Any correspondence concerning this service should be sent

to the repository administrator:

tech-oatao@listes-diff.inp-toulouse.fr

This is an author’s version published in:

http://oatao.univ-toulouse.fr/26637

To cite this version: Eiken, Janin and Subasic, Emir and

Lacaze, Jacques 3D phase-field computations of

microsegregation in nodular cast iron compared to experimental

data and Calphad-based Scheil-prediction. (2020) Materialia, 9.

100538. ISSN 25891529

Official URL

DOI :

https://doi.org/10.1016/J.MTLA.2019.100538

Open Archive Toulouse Archive Ouverte

OATAO is an open access repository that collects the work of Toulouse

researchers and makes it freely available over the web where possible

Full

Length

Article

3D

phase-field

computations

of

microsegregation

in

nodular

cast

iron

compared

to

experimental

data

and

Calphad-based

Scheil-prediction

Janin

Eiken

a,∗,

Emir

Subasic

a,

Jacques

Lacaze

ba Access e.V., Aachen, Germany

b CIRIMAT, Université de Toulouse, Toulouse, France

Keywords: Microsegregation Cast iron Simulation Phase-field Volume change

a

b

s

t

r

a

c

t

Theredistributionofsoluteelementsduringprocessingofanodularcastironalloywassimulatedforthefirst timecomprehensivelyovertimeand3Dspace.Numericalpredictionshadsofarbeenlimitedto1Dmodels, neglectinglocalmorphologicalaspectsandcommonlyalsodiffusionandgrowthinsolid-state.Applicationofthe standardmulti-phase-fieldmethodwashinderedbytheinherentsimplifyingassumptionofequalandconstant molarvolume,causingartificialpiling-upofsoluteandbiasedkineticsduringmodellingofgraphitegrowth.A recentlydevelopedvolumetricmulti-phase-fieldapproachnowaccountsforthechangingpartialmolarvolume oftheindividualelements.TheCalphad-basedphase-fieldstudywasbenchmarkedtoexperimentalcoolingand noduledensitydata,andthepredictedas-castdistributionswerevalidatedbyexperimentalsegregationanalysis. Thecombinednumericalandexperimentalfindingswerefurthermoreusedasa basistodiscusssimplifying assumptionscommonlymadein1DScheil-typemodels.

1. Introduction

3D computations of microsegregation contribute to a better un-derstandingandcontrolofmicrostructureevolutionandas-cast mate-rialproperties.Themulticomponentmulti-phase-field(MMPF)method [1,2]implementedintheMicress(9)software[3]offersthepossibilityto

simulatemicrosegregationinacomprehensivewayunderconsideration offiniteliquidandsoliddiffusivities,nucleationconditionsand mor-phologicalaspects.Thecouplingtothermodynamicdatabasesenables handlingofcomplexmulticomponentmultiphasequasi-equilibria,while diffusionmatrixescanconsistentlybederivedfrommobilitydatabases. Calphad-coupledMMPFsimulationshavebecomestateof theartfor steels[3,4]andmany othertechnical alloys[5–7], however not yet foralloysthatexhibitsignificantvolumechangeduringsolidification. Thisisespeciallytruefornodularcastironswheregraphiteformsina divorcedeutectic transformation,withgraphiteexpandingupon crys-tallizationwhileausteniteisshrinking.Whilethevolumechangeitself mightbeofminorinterestformicrosegregationprediction,itis indis-pensabletoconsidertheintrinsictransportofmatterandsolute,since allelementsformingpartofthematerialarechangingpositionas con-sequenceof local expansion or shrinkage.Neglectof the expansion-relatedsolutetransport during simulationof nodularcast irons was foundtoresultin unrealistickineticsandincorrectmicrosegregation prediction[8]. Inthepresentwork,a novelvolumetric

multi-phase-∗Correspondingauthor.

field(Vol-MMPF)approach[8],whichincontrasttothestandardMMPF formulation[1,2]accountsforvolumechangeandrelatedmatterand solutetransport,wasappliedtostudymicrosegregationina representa-tivenodularcastironalloy.Phase-specificpartialmolarvolumeswere evaluatedasfunctionoftemperatureandcompositionfromthelinked Calphaddatabase.

