Publisher’s version / Version de l'éditeur:

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

Water Management Challenges in Global Change CCWI2007 and SUWM2007 Conference [Proceedings], pp. 69-74, 2007-09-03

READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE. https://nrc-publications.canada.ca/eng/copyright

NRC Publications Archive Record / Notice des Archives des publications du CNRC :

https://nrc-publications.canada.ca/eng/view/object/?id=04440eb1-8e4e-4a2d-b946-76b3f829cd19 https://publications-cnrc.canada.ca/fra/voir/objet/?id=04440eb1-8e4e-4a2d-b946-76b3f829cd19

NRC Publications Archive

Archives des publications du CNRC

This publication could be one of several versions: author’s original, accepted manuscript or the publisher’s version. / La version de cette publication peut être l’une des suivantes : la version prépublication de l’auteur, la version acceptée du manuscrit ou la version de l’éditeur.

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at

Translation of pipe inspection results into condition rating using theory of evidence

http://irc.nrc-cnrc.gc.ca

T r a n s l a t i o n o f p i p e i n s p e c t i o n r e s u l t s i n t o

c o n d i t i o n r a t i n g u s i n g t h e o r y o f e v i d e n c e

N R C C - 4 9 5 1 0

H u a , B . ; S a d i q , R . ; N a j j a r a n , H . ; R a j a n i , B .

A version of this document is published in / Une version de ce document se trouve dans: Water Management Challenges in Global Change CCWI2007 and SUWM2007

Conference, Leicester, UK, Sept. 3-5, 2007, pp. 1-5

The material in this document is covered by the provisions of the Copyright Act, by Canadian laws, policies, regulations and international agreements. Such provisions serve to identify the information source and, in specific instances, to prohibit reproduction of materials without written permission. For more information visit http://laws.justice.gc.ca/en/showtdm/cs/C-42

Les renseignements dans ce document sont protégés par la Loi sur le droit d'auteur, par les lois, les politiques et les règlements du Canada et des accords internationaux. Ces dispositions permettent d'identifier la source de l'information et, dans certains cas, d'interdire la copie de documents sans permission écrite. Pour obtenir de plus amples renseignements : http://lois.justice.gc.ca/fr/showtdm/cs/C-42

Translation of pipe inspection results into condition rating using theory

of evidence

Bai Hua

School of Mechatronics Engineering, Harbin Institute of Technology, Harbin, China

Rehan Sadiq

Institute for Research in Construction, National Research Council, Ottawa, Ontario, Canada

Homayoun Najjaran

School of Engineering, University of British Columbia (Okanagan Campus), Kelowna, BC, Canada

Balvant Rajani

Institute for Research in Construction, National Research Council, Ottawa, Ontario, Canada

ABSTRACT: The effective management of failure risk in large buried pipes requires inspection and monitor-ing, whereby distress indicators are observed, recorded, and subsequently interpreted into condition rating(s). The type, extent and location of observed distress indicators in a buried pipe are dependent on the pipe mate-rial and its surrounding environment. The physico-chemical and biochemical processes that govern deteriora-tion are often not understood well enough to merit an adequate mechanistic or kinetic model.

In this paper, we propose a condition assessment approach based on the theory of evidence as proposed by Dempster-Shafer. In this approach, bodies of evidence (distress indicators) are arranged in a hierarchical (tree-like) structure that corresponds to different levels of pipe deterioration attributes and mechanisms. The basic concepts of the proposed approach are presented and demonstrated with an example using metallic pipes (cast or ductile iron).

1 INTRODUCTION

Typically, large diameter water pipes (trunk mains) bring water from the source to the drinking water treatment plants. Similarly, large diameter wastewa-ter (trunk sewers) pipes take treated wawastewa-ter from the sewage treatment plants to the final disposal in riv-ers or oceans. Most of these pipes are located under-ground and many have been in service far longer than their intended design lives. Many of these net-works are subjected to aging and weathering impacts during their service lives (Hua et al. 2007).

Typically, the failure of large diameter pipes is a rare event, but the consequences can be significant. It is therefore imperative to anticipate and pre-empt failure in large diameter pipes rather than respond to it. It is necessary to develop models that mimic dete-rioration and subsequently to calibrate them based on observed pipe conditions in order to anticipate future pipe condition. However, most water supply systems usually do not have built-in redundancy for large diameter pipes. Consequently, water utilities are reluctant to interrupt their service for inspection and therefore condition assessment data is quite scarce.

