HAL Id: hal-00720725

https://hal.archives-ouvertes.fr/hal-00720725

Submitted on 25 Jul 2012

HAL is a multi-disciplinary open access

archive for the deposit and dissemination of

sci-entific research documents, whether they are

pub-lished or not. The documents may come from

teaching and research institutions in France or

abroad, or from public or private research centers.

L’archive ouverte pluridisciplinaire HAL, est

destinée au dépôt et à la diffusion de documents

scientifiques de niveau recherche, publiés ou non,

émanant des établissements d’enseignement et de

recherche français ou étrangers, des laboratoires

publics ou privés.

Densification and polymorphic transition of multiphase

Y2O3 nanoparticles during spark plasma sintering

Rachel Marder, Rachman Chaim, Geoffroy Chevallier, Claude Estournès

To cite this version:

Rachel Marder, Rachman Chaim, Geoffroy Chevallier, Claude Estournès. Densification and

polymor-phic transition of multiphase Y2O3 nanoparticles during spark plasma sintering. Materials Science and

Engineering: A, Elsevier, 2011, vol.528, pp. 7200-7206. �10.1016/j.msea.2011.06.044�. �hal-00720725�

To link to this article: DOI: 10.1016/j.msea.2011.06.044

URL :

ttp://dx.doi.org/10.1016/j.msea.2011.06.044

This is an author-deposited version published in:

http://oatao.univ-toulouse.fr/

Eprints ID: 5668

To cite this version:

Marder, Rachel and Chaim , Rachman and Chevallier, Geoffroy and

Estournès, Claude Densification and polymorphic transition of multiphase

Y2O3 nanoparticles during spark plasma sintering. (2011) Materials

Science and Engineering A, vol.528 (n° 24). pp. 7200-7206. ISSN

0921-5093

O

pen

A

rchive

T

oulouse

A

rchive

O

uverte (

OATAO

)

OATAO is an open access repository that collects the work of Toulouse researchers

and makes it freely available over the web where possible.

Any correspondence concerning this service should be sent to the repository

administrator:

staff-oatao@listes.diff.inp-toulouse.fr

Densification

and

polymorphic

transition

of

multiphase

Y

2

O

3

nanoparticles

during

spark

plasma

sintering

R.

Marder

a,

R.

Chaim

a,∗,

G.

Chevallier

b,

C.

Estournes

baDepartmentofMaterialsEngineering,Technion–IsraelInstituteofTechnology,Haifa32000Israel bCNRS,InstitutCarnotCirimat,F-31602ToulouseCedex9,France

Keywords:

Sparkplasmasintering Phasetransformation Densification Y2O3

a

b

s

t

r

a

c

t

Multiphase(MP)monoclinicandcubicY2O3nanoparticles,40nmindiameter,weredensifiedbyspark

plasmasinteringfor5–15minand100MPaat1000◦C,1100◦C,and1500◦C.Densificationstartedwith

pressureincreaseatroomtemperature.Densificationstagnatedduringheatingcomparedtothehigh shrinkagerateincubicsingle-phasereferencenanopowder.ThelimiteddensificationoftheMP nanopow-deroriginatedfromthevermicularstructure(skeleton)formedduringtheheating.Interfacecontrolled monoclinictocubicpolymorphictransformationabove980◦Cledtotheformationoflargespherical

cubicgrainswithinthevermicularmatrix.Thisresultedinthelossofthenanocrystallinecharacterand lowfinaldensity.

1. Introduction

Rapidsinteringanddensificationofceramicpowderstofull den-sityare nowadaysa routineprocedure, usingthespark plasma sintering (SPS) method.As wasnoted in many hot-press stud-iesincludingSPS,themaindensificationshrinkageofthepowder aggregatetakesplaceduringtheheatingbyparticlesliding,tothe close-packedarrangement[1–4].Furtherdensificationofthe pow-dercompactmaybeaccomplishedeitherbyplasticdeformation orbydiffusionalprocesses,attheparticlenecks.Nevertheless, dif-fusionalprocessesareinevitableduringthefinalstagesintering, whenisolatedporesformandcanbeeliminatedviabulkorgrain boundarydiffusion[5,6].Consequently,microstructureevolution duringtheSPSprocess,duetothechangeintheprocess param-eters,such astemperature,pressure,time,atmosphere, vacuum level, etc. mayaffectthe densificationmechanism. Many types ofphasetransformationsandtransitions associatedwithcrystal symmetrychangesinvolvechangesinthemicrostructureand mor-phology[7].Therefore,effectsofthephasetransformationsduring thedensificationbySPSmaybeofprimeimportancetothe densifi-cationprocess,aswellastothefinalphaseassemblageinthedense compact.Thephasecontentandassemblageoftenhavea consid-erableimpactonthefinalpropertiesofthesinteredceramic[8]. Inthisrespect,Takeuchietal.[9]investigatedthedensificationof

