Design and Implementation of a Pair of Robot Arms

MASSACHUSETTS INSTITUTEwith Bilateral Teleoperation

OF TECHNOLOGYby

JUL 16 2019

Alexander Hattori

LIBRARIES

ARCHIVES

Submitted to the Department of Mechanical Engineering

in partial fulfillment of the requirements for the degree of

Bachelor of Science in Engineering as Recommended by the Department

of Mechanical Engineering

at the

MASSACHUSETTS INSTITUTE OF TECHNOLOGY

June 2019

@

Massachusetts Institute of Technology 2019.

A uthor ...

All rights reserved.

Signature redacted

)epartment of Mechanical Engineering

Ma 17, 2019

Signature redacted

C ertified by ...

angbae Kim

sociate Professor

Thesis Supervisor

Signature redacted

A ccepted by ...

IMaria Yang

c

Associate Professor of Mechanical Engineering, Undergraduate Officer

Design and Implementation of a Pair of Robot Arms with

Bilateral Teleoperation

by

Alexander Hattori

Submitted to the Department of Mechanical Engineering on May 17, 2019, in partial fulfillment of the

requirements for the degree of

Bachelor of Science in Engineering as Recommended by the Department of Mechanical Engineering

Abstract

Modern robotics has progressed in the manufacturing industry so that many manual labor tasks in assembly lines can be automated by robots with high speed and high positional accuracy. However, these robots typically cannot perform tasks that re-quire perception or disturbance rejection. Humans are still needed in factories due to their innate ability to understand situations and react accordingly. Teleoperated robots can allow human perception to be combined with the dexterity and safety of a robot as long as the user interface and controls are carefully designed to avoid hinder-ing the operator. Force feedback bilateral teleoperation is one method for providhinder-ing users with an intuitive user interface and feedback. This thesis documents the design, construction, and implementation of a pair of bilateral teleoperated robotic forearms, each consisting of a 2 degree of freedom wrist, and a gripper. The forearm uses com-mercial off the shelf actuators in order to keep cost and additional development time

low, while also testing the feasibility of using non-custom actuators. Development of

the forearms included design and manufacturing of the mechanical assemblies, imple-mentation of high-speed communication protocol, and tuning of control parameters.

Thesis Supervisor: Sangbae Kim Title: Associate Professor

Contents

1 Introduction 9 1.1 M otivation . . . . 9 1.2 Scope ... ... 9 1.3 Thesis Organization. . . . . 10 2 Design 11 3 Manufacturing 15 3.1 G ripper . . . . 15 3.2 W rist/Arm . . . . 17 4 Software Implementation 25 4.1 C ontrols . . . . 25 4.2 Dynamixel Communication . . . . 26 4.3 RS-485 Implementation . . . . 275 Summary and Conclusions 33

List of Figures

1-1 Mechanical forearm assemblies . . . . 10

2-1 Arm assembly and forearm assembly . . . . 11

2-2 Wrist differential . . . . 12

2-3 Gripper assembly . . . . 12

3-1 Parallel gripper links . . . . 15

3-2 Parallel gripper links after each operation . . . . 16

3-3 Finished machined spur gears . . . . 16

3-4 A finished mechanical gripper assembly, and two completed grippers . 17 3-5 Wrist triple bearing block . . . . 17

3-6 The manufacturing process to make the wrist bearing block . . . . 18

3-7 Soft jaw flange clearance . . . . 19

3-8 Haas probe clearance . . . . 19

3-9 Completed timing pulley . . . . 20

3-10 Completed forearm structure . . . . 20

3-11 Plastic damping blocks glued in for machining . . . . 21

3-12 Additional soft jaws for machining forearm structure . . . . 21

3-13 Spacer block used for bearing presses . . . . 22

3-14 Completed forearm assembly and additional completed gripper . . . . 23

4-1 Motor Position Tracking ... . . . . 26

4-2 RS-485 Bus . . . . 27

4-4 OpenCM9.04 Serial Bus . . . . 29

4-5 Decoded serial message . . . . 29

4-6 Control loop frequency shown on channel 3. . . . . 30

4-7 Decreased status response time . . . . 31

Chapter 1

Introduction

1.1

Motivation

Modern robotics has progressed in the manufacturing industry so that many manual labor tasks in assembly lines can be automated by robots with high speed and high positional accuracy. However, these robots typically cannot perform tasks that require perception or disturbance rejection. Humans are still needed in factories due to their innate ability to understand situations and react accordingly. Therefore, because a conventional autonomous robot is not always suitable, human health and life is often put at risk on a factory floor doing laborious tasks like welding and grinding. Teleoperated robots can allow human perception to be combined with the dexterity and safety of a robot as long as the user interface and controls are carefully designed to avoid hindering the operator. Force feedback bilateral teleoperation is one method for providing users with an intuitive user interface and feedback.

