Publisher’s version / Version de l'éditeur:

ASHRAE Transactions, 112, Pt. 1, pp. 26-33, 2007-01-07

READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE.

https://nrc-publications.canada.ca/eng/copyright

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la

première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

NRC Publications Archive

Archives des publications du CNRC

This publication could be one of several versions: author’s original, accepted manuscript or the publisher’s version. / La version de cette publication peut être l’une des suivantes : la version prépublication de l’auteur, la version acceptée du manuscrit ou la version de l’éditeur.

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at

Assessment of the enthalpy performance of houses using the energy

recovery technology

Ouazia, B.; Julien, M.; Swinton, M. C.; Manning, M. M.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

NRC Publications Record / Notice d'Archives des publications de CNRC:

https://nrc-publications.canada.ca/eng/view/object/?id=1df0a92e-cae5-488b-9fc2-bcc69d8b757c https://publications-cnrc.canada.ca/fra/voir/objet/?id=1df0a92e-cae5-488b-9fc2-bcc69d8b757chttp://irc.nrc-cnrc.gc.ca

Asse ssm e nt of t he e nt ha lpy pe rfor m a nc e

of house s using t he e ne rgy re c ove r y

t e chnology

N R C C - 4 7 7 3 3

O u a z i a , B . K . ; J u l i e n , M . ; S w i n t o n , M . C . ;

M a n n i n g , M .

A v e r s i o n o f t h i s d o c u m e n t i s p u b l i s h e d i n

/ U n e v e r s i o n d e c e d o c u m e n t s e t r o u v e

d a n s : A S H R A E T r a n s a c t i o n s , v . 1 1 2 , p t . 2 ,

2 0 0 7 , p p . 1 - 1 1

Assessment of the Enthalpy

Performance of Houses using the

Energy Recovery Technology

Boualem Ouazia, PhD Mike Swinton

Michel Julien Marianne Manning

ABSTRACT

This paper provides an experimental evaluation of the efficiency of an Energy Recovery ventilator ( ERV) for a range of summer temperatures in Ottawa including humid summer days. The assessment was achieved using the twin houses, and their ‘side-by side testing’ to measure the real impact of the installation of the ERV in Canadian houses. ‘Side-by side testing’ consists of incorporating into the test

house an innovative energy saving componen, in this case the ERV. Both houses were then operated

identically and monitored. Changes in house performances due to the innovation were observed through comparison of test house performance to the reference house performance, for a range of weather conditions. The two houses operation items compared include: airflow, energy consumption, house air temperature and humidity.

INTRODUCTION

In the past three decades, concentrated efforts have been made to conserve energy by making buildings “tighter”. With tighter building envelopes, there is wider acceptance of the need for mechanical ventilation as recommended by the American Society of Heating, Refrigeration, and Air Conditioning Engineers in ASHRAE Standard 62-1989 and its current revision 62.2 (ASHRAE 1999). Mechanical ventilation systems have the potential of improving indoor air quality by removing contaminants and reducing indoor humidity. However, in hot humid climates, ventilation with outside air may actually increase interior moisture levels potentially doing more harm than good since multiple incidences of building failure, discomfort, and poor indoor air quality have been linked to elevated interior humidity levels (Moyer 2001, Cummings, et al, 1991). It has been noted that some houses built meeting ASHRAE standards in the hot and humid climate and equipped with a dedicated ventilation system were reported to have longer periods of elevated interior relative humidity (RH > 60%) relative to conventional houses without dedicated ventilation systems (Rudd 2003).

In hot humid climates, ambient ventilation air presents a much greater latent load on the buidling than a sensible one. A comprehensive ventilation approach requires not only air exchange but also indoor humidity control. The occupants presently use air-conditioning systems or dehumidifiers in order to reduce the moisture level inside. These systems use large amounts of electricity, are expensive to operate and are useful only a couple of months a year. An energy-efficient home may need little cooling during periods of mild temperature, but humid months may result in insufficient dehumidification and higher than desired indoor humidity.

