Publisher’s version / Version de l'éditeur:

ASTM Special Technical Publication, 444, pp. 15-40, 1969-04-01

READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE. https://nrc-publications.canada.ca/eng/copyright

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

NRC Publications Archive

Archives des publications du CNRC

This publication could be one of several versions: author’s original, accepted manuscript or the publisher’s version. / La version de cette publication peut être l’une des suivantes : la version prépublication de l’auteur, la version acceptée du manuscrit ou la version de l’éditeur.

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at

Downdrag measuremetns on 270-ft compostie piles

Bozozuk, M.; Labrecque, A.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

NRC Publications Record / Notice d'Archives des publications de CNRC:

https://nrc-publications.canada.ca/eng/view/object/?id=b8c515b8-7de0-4ebf-bbbb-f9ad67f2b016 https://publications-cnrc.canada.ca/fra/voir/objet/?id=b8c515b8-7de0-4ebf-bbbb-f9ad67f2b016Michael

Bozozukland Andrk Labrecque2

AN&R,YZED

Downdrag Measurements

on 270-Ft

Composite Piles

REFERENCE: Bozozuk, Michael and Labrecque, Andre, "Downdrag Measu~.ements o n 2 7 0 - F t Conlposite Piles," P ~ r ~ ) r r i z r r r i c r of L1rc.p F o ~ t r ~ d r r t i u n s . A S T M S T P 4 4 4 , American Society for Testing and Mate~ials,

1969, pp. 15-40.

ABSTRACT: The Quebec autoroute on the North Shore of the St. Lawrence River between Montreal and Quebec City traverses deep deposits of compres- sible marine clay. One of the overpass structures at Berthierville is supported on twelve 39-in. (1 m) diameter reinforced concrete piles, which pass through 270 ft (82 m) of soil and finally rest on shale bedrock.

T h e site was preloaded for one year, during which time about 5 ft (1.5 m) of settlement occurred. Steel casings for the piles were then driven and filled with concrete which was reinforced. Each pile was designed to carry 2000 tons ( 1 8 14 metric tons) of which 1200 tons (1090 metric tons) were allowed for neg- ative skin friction loads. Deformation gages were installed at various levels in two of the piles to measure the axial compression as the negative skin friction accumulated.

Contrary to expectations, hydration caused the piles to lengthen about 0.06 in. (1.5 mm) during the 6-week period following placement of the concrete. Five months later this reduced to about 0.04 in. (1.0 mm) as skin friction loads overcame the expansive forces of hydration. In this same period the sub- soils consolidated by more than 0.5 ft (0.15 m). Near the ground surface the pore water pressures and settlements were the same adjacent to a pile and at a dis- tance of 22 ft (6.7 m).

In November 1966 a cut was made to permit construction of the foundations for the overpass, causing the piles to lengthen about l/4 in. (6 mm). In Decem- ber, electroosmosis was applied to relieve the test piles of the accumulated skin friction loads imposed by the consolidating cl;iy subsoil. Subsequent meas- urements showed that they immediately began to accunlulate negative skin friction loads. and that in the following 10-month period they compressed more than l/z in. (13 mm).

Vertical pile deformations were also measured when the overpass was con- structed. From these observations the vertical modulus of deformation of the composite piles was calculated and compared with the values obtained from uniaxial compression tests on test cylinders in the laboratory.

T h e paper presents measurements of settlement and pore water pressures in the soil at various depths under the fill, and of axial deformations in two of the piles. It provides a set of relatively rare field observations on which to base

'

Research officer. Division of Building Research. National Research Council of Canada, Ottawa, Ont., Canada.'

President. Labrecque, Vezina, and Associates. Consulting Engineers, Montreal, P. Q., Canada. Personal member ASTM.16

an approximate evaluation of the rate and magnitude of negative skin friction development under the described field conditions.

KEY WORDS: pile foundations, bearing piles, composite piles, highway embankment, instrumentation, pile friction, downdrag, skin friction. electroos- mosis, deformation modulus, concrete, curing (hydration), evaluation

T h e autoroute along the North Shore of the St. Lawrence River between Montreal and Quebec City passes over deep beds of compres- sible marine clay. At Berthierville, 50 miles (80 km) east of Montreal, the autoroute crosses a railway spur line and Highway 41. F o r the two crossings the Quebec Autoroute Authority used two types of over- passes integrated into one long granular fill. The bridge over the rail- way is supported on large hollow concrete box foundations floated in the subsoil; the bridge over the highway is supported on large diam- eter 270-ft (82-m) long end-bearing piles.

T h e decision to support the highway overpass on piles through the compressible clay provided a unique opportunity to study the phe- nomenon of negative skin friction. The clay subsoil, consolidating under the weight of the sand embankment, would transmit an axial load through skin friction to the piles. The magnitude of this load and its distribution with depth was unknown and yet was so important in the economical design of the piles. T h e Soil Mechanics Section of the Division of Building Research (DBR), National Research Council of Canada, with the cooperation of the owner, designer, contractor, and soils consultants for the project was privileged to design and carry out an extensive instrumentation program to study this problem.

Soil Conditions

The subsoils at the site are marine deposits of the ancient Cham- plain Sea [l].%s shown in Fig. 1, the upper 60 ft (18 m) consist of layers of sand, silty clay, stratified sand and silt, and stratified clayey silt. T h e in sit11 water content varies from 28 to 60 percent with the liquid limits equal to or less than the natural water content. The initial undrained shear strength measured in sit11 with a field vane varies from 300 to 1200 psf (0.15 to 0.59 kg/cm2). Remoulded strengths measured

it1 sit11 by the field vane vary from 20 to 50 psf (0.01 to 0.02 kglcm").

Consolidated undrained triaxial tests on samples taken from 9 ft (2.7 m) and 50 ft ( 1 5 m) indicated an effective friction angle

4'

of 27 and 28 deg, respectively.From 60 to 240 ft (18 to 73 m) the soil changes to gray silty clay with water contents of from 35 to 60 percent. This zone is stronger than the material above, as indicated by the penetration resistance to : ' T h e italic numbers in brackets refer to the list of references appended t o this paper.