∗ Correspondingauthor.Tel.:+97248294589;fax:+97248295677. E-mailaddress:rchaim@technion.ac.il(R.Chaim).

submicrometersizetetragonalBaTiO3 powdersandfoundSPSto beeffectiveforpreservationofthesubmicrometersizemetastable cubicBaTiO3atroomtemperature.Thepreservednanometricgrain sizebySPSwasalsofoundtobeacauseforthecubicphase stabi-lizationatlowertemperatures[10,11].

Kumaretal.[12]tookadvantageofthehigheratomic mobil-ityneartheAnatasetoRutilephasetransformationtemperatureto enhancethedensificationoftheTiO2 nanoparticles.SPSof mul-tiphaseTiO2 (70%Anatase and30% Rutile)with20-nmparticle sizeat 62MPafor 5minand600◦C resultedincomplete phase transformationtoRutile[13].Forcomparison,onlyannealingof the same precursor powder for 5min at 600◦C preserved the multiphasecharacter ofthe powder.This exhibitstheeffect of theappliedpressureandpossiblytheelectricfieldonthephase transformationduringtheSPS.Fundamentalinvestigationofthe currenteffectonsolid-statereactivityduringSPSwasperformed onstackedMo–Si–Molayers[14].Nochangeinthereaction mecha-nismwasobserved,albeittheenhancedgrowthrateofthereaction productlayer(MoSi2),whichwasrelatedtotheenhancedmobility orthechangeinthedefectconcentration.

The present paperfocuses on theeffect ofthe polymorphic phasetransitiononthemicrostructureanddensificationbehavior ofmultiphaseY2O3nanoparticlesduringtheSPS.

2. Experimental

Commercial pure (99%) multiphase (MP) Y2O3 nanopowder (NeomatCo.,Riga,Latvia)withaverageparticlediameterof40nm

Fig.1.X-raydiffractionspectrafromtheY2O3nanoparticles.(a)Singlephase(SP)

cubic.(b)Multiphase(MP)cubic+monoclinic.

wasused.Asecondhighlypure(99.99%)nc-Y2O3powder(Cathay AdvancedMaterials,China)with100%cubicphase,designatedas singlephase(SP),wasalsousedasareferencespecimen[15]. Con-stantamountofthepowdersamplewaspouredintothegraphite dieusinggraphitefoils(Grafoil)toseparatebetweenthepowder, thediewalls and theplungersurfaces.Thepowders were sin-tered(Dr.Sinter,SPS2080)atdifferentconditionsfor5–15minand 100MPaat1000◦C,1100◦C,and1500◦C.Thestartingtemperature wasroomtemperatureforthe1000◦Ctreatment(designated‘cold compaction’),but600◦Cforthe1100◦C and1500◦Ctreatments (designated‘hotcompaction’).Theuniaxialpressurewasapplied eitherafewsecondaftertheprocessstartedorwhentheSPS tem-peraturewasreached.Inbothcases,thepressurewasincreased linearlywithtime,andheldconstantduringtheisothermal treat-mentattheSPStemperature.Theprocessdurationreferstothe isothermalSPStreatment.Aheatingrateof100◦C/minand vac-uumlevelof3Pahasbeenused;thepulsedurationwas3.3ms.The SPSparameterswererecordedduringtheprocess.The tempera-turewascontrolledbyathermocouplefor‘coldcompaction’,while anopticalpyrometerwasusedabove600◦Cfor‘hotcompaction’ andathighertemperatures.Thefinalspecimendimensionswere 8mmindiameterand1.7–2.5mmthick.Theramdisplacements wereexpressedintermsofthelinearshrinkageandthetemporary relativedensity,followingthespecimenthicknessversustime, tak-ingintoaccountthethermalexpansion/shrinkagebehaviorofthe specimenandthegraphiteplungers[15].

