Publisher’s version / Version de l'éditeur:

Build International, 2, 5, pp. 5-9, 1970-01-01

READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE.

https://nrc-publications.canada.ca/eng/copyright

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la

première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

NRC Publications Archive

Archives des publications du CNRC

This publication could be one of several versions: author’s original, accepted manuscript or the publisher’s version. / La version de cette publication peut être l’une des suivantes : la version prépublication de l’auteur, la version acceptée du manuscrit ou la version de l’éditeur.

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at

Sealed double-glazing in Canada

Solvason, K. R.; Wilson, A. G.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

NRC Publications Record / Notice d'Archives des publications de CNRC:

https://nrc-publications.canada.ca/eng/view/object/?id=c8c107e7-8e7f-4307-aa4f-bcff00b8221a

https://publications-cnrc.canada.ca/fra/voir/objet/?id=c8c107e7-8e7f-4307-aa4f-bcff00b8221a

Ser

TH1

N21r2

no.

420

8c.

2

BLDG

PRICE 10 CENTSSEALED DOUBLE

-

GLAZING IN CANADA

BY

K.

R. SOEVASON AND A.

G.

WILSON

R E P R O D U C E D WITH PERMISSION FROM

BUILD INTERNATIONAL

VOL-

2,

1\10.

5,

J U N E

1969

P.

5 - 9

W I L D I N G RESEARCH

-3

[-p?

,-*.RY

-

RESEARCH PAPER NO. 420

O F THE

-..

, .. . ....-.

DIVISION O F BUILDING RESEARCH

OTTAWA

sea

The use of sealed double-glazing in homes and office buildings is

rapidly increasing in Canada and the manufacture of the components

is also showing a marked rise. This development encouraged the

Building Services Section, Division of Building Research, National

Research Council of Canada (DBR/NRC), Ottawa, t o carry out a lengthy

investigation t o evaluate the various types of factory-sealed double-

glazing

in

that country.

K. R. Solvason and A. G. Wilson, both of whom

are connected with that section of the NRC, describe the r e s ~ ~ l t s

of

their research in the accompanying article

Over the past 1 0 years many manufacturers of factory-sealed double-glazing units have entered the Canadian market, and there has been an increasing use of these compo- nents i n both residential and commercial buildings. In 1961, when the Dominion Bureau of Statistics first began to keep records of their use, the total value of annual production was about 9 million dollars; by 1965, the latest year for w h i c h records are published, the value had risen t o about 1 6 million dollars.

The development and availability of n e w organic sealing materials applicable to the construction of sealed glazing units has been one of the factors that has led t o this growth, and all of the new manufacturers have utilized an organic-type sealing arrangement.

The appearance of such large numbers of brands of sealed double-glazing for which there was no history of field per- formance presented a difficult problem t o the Central Mortgage and Housing Cor- poration ( C M H C ) . This Crown Company is responsible for administering the Nation- al Housing A c t of Canada, including the determination of requirements for accept- ability of materials and components used i n

houses constructed under the Act. Because there were n o published standards or test methods for sealed double-glazing units, the Corporation asked D B R / N R C t o assist i n developing a basis for establishing their acceptability as quickly as possible.

During the early stages of the study that followed, discussions w i t h experienced manufacturers provided much valuable

background information. The provision

and maintenance of a l o w d e w - p o i n t temperature i n the air space was quickly identified as the major criterion of perform- ance. A l o w dew-point temperature is necessary t o avoid condensation and eventual fouling of the glass surface from leaching of sodium salts, which are a nor-

mal component of soda-lime glass. A test

method, described i n Reference 1, t o measure the relative d e w - p o i n t tempera- tures of the air space was established; initial measurements showed a wide vari- ation among units, a number having high values of moisture content.

I t was evident from calculations of the amount of moisture required t o produce excessive dew-point temperatures that only very small amounts of moisture trans- fer t o the air space could be tolerated over

the service life of a unit, even when desic- cants were used. Moisture is transferred t o the space by diffusion of water vapour, or, if a leak exists, as a result of the movement of liquid water or air caused by pressure differences across the seal. These pressure differences are induced by temperature or barometer pressure changes, or by w i n d action, and result i n the transfer of large amounts of moisture if leaks are present. Thus, the unit must be hermetically sealed w i t h materials having a high resistance to water vapour diffusion and must remain sealed throughout its life. The primary problem of evaluation is, therefore, the de- termination of the adequacy of the seal.