BOZOZUK AND LABRECQUE ON COMPOSITE PILES 17

F I G . I - S o i l prc<filr c r i r t l .sritrrt~ror.y (!/' rrsr clo/tr. ( A ) .srr.cJ.s.c otrtler c.errro. lirrc t ! l ' 3 0 7 / i

c~rtrOtrt~l;rtrc~rr, 111illr 11'rrrr.s ( ( ! p e r B o r i s s i r r ~ s q ) : ( B ) , f i t ~ o l srr.c,.ss c!fic,r c , r i r ~~.tr.s rtrtrtlo f i w

H i . q l r ~ t ~ r y 4 1 ; (C) o~~erc~orrsolicltr~iorr pre.r.srrre ,qi~,etr hy Terr.trrc,c~l~ Lrd. fkorrr 10 ro IZO,fi: ( D ) l~os.sihle o~~ercorr.solicltr~io~r .fi.orrr 70 f i 10 het1r.oc.l;; otrtl (P,',) irriritrl c:ffi.c.ri~,c, ,srr.e.c..s.

the driving of a 2-in. (5.08-cm) diameter cone and by the field vane tests. The strength increases from 1200 psf (0.59 kg/cm2) at a depth of 60 ft ( 1 8 m) to 1800 psf (0.88 kg/cm2) at a depth of I10 ft (34 m), and the remoulded strength varies from 20 to 190 psf (0.0 1 to 0.09 kglcm". The effective friction angle of the soil within this depth range varies from 22 to 75 deg. The gray silty clay formation is underlain with 30 ft (9 m) of fine sand which in turn rests upon shale bedrock. Consolidation tests indicate that the material is normally consoli- dated to a depth of 40 ft (12 m), overconsolidated by 0.3 ton pel- square foot (0.3 kg/cm" to a depth of 70 ft ( 3 1 m) Line C , Fig. I , and over- consolidated by 0.8 ton pel- square foot (0.8 kg/cm2) below this depth, Line D, Fig. 1.

This test information indicates that the deeper overconsolidated silty clay formation is the original deposit of the Champlain Sea. T h e salt concentration in the pore water of 20 g/liter at a depth of 240 ft (73.2 m) suggests that the soil was deposited in a marine environ- ment. The normally consolidated shallower soils appear to have been reworked and redeposited in fresh or brackish water in which the salt concentration was as low as 3.4 glliter. In constructing large embank- ments on this soil, considerable settlement could be expected, mostly due to the consolidation of the upper 70 ft of the soil profile.

Embankments and Structu~.es

T h e approach embankments, the two bridges and the interconnect- ing fill (Fig. 2) form a structure about l/2 mile (0.8 km) long, rising to a height of 30 ft (9 m). It is 90 ft (27 m) wide at the top with side slopes 2 : 1 , stabilized by 7-ft (2.1-m) high berms having a width of about 300 ft (92 m) from toe to toe. Because the subsoils are very weak and highly compressible, the fill was constructed in two stages. Late in 1964 a preload fill of about 15 ft (4.6 m) was placed in an attempt to increase the strength of the upper soils and thereby reduce the risk of failure of the embankment. This first stage, which did not cover Highway 4 1, was left in place for about six months. The second stage, placed during July to November 1965, raised the fill to a few feet above finished grade. The embankment was then extended to cover Highway 41 early in November 1965, increasing the vertical stresses under the center line to that shown by Line A, Fig. I .

The bridge has prestressed concrete beams and a reinforced con- crete deck slab 90 ft (27 m) wide by 150 ft (46 m) long supported on two concrete abutments, each carried by six 39-in. (I-m) diameter piles seated 8 ft to 10 ft (2.4 to 3 m) into bedrock (Fig. 3). The piles consist of a '/z-in. (1.3-cm) thick steel tube filled with concrete. In each pile 22% tons (20.4 metric tons) of number 18-S deformed rein- forcing bars were installed, varying in number from 8 at the top to 23 at the bottom. The reinforcing bars were high strength steel, ASTM Specification for High-Strength Deformed Billet-Steel Bars for Con- crete Reinforcement with 75,000 psi Minimum Yield Strength

Autoroute

Hwy 41

(b) Cross-section of Abutment, Footings ond Pile Foundation

20

(A-43 1-66). This composite section had a design capacity of 2000 tons ( 1 8 14 metric tons) of which the designers allowed 1200 tons (1090 metric tons) for skin friction. The construction details for the piles and the overpass were described by Verroneau [2].

In November 1966 the f i l l over Highway 41 was removed to permit constl-uction of the bridge abutments reducing the centel- line stresses to that shown by Line B, Fig. I. The piles were cut down to elevation +22 (+6.7 m) and reinforced concrete footings up to 6 ft (1.8 m) deep and 8 ft (2.4 rn) wide cast over them to form a rigid support for the abutments. T o resist the lateral forces tending to push the piles and the abutments inward, reinforced concrete footings 3 ft (0.9 m) wide by 6 ft (1.8 m) deep were placed across Highway 4 1, as shown in Fig. 3. The abutments were then constructed and backfilled, and the bridge completed. This section of the autoroute was opened to traffic at the end of June 1967.

Estimated Skin Friction

Before the instrumentation was designed, preliminary estimates of soil settlement, skin friction load, and pile shortening were made. From consolidation tests i t was estimated that about 8 ft (2.4 m) of settlement would occur in the upper 130 ft (40 m) of soil; the total settlement was expected to exceed 10 ft (3 m).