Thephasecontentoftheas-receivednano-powdersandthe sin-teredspecimenswerecharacterizedbyX-raydiffractionusinga diffractometer(PhilipsPW3710)withmonochromaticCuKa radi-ation (XRD),operatedat 40kVand 30mA.A scanningspeed of 0.5◦/minhasbeenused.Themicrostructureswerecharacterized usingtransmission(TEM,FEITecnaiG2T20,operatedat200kV) andscanning(FEIE-SEMQuanta200,operatedat20kV)electron microscopes.Thespecimensfortheelectronmicroscopy observa-tionswereprepared bytheconventionalmethods.Thethermal stabilityofthenanopowderswascharacterizedusingdifferential scanningcalorimetry(Labsys1600,Setaram)upto1400◦CinArgon atmosphere,ataheatingrateof5◦C/min.Thefinaldensityofthe specimenswasdeterminedbytheArchimedesmethodfollowing ASTMstandardC20-92(±0.5%accuracy).

3. Results

X-raydiffractionspectrafromtheas-receivednanopowdersare showninFig.1.Thesinglephase(SP)Y2O3nanopowderwithcubic

symmetry(JCPDS41-1105)wascharacterizedindetailelsewhere [16](Fig.1a),whereasthemultiphase(MP)nanopowderrevealed polymorphswithcubicandmonoclinic(JCPDS39-1063) symme-tries(Fig.1b).Quantitative analysis ofthe spectrum inFig. 1b, assumingapowdermixture[17],resultedin30%cubicand70% monoclinicphaseinthenanopowder.Theseresultswerein agree-mentwiththe25:75cubictomonoclinicphaseratiodetermined byothers[18].

TEMobservationofthetwopowders(notshownhere)exhibited sphericalmorphologyforthemultiphasepowder,comparedtothe equiaxedpolyhedralshapeforthecubic,singlephasepowder[16]. Bothpowdersexhibitedlog-normalgrainsizedistributions,with averagegrainsizeof18±8nmand41±22nmforthesinglephase andthemultiphasepowders,respectively.

XRDspectrafromtheMPnanopowdercompacts,subjectedto SPSfor5minat100MPaandatdifferenttemperatures(Fig.2a), showedthe transformation of themetastable monoclinic poly-morphtothestable cubic phase tooccurat1100◦C. However, further XRD characterization of the MP nanopowders sintered fordifferentdurationsat1000◦Cand100MPa(Fig.2b)revealed the continuous nature of the phase transformation kinetics alreadyatthistemperature.Themonoclinictocubicpolymorphic phasetransformationwasnotcompleted,evenafter15minSPS duration.

Following the above phase transformation in the sintered specimens,thethermalstabilityofbothnanopowderswere char-acterizedbyDSC(Fig.3).Atthestagewherethefiner,cubicSP nanopowderwasrelativelystable,thecorrespondingcurvefrom

Fig.2.XRDspectraoftheas-receivedMPY2O3nanoparticles,aftersintering(a)for

Fig.3.DifferentialscanningcalorimetryfromnanocrystallineY2O3.(a)Singlephase

(SP)cubic.(b)Multiphase(MP)cubic+monoclinic.

theMPnanopowderexhibitedastrongexothermicpeakstarting at∼980◦C,withthemaximumaround1200◦C.Thisisin agree-mentwiththeexpectedmonoclinictocubicphasetransformation reportedat∼950◦C[19],andinagreementwiththeXRDresults. Therefore,specialattentionwaspaidtothisphasetransformation duringthedensificationbySPS.