The condition assessment of buried pipes can be divided into two essential steps: collect direct obser-vations (visual or instrumental), which yield identi-fication and quantiidenti-fication of distress indicators and translate these distress indicators into an overall

condition rating (Rajani et al. 2006). Factors such as the type and the quality of pipe materials, stability and composition of surrounding soils, internal flow rate and aggressiveness of transported water, con-tribute to the overall deterioration of pipes. Typical types of large diameter pipe used to purvey drinking water are reinforced concrete, cast iron, ductile iron, steel, asbestos cement, and pre-stressed cylinder concrete pipe (PCCP). Most of the large diameter pipes are composites in that their make-up consists of more than one material, e.g., concrete and steel, iron and cement lining, etc. Distress indicators (manifestation of deterioration), which depend on the material types that make-up the composite pipe, include changes in internal and external surfaces, misalignment and displacement of joints, formation of corrosion pits, cracks and spalling of mortar or cement lining, and/or the number of broken pre-stressed wires, etc. The deterioration process may start with an initial structural defect before leading to an overall failure of the pipe. Each of these dis-tress indicators contributes differently to the condi-tion rating of a given segment of a pipe. This makes the assessment of pipe condition rating a challenging task and requires a large body of data as well as ex-perts' judgment.

Typically, a given sensor or technology provides data about a specific aspect of a distress indicator. Condition rating estimated from distress indicators is generally imprecise due to the limitation of the

knowledge and understanding about the process(es), and sometimes even leads to a conflicting or contra-dicting assessment depending on the outcome of the measurements or assessment methods used. There-fore, a comprehensive and credible condition rating requires fusion of data obtained from several sources (sensors or distress indicators).

The Dempster-Shafer (DS) theory is a relatively new data fusion approach, which extends the tradi-tional Bayesian approach. The DS theory can be in-terpreted as a generalization of the Bayesian theory, where probabilities are assigned to subsets and not only to mutually exclusive singletons.

In this paper, a hierarchical evidential reasoning (HER) model, which employs the DS theory of evi-dence, is proposed to evaluate condition ratings of large diameter pipes. The rest of the paper is organ-ized as follows: Section 2 briefly introduces the DS theory of evidence. Section 3 describes the frame-work of the proposed HER model. An example of pipe condition assessment is briefly discussed in Section 4. Finally, conclusions are provided.

2 THEORY OF EVIDENCE

The Dempster-Shafer (DS) theory is a powerful tool to address epistemic uncertainty (ignorance). The DS theory was first proposed by Dempster (1967) and subsequently extended by Shafer (1976). In DS theory, a finite nonempty set of mutually exclusive alternatives is called the frame of discernment, de-noted by Θ, and has 2Θ

subsets in the domain. For example, in the evaluation of a condition rating, we have a set of condition states, i.e., Θ = {good, fair, bad}, where good is the hypothesis of “condition state good is present”.

The basic probability assignment (BPA), an im-portant concept in DS theory, reflects a degree of belief in a hypothesis or the degree to which the evi-dence supports the hypothesis. BPA has the follow-ing properties, 1 ) ( = ∑ Ψ Θ ⊆ Ψ m ; m(φ)=0; 0≤ m(Ψ)≤1, (1)

where represents the direct support of evi-dence on Ψ, i.e., indicates that portion of the total belief exactly committed to hypothesis Ψ given a body of evidence. BPA can be assigned to every subset Ψ (where Ψ ⊆ Θ) and takes a value in the in-terval [0, 1]. If the existing evidence cannot differen-tiate between two hypotheses, say, C

) (Ψ m

i and Cj, a BPA could be assigned to the subset that consists of both of these hypotheses, denoted by m({Ci , Cj}). The quantity m(Θ) is a measure of that portion of the to-tal belief that remains unassigned after commitment of belief to all subsets of Θ. If m(Ψ) = s, and no BPA is assigned to other subsets of Θ, then m(Θ) = 1 - s. Thus, the remaining BPA is assigned to Θ

it-self, but not to the negation of a subset Ψ. This value of BPA m(Θ) represents ignorance.

For example, consider Θ = {good, fair, bad}, de-noted as H = {H1, H2, H3} which represents three condition states of a pipe. Assume that the informa-tion obtained indicates that m({H1}) = 0.5, m({H2}) = 0.3, and m({H2, H3}) = 0.1, i.e., the degree to which the evidence supports these condition states is 50%, 30% and 10%, respectively. Hence, BPA as-signed to ignorance is m(H) = 1 - (0.5 + 0.3 + 0.1) = 0.1. It can then be interpreted that the set of all con-ditions states {H1, H2, H3} possess 10% unassigned mass based on available incomplete evidence.