Field studies of Johannessen and Bjerrum [3] suggested that negative skin friction is related to the effective stresses in the ground. They proposed that the unit skin friction be determined from F,, = cr,.' ( K tan ct,,,') where a , ' is the vertical effective stress, K is the ratio of horizontal to vertical stress and

(p,,'

is the effective friction angle. For the Norwegian soil studied, K tan 4,,' was found to range from 0.12 to 0.20. For conditions at Berthierville it was assumed initially that F,, = 0. 1 8 a t 1 . If the negative skin friction developed to the bottom of the silty clay formation under the effective stress, Line B (Fig. I), a total negative skin friction load of 1470 tons (1340 metric tons) could be expected after consolidation was completed under the overpass. Assuming that+,,'

= 26 deg and K = 0.7 are representative values for the soil profile, the total skin friction load could be as high as 2700 tons (2450 metric tons) under the effective stress, Line B. These esti- mates are based on the assumption that the soil to a depth of 240 ft would settle relative to the pile, creating a downdrag over most of its length. This may be a conservative assumption.For the actual design value of 2000 tons (I 8 14 metric tons) the verti- cal compression for each pile was calculated to be about 1.4 in. (3.56 cm). This was based on the assumption that by adding '110 of the area of the concrete to the area of steel at any cross section, the elastic

BOZOZUK AND LABRECQUE ON COMPOSITE PILES 21

modulus of steel (30 X l o G psi or 2.1 1 x 10%g/cm2) could be applied

over the equivalent area. Instrumentation

Following this assessment of probable soil settlement and pile de- formation, instrumentation was prepared to measure:

( u ) magnitude and rate of consolidation of the subsoils under the

highest part of the fill and in the vicinity of the piles; and

( 6 ) magnitude and rate of vertical pile deformations due to the devel-

opment of negative skin friction and t o the loads imposed by the bridge. T o study the rate and magnitude of consolidation, ten settlement gages [ 4 ] , a deep bench mark [ 5 ] , and eight "Geonor" piezometers were installed during the period from March to May 1966 at the depths and locations given in Tables 1 and 2.

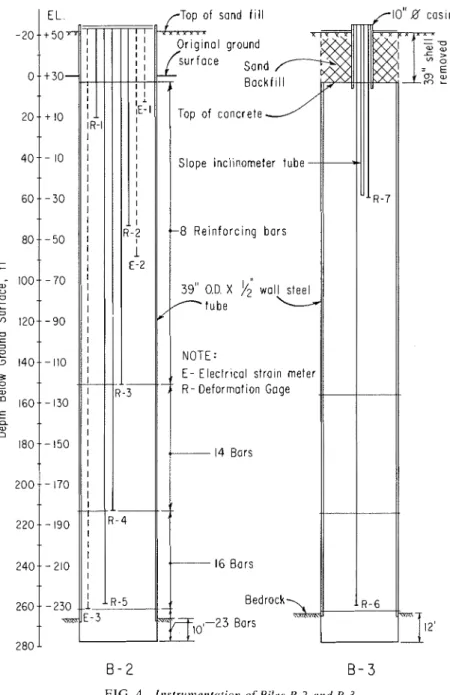

Two piles nearest the highway center lines, B-2 and B-3 (Fig. 3), were selected for detailed study. In B-2, the instrumentation [ 6 ] (Fig. 4) consisted of five deformation gages, three electrical strain meters containing thermocouples, and a differential movement gage between the steel shell and the concrete.

T h e instrumentation in Test Pile B-3 (Fig. 4) consisted of two de- formation gages and a slope inclinometer tube. T h e inclinometer tube was to be used for measuring lateral pile movements during and after construction of the bridge. Unfortunately, during the construction of the abutments the top of the tube was blocked so that the latter meas- urement could not be made.

T h e deformation gages and strain meters were located so that they coincided with joints or changes in the steel reinforcing. As negative

T A B L E 1 - Loctitiorl c?f'srrrlen~ent gcrges. Depth Below

Original Ground

No. Surface. ft 1-ocation

S- I ... 100 3 ft east of Q. 133 ft south of B-2 S-2 ... .... 60 3 ft east of Q. 138 ft south of B-2 S-3 ... 40 3 ft east of Q. 143 ft south of B-7_ S-4 ... 20 3 ft west of Q, 135 ft south of 8-2 S-5 ... -I 3 ft west of Q. 140 ft south of B-2 S-6 ... 10 I ft from Test Pile B-2

S-7 ... 6 1.5 I ft from Test Pile B-2

S-8 ... 1 I 22 ft east of Q. 10 ft ~ 0 ~ 1 t h of 8 - 2 S-9 ... 6 1 22 ft east of Q. 7 ft ~ 0 ~ 1 t h of 8-2 S-I0 ... 145 on Q. 180 ft south of 8 - 2 T - I 1 ... 0 on Q. 170 ft south of 8-2 DBM ... 375 ft east of Q. on north shoulder

22

TABLE 2 -Location of piezometers and pore pressitre measurements.

Depth Below Original Ground No. Surface, ft P-l ... 48 P-2 ... 60 P-3 ... 20 P-8 ... 87 P-4 ... 58.1 P-5 ... 57.6 - -Total Pore Water Pressures,

ft of water Max Min Head Date 58 May1966 90 May 1966 21 May1966 121 Aug. 1966 79 May 1966 78 May 1966 Head Date 45 Feb. 1968 79 Feb. 1968 19 Feb. 1968 119 Nov.1967 62 Nov. 1966 63 Nov. 1966 P-6A ... 30 28 May 1966 P-6B ... 70 68 July 1966 ... P-7A 10 9 May 1966 P-7B ... 50 47 July 1966 ... 2-8 10 27 Dec. 1964 16 May 1965 Location on Q, 150 ft south of B-2 on Q, 153 ft south of B-2 on Q, 155 ft south of B-2 on Q, 204 ft south of B-2 on Q, 1.8 ft south of B-2 22 ft east of Q, 14 ft south of B-2 in field, 475 ft east of P-1 in field, 475 ft east of P-l in field, 475 ft east of P-l in field. 475 ft east of P-l on Q, 280 ft south of 8-2

skin friction can develop very rapidly [3] they were installed and the concrete placed a s soon as possible after the steel tubes were driven. About two days were required to complete the test piles after the steel tubes were driven.