Followingthedensificationbehaviorofthetwonano-powders, severalimportantfeatureswereobserved.First,averyrapid com-pactionoftheMPpowderwasdirectlyassociatedwiththepressure whenappliedatroomtemperature(Fig.4a);thisroom tempera-turecompactionwiththepressureincreasepersistedforallSPS temperaturesinvestigated.However,furtherdensificationat ele-vatedtemperaturesdependedonthefinalSPStemperature.Inthe 1000◦C‘coldcompaction’treatment(Fig.4a),thedensityincreased

Fig.4.Relativedensity–time–temperature–pressuredependenciesduringSPSof (a)MPand(b)SPY2O3nanoparticlesat1000◦Cfor5minand100MPa.

simultaneouslywiththepressureincreasefromroomtemperature (i.e.SPSstartingtime),andleveledat67%within2min,whenthe pressurereacheditsmaximumvalue(100MPa).Sincethe temper-aturewasincreasedonlyafter5minfromtheSPSstart(Fig.4a), theobserveddensificationatroomtemperaturecanberelatedto particlesliding withnegligiblecontributionfromthediffusional processes.However,negativeramdisplacementwasrecordedat ∼600◦Cduringheatingataconstantpressure.Thisdisplacement couldbeassociatedwithacertaindecreaseindensity,butasitis ceasedwhentheSPStemperatureof1000◦Cwasreached,itcan berelatedtothethermalexpansionmismatchesbetweenthatof thegraphiteplungersandtheclosepackednano-particlenetwork. Apparently,theclosepackednano-particlesundergosurface dif-fusionduringtheheatingtoformarigidskeleton.Insuchacase, therigidskeletonmayopposefurther shrinkageunderthe con-stantpressure;ifthethermalexpansionofthisskeletonishigher thanthatofthegraphiteplunger,negativeramdisplacementmay occur. (Negativedisplacement due tothermal expansionofthe graphitemold,plungersandspacersisusuallyobservedwiththe increasingtemperatureusingblankspecimens.)Thisaspectwillbe discussedlaterindetail.Thedensitydidnotchangesignificantly duringtheSPSisotherm.Inaddition,increaseintheSPSduration to10 and15minresultedinhigherdensitiesof74.6and76.0%, respectively.

DensificationoftheSPreferenceY2O3nanopowderwasrecently investigatedindetailundersimilarSPSconditions[20].Someof theresultswillbeusedhereforcomparison.ThedensityoftheSP referencespecimenat1000◦Ctreatmentincreasedwiththe pres-sureincreaseatroomtemperature(Fig.4b),althoughitleveledoff atamuchlowerdensityof42%.However,incontrasttotheMP nano-powder,furtherincreaseinthedensitywasobservedduring theheatingprocess.Densificationwasacceleratedaround∼680◦C andreacheditsmaximumvalueof93%around∼880◦C,beforethe finalSPStemperatureof1000◦Cwasreached.

TheheatingratetotheSPStemperatureof1100◦Cwasof‘hot compaction’anddifferedfromthatat1000◦C.Inthisrespect,a heatingpulsewasusedtoreach600◦Cwithin3minunderthe holdingpressureof 2MPa(Fig.5a).Thiswasfollowed by heat-ingto1100◦Cforadditional5min.Thenthepressurewaslinearly increasedto100MPa,resultingin simultaneousincrease inthe density to its final value of 66%; nofurther densification was observedattheSPSisotherm.Similardensities(i.e.63.4and62.8%) were reached with further increase of the SPS duration to 10 and15min,respectively.Comparisonbetweenthedensities mea-suredattwoSPSregimes,i.e.at1000◦Cand1100◦C,revealedthat theapplicationofpressure atthebeginning (‘coldcompaction’) resultedinhigherdensities.

ThecorrespondingSPspecimenexhibitedsignificantincrease in the density during theheating process between800◦C and ∼1050◦C, underthe2MPa holdingpressure only(Fig.5b)[20]. The maximum displacement/(shrinkage)rate was10−2mms−1. Thisindicated thehigh capillaryforces in theSPto drive den-sification,incontrasttotheMPpowder,wherenodensification was recorded during the heating up. A higher densification rate(1.5×10−2mms−1)wasmeasuredwhen the pressure was increasedtoitsmaximumvalue.Afinaldensityof93%,whichis higherthanthatoftheMPspecimen,wasreached.