More ventilation designs are including Energy Recovery Ventilators (ERVs) to improve the systems efficiency. Besides providing controlled ventilation, ERVs are able to filter, humidify, dehumidify, heat, or cool the incoming fresh air. ERVs and HRVs (heat and energy recovery ventilators) were both initially designed and used in the northern part of the country, using cold-climate ventilation strategies. ERVs are now beginning to see wider use in the southern climate for removing moisture from the incoming air. Therefore, when ventilating in the summer, less moisture brought into the home means less work for the air conditioner, and energy savings for the owner.

This paper presents a study conducted by the Canadian Centre for Housing Technology assessing the energy performance of an Energy Recovery Ventilator (ERV) in a single-detached house at the Centre, compared to the energy performance of a conventional Heat Recovery Ventilator (HRV) in an identical house next door, to achieve appropriate indoor humidity levels.

THE CCHT TEST FACILITY

The Canadian Centre for Housing Technology‘s research facility consists of two identical research houses – the reference house and the test house. These were built to the R-2000 standard and feature identical simulated occupancies. The houses are extensively monitored for energy performance and thermal comfort. These houses have been calibrated and are very nearly identical. The test house is modified using innovative energy saving components or systems that are being assessed – the Energy Recovery Ventilator (ERV) in this case. The resulting change in performance was documented relative to the benchmark configuration.

Figure 1 CCHT Houses

Reference House

The reference house is a typical 2-storey wood-frame house, with 210 m2 liveable area. It is built with a cast-in-place concrete basement, and with style and finish representative of current houses available on the local housing market. It meets the R-2000 Standard while having a standard ‘2 x 6’ wall. It has a high efficiency sealed combustion condensing gas furnace, a power vented conventional hot water heater and a heat recovery ventilator, along with a number of well insulated and tight assemblies to complete the R-2000 package. The house has an air tightness characteristic of 1.1 ach @ 50 Pa – 30% below the R-2000 requirement.

Test House

The test house was initially identical to the reference house, but was modified to incorporate an Energy recovery Ventilator (ERV). In the assessment, the test house is shown to be very nearly identical to the reference house from the point of view of energy performance. This performance comparison forms the benchmark against which other technologies can be compared. The test house is then modified to assess the impact of innovative energy systems and components on the overall energy and comfort performance of the house. The test house is used to assess only one component at a time, on a week-by-week basis. On completion of the assessments, the test house is returned to its starting (benchmark) configuration and the benchmark was re-confirmed.

The houses shown in Figure 1 are fully instrumented and are unoccupied. To simulate the normal internal heat gains of a lived-in house, these houses feature identical ‘simulated occupancies’, activated by the latest in electronic controls used in home automation packages.

An important and unique feature of the Twin House facility is its simulated occupancy system, with over 60 on/off events per day. The system is based on home automation technology and simulates the activities of a family of two adults and two children.

Electrical consumption is typical for a family of four and hot water draws are set in accordance with ASHRAE standards for sizing hot water heaters. Simulated events include: the operation of major appliances (dish washer, stove, washer & drier), lights, and water draws (shower, bath, kitchen sink). Incandescent bulbs are used to simulate heat gains from humans (60W per adult, 40W per child) at various locations in the house.

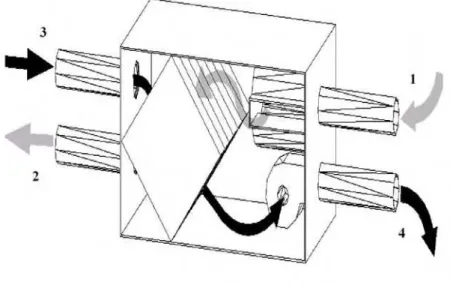

AIR-TO-AIR ENERGY RECOVERY HEAT EXCHANGERS

Air-to-air energy recovery heat exchangers include Heat Recovery Ventilator (HRVs) and an Energy Recovery Ventilator (ERVs). A typical heat or energy recovery unit is shown in Figure 2, both are designed to provide fresh air into a building while exhausting an equal amount of stale air.