Microsegregationincastironsisofimportanceasitaffectsthe me-chanicalandchemicalpropertiesofcastironnotonlydirectly,butalso indirectlybyitsinterplaywithmicrostructureevolution.Negative segre-gationofgraphitizers(Si,Al,Cu,Ni)andpositivesegregationof cemen-titestabilizers(Mn,Cr,Mo,V)isknowntodecreasethestable graphite-austeniteeutectictransformationtemperatureandpromoteformation ofdetrimentalintercellularcarbidesinthelaststageofsolidification, while local impoverishmentof nodularizers(Mg,Ce)mayaffect the graphitemorphology[9–12].Highconcentrationgradientsofspecific substitutionalelementssuchasNiandSihavebeenclaimedtoreduce thecarbondiffusionfluxandthus favourdetrimentalchunkygrowth [15].Microsegregationalsocontrolsthesubsequentsolid-state eutec-toidtransformationwithsomeofthenamedelementspromoting fer-rite,whileotherspromotingpearliteformation[16–19].Inthestudied representativenodularcastironalloy(Fe-3.66C-1.97Si-0.18Mn-0.048 Mg),diffusionofCcontrolstheoverallevolutionkinetics,Siisactingas graphitizer,Mnascarbide-stabilizerandMgasnodularizer.

Toourknowledge,thisisthefirsttimethatmicrosegregationduring processingofamulticomponentcastironwassimulatedin3Dspace.

E-mailaddress:j.eiken@access-technology.de(J.Eiken).

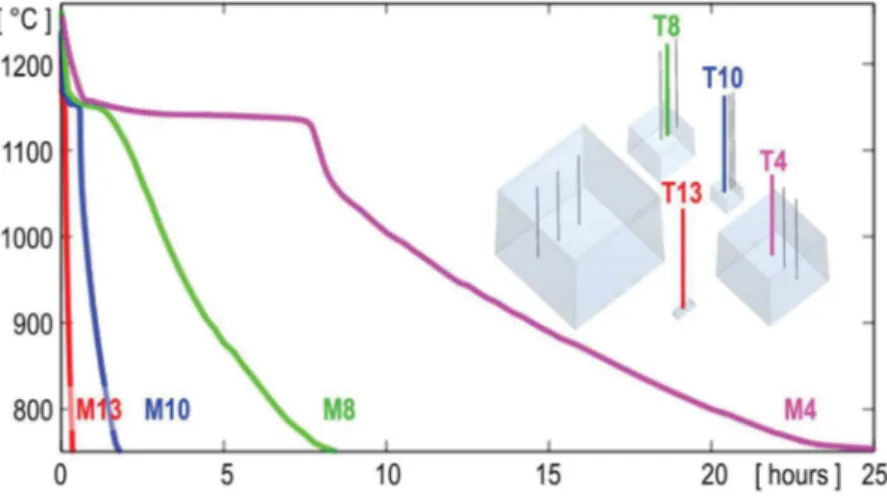

Fig.1. MeasuredcoolingcurvesforsamplesM4,M8,M10and M13.