The DS rule of combination, also sometimes re-ferred to as the orthogonal sum of evidence, can be used to aggregate multiple sources of information. Assume two bodies of evidence exist in Θ, i.e., two basic probability assignments m1(Ψ) and m2(Ψ) to a

subset Ψ ⊆ Θ. The combined probability assign-ment, m12(Ψ), based on the DS rule of combination

is, ⎪⎩ ⎪ ⎨ ⎧ Φ ≠ Ψ − ∑ Ψ=Φ = Ψ ⊕ Ψ = Ψ Θ ⊆ ∀ Ψ = ∩ when 1 ) ( ) ( when 0 ) ( ) ( ) ( , , 1 2 2 1 12 K B m A m m m m B A B A (2) where = ∑ Θ ⊆ ∀ Φ = ∩B AB A B m A m K , , 1 2 ) ( ) ( .

The combined mass probability assignment, m12(Ψ), for a subset Ψ is computed from m1 and m2

by adding all products of the form “m1(A) • m2(B)”,

where A and B are the subsets and their intersection is always Ψ. The conflict between subsets A and B is represented by factor K, where the intersection of A and B (i.e., A ∩ B = Φ) is an empty or void set. The commutative property of the DS rule of combination ensures that the rule yields the same value regardless of the order in which the two bodies of evidence are combined (Sadiq et al. 2006). Therefore, the DS combination rule can be generalized to more than two bodies of evidence. The DS combination rule for M bodies of evidence can be written as,

M

M m m m

m1,2,..., = 1⊕ 2⊕L⊕ (3) The direct use of the combination rule will result in an exponential increase in the computational complexity. Generally, the DS rule of combination is used recursively to avoid this complexity. In this paper, the recursive DS algorithm is applied to hier-archical systems, as discussed in following section.

3 PROPOSED MODEL - HER

The hierarchical evidential reasoning (HER) model is a generic framework to aggregate and to handle various bodies of evidence in a recursive manner. In HER, elements of basic evidence are referred to as

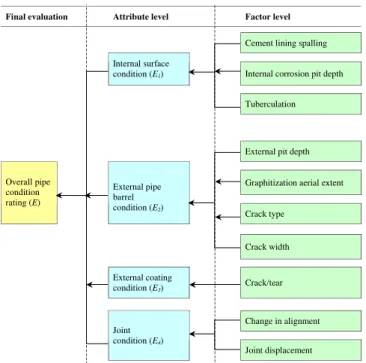

factors. These factors are aggregated into attributes to provide more general evidence. To apply a HER model to pipe condition assessment, we define fac-tors, which refer to distress indicators and attributes, which refer to categories (Figure 1). These termi-nologies are used interchangeably in this paper.

Figure 1. Hierarchical framework for condition assessment of cast/ductile iron pipes

In a HER framework, the attribute at a higher-level is evaluated based on the assessment of its as-sociated lower-level factors. The condition rating of the kth attribute, Ek, is evaluated based on a number of factors, which can be directly observed or esti-mated. The evaluation of an attribute Ek with con-tributory factors eki(i = 1, 2,…, Lk) is given by, Ek =e1k⊕ ⊕ … ⊕ (4) 2 k e Lk k e

where Lk denotes the number of factors that contrib-ute to the kth attribute. The BPA for each factor is based on the degree of confidence esti-mated/assigned to these condition states, as well as the associated importance and reliability of the data (or a credibility of experts' judgment).

Assume that the frame of discernment, H, that de-scribes the condition states of a pipe is given by, H = {H1, H2, …, Hn, …, HN}; n = 1, …, N (5) where N is the number of possible condition states, Hn represents the nth condition state, and H1 and HN are the best and the worst possible condition states, respectively. An expert may not always be 100% sure that the observed condition is exactly confined to only one condition states. In most instances, ob-served condition rating will be confined to two or no more than three contiguous condition states with a total degree of confidence equal or smaller than 100%.

For example, two contributory factors for the evaluation of a pipe joint condition (E4) can be:

Change in joint alignment (e ): Condition rating 4 = good with a 90% degree of confidence; and

1

Joint displacement (e ): Condition rating = good 4 with a 40% degree of confidence and fair with 60% degree of confidence.

2

Here, the frame of discernment, H, for each of these factors consists of three condition states, namely, good, fair and bad, which can be written as,

Final evaluation Attribute level Factor level

H = {good (H1), fair (H2), bad (H3)}. These condi-tion states have specific meaning for each factor and represent increasing levels distress in each case. In this assessment, degrees of confidence of 90%, 40%, and 60% are referred to as BPAs obtained from an inspector’s experience and/or related to inspection precision.