Figure 2 HRV and ERV schematic

The core in an HRV (Heat Recovery ventilator) transfers heat from one air stream to the other. This is called sensible heat. The term ERV (Energy Recovery Ventilator) is usually used to describe a unit with an enthalpic core that transfers moisture as well as heat from one air stream to the other. This (moisture transfer) is called latent heat. During the winter months, the incoming cold fresh air is warmed by utilizing the heat recovered from the stale air before it is exhausted to the outdoors. During summer months when the indoor space is air conditioned, the Heat Recovery ventilator will help in cooling the incoming fresh air with the stale air that is being exhausted.

An ERV is designed for use in warm humid areas with heavy air conditioning use. The ERV will transfer both sensible and latent heat from the incoming fresh air to the outgoing stale air thereby reducing the load (due to ventilation) on the air conditioning system.

METHOD

The HRV and ERV units were operated over two weeks to develop a comparison between the whole house energy performances of the house with the Energy Recovery Ventilator (ERV) to the house with the Heat Recovery Ventilator (HRV). The benchmark configuration in the test house with an HRV was conducted for one week before starting the two weeks testing at low and high air flow rates with an ERV installed in the test house.

Benchmarking

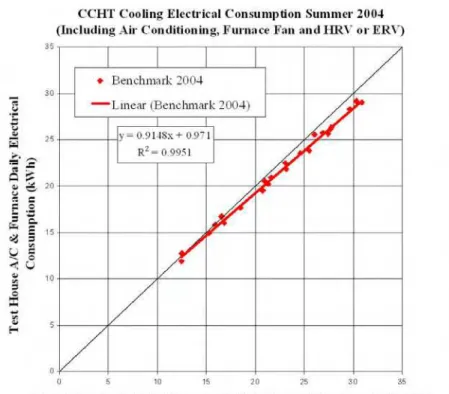

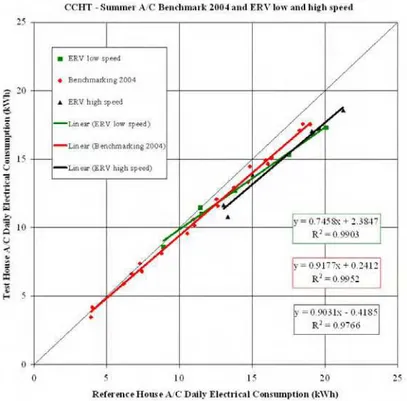

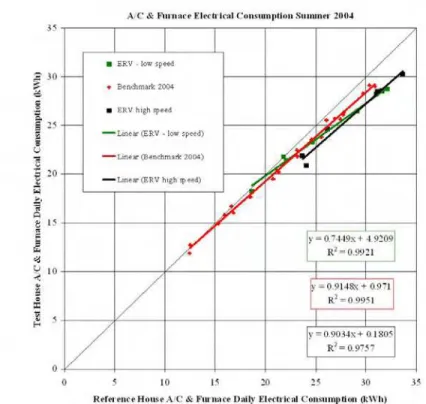

The houses with existing high efficiency HRVs currently installed in each house have been operated to show that they are thermally identical as possible, before the testing them with ERVs. Benchmarking the houses occurred over three different periods, first period in July, second period in August and third period in September 2004. Figure 3 shows the benchmarking of the test house against the reference over the same period. Statistically, these represent a good fit; with the slopes being measured few percent lower than a perfect fit (slope of “1”).

Figure 3 Cooling benchmark data and statically fitted line

Testing

“Side-by-side testing” consisted of incorporating into the test house an innovative energy saving component, the ERV. Both houses are then operated identically and monitored. Changes in house performances due to the innovation are observed through comparison to of test house performance to the reference house performance, for a range of weather conditions, over the two testing periods at 65 and 115 cfm. During the weeks of assessment, the consumption of the A/C and the furnace in the test house was measured. The air conditioning, furnace and total cooling energy consumptions for each house were recorded for each day of operation and compared graphically.

The house temperature is regulated by a standard programmable thermostat located in the main floor hallway at mid-wall height. Throughout the summer of 2004, the thermostat set point was 24°C, maintaining the house main floor temperature at roughly 23°C. Temperatures on the second floor were approximately 2 to 3 degrees warmer than the main floor temperature, while the basement remained 2 to 3 degrees cooler. The conventional thermostat had a very narrow band in both houses, about ± 0.1 ºC.