Apreviousmulticomponent2DMMPFstudy[20]wasrestrictedto nu-cleationandgrowthofgraphiteintheearlysolidificationstagewhere volumechangeisstillnegligible.Theimportantroleofvolumechange duringgraphitegrowthwasdemonstratedforabinaryFe-Calloyby 2Dcellularautomatonsimulations[21,22],howeverthepragmaticway expansionwashandledisnotextendabletomulticomponentalloys.A generalproblemof2Dsimulationscomparedto3Dsimulationsisthat diffusionlengthsaresystematicallyoverestimatedbecausethevolume toradiusratioofthenodulesandthesurroundingshellsisnotcorrectly reproduced.Todate,1Dmodelsbasedonsphericalcoordinatesarestill themethodofchoicetopredictmicrosegregationin castironalloys. ThemajorityofexistingmodelsisbasedontheScheilapproach,i.e.the massbalanceissolvedforaclosedvolumeunderassumptionofinfinite diffusioninliquidandzerodiffusioninsolidphases[23].Scheil-type modelsneglectlocalmorphologicalaspectsandcannotprovide multi-dimensional distributionmaps,but allowforafastestimation of so-lutecontents asfunctionof solidfraction.Thepredictivityof Scheil-typemodelswasin earlyapplications [24,25]stilllimitedbyuseof calibratedpartitioncoefficients,butstronglyincreasedwithcombined multicomponentthermodynamicmodelling[26].Forcomparisonwith theVol-MMPFsimulations,wegeneratedconcentrationscurveswiththe TC-ScheilmoduleoftheThermoCalcsoftware[27].TheTC-approachis incontrasttosomeextendedScheil-typemodels[28,29]merelybased onthermodynamicdataanddoesnotconsideranyprocessconditions. Amongstotheraspects,wetrytoclarifythecontroversiallydiscussed questionwetherchangeincoolingconditionsornoduledensityhasa strongimpactonmicrosegregation[12–16,28–31].

Thestudyfurtherencompassesacastingexperimenttoprovide re-alisticprocessconditionsforinputandtovalidatetheVol-MMPF simu-lations.Thepaperstartswithadescriptionoftheexperimentalcasting procedureandtheexperimentalmicrosegregationanalysis.Afterwards thenovelVol-MMPF-approachisexplained,followedbythesimulation scenarioandthenumericalmicrosegregationanalysis.Both experimen-talandnumericalresults arethendiscussedtogether andeventually comparedtoScheilpredictions.

2. Experimentalprocedure

Thesamplesusedinthisworkwereobtainedbycastingaferritic SGI gradeEN-GJS-400–18-LT in afuran resinsand mould.Thetotal castingweight– includinggatingsystemandpouringbasin– was ap-prox.6000kg.Thecastingexperimentwascarriedoutusingan induc-tionmeltingfurnace,anautomatizedmagnesium-wiremelttreatment, in-ladleinoculationandmanually controlledmeltpouring.Themelt qualitywascontrolledbyQuik-Cupthermalanalysisandcomposition measurementinthefoundrylaboratoryusingLECOanalysisforcarbon andsulphurandmassspectrometryforallotherelements.Themelt

tem-peraturewasmeasuredbyuseofathermocouplelanceduring succes-sivestagesofmeltpreparation.Justbeforepouring,itwas1320°Cand thechemicalcompositionwasslightlyhypoeutecticat3.66C,1.97Si, 0.18Mnand0.048Mg(inweight%withallotherelementsastraces). Thecastinggeometryconsistedoffiveblocksofdifferentsizeswhich enabledstudyingtheeffectofvaryingcoolingrates.Allblocksbutthe smallestone(50×50×150mm)werecube-shapedwithedgesof150, 300,500,and750mm.Thetemperatureprofileswererecordedduring solidificationandsubsequentcoolingtoroomtemperatureby13type Nthermocouples.Foursamples-namedM4,M8,M10,andM13-were takenfromdefinedpositions,suchthatthemetallographyanalysiscould clearlyberelatedtotherecordedtemperaturesprofilesT4,T8,T10,and T13depictedinFig.1.