I n service, stresses leading t o seal fail- ures (and glass breakage) are imposed on double-glazing units in several ways: by pressure differences between the air space and the surrounding air due t o temperature and barometer pressure changes; b y dif- ferential expansion or contraction of com- ponents caused by unequal thermal expansion coefficients and differential temperatures; by w i n d pressures; and by forces that may develop due t o faulty in- stallation. Sealing systems must withstand the repeated action of these forces and

must also retain the necessary physical properties under normal conditions of ex- posure over their required service life.

The development of methods t o deter- mine the resistance t o chemical degrada- tion of the sealing system under service conditions was regarded as a long-term problem and efforts were, therefore, con- centrated on developing methods of evaluating the ability of the sealing systems t o withstand repeated cycles of stress with- o u t developing leaks. Attention was directed towards methods that could be applied t o the units as a whole, rather than t o the individual components, because the performance of the unit depends upon the interrelation of components and manu- facturing techniques.

Simulated weather cycles

It was decided that for this purpose it was necessary t o accelerate both the effects of various kinds of mechanical stresses that could occur in service and the nioisture transfer process, particularly that due to total pressure differences across the seal, so that tests could be conducted i n a reasonable time. I t was also considered desirable t o stress the sealing systems over the range of temperatures that could occur i n service in order t o expose weaknesses associated w i t h temperature-dependent properties of sealants. The test established for this purpose consisted of exposing one side of the specin~ens t o room conditions controlled t o 73°F (23°C) and' 50 per cent RH, while exposing the other side t o a simulated weather cycle of: heating t o 125

:;:

5°F ( 5 2 & 3°C) over a period of 90min, air circulation alone for 25min, water spraying at 7 5 :i- 5'F for 5niin, air circulation alone for 60min, and cooling t o -25 ::I 5'F (-32: -

3°C) over a periodof 60niin. The apparatus is shown i n Fig-

re 1. The dew-point temperature of the air space after exposure t o the weather cycle was taken as the criterion of seal adequacy.

Because oF the possibility of wide variations in quality from faults in the assembly process, it was decided that several specimens of each brand should be tested. Owing t o space limitations and the large numbers of specimens involved, there was considerable incentive t o use small specimens. A size of 1 4 x 20in, (35.5 :.: 51cm) was selected, somewhat arbitrarily as a practical minimum.

The size (the small dimension particu- larly), the air space thickness, the glass thickness, and the rigidity of the edge, all influence the air pressure differences de- veloped between the air in the space and ambient. The pressure difference, in turn, largely determines the stress imposed on the sealing system under the conditions of test. A rise i n air temperature within the space results in an increase i n pressure, a glass deflection and, hence, an increase i n volume. The pressure rise and deflection are interrelated, so that o n srnall units the deflection is relatively small and the pres- sure rise relatively large. A larger pressure rise occurs with thick glass than w i t h thin because of the smaller deflection. Both pressure rise and deflection increase as the air space thickness increases. The shape of the deflection curve o n the glass

is influenced by the rigidity of the edge arrangement. Larger pressure increases occur with rigid edges, as this arrangement results i q a smaller mean deflection (and, hence, a smaller volume increase).

Exposure i n the weather cycling appar- atus sometimes results in breakage of glass adjacent t o the spacer o n units having rigid sealing arrangements. As there was n o evidence of such occurrences in the field, i t had t o be assumed that this effect was peculiar t o the unit size, glass thick- ness, and rate of change in the cycle. The weather cycling apparatus was, therefore, deemed unsuitable for tests on units hav- ing all-glass edges or glass-to-metal seals.

The structural arrangements at the edges of various units utilizing an organic- type seal are very similar. Brands with several years of good field performance withstood many cycles i n the apparatus, whereas units having poor field perform- ance records failed in relatively f e w cycles. The apparatus, therefore, provides a g o o d basis of comparison of different un- its of this type, provided that the unit size, glass thickness, and air space thickness are the same. Thirty-two oz (4mm) glass and a :in (1.3cm) air space were selected for purposes of acceptance testing.

Some tests were conducted on 2 0

x

2 8 in (51 , f 71cm) and 2 8 :.: 40in (71:<

Figure 1 Weathering apparatus for sealed double-glazing units

102cm) (approx) units t o assess the in- fluence of size. I t was possible t o test only a f e w units because of space limitations. The larger sizes did, however, withstand many more cycles than the smaller ones.

There was n o way of comparing com- bined effects of stresses and moisture transfer potentials produced i n the weath- er-simulating apparatus w i t h those in

service, and it was not possible t o relate

laboratory exposure directly to field con- ditions. It was accepted from the beginning that the test provided only a basis for comparing the behaviour of sealing systems under conditions of fluctuating mechanical stress and temperature com-

parable t o those that might occur i n ser- vice. Tests were, therefore, conducted on specimens of most of the units on the mar- ket, including a f e w for which there was some history of field performance. I n addition, a simple initial screening test t o identify gross leaks i n the seal was adopted: this consisted of determining the ability of a unit t o maintain a deflection of the t w o panes induced by a small change i n ambient pressure.