Settlement and Pore Pressure Measurements

T h e vertical settlements measured under the center line of the high- est part of the embankment are plotted in Fig. 5. From October 1964 t o June 1965 the ground surface had settled 32 in. (82 cm) under the 15-ft (4.6-m) preload fill. Raising the embankment t o a height of 36 ft (1 I m) caused a considerable increase in the rate of settlement. By April 1966, when the piles were driven, the settlement had amounted t o 64 in. (1.64 m). T h e subsequent removal of 3 t o 4 ft (1 m) of fill t o bring the fill back t o grade in October 1966 reduced the settlement rate, but, by the end of 1967, 6 % ft (2 m) of settlement was recorded.

A t a depth of 60 ft (18 m) the soil consultants, Terratech Ltd., measured a settlement of 0.22 ft (6.7 cm) from February 1965 to December 1966. It was evident that most of the measured settlement at the ground surface was due t o consolidation of the upper 60 ft (18 m) of soil.

T h e settlement gages installed by D B R show that very little con- solidation has occurred in the upper 40 ft (12 m) since April 1966. Most of the settlement since then has been due t o consolidation of the soil between the depths of 40 ft (12 m) and 100 ft (30 m). At a depth of 145 ft (44 m) a settlement of 0.05 ft (1.5 cm) occurred from July

BOZOZUK AND LABRECQUE ON COMPOSITE PILES 23

8 - 2

8 - 31966 to December 1967, indicating that negative skin friction was developing in the piles to depths greater than this.

Under the initial 15 ft (4.6 m) preload fill, the pore pressure response at a depth of 10 ft (3 m) was approximately 64 percent of the applied load. This dissipated to about 23 percent by the time the second stage was started. Unfortunately, the piezometer at this location ceased to function when the fill height was increased so that further measure- ments could not be obtained. Pore pressures measured with the new piezometers installed in May 1966 are recorded in Table 2. T h e pore pressures at four depths in the field some 475 ft (145 m) away from the center line of the fill showed almost hydrostatic conditions with the ground water table about 1 ft (0.3 m) below the surface.

Under the center line of the fill the excess pore pressures at depths of 20 and 48 ft (6 and 15 m) were quite small, and they dissipated com- pletely by February 1968. At a depth of 60 ft (18 m) the measured pore pressure was 70 percent of the applied load, and this reduced to 46 percent by February 1968. At the 87 ft (28-m) depth the pore pres- sure was 92 percent of the applied load, dissipating to 87 percent at the end of 1967. These pore pressure measurements show that during this period most of the settlement was due to consolidation of the soil between the depths of 20 ft (6 m) and 87 ft (28 m). T h e very slow rate of dissipation below the 87 ft (28-m) depth indicates that a consider- able length of time will be required for full consolidation of the deeper soils.

When the fill was extended to cover Highway 41, Terratech Ltd. measured the subsequent settlement at the ground surface and the pore water pressures at a depth of 10 ft (3 m). Samson [7] reported that this short section settled 3.9 ft (1.19 m) in eleven months. At a depth of 10 ft (3 m) the pore pressure response was 85 percent of the applied load, and it dissipated to 11 percent in the same period.

T h e ground movements and pore water pressures in the vicinity of Test Pile B-2 are shown in Fig. 6. At a depth of 10 ft (3 m) the settle- ments were about the same 1 ft (0.3 m) and 24 ft (7 m) from the pile. T h e pore pressures behaved in a similar way. T h e excess pore pressures at a depth of 58 ft (18 m) were almost identical 1 ft (0.3 m) and 25 ft (8 m) from the pile. T h e settlements measured at the 61 ft (19 m) depth did not follow the same pattern. N o explanation can be offered for the smaller settlement 23 ft (7 m) from the pile.

When the fill over Highway 41 was removed the measured rebound was about 0.5 in. (1.3 cm) at distances of 1 and 24 ft (0.3 and 7 m) from the pile at a depth of 10 ft (3 m). T h e soil consultants measured a rebound of 1.7 in. (4.3 cm) of the ground surface at the center line of Highway 41. Correspondingly, the reduction in pore water pressures at a depth of 58 ft (18 m) was about the same 1 ft (0.3 m) and 25 ft

BOZOZUK AND LABRECQUE ON COMPOSITE PILES 27 (8 m) from the pile. These measurements indicate that the pile has little influence on the surrounding soil mass more than 1 ft (0.3 m) from its surface.

Expansion of Piles

For Pile B-2 the initial readings on the strain meters and thermo- couples were taken immediately after the concrete was placed. Due to uncontrollable circumstances, the deformation gages were completed and read six days later, emphasizing some of the difficulties with ob- taining good field measurements. Owing to hydration of the cement, the temperature had increased about 15 F close to the pile wall, then decreased slowly for about two months until it reached equilibrium with the surrounding soil. The temperatures at the three strain meter locations after six days and at the end of five months are given in Table 3.

In the first six days the strain meters showed that the concreted piles compressed initially as the fresh concrete setup, followed by expan- sion as it hydrated (Fig. 7). It is not known how much shrinkage oc- curred or when the concrete started to expand, but on the sixth day it was in the process of expanding. T h e deep strain meters E-2 and E-3

showed that the pile expanded for about a month, after which there was relatively little change for six months. At the top of the pile the concrete was continuously under water. This must have affected the concrete, for it continued expanding until strain meter E-1 failed six months later.

These observations were a complete surprise because the pile was expected to compress under the negative skin friction loads. T h e deformation gages also indicated that the pile was expanding, show- ing that the expansive forces of the hydrating cement had exceeded the negative skin friction loads. T h e measured deflections in Fig. 8 showed that during the first two weeks the pile elongated rapidly be- fore levelling off at 0.05 in. (1.3 mm) on 20 May. At this stage the expansive forces of hydration and the skin friction loads must have been about the same. Vertical compressions were then expected as the skin friction loads continued to increase with time. On 26 May, TABLE 3- M e o s ~ ~ r e d ternpernltl~res it1 concrete, 3 iri.f,orn steel sliell i r ~ T e s t Pile 8 - 2 .