Fromeachofthefoursamples,fivemicrographswerepreparedto characterizethegraphitenodulesizeandspatialdensity.Thenodule densityNA,thenodulediametersdA,andtheoverallfractionofgraphite fGwereevaluatedusinganautomaticimageanalysissoftware.Toavoid biasbymicroporesorinclusions,onlygraphitenoduleswithadiameter aboveacertainthresholdweretakenintoaccount[32].Areafraction andvolumefractionofgraphitewereassumedtobeequal.3Dnodule densitiesNVandmeandiametersd̄Vwerederivedintwodifferentways:

a) basedonthesimplifyingassumptionofrandomlydistributed mono-sizedspheresandb)basedonSaltykov’smethodofinversediameters [33]: NV= NA dV witha)d̄𝑉 = 4 πdAorb)dV= π 2 ( d−1 A )−1 . (1)

Table1givesboththedirectlymeasuredaswellasthederiveddata forthedifferentsamples.Asexpected,thenodulediameterdecreases withincreasingcoolingratewhilethenoduledensityisincreasing.No cleartendencycould befoundfor theimpactof thecoolingrateon graphitefraction.

3. Experimentalmicrosegregationanalysis

Two samples,M10 andM13, wereselected for experimental mi-crosegregationanalysis.Foranalysingthedistributionofsubstitutional solutesSiandMn,energydispersiveX-rayanalyses(EDX)werecarried outwithaXFLASH6130fromBrukerfittedinaFEIQuantascanning electronmicroscope(SEM).Theprocedurewastwo-fold:First,acquiring 2Dmapsforvisualizationofthemicrosegregationfeatures(seeFig.2); Second,recordingspectrabyspotcountingonaregulargridfor quan-titativeanalysis.Duringtheseanalyses,Fe,Si,andMnweremeasured togetherwithAlthatwassometimesdetected,butassociatedtothefinal polishingofthesamplesandthusdisregarded.Amongsttherawdata,a significantnumberofdatapointsshowasummuchlowerthan100%. Thesepointswererelatedtographiteparticlesandremovedfrom fur-theranalysisofthesolutedistributioninthematrix.Theselecteddata

Table1

Experimentalcharacterizationofgraphitenodulesizeandspatialdensity.

sample fraction mean nodule diameter [mm] nodule density [mm −2 ], [mm −3 ] fG d ̄A d ̄V (a) d ̄V (b) N A N V (a) N V (b)

M04 0.10 0.062 0.079 0.083 35 443 424

M08 0.11 0.043 0.055 0.058 69 1260 1171

M10 0.08 0.028 0.036 0.041 116 3254 2824

M13 0.10 0.023 0.029 0.030 225 7683 7553

Fig.2. Measureddistributionsmapsofsiliconandmanganesefor samplesM10andM13.

Fig.3. ExperimentalsegregationcurvesforsiliconandmanganeseinsamplesM10andM13.

werecorrectedforatomicnumber,fluorescenceandabsorption,andthe sumofFe,Si,andMnwasnormalizedto100%.

Gridanalyseswereperformedwithagridspacingof175µminboth directions,largeenoughtoensurearepresentativestatistics indepen-dentofthedifferentspacingofdendritearms,nodulesandeutecticcells. Thecorrectedconcentrationsvalueswerethensortedindecreasing or-derforSiandinincreasingorderforMnaccountingfortheiropposite segregationbehaviour.Theresulting 1D-distributionprofiles(Fig.3) provideastatisticalcharacterizationoftheelementdistributioninthe entiremultidimensionalstructure.Thisisincontrasttosomeprevious studiese.g.[12,31],whereonlylimitedareasbetweenselectedadjacent noduleswereanalysedandextremevaluesdistributedatascalemuch

largerthanthenodulespacingmaynothavebeenconsidered.Itshould howeverbenotedthattheevaluationoftheextremeconcentrations gen-erallyexhibitsaveryhighuncertaintyduetotheintrinsicscatteringof X-rayemission[34]aswellasduetothestatisticalrandomnessto di-rectlyhitthesingularpointsoflastsolidification.Toavoidbiasbythe finitesizeandnumberofthemeasuringpoints,werestrictedtherange ofthecumulativedistributionfrom0to99%.

