e c t of two t a p s of t h e s t a n d a r d drop hammer. Both t h e time f a c t o r and t h e h e a v i e r t a p w i l l be changed

i n

t h e n e x t panel program.The r e s u l t s o b t a i n e d u s i n g

1:4

limo m o r t a r s were u n s a t i s r f a c t o r y both w i t h r e g a r d t o leakage and bond. Examination of t h e mortar a f t e r f r a c t u r i n g t h e j o i n t s i n d i c a t e d t h a t t h e r e wase x c e s s i v e sand f o r t h e lime c o n t e n t of t h e m o r t a r o

R e s u l t s o b t a i n e d f o r panels u s i n g cored and s o l i d b r i c k s of t h e same type were comparable.

C e r t a i n i n c o n s i s t e n c i e s were n o t e d d u r i n g the s t u d y and s t e p s w i l l be t a k e n t o c o r r e c t the111 i n f u t u r e p a n e l programs.

Mortar flow v a r i o d from

106

per c e n t t o 120 p e r c e n t a l t h o u g h a l l m o r t a r s w e r e mixed w i t h predetermined q u a n t i t i e s of water found by experiment t o produce flows between115

p e r c e n t and 120 p e r c e n t ,Rate of spray i n t h e leakage chamber v a r i e d from

450

t o750

co p e r minute, the d e s i r e d r a t e b e i n g 600 c c p e r minute. Holes i n t h e spray tube were c l e a n e d f r e q u e n t l y w i t h a needle. It was found t h a t t h e head of water i n the r e s e r v o i r of t h e a p p a r a t u a was seven inches lower t h a n t h a t of tbe a p p a r a t u s a t Ottawa. T h i s h a s been c o r r e c t e d and a l t h o u & i t does n o t e x p l a i n f l u c t u a t i o n s , t h e a d d i t i o n a l h e i g h t may produce s t e a d i e r flow.To elimina t e p o s s i b l e i n c o n s i s t o n c i e s due t o v a r i a t i o n s of temperature and r e l a t i v e humidity, f u t u r e work w i l l be done i n a room c o n d i t i o n e d t o

70°F

and50

p e r c e n t R.HoAlthough t h e bond s t r e n g t h r e s u l t s o b t a i n e d w i t h t h e

bending machine a r e n o t comparable w i t h t h o s e o b t a i n e d on a direct-tension machine, t h e t e s t s were h e l p f u l i n s t u d y i n g t h e e x t e n t of bond and leakage. R e s u l t s a l s o i n d i c a t e d t h a t t h e r e was good bond f o r p a n e l s which d i d not leak. For b r i c k s "A" #

"c''

and"Dl'

t h e h i g h e s t bond s t r e n g t h s were o b t a i n e d from TypePROPERTIES OF

Tm

BRICKS I n i t i a lR a t e

A b s o r p t i o n of A b s o r p t i o n ($ D r yV v ' t )

( S u c t i o n ) 24-hr

5-hr

b o i l i n g Sa t w a t i o nB r i c k Type p / 3 O sq

In.

( a ) immersion ( b ) h e r s i o - n ( o ) c o e f f i c i e n t ( d )A

-

( s t i f f - n u d s h a l e0.5

t o2.3

0.3

t o 2.20.6

t o 2 . 9 0.43 t o0 ~ 7 3

a n d c l a y ) B-

( s t i f f - m u d s h a l e7.2

t o47.3

5.8

t o9.9

7.2

t o11.6

0.81

t o 0185 and c l a y )c

-

( s t i f f - m u d s h a l e3.6

t o6.3

3.5

t o4.8

4.2 t o6.2

0.77

t o6.84

and clay, c o r e d ) D-

( s t l f f - ~ u d s h a l e 1.1 t o6.0

2.0 t o3.3

2.2 t o3.5

0.89

t oO a 9 4

and c l a y )( a )

in

grams of w a t e r a b s o r b e d by a d r y b r i c k when p l a c e di n 1/8"

of w a t e rfor

onsnllr~ute

( f l a t

s i d e donn), c o r r e c t e d f o r a s t a n d a r d a r e a of30

sqi n o

( 5 ) Rnounl o r v r a t e r a b s o r b e d by a b r i c k , expressed a s a p e r c e n t a g e of i t s d r y w e i g h t when

ths b r i c k i s b m r s e d i n w a t e r a t room t e m p e r a t u r e f o r 2 4 h r s .