1.2

Scope

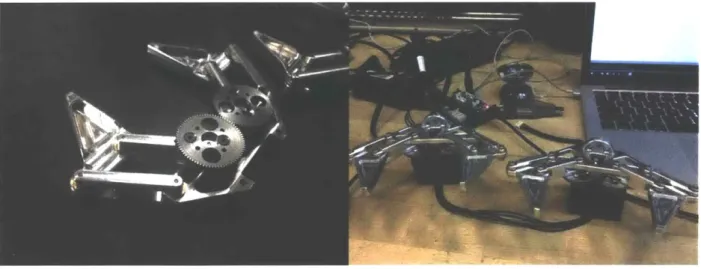

This thesis documents the design, construction, and implementation of a pair of bilat-eral teleoperated robotic forearms, each consisting of a 2 degree of freedom wrist, and a gripper. Each forearm assembly will be attached to an already existing 3 degree of freedom teleoperated robot arm to provide additional user degrees of freedom. The

forearm uses commercial off the shelf actuators in order to keep cost and additional

development time low, while also testing the feasibility of using non-custom

actu-ators. Figure 1-1 shows the completed mechanical assemblies of the two forearms.

Development of the forearms included design and manufacturing of the mechani-cal assemblies, implementation of high-speed communication protocol, and tuning of

control parameters.

Figure 1-1: Mechanical forearm assemblies

1.3

Thesis Organization

"

Chapter 2 details the design of the forearm assemblies." Chapter 3 details the in-house manufacturing of the forearm assemblies. " Chapter 4 details the software and controls implementation of the forearm

assemblies.

Chapter 2

Design

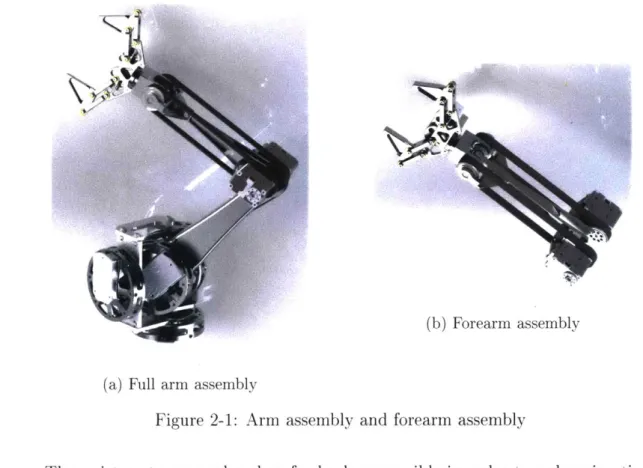

The forearm was designed to be appended to an already existing 3 degree of freedom

arm developed by Ben Katz. Figure 2-la shows the assembly in the context of the

full arm. The forearm assembly is shown on its own in Figure 2-1b.

k~

(b) Forearm assembly

(a) Full arm assembly

Figure 2-1: Arm assembly and forearm assembly

The wrist motors are placed as far back as possible in order to reduce inertia of the forearm assembly. The motors take up almost 20% of the mass of the forearm so keeping them close to the rotational axis was important. They were not placed any

farther back in order to keep the original 3 degree of freedom arm unaltered. The wrist uses a bevel gear differential, shown in Figure 2-2, which allows the wrist to

rotate indefinitely (if not for the gripper wiring).

Figure 2-2: Wrist differential

This differential also allows the wrist to utilize the power of two motors.

When-ever either wrist degree of freedom (bending or rotating) is used independently, both motors can provide torque, effectively doubling the power.

The gripper, shown in Figure 2-3, was designed to be simple and easy to swap.

Figure 2-3: Gripper assembly

Typically, one robotic gripper attachment is not effective for all scenarios so for

the purpose of testing, a simple parallel linkage gripper was used, with the actuator put on the gripper itself. The gripper is attached with a bolt and pin circle and can be swapped for any other tools/attachments in the future. In order to minimize backlash, gears with small pitch were used to transmit torque from the driven to non-driven side of the gripper.

.1

Chapter 3

Manufacturing

Most parts used in this thesis were carefully designed to be as lightweight as possible

while maintaining structure, which made the in-house manufacturing more

compli-cated.

3.1

Gripper

The gripper consisted of many small parts which were all made on a Dyna-Myte 1007

CNC mill in MITERS. The parallel gripper links are shown in a hand for scale in

Figure 3-1.

I

Many parts made for this thesis required multiple setups and fixturing and so an

example of the process of making a single gripper link is shown in Figure 3-2.

Figure 3-2: Parallel gripper links after each operation

The machined gears, shown in Figure 3-3, were parted off spur gear stock, and then post machined on the CNC mill.