RESULTS

This section compares the operation of the two houses, reference house incorporating a Heat Recovery Ventilator (HRV) and the test house incorporating an Energy Recovery Ventilator (ERV) over two different periods with respectively air entering flow of 65 cfm and 115 cfm. The items compared include: airflow, Energy conception, house air temperature and humidity.

Low Entering Air Flow (65 cfm)

The first testing period consisted of monitoring the reference and test houses, and determine the change in overall house energy performance and indoor relative humidity balance associated with the incorporation of an Energy Recovery Ventilator (ERV) compared with a Heat Recovery Ventilator (HRV) at an entering air flow rate of 65 cfm.

Figure 4 Indoor and outdoor temperatures at CCHT houses - 65 cfm

The average indoor temperature in the reference house (with HRV) and the test house (with ERV), and also the outdoor temperature over the testing period with an air entering flow of 65 cfm are shown in Figure 4. The average indoor temperatures in the reference and test house were very close.

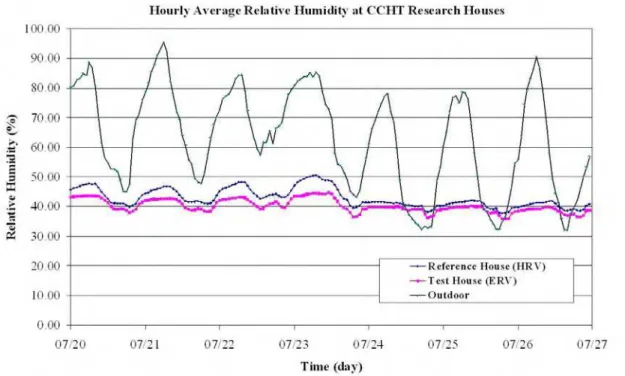

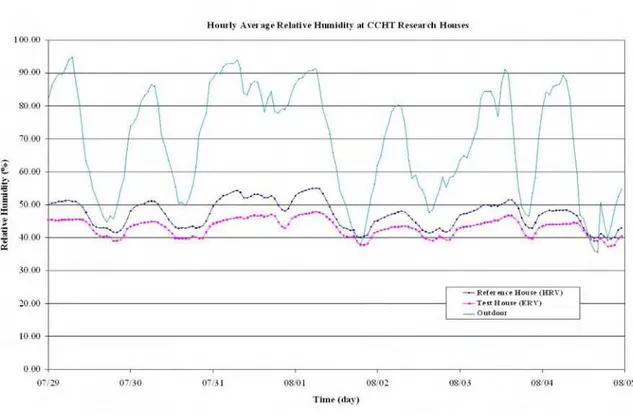

The indoor average relative humidity in the reference (with HRV) and test (with ERV) houses is shown in Figure 5. The relative humidity in the test house is substantially lower compared to the value in the reference house, showing that ERV better control humidity in the house by transferring some of the water vapor in the incoming air to the drier air that’s leaving the house.

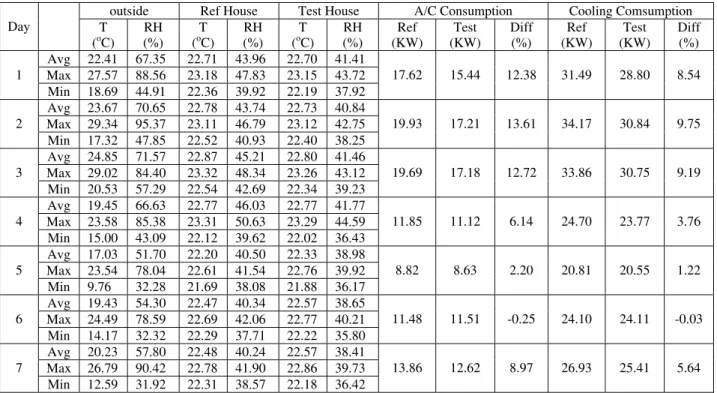

The daily average, maximum and minimum indoor and outdoor temperature and relative humidity are shown in Table 1. The table presents also the daily cumulative air conditioning electricity and cooling electicity consumption. The air conditioning electricity consumption saving using an ERV instead an HRV went up to 13.6%. The corresponding cooling electricity consumption saving went to 9.75%.