4. Thevolumetricmulticomponentmulti-phase-fieldmodel (Vol-MMPF)

MicrostructuresimulationswereperformedwiththeMicress○R

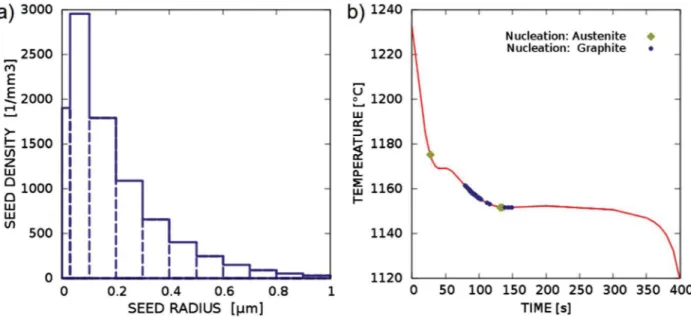

Fig.4. a)Calibratedseeddistributionforgraphitenucleation,b)nucleationeventsinsampleM13.

forvolumechangesduringphasetransformationandcooling. Thermo-dynamicdatawerederivedfromthedatabaseTCFe8[35]and diffusiv-itiesfromthemobilitydatabasemobFe3[36]viatheTQ-interfaceof theThermo-Calcsoftware[27].Inthefollowing,thematerial-specific modellingofnucleation,anisotropicgrowth,solutesegregationand vol-umetricexpansionareshortlydescribed.

4.1. Modellingofausteniteandgraphitenucleation

Nucleation ishandledin Micress○R by asubmodel. Nuclei,whose

radiicanbemuchsmallerthanthegridspacingΔx,aregeneratedwhen thelocalundercooling-evaluatedfromthethermodynamicdatabase -exceedsthespecifiedcriticalundercooling.Inordernottoviolatethe concentrationbalance,theinitialnucleuscompositionstillequalsthat ofthesurroundingmelt,butlocalequilibriumissoonobtainedby so-luteredistribution.Aslongasanucleusistoosmalltobenumerically resolved,itscurvatureisanalyticallyevaluatedfromthevolume frac-tionunderassumptionofsphericalgeometry[2].Austenitewas mod-elledtonucleatewithlownucleationundercooling(ΔTcrit=1°C)inone ofthedomaincornersandwithhigherundercooling(ΔTcrit=10°C)on theliquid/graphiteinterface.Nucleationofgraphitewasmodelledon seedsrandomlydistributedinthemeltaccordingtoasize-density func-tionwithalmostexponentialcourse(Fig.4).Theseedsweredistributed toelevenclasseswithradiirangingfrom0to1µmandthe correspond-ingcriticalundercoolingfornucleationΔTcritwasevaluatedaccording toTurnbull’sfreegrowthcriterion[37]by:

Δ𝑇crit= 2σ0 LG ΔsLGrseed . (2) whereσ0

LGdenotesthemeaninterfacialenergyandΔsLGthelocal

en-tropyoffusionevaluatedfromthedatabase.Sincethecritical undercool-ingisinverselyproportionaltotheseedradiusrseed,nucleationstartsat thelargestseeds.Underslowcoolingconditionsonlyalowundercooling isreachedandsmallerseedsdonotbecomeactive,hencelessgraphite nodulesarenucleatedthanforhighercoolingrates.Thetotalseed den-sitywasadjustedtoapproximatelyreproducetheexperimentalnodule densitiesgiveninTable1.Notethattheintentionwasnotatalltoobtain aperfectfitting,butrathertostudywhether,andifso,howchanging noduledensitiesaffectmicrosegregation.