The condition rating (S) for a given factor can be written as,

i k e S(eki ) = {(Hn / βn,i), n = 1, …, N}; i = 1, 2,…, LN k (6)

where βn,i ≥ 0 and

∑

≤ 1.= n i n 1 , β λ e H m

In practice, not all the factors have the same im-portance in the assessment of an attribute. In addi-tion, data collected from different sensors may be er-roneous (less reliable) or experts’ judgment may have different levels of credibility. All these influ-encing factors are lumped together into a single pa-rameter, k, which is a normalized relative to the weight of evidence for a factor, k, towards the evaluation of an attribute, E

i

i

k. Therefore, the weight matrix for an attribute, Ek, can be written as,

1 0 where } , , ..., , { 1 ≤ ≤ = i k L k i k k k k λ λ λ λ λ K (7)

The basic probability assignment m( ) for a fac-tor can be determined by discounting the degrees of confidence, β i k e i k e

n,i, assigned earlier. m(eki ) = S( )× = {(H i k e λik n/ ); n = 1,2, …, N} (8) n H i k m , where Hn= β i k m, λik n,i and = H i k m ,

∑

= − N n i n i k 1 , 1 λ βBy applying the recursive DS rule of combina-tion, the combined evidence, I (i)

k

e , based on i factors that contribute to the kth attribute is obtained as fol-lows, k i k k k i I e e e i L e k ... 1,2,..., 2 1 ) ( = ⊕ ⊕ = (9) Assume k i

I ()is a basic probability assignment of

a subset (singleton) H

n

n ⊆ H, which is confirmed by combined evidence, eIk(i), and can be written as,

} , , 2 , 1 , ) {( ) ( ) ( ) ( n N m H e m n k k H i I n i I = = K (10)

By applying DS rule of combination for the ag-gregation of multiple factors, the same result is ob-tained regardless of the order in which the evidence is combined because of the associative nature of DS rule of combination. For computational simplicity,

Cement lining spalling

Internal surface

condition (E1) Internal corrosion pit depth

Tuberculation

External pit depth

Graphitization aerial extent Overall pipe condition rating (E) External pipe barrel condition (E2) Crack type Crack width External coating condition (E3) Crack/tear Change in alignment Joint condition (E4) Joint displacement

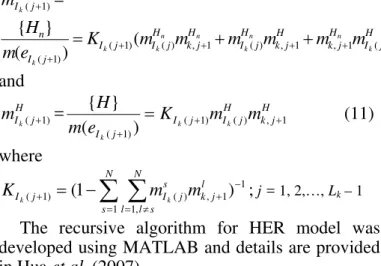

we combine one factor at a time using the following formulae, recursively. n k H j I m ( +1)= ) ( ) ( } { ) ( 1 , 1 , ) ( 1 , ) ( ) 1 ( ) 1 ( H j I H j k H j k H j I H j k H j I j I j I n k n n k n n k k k m m m m m m K e m H + + + + + + + = and H j Ik m ( +1)= I j IH j kHj j I m m K e m H k k k 1 , ) ( ) 1 ( ) 1 ( ) ( } { + + + = (11) where 1 1 1, 1 , ) ( ) 1 ( (1 ) − = = ≠ + + = −

∑ ∑

N s N s l l l j k s j I j I m m K k k ; j = 1, 2,…, Lk – 1The recursive algorithm for HER model was developed using MATLAB and details are provided in Hua et al. (2007).

4 AN EXAMPLE FOR PIPE EVALUATION The attribute, internal surface condition of a lined cast iron pipe, is selected here to serve as an exam-ple how the remaining attributes would be evaluated for the complete the HER model for pipe condition assessment. The internal surface condition (k = 1) depends on three contributory factors, namely, spalling of the cement lining, internal corrosion pit depth, and tuberculation. The corresponding data set is provided in Table 1.

To simplify the problem, we assume that the sub-jective judgment for each contributory factor is available. The subjective judgments for each factor are based on three condition states Hn as described earlier. The aggregation of factors for the attribute, internal surface condition (E1), i.e., k = 1 is given by:

E1 = Spalling ( ) ⊕ Pit depth ( ) ⊕ Tuberculation ( ) (12) 1

1

e e12 e13

With the results provided in Table 1, the value of final condition rating for E1 is{G 0.32, F 0.28,B 0.31}. The degree of confi-dence for the pipe internal surface conditionas good is the highest. However, this pipe condition rating assessment is good based on information from only on one of the four attributes. It is important to note that the degrees of confidence for the conditions fair and bad are not too different from the good, and this may be a result of the contradictory bodies of evi-dence, namely, spalling of the cement lining and in-ternal corrosion pit depth, or spalling of the cement lining and tuberculation. In practice, we would an-ticipate internal pits and tubercles only if spalling of the cement lining had previously occurred and ob-served. Therefore, these results are not conclusive and there is the need to involve other attributes for a more reliable decision.