Table 1 Daily indoor and outdoor conditions and cumulative A/C and cooling energy consumption (65 cfm)

outside Ref House Test House A/C Consumption Cooling Comsumption

Day T (oC) RH (%) T (oC) RH (%) T (oC) RH (%) Ref (KW) Test (KW) Diff (%) Ref (KW) Test (KW) Diff (%) Avg 22.41 67.35 22.71 43.96 22.70 41.41 Max 27.57 88.56 23.18 47.83 23.15 43.72 1 Min 18.69 44.91 22.36 39.92 22.19 37.92 17.62 15.44 12.38 31.49 28.80 8.54 Avg 23.67 70.65 22.78 43.74 22.73 40.84 Max 29.34 95.37 23.11 46.79 23.12 42.75 2 Min 17.32 47.85 22.52 40.93 22.40 38.25 19.93 17.21 13.61 34.17 30.84 9.75 Avg 24.85 71.57 22.87 45.21 22.80 41.46 Max 29.02 84.40 23.32 48.34 23.26 43.12 3 Min 20.53 57.29 22.54 42.69 22.34 39.23 19.69 17.18 12.72 33.86 30.75 9.19 Avg 19.45 66.63 22.77 46.03 22.77 41.77 Max 23.58 85.38 23.31 50.63 23.29 44.59 4 Min 15.00 43.09 22.12 39.62 22.02 36.43 11.85 11.12 6.14 24.70 23.77 3.76 Avg 17.03 51.70 22.20 40.50 22.33 38.98 Max 23.54 78.04 22.61 41.54 22.76 39.92 5 Min 9.76 32.28 21.69 38.08 21.88 36.17 8.82 8.63 2.20 20.81 20.55 1.22 Avg 19.43 54.30 22.47 40.34 22.57 38.65 Max 24.49 78.59 22.69 42.06 22.77 40.21 6 Min 14.17 32.32 22.29 37.71 22.22 35.80 11.48 11.51 -0.25 24.10 24.11 -0.03 Avg 20.23 57.80 22.48 40.24 22.57 38.41 Max 26.79 90.42 22.78 41.90 22.86 39.73 7 Min 12.59 31.92 22.31 38.57 22.18 36.42 13.86 12.62 8.97 26.93 25.41 5.64

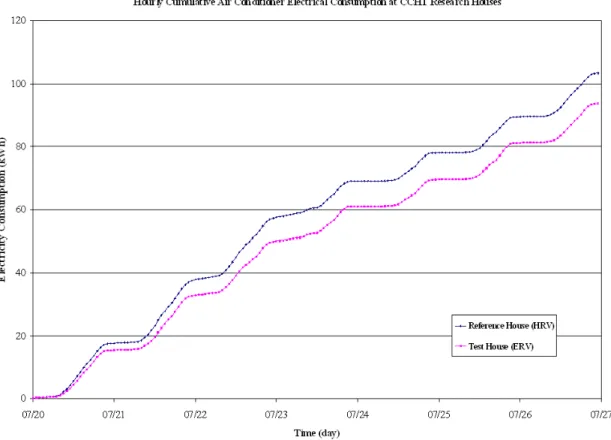

The hourly cumulative air conditioning electricity at CCHT research houses, reference house incorporating an HRV and test house incorporating an ERV is presented in Figure 6. The air conditioning electricity consumption in the test house is 9.3% lower than the reference house over a testing period with an entering air flow of 65 cfm.

Figure 6 Cumulative A/C electricity consumption at CCHT houses - 65 cfm

High Entering Air Flow (115 cfm)

The second testing period consisted of monitoring the reference and test houses to determine the change in overall house energy performance and indoor relative humidity (RH) balance associated with the incorporation of an Energy Recovery ventilator (ERV) compared with a Heat Recovery Ventilator (HRV) at an entering air flow rate of 115 cfm.

Similar results presented above for testing period with an entering air flow of 65 cfm are presented this time for much higher air flow of 115 cfm.