Depth Below Temperature Temperature Equilibrium

Thermocouple Original Surface, of Raw (aFter 6 Temperature (after

N o. ft Concrete, deg F days), deg F 5 months), deg F

E-1 ... 12 50 5 8 41.1

E-2 ... 88 5 2 66 49.6

however, a sudden expansion was noticed, increasing the total elonga- tion of the pile to 0.06 in. (1.5 mm). This could only be explained as a bond failure between the concrete and the steel wall, allowing the concrete to slide up inside the steel tube. Attempts were made to measure the relative movement between the concrete and the steel casing, but no further movements were detected. After 26 May vertical compressions were measured until the fill over Highway 41 was re- moved. D u e to the stress release, the subsoils rebounded around the piles, causing elongation to 0.26 in. (6.6 mm).

F o r Test Pile B-3, located on the other side of Highway 41, initial readings on the deformation gages were obtained four days after the concrete was placed. T h e observations were similar to that of B-2. Owing to hydration of the cement, the pile elongated initially about 0.07 in. (1.8 mm) before it started to compress again under the neg- ative skin friction loads. T h e removal of the fill over Highway 41 caused this pile to elongate to about 0.32 in. (8.2 mm), which was the same order of magnitude as that for Pile B-2.

The complicated interaction between concrete and steel in these composite piles has concealed the true strains so that the true stresses cannot be computed accurately. As concrete itself increases in strength as it ages, the elastic modulus of deformation of the composite pile will increase with time. I t was necessary to make a fresh start with piles containing well-aged concrete and free of negative skin friction loads. When the fill was removed from Highway 41 and the test piles exposed, an attempt therefore was made to eliminate the skin friction loads with electroosmosis.

Electroosmosis

T o relieve the negative skin friction loads, the pore pressures in the soil immediately adjacent to the pile would have to be increased until the effective stresses were reduced to zero. This could be achieved by passing a d-c current through the soil using the test pile as a cathode and two neighboring piles 44 ft (1 3 m) away as anodes. Because of the variable soil profile and the increase of salt content in the pore water from 4 g/liter in the upper layers to 20 g/liter near the bottom of the soil profile, the electrical power requirement was difficult to evaluate. A rough estimate was 30 V dc at 4000 A applied for 30 min [8]. Be- cause this amount of power was not available, the experiment was car- ried out in December 1966 using a 50-kVA a-c gas-driven generator normally used for driving a 500-A d-c welding machine. Pile deforma- tions were measured during the experiment. T h e power was applied until all measurable deformations had ceased. For Pile B-3, an aver- age current of 475 A at 20.5 V was applied for I l/z h, in which time the

BOZOZUK AND LABRECQUE ON COMPOSITE PILES 31

pile shortened about 0.01 in. (0.25 mm). F o r Pile B-2, a current of 475 A at 17.5 V was applied for 2'12 h. Its effect o n the behavior of the pile is shown in Figs. 7 and 8. T h e marked change in the output of strain meters E-2 and E-3 shows that the electroosmosis was at least partially effective t o the bottom of the pile. T h e deformation gages supported this observation, as the pile deformed differing amounts t o varying depths, resulting in a total reduction in length of 0.01 in. (0.25 mm).

T h e r e was no direct way of gaging the effectiveness of electro- osmosis in eliminating the negative skin friction loads. T h e pore pres- sures in the vicinity of the piles could not be measured a s the piezom- eters had been damaged during the excavation over Highway 41, prior t o the experiment. Because the piles compressed instead of ex- panding during the application of electroosmosis, they must have been in tension due t o soil rebound after the fill was removed. T h e small compression indicates that the skin friction loads were small a t this stage. T h e field measurements therefore were continued on the as- sumption that any residual negative skin friction loads would b e in- significant after the application of electroosmosis.

Pile Colnpressions

T h e axial compressions measured in Piles B-2 and B-3 since the application of electroosmosis are shown in Fig. 9. T h e piles have been compressed 0.6 and 0.5 in. (1.5 and 1.3 cm), respectively, after o n e year and have continued t o compress with time. About 70 percent of this amount occurred in the first six months when the bridge was con- structed and backfilled.

T h e compression curves show that most of the negative skin friction load has developed down t o a depth of 15 1 ft (46 m), but some com- pression was observed in the pile t o a depth of 215 ft (66 m). This indicates that, as the pore pressures continue t o dissipate at these depths, greater negative skin friction loads will develop in the future. T o compare the pile behavior before and after electroosmosis, the deformations in Pile B-2 were replotted in Fig. 10. Hydration of the cement caused an overall expansion of 0.06 in. (1.5 mm), which is quite small taken over the length of the pile. Greater elongations oc- curred when the soil rebounded after the fill was removed from High- way 4 1. Following electroosmosis the pile began t o be compressed. T h e effects of bridge loading, backfilling, and the subsequent negative skin friction loads were much more pronounced and extended the full length of the pile. If the modulus of vertical deformation of the com- posite piles can b e determined, it should b e possible t o estimate the load distribution from the measured compressions.