Similarly, contributions of the remaining three at-tributes - external pipe barrel, external coating, and

joint conditions - are also determined (Table 1). Fi-nally, the latter results are combined and the overall condition rating (E) of a lined cast iron pipe is de-termined as {G 0.05, F 0.86, B 0.08}. Therefore, the most likely condition rating of this lined cast iron pipe is “fair”. It can also be noticed that the overall condition rating is very distinct from the condition ratings determined for each individual at-tribute or category. The epistemic uncertainty (igno-rance) in the overall assessment is very low (0.01 = 1 - 0.05 - 0.86 -0.08), whereas the epistemic uncer-tainty (ignorance) for the individual attributes varies from 0.03 to 0.20 (Table 1).

Table 1. Summary of attributes and contributory factors that efine the overall condition rating of a lined cast iron pipe d Attributes, k Contributory factors, i *S( ) i k e λik

Cement lining spalling (e11)

B/0.80 1.0

Internal corrosion pit depth (e12)

G/0.40, F/0.40 1.0

Internal sur-face (E1)

Tuberculation (e13) G/0.50, F/0.40 0.6

External pit depth (e12) G/0.35, F/0.45 1.0

Graphitization aerial ex-tent (e22) F/0.30, B/0.60 1.0 Crack type (e23) F/0.50, B/0.30 1.0 External pipe barrel (E2) Crack width (e24) G/0.80 0.6 External coating (E3) Crack/tear (e13) G/0.20, F/0.60 1.0 Change in alignment (e14) F/0.50, B/0.30 1.0 Joint condi-tions (E4) Joint displacement (e42) G/0.65 0.6

Evaluation Attributes, k S(Ek) γk Internal surface (E1) G/0.32, F/0.28,

B/0.31;

Ignorance = 0.09 1.0

External pipe barrel (E2) G/0.06, F/0.67,

B/0.24; Ignorance = 0.03 1.0 External coating (E3) G/0.20, F/0.60, B/0.00; Ignorance = 0.20 1.0 Condition assessment (E) Joint conditions (E4) G/0.11, F/0.44, B/0.26; Ignorance = 0.09 0.3

*The evaluation grades for the related factors are defined as {good/β, fair)/β, bad(β}, where β represents the degree of con-fidence, and G = “good”; F = “fair”; B = “bad”

5 CONCLUSIONS

A pipe condition assessment method requires a ra-tional, repeatable, and transparent approach. Evalua-tion process for pipe condiEvalua-tion rating is a challeng-ing task as it involves aggregation of a diverse set of distress indicators. The problem becomes increas-ingly complex due to uncertainties attributable to in-herent subjectivity in the interpretation process. In this paper, a hierarchical evidential reasoning (HER) model is proposed for pipe condition assessment which can combine subjective, imprecise and in-complete information, and even conflicting data.

In the real-world situation, the multiple factors (or attributes) that contribute to overall evaluation are generally dependent (or correlated), and may also provide highly conflicting evidence, which re-duces the reliability of results in case of direct use of D-S rule of combination (Zadeh 1984). The present model is built on a hierarchical framework for pipe condition assessment in which all contributory fac-tors (or attributes) are assumed independent, and only the parallel aggregation of factors (or attrib-utes) are performed using D-S rule of combination. The proposed model presented in this paper is still in infancy, and extensive work needs to be done to make algorithm HER more robust to deal with de-pendent factors as well as to effectively deal with the issue of “conflict” using alternative rules of

ombination. c

PREFERENCES

Dempster, A. 1967. Upper and lower probabilities induced by a multi-valued mapping, The Annals of Statistics, 28: 325-339.

Hua, B., Sadiq, R., Najjaran, H., Rajani, B. 2007. Condition assessment of buried pipes using hierarchical evidential reasoning (HER) model, ASCE Journal of Computing in

Civil Engineering (forthcoming).

Rajani, B., Kleiner, Y., and Sadiq, R. 2006. Translation of pipe inspection results into condition rating using fuzzy syn-thetic evaluation technique, Journal of Water Supply:

Re-search & Technology – AQUA, 55(1): 11-24.

Sadiq, R., Kleiner, Y., and Rajani, B. 2006. Estimating risk of contaminant intrusion in distribution networks using Dempster-Shafer theory of evidence, Civil Engineering and

Environmental Systems, 23(3): 129-141.

Shafer, G. 1976. A mathematical theory of evidence, Princeton University Press, Princeton, N.J.