Thedensificationbehavior intheMPspecimenat1500◦C is shown in Fig.6, as in the other experiments,a very fast den-sification rate(1.5×10−2mms−1)wasrecordedsimultaneously with the pressure increase. However, in this ‘hot compaction’ experiment(i.e.,aheatingpulseto600◦Cwasappliedbeforethe pressurewasincreased),densificationceasedwhenthemaximum pressurewasreached.Densitywasstagnatedduringfurther heat-ing upto 1350◦C, where anadditional rapid densificationrate (5×10−3mms−1) upto thefinal density wasrecorded. During

Fig.5.Relativedensity–time–temperature–pressuredependenciesduringSPSof (a)MPand(b)SPY2O3nanoparticlesat1100◦Cfor5minand100MPa.

theperiodofdensity stagnation(i.e.,between200and650sin Fig.6), thepressureexperiencedtwodisturbancesexpressedby adecreaseof8–10MPaintherecordedpressure.Thesedecreases inpressureoccurredaround1030◦Cand1280◦C,andwere recov-eredat 1130◦C and 1350◦C, respectively. The second pressure recovery(increase)wasresponsiblefortherepeatedincreasein densificationat1350◦C,aswasmentionedabove.Thesepressure disturbancesareassociatedwithincreaseintheresistanceofthe nano-particlestoundergosliding,whetherduetotheformation ofarigidskeletonorjammingoftheagglomeratednano-particles. Ineithercase,thermalexpansionsofboththegraphiteplungers andthespecimentogetherwiththelackofplasticityinthe speci-men,introduceinternalcompressivestresses.Sincetheexternal pressureappliedinthesystemisregulatedtoremainconstant, itsactualvalueshoulddecreaseinordertobalancetheinternal

Fig.6.Relativedensity–time–temperature–pressuredependenciesduringSPSof MPcubicY2O3nanoparticlesat1500◦Cfor5minand100MPa.

Fig.7.SEMimageshowingthehomogeneousdistributionofthesphericalgrains throughoutthespecimensinteredat1100◦Cfor5minand100MPausing

multi-phaseY2O3nanoparticles.

thermalpressuresformed.Thismayleadtothedisturbancesand decreasesobservedinthepresentSPSexperiments.

SEMimagesfromthespecimenssinteredat1100◦Cfor differ-entdurations(i.e.5min,Fig.7)showedhomogeneousdistribution ofmanysphericalshapegrainsthroughoutthematrixoftheMP Y2O3 nanoparticles.Thelargestdiameterofthesphericalgrains was∼15mmafter5min,and∼60mmafter10mindurations,with verywidegrainsizedistributions.Thesesphericalgrainsexhibited alowvolumefractionofthespecimensevenafter15minof sinter-ingat1100◦C.Thesesphericalgrainswereabsentaftersintering at1500◦C;aregularpolyhedralshape grainmicrostructurewas observed.

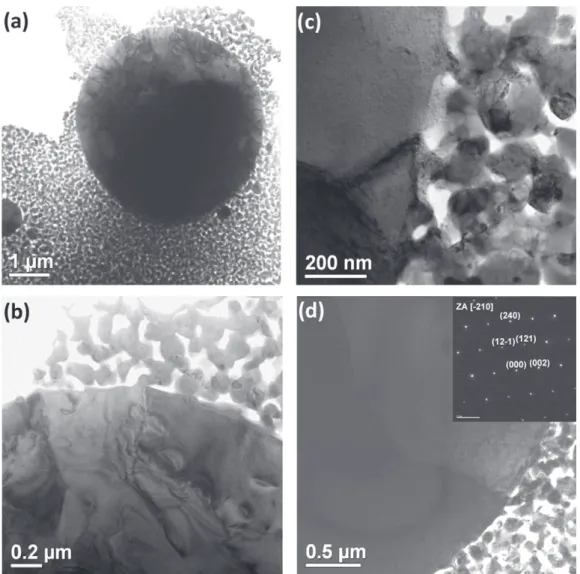

TEMimagesfromthespecimenssinteredatdifferent temper-aturesclearly revealedthe microstructureevolution duringthe SPS. First, at 1000◦C and 1100◦C, closeto the phase transfor-mationtemperature,many polycrystallinesphericalparticles of submicrometerandmicrometer-sizeindiameterwereobserved withintheporousnanoparticlematrix(Fig.8a).Higher magnifica-tionprovedtheinternalstructureofthelargeparticles(Fig.8band c)tobecomposedofsub-grainsseparatedbydislocationnetworks; insomeoccasions,internalsubmicrometer-sizeporeswerealso observed.Thematrixwascomprisedofpartiallysintered nanopar-ticleswhichformedaporousnetworkresemblingthevermicular structure(theupperpartinFig.8b).Detailedexaminationofthe interfacebetweenthesphericalparticlesandthevermicular struc-turerevealedthattheformergrowontheaccountoftheporous nanoparticleskeleton(Fig.8c).Selectedareadiffractionpatterns confirmedthecubiccrystal symmetryof thesphericalparticles (Fig.8d).Therefore,itseemsthatthesphericalparticlespresent nucleationandinterface-controlledgrowthofthecubicgrainson theaccountofthemonoclinicnanoparticles.