32

I

I

'

"

A C C C R - l (20'1-

0 . 2 - - - - R-3 ( 1 5 1 ' ),i

0 . 4 -a

Abutment under c o n s t r u c t i o n ' C - 0 .-a

Abutment concreted 0 . 6 - B r i d g e deck beams i n s t a l l e d ,- R-5 1259')FIG. 9- Verticnl cottlpressiurls it1 Piles B-2 atzd B-3 sitlce electroosnzosis.

a - E

0 0

Ban

( a ) Test p i l e 8 - 2 - _f 0 . 4 - - lbl Test p i l e 8 - 3 R-6 (259'1 - - 0 . 6 I l l 1 / 1 1 I I I I I I I I A 8 u-

\

y

I

.I 0 . I .3 .2 . I 0 . I 0 . I .2 .3 . 4 .5 .6 Expans~on, ~n Compression, ~n - I I I 1 I I I I I I IFIG. 10-Expansion crtld cotnpressiotl of Pile 8-2. ( A ) expnt~sion crfter 50 days; (B)

expansion followitlg Jill renzuvrrl f i o n ~ H i g h ~ v n y 4 1 ; ( C ) ns.srrtt?ed dnlrrtn ~if1c.r eleclru- osmosis (20 D e c . 1966); (D) compressiotl before ublrltnetzl slnrted; ( E ) cunlpressiotl nfier abrrlment completed; (F) cotnpression crfier a b ~ r l m e t l l bnckjilled; and (G) corn- pression on 14 F e b . 1968. ; 0 . 0 U i . _ L i - m - - .- R-7 159') X a 0 . 2 - - @ Backfilled I l l 1 D J F M A M J J A S O N D J F M A M 1967 1968

33

Estimate of Pile Load and Skin Friction

Immediately after they were driven, the steel shells were subject to compression as the negative skin friction loads developed. When filled with concrete, the expansive forces of hydration introduced tensile forces. Furthermore, the increased temperatures due to hydration and the subsequent temperature dissipation created additional stresses. By the time the fill was removed from Highway 41, eight months after the piles were installed, the composite concrete and steel sections should have attained a relatively stable condition. When the negative skin friction loads were eliminated or reduced with electroosmosis the test pile should have attained axially a relative stress-free state with respect to the surrounding soil. Measurement of the deformation modu- lus at that time would permit the determination of additional loads and their distribution along the pile from subsequent compression measure- ments. This measurement may be made from laboratory tests on con- crete filled steel tubes, from test loading a model of the prototype, or from direct field measurements.

Gardner and Jacobson [9] conducted numerous uniaxial strength tests on various sizes of concrete-filled steel tubes and control cylin- ders. Their test curves were used to determine an elastic modulus at 50 percent of the failure load for each of their specimens (Table 4). The deformation moduli of the concrete-filled tubes were then calculated from:

where:

A = total cross-sectional area, A , = cross-sectional area of steel, A,. = cross-sectional area of concrete,

E , = elastic modulus of steel, and

E, = elastic modulus of concrete, obtained from the control cylinders,

assuming that the vertical strains in both the concrete and the steel were equal. T h e values listed in Table 4 show that the calculated mod- uli were a little less than the test values.

This method was used to estimate the moduli of deformation of the test piles at Berthierville. A number of control cylinders 6 in. (15 cm) in diameter by 12 in. (30 cm) long, obtained at the time the piles were constructed and cured in a temperature-controlled humid room, were loaded uniaxially to failure after different periods of time. T h e failure strengths and the secant moduli measured at 1 1 , 2 6 , 180, and 369 days are given in Table 4. The failure strengths and the secant moduli in-

0

rn

n

Control Cylinder

z

nDeformation Modulus D, psi E

Specimen Diameter. Length, ASIA. f

:..

Ec.

Es , D zNo. in. in. '5% psi psi psi Calculated From Load Test o rn

I ... 4.003 6 0 1 1.70 4990 4.14 x 101; 30.03 x 1 0 9 . 2 x 1 0 P . 2 x 10"

%

3 ... 4.004 8.003 11.76 4990 4.14 30.03 7.2 8.8 o rn 5 ... 4.750 41.34 13.12 4800 4.13 27.78 7.2 7.1 rn 0 8 ... 4.757 9.50 1 13.01 4800 4.13 27.78 7.2 8.6 -n 12 ... 6.012 66 8.1 1 3360 3.22 29.50 5.4 4.8 o C 14 ... 6.008 12.005 8.09 3360 3.22 29.50 5.4 7.9 z 18 ... 3.01 1 60 8.69 3620 3.29 28.68 5.5 5.2 0 19 ... 3.009 5.998 8.68 3620 3.29 28.68 5.5 5.9g

29.0 0 h4odel pile ... 16.003 60.000 7.72 6390 (27) 4.18 6.1 6.3 z B-2 ... 39 7.70 4975 ( 1 1) 4.60 "30 6.6 9.9 after 10 months 5639 (26) 5.66 '"30 7.5 7003 (180) 5.80 "30 7.7 8029 (369) 6.36 :': 3 0 8.2 B-3 ... 39 7.70 ::- 3 0 9.5 after 10 monthsNOTE- 1. lnforniation on specimens I to 19 obtained from Gardner &Jacobson, 1967. 2. '"assumed values.

3. ( )-age of concrete in days. 4. ASIA -area of steel/total area. 5. f:.-failure strength of concrete.

6. E,.-secant modulus of concrete at 50% of failure load. 7. Es-Young's modulus of steel.

BOZOZUK AND LABRECQUE ON COMPOSITE PILES 35 creased greatly during this period. The calculated modulus of deforma- tion of the pile also increased from 6.6 X 10" psi (0.475 x 10" kg/cm2) at 1 1 days to 8.2 X 10" psi (0.577 X 10" kg/cm2) at 369 days. For ten- month-old concrete the modulus would be about 8.0 x 10" psi (0.563

x

1 0"g/cm2).

T h e pile compressions were measured at various stages of bridge construction; therefore, it was possible to obtain a field value of the modulus of deformation. The embankment had been removed to a dis- tance about 50 ft (15 m) beyond the pile groups, and a steel sheet pile wall driven to a depth of 30 ft (9 m) at the toe of the slopes to prevent a toe failure. T h e electroosmosis, together with this construction, should have eliminated all skin friction loads in the top part of the pile. Therefore, the compressions measured with the shallow deformation gages under various bridge loadings should give a good field value for the modulus of deformation.