4.2. Modellingofausteniteandgraphitegrowth

Asetofmultiplephase-fields𝜙𝛼(𝐱,t)mapsthespatialdistributionof thephasesliquid(L),austenite(A)andgraphite(G)inthesimulation domain.Additionally,grainsofsamephase,butdifferentorientation, maybedistinguished.Theevolutionofthestructureisdescribedbya setofmultiphase-fieldequations:

̇ 𝜙𝛼(𝐱,t)=∑ βM 𝜙 αβ (| | |∇𝜙αβ|||v−1mol,αβ ) Δμαβ−𝜎αβKαβ+∑ γJαβγ, (3)

wherethephasefieldvariable𝜙𝛼isassociatedwiththelocalmole frac-tionofphase𝛼,interactingwithmultiplephases𝛽.Δµ𝛼𝛽 denotesthe

differenceinchemicalpotentialand𝜈mol,𝛼𝛽themeanmolarvolumefor

interactinggrains𝛼 and𝛽.Theirratiorepresentsthethermodynamic drivingforcefortransitionandisevaluatedviatheTQ-interfaceofthe Thermo-Calcsoftwareasfunctionoflocalcompositionandtemperature. Thepairwiseinterfacecontributions𝜎𝛼𝛽·K𝛼𝛽correspondtothe

capillar-ityforce.Third-orderinterfacecontributionsJ𝛼𝛽𝛾accountforforcesonly

actinginjunctionswheremorethantwograinsarelocallycoexisting, fordetailssee[1,2].𝜎𝛼𝛽denotestheinterfacialenergyandM𝛼𝛽the

inter-facialmobility,spceificallydefinedforeachpairwisephaseinteraction. Theanisotropydescriptionoftheliquid-austeniteinterfaceaccountsfor thecubicsymmetryofthefcc-lattice:

MLA=M0 LAacubic(𝐧), (4) 𝜎LA=𝜎0LAacubic(𝐧), (5) acubic(𝐧)=1−δLA4(n4 x+n4y+n4z−0.75 ) , (6)

wherethemeaninterfacemobility M0LA wasdefined in thediffusion controlledlimit[39]andthemeanliquid/austeniteinterfaceenergywas settoσ0

LA=0.17Jm−2withananisotropyof𝛿LA=0.05.

Graphitenodulesaresupposedtobemulti-crystalline,builtof mul-tipleconicalsectorsassketchedinFig.5a.Theeffectiveinterfaceofa spheroidishenceformedofbasalc-facetsmodelledintheMicress soft-wareby:

MLG=M0LGafacet(θ), (7)

𝜎∗LG= 𝜎LG0 a−1

Fig.5.Schematiccutthroughagraphitenodule(a)and Wulff-shapeoftheeffectiveanisotropyfunction.

afacet(θ)=δLG+

( 1−δLG

)

|tanθ|tanh(|tanθ|−1), (9) withphase-specificvaluesM0

LG=5·10−15m4J−1s−1,𝛿LG=0.5andσ0LG=

1.5Jm−2[38].𝜃denotestheanglebetweenthelocalinterfacial

nor-malvectorandthenearestfacetvectorand𝜎∗

LGistheregularized

in-terfacialstiffness.Fig.5bshowstheeffectiveWulff shapeofagraphite spheroidmodelledwith50facets.Thegraphite/austeniteinterfacewas modelledbasedonthesameanisotropyfunctionwithspecificvalues M0

GA=8·10−16m4J−1s−1andσ0GA=1.2Jm−2.Notethattheinterface

anisotropyisofmarginalimportanceforthestudiedmicrosegregation andisonlydescribedforthesakeofcompleteness.Allinterfacial mo-bilityvalueswerecorrectedinthethin-interfacelimitby:

M𝜙αβ= Mαβ 1+ηGMαβ

, (10)

wherethefactorGislocallyevaluatedfromthedatabasetoconsider thegrowthrestrictingeffectofthediffusion-controllingelementsinthe multiphaseinterface region[39]. Thenumericalinterfacialthickness wassetto𝜂=3.5ΔxwithΔxbeingthenumericalgridsize.High accu-racywasensuredbyaspecialfinite-differenceformulationwithimplicit correctionofsystematicdiscretizationerrors[40].