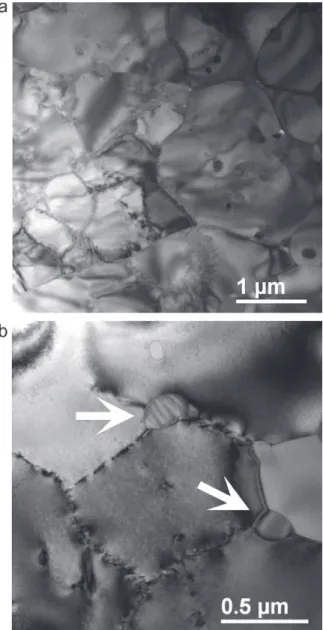

Finally, TEM images from the 1500◦C treated specimen, shown in Fig. 9, exhibit the micrometer size polyhedralshape grains with nanometric closed pores. Many grains were com-prisedofsub-grainsseparatedbydislocationnetworks(Fig.9b). A few nanometer size grains and closed pores were still visible along the sub-grain boundaries and at their corners (arrowed in Fig. 9b).This microstructure can beconsidered as analmostfullytransformedversionofthevermicular structure to thecubic grains. The microstructure evolution in the refer-ence single-phase cubic nanoparticle compactsduring the SPS were described in detail elsewhere [15,16,20]. At SPS temper-atures below 1100◦C, the nanometric character of the dense

Fig.8.TEMimagesshowingthe(a)nucleationandgrowthofthesphericalcubicY2O3grainsonaccountofthemultiphasenanocrystallinematrixat1000◦C.(b)Higher

magnificationof(a)showingthevermicularstructureofthematrixnanoparticles.(c)Theinterface-controlledgrowthofthesphericalcubicgrainsat1100◦C.(d)Selected

areadiffractionpatternconfirmedthecubicsymmetryofthesphericalY2O3grains.

compacts waspreserved. However, significant grain growthto micrometer-sizegrainswasobservedathighertemperatures[16]. The microstructural evolution associated withthe polymorphic phase transformationisthebasisfor theobserveddensification behavior ofthemultiphasenanoparticlesand willbediscussed below.

4. Discussion

Theobserveddensificationbehaviorofthetwonanopowders canbeexplainedbythemetastablenatureofthemonoclinic poly-morph.ThemonoclinicphaseisahighpressureversionofY2O3, but can be retained in a metastable state at the atmospheric conditionswheninthenanoparticleform.Theseaspectsof poly-morphism,especiallyintheY2O3nano-particles,werediscussed indetailelsewhere[19,21,22].Althoughbothpowdersexhibiteda closetonanocrystallineparticlesize(18-nmvs.41-nm),the sur-faceenthalpyofthemonoclinicpolymorphissignificantlyhigher (2.78Jm−2)thanthatofthecubicphase(1.66Jm−2)[19]. There-fore,thehighlyactivesurfacesofthemonoclinicnano-particles act as an efficient driving force for low-temperature sintering andneckformation.Thistypeofhighsinterabilityiswell char-acterized in transition alumina (g-alumina) and lead to rapid formationofa rigidporousskeletonbysurfacediffusionatlow

temperatures [23]; the resultant vermicular structure leads to low-densitysintered compacts.In this respect,consolidation of aluminananoparticlesbySPSshowedenhanceddensificationof the a-alumina compared to that of transition g-alumina [24]. Surprisingly, dense a-alumina was obtained at a considerably lowerSPStemperature,albeitoriginallywithalargerparticlesize. Thisbehaviorwasrelatedtog→aphasetransformationduring the SPS, which in turnled to the formation of the vermicular structure.