T h e weights of the various bridge components supported by the test piles are given in Table 5. Because the tie beams were cast directly onto the ground, it was considered that this load was not carried initially by the piles. For Pile B-2, the load from the abutment and deck slab of 407 tons (369 metric tons) caused an axial compression of 0.0125 in. (0.32 mm) to a depth of 20 ft (6 m) giving a modulus of deformation of 9.9 x

10"si (0.697 kglcm" (Table 4). For Pile B-3 the abutment load of 23 1 tons (210 metric tons) caused a compression in the pile of 0.0249 in. (0.63 mm) to a depth of 59 ft (18 m) giving a modulus of 9.5 x

10" psi (0.668 x 10" kg/cm2) (Table 4). The average of 9.7 x 10" psi (0.682 x 10" kg/cm2) was 2 1 percent greater than the estimated 8 X 10" psi (0.564 x 10" kg/cm" for a ten-month-old pile.

T o obtain an additional check on the modulus, a model pile 16 in. (40 cm) in diameter by l14-in. (6.35 mm) wall steel tube 60 in. ( 1 53 cm) long filled with 5000-psi (2.4 kglcm" concrete was'constructed at the Division of Building Research. Seven deformed steel vertical reinforc- ing bars 3/4 in. (1.9 cm) in diameter were added to keep the steel-con- Crete ratio the same as in the prototype. The concrete was prepared using the same mix proportions and retarding agent as that used for

T A B L E 5 - Weig11r.s of' hriclgr conlporierirs tipplierl ro Pi1c.s B-2

OIICI B - 3 .

Load, tons

Components Pile B-2 Pile B-3

...

Abutment, wing walls, footings 237 23 1

...

Deck slab, asphalt, etc. 170 170

...

Earth pressure on abutment beam 17 17

the field piles. After curing under humid conditions for four weeks the pile was loaded to 200 tons (181 metric tons), which was about 30 percent of its capacity. T h e deformation modulus of 6.3 x 10"si (0.44 X lo6 kg/cm" (Table 4) is about the same as the calculated value. T h e model pile will be reloaded after different time periods to investi- gate the increase in modulus with time.

Although the modulus of deformation measured in the field was sig- nificantly greater than those determined from laboratory tests, to determine a load distribution in the pile a value of 9.7 x 10" psi (0.682 x lo6 kg/cm2) was assigned to the upper part containing eight steel reinforcing bars. This was increased to 10.0 X 10" psi (0.704 x

10" kg/cm" where the number of bars was increased to fourteen, and 10.2 x 10" psi (0.719 X 10"g/cm2) at the bottom of the pile where there are sixteen bars. Using these moduli, the load distribution in Pile B-2 was determined for the survey carried out on 14 Feb. 1968, and the results are plotted in Fig. 11.

The accuracy of the measured load of 1470 tons (1336 metric tons) at the top of the pile is open to question. The difference between this

- 3 0 0

0 4 0 0 8 0 0 1 2 0 0 1 6 0 0 2 0 0 0 I n c r e a s e i n A x i a l L o a d S i n c e E l e c t r o o s r n o s i s , t o n s

37 value and the 546-ton (496-metric ton) bridge load cannot be due en- tirely to skin friction. Near the top of the test pile the effective stresses in the soil are small; therefore, the negative skin friction loads cannot be very great. Part of the excess load could have been transferred from the neighboring piles. Their location with respect to the embankment places these piles in a region of greater effective stress, and, there- fore, they have to support greater skin friction loads. As all the piles are rigidly connected to the heavily reinforced pile cap and footing complex (Fig. 4), there may be a substantial load transfer. There is also the possibility of instrumentation errors due to shrinkage of the concrete within the abutment. T h e upper part of the gages was cast into the pile cap and abutment early in 1967. The leads from all deforma- tion gages now terminate in a well at elevation +33 ft (+I1 m). When the abutment was exposed to the atmosphere the concrete was free to dry out. This would normally result in some shrinkage. Any shrinkage around the deformation gage would affect the measurements. Eventu- ally shrinkage will cease, so that this effect will become constant. As no deformation gage was installed to the top of the test pile, it was not possible to determine the amount of shrinkage, nor the proportion of the excess load due to load transfer.

T h e dashed line in Fig. 11, drawn roughly through the midpoints of the load rectangles, is an attempt to obtain the most probable load dis- tribution curve for the pile. I t shows that negative skin friction loads were occurring to a depth of about 180 ft (55 m). Below this depth the pile loads were partly dissipated by positive skin friction mostly in the dense sand layer overlying the bedrock. This load distribution curve gives values for the unit negative skin friction of 700 psf (0.33 kg/cm2) in the upper 40 ft (12 m) of the pile, and for the unit positive skin fric- tion for the bottom 60 ft (18 m) about 1600 psf (0.78 kg/cm"). These should be considered very rough approximations. As consolidation of the subsoils continues, the skin friction loads will increase, and the

load distribution curve will become better defined. Discussion and Conclusions

T h e engineering literature contains few measurements of the load distribution in full-scale piles subject to negative skin friction. T h e measurements obtained in this field study revealed some unexpected results. Initially the piles elongated about 0.06 in. (1.5 mm) as the cement hydrated. This included what appeared to be a slip of 0.01 in. (0.25 mm) between the concrete and the steel shell. When the fill was removed from Highway 41 the piles elongated further to about 0.3 in. (7.6 mm).

The electroosmosis experiment was considered to be reasonably successful, but to what extent the negative skin friction loads were

38

eliminated could not be ascertained. Subsequent measurement of pile deformation indicated that the negative skin friction loads began to build up again soon after the experiment was finished.

T h e modulus of deformation of the test pile was difficult to deter- mine. Calculations based on results from test cylinders give values that appear to be on the low side. They also show that as the concrete gains strength with time, the strength and the modulus of deformation of the test piles also increase with age. Measurement of the modulus in the field after ten months gave approximately 9.7 X 10" psi (0.682 x lo6

kglcm".

The axial load and its distribution along the pile was determined by applying the modulus of deformation to the compressions measured since electroosmosis. T h e high loads at the top indicated that a sub- stantial load was being transferred from the other piles. It appears that negative skin friction loads are occurring to a depth of 180 ft (54 m), and that some of the pile load is being dissipated in positive skin friction near the bottom. Because of the influence of the neighbor- ing piles and the changing modulus of deformation with time, it is difficult to obtain an accurate assessment of the unit skin friction forces from these field measurements. It is intended to continue the measure- ments for a few more years.