Figure 7 shows the indoor average relative humidity in the reference house (with HRV) and the test house (with ERV). And again running an air conditioner in the summer, an ERV offers better humidity control than an HRV.

Figure 8 shows the hourly cumulative air conditioning electricity at CCHT research houses. The use of an ERV during the summer helped to reduce the air conditioning electricity consumption in the tes house by up to 12%.

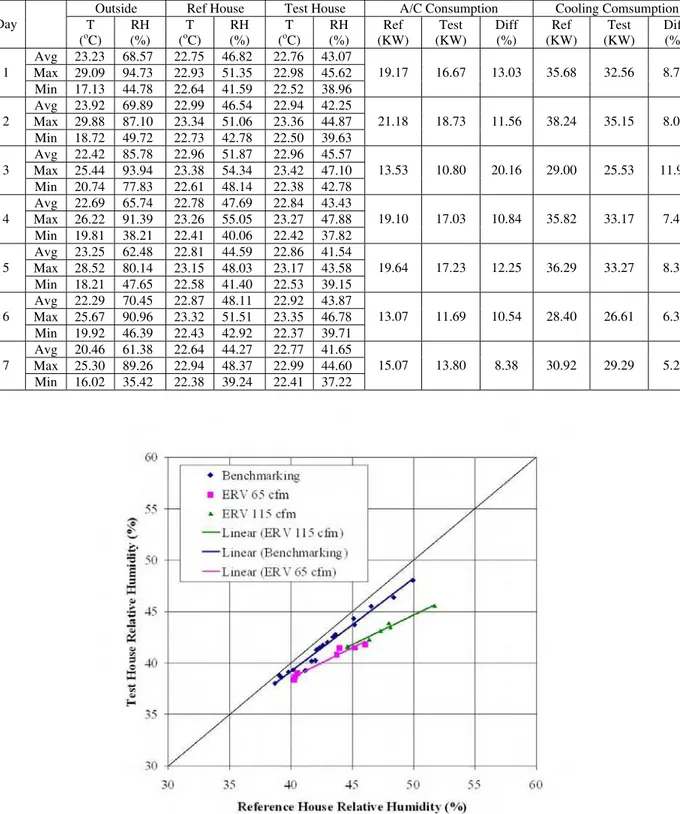

The daily average indoor and outdoor conditions (temperature and relative humidity) are given in Table 2. The table icludes also the air conditioning electricity consumption, which shows that the use of an ERV instead an HRV saved from 8% to 20% in air conditioning electricity consumptionin. The corresponding cooling electricity consumption saving went from 5.3% to 12%.

Figure 7 Outdoor and indoor relative humidity at CCHT houses - 115 cfm

Table 2 Daily indoor and outdoor conditions and cumulative A/C and cooling energy consumption – 115 cfm

Outside Ref House Test House A/C Consumption Cooling Comsumption

Day T (oC) RH (%) T (oC) RH (%) T (oC) RH (%) Ref (KW) Test (KW) Diff (%) Ref (KW) Test (KW) Diff (%) Avg 23.23 68.57 22.75 46.82 22.76 43.07 Max 29.09 94.73 22.93 51.35 22.98 45.62 1 Min 17.13 44.78 22.64 41.59 22.52 38.96 19.17 16.67 13.03 35.68 32.56 8.76 Avg 23.92 69.89 22.99 46.54 22.94 42.25 Max 29.88 87.10 23.34 51.06 23.36 44.87 2 Min 18.72 49.72 22.73 42.78 22.50 39.63 21.18 18.73 11.56 38.24 35.15 8.07 Avg 22.42 85.78 22.96 51.87 22.96 45.57 Max 25.44 93.94 23.38 54.34 23.42 47.10 3 Min 20.74 77.83 22.61 48.14 22.38 42.78 13.53 10.80 20.16 29.00 25.53 11.99 Avg 22.69 65.74 22.78 47.69 22.84 43.43 Max 26.22 91.39 23.26 55.05 23.27 47.88 4 Min 19.81 38.21 22.41 40.06 22.42 37.82 19.10 17.03 10.84 35.82 33.17 7.40 Avg 23.25 62.48 22.81 44.59 22.86 41.54 Max 28.52 80.14 23.15 48.03 23.17 43.58 5 Min 18.21 47.65 22.58 41.40 22.53 39.15 19.64 17.23 12.25 36.29 33.27 8.32 Avg 22.29 70.45 22.87 48.11 22.92 43.87 Max 25.67 90.96 23.32 51.51 23.35 46.78 6 Min 19.92 46.39 22.43 42.92 22.37 39.71 13.07 11.69 10.54 28.40 26.61 6.31 Avg 20.46 61.38 22.64 44.27 22.77 41.65 Max 25.30 89.26 22.94 48.37 22.99 44.60 7 Min 16.02 35.42 22.38 39.24 22.41 37.22 15.07 13.80 8.38 30.92 29.29 5.27