While the:e initial laboratory tests were being conducted, a few specimens of each brand were exposed t o outdoor weather, mounted i n a vertical position on a plywood support facing south, and de-,+-point

Figure 2 Outside exposure racks

BUILD International, June 1933

temperatures measured periodically (Fig- ure 2). The primary purpose was to expose the specimens t o ultra-violet radiation t o determine whether the sealing systems were sensitive t o failure from this cause.

The results of these initial studies were reported in Reference 1. Based on those results, C M H C established initial require- ments for acceptability. I n tests on 1 8 specimenssubmitted by the manufacturers, at least 1 7 were required t o pass the initial screening seal test and t o have dew-points no higher than 30°F (-1°C). Twelve of the specimens were exposed t o 320 cycles ( t w o months) in the weather cycling appa- ratus and at least 1 0 were required t o have dew-points no higher than 30°Fatthe end. Results of tests on 3 3 sets of units were as follows: units from 2 3 sources passed the initial seal test on first submission; units from 1 0 sources failed, and 9 subsequently passed on re-submission. Of the 3 2 sets that ultimately passed the initial seal test, at least 1 7 failed the weather cycle based on the above requirements. Fourteen of 3 2 sets mounted o n the outdoor racks had at least one failure after one year of exposure.

T e s t i n g m a n u f a c t u r e r s '

p r o d u c t s

Following the establishment of these acceotance reauirements i n 1961. DBR began t o c o n d k t tests on a commercial basis for manufacturers. These were re- quired t o submit a detailed description of the units i n applying t o C M H C for accept- ance, and n o attempt was otherwise made t o ensure that specimens submitted by manufacturers for qualification testing represented typical production. Accept- ance of products by C M H C was, therefore. based on the ability of manufacturers to meet the current test requirements rather than on any positive assurance that the units being marketed met these require- ments.

A t this time, development was begun on a further qualifying test procedure involv- ing exposure of the units t o an elevated temperature cycle of 70-1 30°F (21-54OC) and high humidity atmosphere. One of the purposes of the test was t o provide a high average water vapour pressure, not present i n the weather cycle apparatus, in order to obtain some indication of the resistance of the sealing systems t o water vapour diffu- sion. I n addition, there was need for a simpler qualifying test because of the large volume of testing and the limited capacity of the weather cycling apparatus, as well as for an inexpensive apparatusthat could be reproduced by manufacturers for use in product development. The final form of the

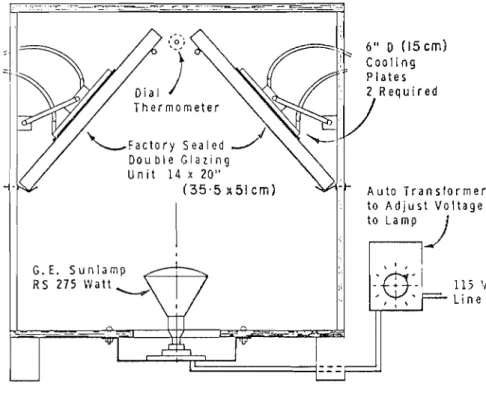

apparatus is shown i n Figure 3. Again, the

dew-point temperature of the air space. following exposure t o the elevated tem- perature cycle, was taken as the criterion of seal adequacy.

During the development phase, an ex- tensive series of tests was conducted t o compare the performance of a number of sets of units exposed t o both the weather

cycle and the high humidity cycle. In

general, brands that failed i n the weather cycling apparatus in less than 320 cycles failed i n the high humidity cycling appara-

tus in less than 24 cycles (four weeks); brands that withstood more than 320 cycles of the former, usually withstood over eight weeks of exposure i n the latter. Exposure t o the high humidity cycle did not cause abnormal failures, such as break- age of the glass adjacent to the spacers, in units having rigid edges. The apparatus was therefore used in evaluating sealing systems of this type as well as those w i t h organic seals.

I n 1 9 6 3 C M H C included exposure of six specimens t o the high humidity cycle as a part of its acceptance requirements, and the number of specimens in the

weather cycle was reduced t o six. I n

1 9 6 4 the requirements for acceptance were reviewed i n relation t o the range of test results being obtained. I t was apparent that the majority of manufacturers could produce units that provided initial d e w - point temperatures below -40'F (-40°C) and values after weather and humidity cycling below 0°F (-1 8'C). I t was observ- ed during the weather cycle that conden- sation sometimes occurred between panes w i t h reference dew-points above 0 F

(-18'C). As a result. C M H C altered the

initial and final d e w - p o i n t requirements t o -40°F (-40'C) and O F (-1 8' C), and a n e w round of qualification testing was begun on this basis.