Most of the instrumentation has pelformed well since it was installed two years ago and should continue to provide good measurements in the future. T h e settlement gages and piezometers located at the center line of the highest part of the embankment are providing a good record of the magnitude and rate of consolidation. They have shown that con- solidation has occurred to a depth of 145 ft (44 m) and negative skin friction loads therefore could be expected in the piles to this depth. Of the six settlement gages, only S-2 installed at a depth of 60 ft (18 m) is unsatisfactory.

Within the pile group the piezometers pelformed well until they were damaged by construction equipment. With the exception of S-9, the settlement gages also provided good results until they too were lost. They were effective long enough to show that the pile had little ef- fect on the surrounding soil beyond a distance of 1 ft (0.3 m).

When the strain meters were installed in Pile B-2, it was intended that they would serve as load cells to supplement the deformation gages. T h e field measurements showed that they were unsatisfactory for this purpose. They could be used only to indicate pile behavior as the cement hydrated, as electroosmosis was applied, and as negative skin friction loading developed.

The deformation gages in Test Piles B-2 and B-3 provided a simple and trouble-free measure of pile deformations. Only one gage, R-2, was lost. It performed very well until it was damaged when 5 ft (1.5 m) of

excess concrete at the top of the pile was removed to bring the pile to the required elevation. It is a credit to the c o n t r a c t o ~ that more gages were not damaged.

T h e program revealed a number of details which should be consid- ered when planning similar experiments in the future. Simple and re- liable instrumentation should be used whenever possible. Sufficient settlement gages and piezometers should be installed to provide a good record of the amount and rate of consolidation of the subsoils. T h e bench mark should be located close to the instrumentation to re- duce survey errors, and, if possible, precise level surveys should be run to the test pile. From this and the measured deformation in the pile, it should be possible to determine the extent to which the pile tip penetrates the material below.

When studying a pile within a group, a load cell should be installed at the top in order to measure the load transferred through the pile cap. Deformation gages which must pass through the pile cap or footing should be shielded. If this is not possible, an additional deformation gage should be installed at the top of the pile to provide the needed correction for the other gages. If lateral subsoil movements are ex- pected which could bend the pile. a slope inclinometer tube should be installed so that these movements can be monitored.

Further s t ~ ~ d y of the relative movement between the concrete core and the steel shell is needed. F o r this purpose a differential movement gage should be installed as soon as the concrete is placed.

Better control of constl-uction is necessai-y in order to obtain a re- liable set of initial readings on the instrumentation. In this project it was not possible to observe the behavior of the composite pile until a few days aftel- the concrete was placed.

This field study has provided a set of rare field observations on which to base an approximate evaluation of the I-ate and magnitude of nega- tive skin friction developed under the described conditions. The ex- periences with instrumentation are expected to be of great value in planning additional field experiments.

Ac k t l o ~ ~ ~ l e c l g t ~ ~ c n t s

T h e help and cooperation of the Quebec Autoroute Authority; Petrifond Ltd., the piling contractor: and Terratech Ltd., the soil consultants who provided much of the information reported herein are acknowledged. Special thanks are also due to C. B. Crawford, head. Soil Mechanics Section; P. M. Jan-ett; and other members of the Soil Mechanics staff who assisted at all stages of planning and design. T h e cooperation of all groups enabled the instrumentation to be suc- cessfully installed.

National Research Council, and from Labrecque, Vezina, and Asso- ciates, consulting engineers for the bridge. It is submitted with the approval of R. Trudeau, of the Quebec Autoroute Authority, and of R. F. Legget, director of the Division of Building Research, National Research Council of Canada.

References

[ I ] Karrow, P. F., "The Champlain Sea and its Sediments," Soils irz Catlado, University of Toronto Press, Toronto, 1961, pp. 97-108.

[ 2 ] Verronneau, G . P., "Le Phenomene de la Friction negative etudie sur I'Autoroute Rive-Nord," Getlie Cotlsrrtrcriotl, Vol. 9, No. 5, May 1966, pp. 36-39.

[ 3 ] Johannessen, 1. J. and Bjerrum, L., "Measurement of the Compression of a Steel Pile to Rock due to Settlement of the Surrounding Clay," Sixth International Soil Mechanics Conference, Montreal, 1965, University of Toronto Press, Toronto, Vol. 2, pp. 261-264.

[ 4 ] Bozozuk, M., "A Spiral Foot Settlement Gauge," Cntlndinn Georeclzt~ical Jo~trtzal, Vol. 5, No. 2, May 1968, pp. 123-125.

[ 5 ] Bozozuk, M., Johnston, G . H., and Hamilton, J. J., "Deep Bench Marks in Clay and Permafrost Areas," Field Testit~g of Soils, ASTM STP 322, American Society for Testing and Materials, 1962, pp. 265-279, reprinted as NRC 7289.

[ 6 ] Bozozuk, M. and Jarrett, P. M., "Instrumentation for Negative Skin Friction Stud- ies on Long Piles in Marine Clay on the Autoroute du Quebec," Proceedit~gs, In- ternational Bridge Tunnel and Turnpike Association, 1967, pp. 44-64, reprinted as NRC 10046.

[7] Samson, L., discussion on "Settlement Observations at Kars Bridge" by Eden, W. J. and Poorooshasb, H. B., presented at 20th Canadian Soil Mechanics Con- ference, Lava1 University, Quebec, 1967.

[ 8 ] Casagrande, L., "Electro Osmosis in Soils," Geotecllt~iqrre, Vol. 1 , No. 3, June 1949, pp. 159-177.

[ 9 ] Gardner, N. J. and Jacobson, E. R., "Structural Behaviour of Concrete Filled Steel Tubes," Part 2, available from ACI Depository, first part in Jo~rrtlnl of At~zericut~ Cotzcrere Itlsrirlrre, Vol. 64, No. 7, July 1967, pp. 404-413.