( c ) kmount of w a t e r a b s o r b e d by a briclr, a s a p e r c e n t of dry w e i g h t , mhen a f t e r t h e 2 4 - h r

immersion i t i s i m r s e d i n b o i l i n g w a t e r f o r

5

hrs then c o o l s d t o room t e m p e r a t u r e I n vrater.TABLE I1

YllATER RETENTIVITY OF MORTARS -.-

Type A Mortar

-

1 p a r t by v o l e masonry cement :3

p a r t s sand.-3

Type B Mortar

-

1 p a r t b vol. p o r t l a n dcement

: 1 p a r tlime

p u t t y :

8

p a r t s sand.Type C Mortar

-

1 p a r t by vol. p o r t l a n d cement : 2 p a r t s lime p u t t y :9

p a r t s sand, Mortar I n i t i a 1 Water R e t e n t i v i t y Flow Value Type A 11805%73

04

T s p e B116

00%79

.o

Type C116

.o$

87.9 Type E105

.0$91

04

Type E Mortar

-

1 p a r t by v o l e lime p u t t y :4

p a r t s sand.TABLE I11

WEIGHT OF WATER ABSORBED BY PANELS DURING TEST

Panel No, Wt. of Bricks

A

Wt. of Panel (-1 W t . of Mortar Used (gm) W t . of Panel Before Teat 13,255 13557

13 A91 13,486 13,601 13,&4 13,653 13,969 13,810 13,547 13,968 13,54211,354

11,597 11,473 12,551 12,873 12,768 13,73713,595

14,042 13,987 12,665 12,810 12,692 Wt. of Panel After Teet0

W t . of Water Absorbed by Panel During s:- Keight of panel 2 4 hrs a f t e r . f a b r i c a t i o n .Note: Weight of panel before t e s t i n c l u d e s weight of p a n e l , covering of Lasto-Keric compound and

-

polyethylene f l a s h i n g s t r i p ,TABLE I V RATE OF LEAKAGE Panel xo c

-

1 2;

5

6

7 89

10 11 12 13 l i b 15 16 17 18 13 2 0 21 22 23 24

25 Immediate Lea ka ge No No No No No No Y e s Y e s Y e s Ye 3 Ye s Y e a NO No Y e s No Ye s Y e e Y e s No No Y e s No No No 0-2 1 2 3 Min'-

Min 0 0 0 0 0 0 0 0 0 0 0 05

7 Min Min- -

0 0 0 0 0 0 0 0 0 0 0 0 Rate of Leakage i n ml/mln 10 15' 20 25 3 045

1 Min M l n Min Min Min Mln HrTo ta 1 Leakage i n 1st

hr

(U r l d r - u \ 0 0 0 0 0 C U 0 0 ~ f P d 0 0 0 m r - d r-3 m z f CV

..

2

c u d d+ +

0 0 0 0 0 0 ' 2 ? ' ? ? ? ?

+ - P O a o o ~ n o m c u m a c u o o o o rl 0 - a m m m r -mcuaa..r-

A + ; f r l r ( r l 0 CV * d d A h - h h - h h h h h h h h h - % T n : - ~ : ? h h - h - n % : ? ? A h - .a ? y y s

~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ o P o ' C r m ~ ? o , Y d d d d m - t u \ u \ u \ u \ 1 1 , 1 1 1 1 I Y t l C U C U a t t r l I 1 1 1 1 k '='C".",r'.rl.O 3a,aa, \n u\ m 0; y 01 d d d d d r l o e u d d d r l d d d d d d d z m m m m m m d d d rl r l V V V V V V V W V W W Y ~ V V W ~ V W W W V V -b r: x 4 0 m a r-l a, Pa, c r l mTABLE V I

MOISTURE CONTENT LOSSES

-

Panel

No 6 1.R.A. of pa irs Brick-

( w )

A1.5

and

1,s A 2.0and

2.0 A 2.0and

2.0 A1.9 and

2.1 A1.9 and

2.1 B13.3 and 13.4

B13.3 and 13.4

B13.2 and 13.2

B12.7 and 12.7

B13.3 and 13.3

B13.3 and 13.3

C3.5

and3.5

C3.5 and 3.5

C3.6 and 366

D3.0 and 3.0

D3.0 and 3.0

D3.0 and 3.1

B16.8 and 17.0

B16.8 and 17.0

B

17.7 and 18.0

B

17.7 and 18.0

D1.4

and

1.4

D

1 . 4 a n d 1 . 4

D1.3

and1.4

MortarLoss

M.C.%

TABLE

VII

AVERAGE

VALUES FOR LENGTH AND WIDTH OF BRICKSTABLE V I I I

AVERAGE STRESSES FOR VARIOUS BRICK

-

MORTAR COMBINATIONS BRICKA

B

c

D S t r e s s ( p s i ) f o r v a r i o u s mortars. b=

l e n g t h o f b r i c k d=

width of b r i c k rt b1t7 7/8If

81/161f

8"

7

3/4"

MORTAR

1:3

1:1:6

.

Note :-

tt dlf1:4

mortar ( 1 b e putty: Chezzetcook sand). No values obtained f o r1:4

(limo putty: Lamencetovm sand) m o r t a ~ " JTYPE

OF BRICK L .D

C 162.9 31.8 i85.4

19.3

,1.5

33.7

% J53.7

10.7)

I

-

L I M I T S OF-

ASTM-

-

C 144 5 2 T-

-

-

-

SAMPLES OF-

SAND AS USED-

I N MORTARS-

-

-

-

-

I

100 5 0 30 16 8 4STANDARD SIEVE NO.

FIGURE I

PARTICLE S I Z E ANALYSIS OF

SAND USED IN MORTARS

INVERTED

C 33

B O T T L E

- -

-

- -

AIR VENT TUBE

- -

- ---

- -

- - - - - - - - - - -- - - - -- - -- -