SUMMARY AND DISCUSSION

The real impact of the installation of an Enrgy Recovery Ventilator (ERV) in Canadian houses has been evaluated for a range of summer temperatures in Ottawa including humid summer days. Changes in house performances due to the innovation are through comparison to of test house performance (incorporating an ERV) to the reference house performance (incorporating an HRV).

Summer 2004 cooling data revealed that the Test House in which an ERV has been installed presented much lower level of relative humidity than the Reference House with a HRV for the two entering air flows (low and high)as shown on Figure 9.

These results show that the ERV is more efficient than HRV in controlling indoor humidity during the summer by transferring some of the water vapor in the incoming air to the theoritically drier air that’s leaving the house as shown in Figures 10 and 11.

Figure 10 Air conditioning electricity consumption

Overall, the energy recovery ventilator, produced improvements in humidity control and substantial cooling energy consumption. Despite the mild weather we had this summer (temperature not exceeding 28oC), the ERV performance showed potential in cooling energy saving. An experiment should be conducted under more extreme hot and humid conditions, would verify such application of ERV.

The releases of vapor due to occupants and their activity are significant and can reach up to 20 L of water per day for a family of four people. Further experiments should be conducted with internal moisture generation to take into account the contributions due to the occupants.

CONCLUSION

Incorporating an Energy Recovery Ventilator (ERV) in the Test House not only offered more efficient humidity control than in the Reference House with a Heat Recovery Ventilator (HRV), but showed also a reduction in air conditioning electricity consumption (up to 20%) in particular and cooling electricity consumption (up to 12%) in general.

Comparison of the performance of the Test House with an Energy Recovery ventilator (ERV) to the Reference House with a Heat Recovery ventilator (HRV) operating normally in cooling mode revealed the following:

• Improved indoor humidity control on warm and humid days.

• Substantial reduction of air conditioning and fan circulation energy consumption.

• The benefits are strongly dependant on the outside conditions, high performance (high energy saving) under hot and humid conditions.

• Measured trends indicate potential for even higher cooling energy saving under extreme summer conditions.

Figure 11 Cooling electricity consumption

ACKNOWLEDGEMENTS

The authors would like to thank Michel Julien and Benoit Arpin from Venmar Ventilation Inc. for providing guidance and technical information during this project. We are especially grateful for the support and encouragement provided by Dr. Morad Atif, Director, Indoor Environment Program, IRC and Mr. Daniel Forest, V-P General Manager, Venmar Ventilation Inc.

REFERENCES

ASHRAE 1999. ASHRAE Standard 62.2P-1898: Ventilation and acceptable Indoor Air Quality in Low-Rise Residential Buildings, American Society of Heating, Refrigerating and Air-Conditioning Engineers, Atlanta, GA.

Moyer, Neil, D. Beal, D. Chasar, J. McIlvaine, C. Withers, S. Chandra, 2001. Moisture Problems in Manufactured Housing: Probable Causes and Cures. ASHRAE Conference Proceedings IAQ2001. American Society of Heating, Refrigerating and Air-Conditioning Engineers, Inc. Atlanta, Georgia.

Cummings, J., J. Tooley, N. Moyer, 1991. Investigation of Air Distribution System Leakage and its Impact in central Florida Homes. Contract Report, Florida Solar Energy center, Cocoa, FL, FSEC-CR-397-91.