Thetheoreticaldensitiesofthecubic(c)andmonoclinic(m) Y2O3polymorphsare5.030gcm−3and5.468gcm−3,respectively

[19]. Consequently, the polymorphic m→c phase transforma-tion is associated with∼8% volume increase. Nevertheless,the DSC results indicated the polymorphic transformation temper-ature to be around1000◦C, where a rigid skeleton of mY

2O3 hasbeendevelopedfairlywell.Ononehand,thekineticsofthis interface-controlled polymorphic phase transformation is more sluggish compared tothe SPSheating time scale, as evidenced byXRD analysis.Ontheotherhand, thepresenceof the nano-poreswithinthesphericalparticlesisanevidenceforaveryrapid interface-controlledprocess(i.e.nano-poreswerenotannealedby diffusion).Consequentlythechangeinthecompactvolume dur-ingtheheating,duetothephasetransformation,maybemarginal. SimilareffectswerereportedduringdensificationofSi3N4 with

Fig.9.TEMimagesshowingthe(a)micrometer-sizecubicgrainsformedat1500◦C.

Afewporesarevisiblealongthegrainboundaries.(b)Manysub-grainboundaries decoratedwithdislocationnetworksandnano-grainswerepresent(arrowed).

metallicsinteringadditivebySPS[25],wheresignificant shrink-ageoccurredbyparticlerearrangementandwhilealiquidphase wasformed.However,minorshrinkagewasobservedwhenphase transformationandgraingrowthviasolution-reprecipitationtook place.

Based on the microstructure developed in the multiphase nanoparticlecompacts,thefollowingprocessesmaybeconsidered. First, theapplication ofexternal pressure at roomtemperature enablesparticlesliding andrearrangement.Theearlyand rapid densificationstageceaseswhenreachingthemaximal pressure applied.Second,highlyreactivesurfacesof themnanoparticles enableenhancedneckformationandgrowthbysurfacediffusion duringtheheating.The partiallysinteredmnanoparticlesform a rigidand porous skeleton witha vermicular structure which opposesfurtherdensificationbyparticlesliding.Atandabovethe polymorphicm→cphasetransformationtemperature,nucleation ofthestablecphasetakesplace,homogeneouslythroughoutthe porousskeleton(thehomogeneous/heterogeneousnatureofthe nucleationeventwasnotinvestigatedhere).Furthergrowthofthe cubicnucleibythisinterfaced-controlledtransformationresults insphericalpolycrystallineparticles.Apparently,the8%volume

increaseaccompaniedtothetransformation,is notsufficientto overcomethevolumeconstraintsimposedonthegrowing spher-icalparticles withintherigid porousmatrix. Consequently,the elasticconstraintsmaybereducedbytheformationofdislocation networksandsub-grains,which,inturn,growontheaccountof them+cnanoparticles,attheirgrowingfront.Whentherapidly growingfrontofthesphericalparticlefacesalargecavityofthe vermicularstructure,itmaysurpassit,duetoinsufficienttimefor diffusion,resultinginoccludednano-pores.Athighertemperature, whenthephasetransformationisaccomplished,particlesliding, dislocationcreep,andgraingrowthmayberesponsibleforthelater stagedensificationclosetofulldensity.

Finally,theeffectofthevolumechangeduringthe polymor-phicphasetransformationtodensificationofthemultiphaseY2O3 nanoparticleswasnegligible.Nevertheless,themetastablenature andthehighsurface activityofthis polymorphwerethemajor causefortheformationofthevermicularstructure,whichinturn, inhibitedthedensificationduringtheheatingbySPS.The interface-controlledcharacterof thetransformation ledtotheformation ofverylargecubicgrains,responsibleforthelossofnanometric characterofthecompactsubjectedtodensification.

5. Summary

Sparkplasmasinteringofthemultiphasemonoclinicandcubic Y2O3 nanoparticles at 1000◦C exhibited limited densification comparedtotherapiddensificationofthecubicsingle-phase coun-terpart.XRDofthemultiphasesinteredcompactsrevealedthatthe polymorphicmonoclinictocubicphasetransformationoccurred duringtheSPS around1000◦C, andwascompletedbyreaching 1100◦C.Themetastablemonoclinicphaseledtorapidneck forma-tionduringtheheatingwhichresultedinavermicularnanometric matrixwithopenporositynetwork;thislimitedfurther densifi-cationofthemultiphasenanopowderandendedinverylowfinal densities.AtSPStemperaturesabovethepolymorphic transforma-tiontemperature,homogeneousnucleationofthesphericalcubic Y2O3grainswasobservedwithinthevermicularmatrix.This inter-facecontrolledmonoclinictocubicphasetransformationresulted inthelossofthenanocrystallinecharacterofthecompact.SPSofthe multiphasenanoparticlesat1500◦Cshowedsimilardensification behaviorasthepurecubicY2O3,resultinginadensemicrostructure andcoarsemicrometer-sizepolyhedralshapedgrains.