Figure 3-3: Finished machined spur gears

A completed mechanical gripper assembly and a pair of finished grippers with

Figure 3-4: A finished mechanical gripper assembly, and two completed grippers

3.2

Wrist/Arm

The parts for the wrist/arm required more fixturing, and so in order to save time, the rest of the machining was done on a Haas VF2 and Haas Super Mini Mill due to their higher power spindles, and zeroing probe.

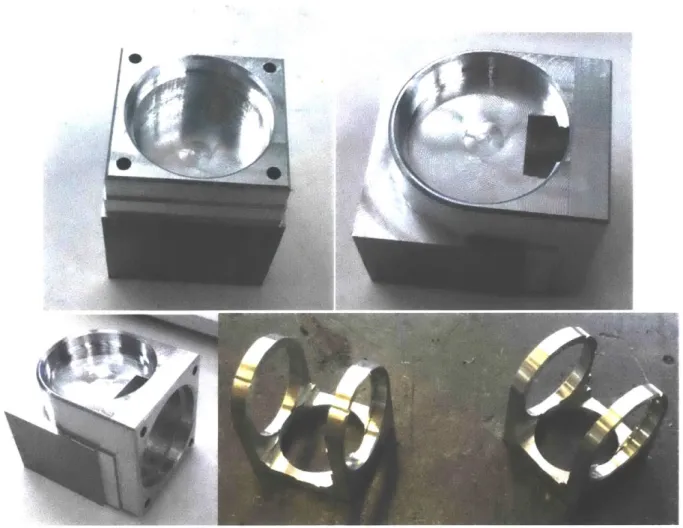

The wrist bearing block, shown in Figure 3-5, was one of the most difficult parts

to machine due to its need for accuracy, combined with its spindly design.

Figure 3-5: Wrist triple bearing block

This part was made in four setups, with the last one removing the majority of the

Figure 3-6: The manufacturing process to make the wrist bearing block

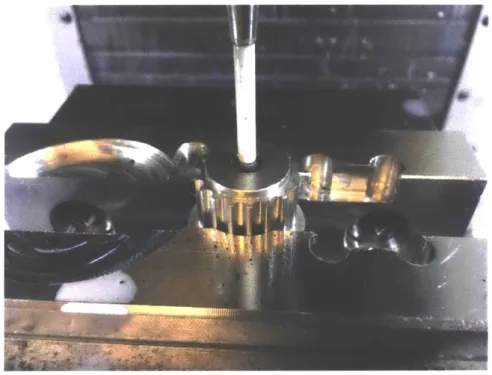

The timing pulleys were made from existing timing pulleys and required unique

fixturing and zeroing. In order to hold the pulley in the vice, a channel had to be milled in the soft jaws to clear the flange. The flange clearance channel is shown in

Figure 3-7.

Figure 3-7: Soft jaw flange clearance

The Haas zeroing probe only barely fit in the stock pulley bore, but it was still

successful. The clearance is shown in Figure 3-8.

Figure 3-8: Haas probe clearance

Figure 3-9: Completed timing pulley

In order to make the main forearm structural piece, shown in Figure 3-10, plastic

blocks (Figure 3-11) had to be glued in between operations to add damping and structural rigidity while machining, and more soft jaws had to be machined (Figure

3-12).

t

Figure 3-11: Plastic damping blocks glued in for machining

Figure 3-12: Additional soft jaws for machining forearm structure

Final assembly of the wrist is semi-permanent and so extra care was taken to not damage any of the spindly parts during assembly. Figure 3-13 shows the spacer blocks

Figure 3-13: Spacer block used for bearing presses

Chapter 4

Software Implementation

4.1

Controls

Each joint in the forearm assembly utilizes pseudo-impedance control in the form of a symmetric PD controller. The difference in position between the two joints is used to calculate the correcting torque. The proportional term acts as the spring constant, and the derivative term provides damping. This PD control is done on each joint directly on the actuator, a Dynamixel XM-430. Each joint attempts to maintain the position on the corresponding joint on the other forearm.

In order to create a realistic haptic feedback experience for the user, in particular when one joint encounters a very stiff obstacle, the individual joints need to be very stiff. This requires a large proportional gain. However, with too high of a propor-tional gain, the system tends to go unstable as the actuators overshoot. Damping can be used to make the system more stable, but this damping affects the user experience because it can be felt as drag in the system. The maximum stable proportional gain can be increased as long as the control bandwidth increases and thus,

communica-tion and control loop speed were heavily emphasized in the software implementacommunica-tion for this project. Figure 4-1 shows position data of two wrist joints trying to track each other's position. Overshoot and underdamping can be seen between 2000-3000 milliseconds.