National standard developed

As a result of widespread recognition of the qulaifying tests being used for C M H C acceptance, they were accepted as the basis of a national standard, preparation of w h i c h was begun in 1 9 6 5 under the auspi- ces of the Canadian Government Specifi- cations Board (CGSB). The CGSB Com- mittee on Sealed Double-Glazing Units consisted of representatives of sealed glazing manufacturers, sealant suppliers, and Government users. Consideration was initially given t o establishing require- ments for t w o grades of units, one based o n the existing C M H C requirements and a second, and higher, grade based on initial and final dew-point temperatures of -60°F (-51 'C) and -40°F (-40°C). Results of the most recent qualifying tests for C M H C at that time indicated that a large percentage of the manufacturers were capable of making units that could meet the requirements of the higher grade. At the urging of the industry representatives, the Committee decided to include only the higher grade.

Staining problems

The Committee was concerned that the tests developed for C M H C acceptance did not include one t o determine the likelihood of glass staining by the condensation of organic vapours evolved from the sealing system. Staining problems had been ex- perienced w i t h many early brands. Tests o n individual components were consider- ed, but preference was given t o a single test o n an assembled unit, a n d the 'Ultra-

Violet Exposure Fogging' test (Figure 4)

was developed for this purpose. Test units are heated t o about 150°F (71 'C) so that if volatiles are present in the sealing system components or have been absorbed b y t h e

desiccant they w i l l be driven off and c o n - dense on the glass area cooled b y the c o o l - i n g plate. An ultra-violet lamp is used for heating because i t was suspected that a breakdown of components of the sealing system might occur under ultra-violet ex- posure. Very faint deposits can be detected if an appropriate lighting and viewing technique is used. Deposits appear to be produced by traces of oil o n spacers, small amounts of resin binder on mineral w o o l used t o retain the desiccant i n spacers, certain glass cleaning agents, and some plastic inserts for spacer corners, as well as b y the sealants used.

To assess theimplications of themethod, tests were conducted on specimens, from all manufacturers that h a d met the other test requirements. Among some 1 7 4 units, no deposit was visible on 54, a faint deposit was visible o n 42, a medium deposit was visible o n 43, and a heavy deposit was visi- ble o n 35.

The results indicated that many manu- facturers could produce units having no deposit or only a faint deposit. Further- more, there was no evidence of field problems o n brands having only faint de- posits. A viewing arrangement was there- fore developed i n w h i c h a faint deposit is not apparent but a medium deposit is readily visible.

Applying t h e standards

CGSB Specification 1 2 - G P - 8 is n o w be- ing applied widely i n the specification of sealed double-glazing for Federal Govern- ment buildings. The test apparatus has been reproduced b y the testing labora- tories of the Department of Public Works a n d results of tests i n accordance w i t h the standard are being used by an inter-depart- mental qualification board t o develop a

H e a l e r a n d cooling w a l e r v a l v e c o n t r o l l e d l n d i c a t e r a i r b y l i n e r c i r c u l a t i o n c r e a t e d b y spray

Figure 3 High-humidity cycling cabinet

6 "

0

( 1 5 c m ) C o o l i n g=i

P l a t e s2

R e q u i r e d h e r m o m e t e r F a c t o r y S e a l e d D o u b l e G l a z ~ n g U n ~ t 1 4 x 20"(35.5

x 5 l c m )

T r a n s f o r m e r : t o A d j u s t V o l t a g e t o L a m pG.E.

S u n l a m pN o t e :

2 2 " x 22"x 22"

( 5 6

cm.) Box C o n s t r u c t e d o f

P l y w o o d and L i n e d w i t h A l u m i n u m F o i l

Figure 4 Ultra-violet fogging test apparatus

list of qualified brands. The results of laboratory as well as outdoor exposure tests indicate a steady and marked i m - provement i n the quality of units produced since the programme was started.

Interim results for 3 3 sets of units re- ceived before 1961 are given i n Reference 1 . Only five of these sets w o u l d have passed the 1 9 6 4 C M H C requirements and

three sets the CGSB requirements. Six

unitsfrom 2 9 of the sets were exposed o u t - side and d e w - p o i n t temperatures measured periodically. After one year all units had failed o n seven sets; after t w o years all had failed o n 1 4 sets; after three years all had failed o n 21 sets; and after six years all had failed o n 2 2 sets. After seven years only one set was free of failures. Stains from materials in the sealing system ap?eared on at least three sets. At least t w o of the fail- ures resulted from a rapid de3radation of the sealant, presumably from ultra-violet radiation.