Acknowledgments

ThefinancialsupportoftheIsrael MinistryofScienceunder contract#3-3429isgratefullyacknowledged.WethankDr.Ori YeheskelfromNRC-NegevforsupplyingtheMPnanopowder. References

[1]S.-J.L.Kang,Sintering,Densification,GrainGrowth&Microstructure,Elsevier, Amsterdam,2005.

[2]J.Liu,D.P.DeLo,Metal.Mater.Trans.A32(2001)3117–3124.

[3]C.L.Martin,D.Bouvard,S.Shima,J.Mech.Phys.Solids51(2003)667–693. [4]R.Chaim,R.Reshef,G.Liu,Z.Shen,Mater.Sci.Eng.A528(2010)2936–2940. [5] E.Artz,M.F.Ashby,K.E.Easterling,Metall.Trans.A14A(1983)211–221. [6]R.Chaim,M.Margulis,Mater.Sci.Eng.A407(2005)180–187.

[7]D.A.Porter,K.E.Easterling,M.Y.Sherif,PhaseTransformationsinMetalsand Alloys,3rdedition,CRCPress,BocaRaton,2009.

[8]B.Li,X.Wang,L.Li,H.Zhou,X.Liu,X.Han,Y.Zhang,X.Qi,X.Deng,Mater.Chem. Phys.83(2004)23–28.

[9]T.Takeuchi,M.Tabuchi,H.Kageyama,Y.Suyama,J.Am.Ceram.Soc.82(1999) 939–943.

[10]X.Deng,X.Wang,H.Wen,A.Kang,Z.Gui,L.Li,J.Am.Ceram.Soc.89(2006) 1059–1064.

[11]J.Liu,Z.Shen,M.Nygren,B.Su,T.W.Button,J.Am.Ceram.Soc.89(2006) 2689–2694.

[12] K-N.P.Kumar,K.Keizer,A.J.Burggraaf,T.Okubo,H.Nagamoto,S.Morooka, Nature358(1992)48–51.

[13]Y.I.Lee,J.-H.Lee,S.-H.Hong,D.-Y.Kim,Mater.Res.Bull.38(2003)925– 930.

[14]U.Anselmi-Tamburini,J.E.Garay,Z.A.Munir,Mater.Sci.Eng.A407(2005) 24–30.

[15]R.Marder,R.Chaim,C.Estournes,Mater.Sci.Eng.A527(2010)1577–1585. [16]R.Chaim,A.Shlayer,C.Estournes,J.Eur.Ceram.Soc.29(2009)91–98. [17]C.Suryanarayana,M.GrantNorton,X-rayDiffraction,APracticalApproach,

PlenumPress,NewYork,1998,pp.223–236.

[18]I.Halevy,R.Carmon,M.L.Winterrose,O.Yeheskel,E.Tiferet,S.Ghose,J.Phys. Conf.Ser.215(2010)012003.

[19]P.Zhang,A.Navrotsky,B.Guo,I.Kennedy,A.N.Clark,C.Lesher,Q.Liu,J.Phys. Chem.C112(2008)932–938.

[20]R.Marder,R.Chaim,G.Chevallier,C.Estournes,J.Eur.Ceram.Soc.31(2011) 1057–1066.

[21]A.Camenzind,R.Strobel,S.E.Pratsinis,Chem.Phys.Lett.415(2005)193–197. [22]B.Guo,A.Harvey,S.H.Risbud,I.M.Kennedy,Phil.Mag.Lett.86(2006)457–467. [23]F.W.Dynys,J.W.Halloran,J.Am.Ceram.Soc.65(1982)442–448.

[24] R.S.Mishra,S.H.Risbud,A.K.Mukherjee,J.Mater.Res.13(1998)86–89. [25]G.H.Peng,X.G.Li,M.Liang,Z.H.Liang,Q.Liu,W.L.Li,ScriptaMater.61(2009)