2100 2000 1900 1800 1700 1600 1500 1400 1300 1200 1100 2000 3000 4000 Time (ms) 5000 6000 7000

Figure 4-1: Motor Position Tracking

4.2

Dynamixel Communication

Communication with the Dynamixel occurs over RS-485 differential serial. An exam-ple of the RS-485 protocol for the Dynamixel is shown in Figure 4-2. Although there

are two signals, only on'e send or receive can be on the bus at a time because the two

signals form a differential pair.

Timing is important in order to prevent corrupt data because all messages are sent and received on the same bus. Position data is retrieved over this serial bus

from the built in 4096 steps/turn absolute encoder on the Dynamixel, and new gains

and position setpoints can be set by sending serial messages. Additional parameters

like temperature, current, and feedforward gains can also be retrieved or set on the Dynamixel but were not used for this implementation [2].

U 0 0

0,

C

Motor position tracking

Motor 1 Motor 2

AI

Figure 4-2: RS-485 Bus

4.3

RS-485 Implementation

Initial communication was done using an OpenCM9.04 microcontroller which contains

an STM32F103. The Dynamixel library from Robotis was used but performance was poor. Even with only a single degree of freedom enabled, the proportional gain could

not be set high enough to resist a human's finger strength without going unstable, unless large amounts of damping was used. Figure 4-3 shows the debugging setup

-j

Figure 4-3: Debugging setup for RS-485

Using an oscilloscope and its built-in serial decoder, the issue with the initial

software implementation became very clear. Figure 4-4 shows a few messages being sent and received on the serial bus.

- - -- - --- - - --- __ -A

Figure 4-4: OpenCM9.04 Serial Bus

Figure 4-5 shows a decoded serial message sent to the Dynamixel.

Figure 4-5: Decoded serial message

Although the messages were being sent and received from the Dynamixel at IM

baud, there were large delays between messages being sent or received. With all three

forearm degrees of freedom enabled, the control loop ran at around 65 Hz, as shown

Figure 4-6: Control loop frequency shown on channel 3.

One simple improvement involved decreasing the status message delay time on the Dynamixel. Whenever the Dynamixel receives a message, it replies to the serial bus

with a status message. By default, the Dynamixel delays 500 microseconds before

responding with this message in order to ensure the serial has finished sending its

message, but due to the frequency and repeatability of commands used to control the forearms, that delay time can be reduced significantly. The initial improvement can

be seen in Figure 4-7 where a reduced latency message is sent, followed by a normal latency message, and a reduced latency message.

Figure 4-7: Decreased status response time

While this did improve communication speed marginally, there are still large gaps between messages sent. Thus, a new implementation of RS-485 for a different

micro-controller was written. Using the ARM MBED Serial library and an STM32F446, communication at 115K baud could be achieved in a few lines of code. IM baud signals dropped bytes and was not achievable using the Serial library's functions. At

115K baud, the delay time between messages was removed, and a control bandwidth

of 193 Hz for the three degrees of freedom was achieved. An oscilloscope screenshot of the serial bus is shown in Figure 4-8.

Figure 4-8: Serial bus with MBED serial library communication.

Serial bus with MBED serial library communication. Channel 2 shows the control loop frequency, and Channel 3 shows the communication signals directly.

At 115K baud communication performance was maximized because messages were

always being sent or received, with no idle time. However, communication could still be improved.

In order to achieve IM baud communication on the STM32F446, Direct Memory Access or DMA had to be implemented because the processor was unable to read all the serial data fast enough.

DMA utilizes a hardware subsystem on the microcontroller to watch for incoming

serial bytes on the microcontroller, and automatically store them in a buffer so that

the processor can access the data in the buffer when it is ready. For this implementa-tion of IM baud serial, DMA was only used for receiving data because the processor could already send serial bytes at IM baud. A future software revision will implement DMA for serial sending as well, in order to increase serial communication to speeds

around 4.5M baud which is the fastest communication the Dynamixel supports [1. With 1M baud communication, a control bandwidth of around 700 Hz could be achieved with all three degrees of freedom pairs on one microcontroller. A notable

stiffness increase was seen, and less damping was needed, leading to a better user experience.

Chapter 5

Summary and Conclusions

5.1

Design Summary

This thesis documents the design, construction, and implementation of a pair of bilat-eral teleoperated robotic forearms, each consisting of a 2 degree of freedom wrist, and a gripper. The forearm uses commercial off the shelf actuators in order to keep cost and additional development time low, while also testing the feasibility of using non-custom actuators. Development of the forearms included design and manufacturing of the mechanical assemblies, implementation of high-speed communication protocol, and tuning of control parameters.

Bibliography

[1] STM32F446 Manual, 2018. [Online; accessed 16-May-2019].

Acknowledgments

The author would like to thank Joao Ramos, Sangbae Kim, Jared DiCarlo, Bayley Wang, Ben Katz, Pat McAtamney, and Harriet Chiu for their help with this thesis.