The results for some 6 7 sets of units re- ceived from November 1 9 6 0 t o J u l y 1963, analysed o n the basis of the standards set b y C M H C i n 1 9 6 4 (-40'F (-40°C) initial d e w - p o i n t and O'F (-18°C) after weather cycle) and on the basis of the present

CGSB specification (-60'F (-51°C)

initial and 0°F (-1 8' C) after weather cycle), are as follows: 1 9 6 4 C M H C CGSG Per Per cent cent Pass 1 8 2 7 1 1 1 7 Failed seal leakage 7 1 0 7 1 0 Failed initial d e w - p o i n t 1 6 2 4 1 8 2 7 Failed weather cycle 2 6 2 9 31 4 6

Units from 3 7 o f these sets were e x - posed outdoors. Of them 1 7 failed i n 2-5 years; 1 0 s h o w essentially n o change i n d e w - p o i n t ; stains are visible i n six.

The results for units received from August 1 9 6 3 t o J u l y 1 9 6 5 are as f o l l o w s : 1 9 6 4 C M H C CGSB Per Per cent cent Pass 3 6 3 7 2 0 2 0

Failed sealed test 1 4 1 4 1 4 1 4

Failed initial d e w - p o i n t 21 2 2 2 5 2 6 Failed high humidity cycle 6 6 1 0 1 0 Failed weather cycle 6 6 1 1 1 1 Failed i n b o t h H.H. and W.C. 1 5 1 5 1 8 1 9

Units from this group were exposed o u t - doors i n November 1 9 6 4 and t o date only three of 1 6 sets have failed. One set has

e l ~ i d e n c e of staining.

Units received from J u l y 1 9 6 5 t o t h e pre- sent time performed as f o l l o w s o n t h e basis of the CGSB stnndard:

Per cent

Pass 5 8 4 4

Failed seal test 1 0 7

Failed initial d e w - p o i n t 1 0 7

Failed high humidity cycle 1 8 1 4

Failed weather cycle 8 6

Failed b o t h H.H. and W.C. 2 9 2 2

After one-and-a-half years'outdoor ex- posure o n t w o units esch of 3 9 sets, one unit i n each of three sets has failed, and three of t h e sets s h o w signs of staining.

These figures include the results of tests carried out f o r manufacturers for purposes of product development and qualification b y Central Mortgage and Housing Cor- psration. Some of the sealing systems were never marketed or were marketed for only a brief. period. A substantial improvement i n quality of specimens submitted since the programme began is, nevertheless, apparent. Approximately 9 per cent of the units received u p t o November 1 9 6 0 w o u l d have passed the current CGSB require- ments; 1 7 per cent received from Novem- ber 1 9 6 0 t o J u l y 1963; 2 0 per cent re- ceived from August 1 9 6 3 t o J u l y 1965; and 4 4 per cent received from J u l y 1 9 6 5 t o the present. Essentially, all of the units current- ly marketed incorporate a design t h a t has met t h e test requirements of the Canadian Government Specifications Board stan- dard. A l t h o u g h there has been n o formal survey of f i e l d performance, the incidence of seal failure reported t o t h e division has

greatly decreased. It seems, therefore.

reasonable t o assume that the average quality of units has greatly improved since the beginning of t h e rese3rch programme.

Conclusions

The procedure f o r evaluating sealed double-glazing n o w i n w i d e use i n Canada appears t o provide a reasonably g o o d basis for judging t h e quality of assembly and t h e relative ability of the various sealing sys- tems t o withstand mechanical stresses i n

service. I t is mainly deficient i n n o t

identifying t h e effects of ageing o n t h e re- quired physical properties, and some further consideration of t h i s is desirable.

The severity of t h e acceptance require- ments set b y C M H C were gradually i n - creased during t h e period of development of procedures, so that there w a s continuing pressure o n the industry f o r improvement of the product. Competent manufacturers

have ;esponded and there has been a

major increase i n t h e average quality of units since t h e programme began, t o t h e benefit of b o t h consumer and producer. The CGSB standard n o w provides a good technical basis for specifying sealed double-glazing and for further develop- ment a n d .mprovement of b o t h t h e methods of test and the product.

Reference

1 WILSON, A. G. and SOLVASON, K. R . 'Perform-

ance of sealed double-glazing un~ts', J. Can.

Ceram. Soc., 1962. 31, 68-82.