4.3. Modellingofsolutesegregationanddiffusion

Thecompositionvectorfield⇀χ(𝐱,t) mapsthedistributionofthe al-loyingelementsduringsimulation.Thecomponentsofthisvectorgive thecontentofthesoluteelementsC,Si,Mn,andMgintermsofmole fractions,withni

moldenotingthenumberdensityofmolesofthis

compo-nentandnmolthetotalnumberdensityofmoles(Eq.(11)).Withinthe diffuseinterfaceregionwheretheadjacentphasesoverlap,thevector

⇀

χisdefinedasamixturecompositionconsistingintheweightedsum ofindividualphase-specificcompositionvectors⇀χα,evaluatedfromthe

phase-relatedmolenumberdensitiesni

mol,αandnmol,𝛼.

⇀ χ(𝐱,t) = Σα α(𝐱,t) ⇀ χα(𝐱,t),with χi= ni mol nmolandχ i α= ni mol,α nmol,α . (11)

Redistributionofthemixturecomposition⇀

χintoindividual phase-specificcomposition⇀χαisdoneaccordingtothequasi-equilibrium

ap-proachwhichpostulatesequaldiffusionpotentials̃μi

α=̃μiβforeach

com-ponentinlocallycoexistingphases.Thisconstraintcorrespondstoa par-alleltangentconstructionandisevaluatedbycouplingtothedatabase TCFe8withintermediateextrapolation[1,2].Solutediffusionofthe ele-mentsC,Si,Mn,Mg(includingcrossdependencies)issimulatedinboth liquidandaustenite:

̇ ⇀ χ(𝐱,t)= n−1 mol(𝐱,t)⋅ ( Σα𝛁⋅ [ nmol(𝐱,t)⋅ ⃗jα(𝐱,t)] +𝛁⋅ [ nmol(𝐱,t)⋅ ⃗jatc(𝐱,t)]), (12)

withdif f usionfluxes⃗𝐣α(𝐱,t) = Dα⋅𝛁⋅ ⇀

χα(𝐱,t). (13)

Eq.(12)representsageneralizedformulationofthediffusion equa-tion,allowingforlocallychangingmolenumberdensitiesnmol(𝐱,t).The

phase-specificdiffusionmatricesDαareevaluatedasproductof

ther-modynamic factorand chemical mobility from thedatabases TCFe8 [35]andmobFe3[36].Inbetweenthefrequentdatabasecalls,the diffu-sioncoefficientsareinterpolatedbasedonArrhenius-typefunctions.By default,antitrappingcurrents→𝐣atc[39]wereevaluatedbytheMicress(9)

software,butfoundtobenegligibleexceptforthefirstsecondsof den-driticgrowth.Itis importanttonotethatEq.(12)ensures conserva-tionofthetotalnumberofmolesofeachspeciesoverthesimulation domain,whiletheconstraintof conservedmolefractionsusedinthe standardmulti-phase-fieldmodel[1,2]isnotvalidinthegeneralcase of unequalmolenumberdensity.Thelocal numberdensityofmoles nmol(𝐱,t)remainsunaffected by substitutionaldiffusion, but changes duringinterstitialdiffusionofCattherateof:

̇nmol(𝐱,t) =𝛁⋅ [nmol(𝐱,t)𝐣CA(𝐱,t)

]

, (14)

where 𝐣CAisthediffusionfluxofCinausteniteasdefinedinEq.(13). Theexplicitcomputationofthecompositionvectoraccountsforboth thechange inmole fraction(Eq.(12)) andthechange in totalmole numberdensity(Eq.(14)):

⇀ χ(𝐱,t+Δt)= [ ⇀ χ(𝐱,t)+⇀χ(̇ 𝐱,t)Δt ] n mol(𝐱,𝑡) nmol(𝐱,t)+̇nmol(𝐱,t)Δt. (15)

4.4. Modellingofvolumechange

Theeutectictransformationinnodularcast-ironiscontrolledby car-bontransportthroughtheausteniteshell.Aslongasthecarbonatoms areinterstitiallydissolved inaustenite theyhardly contributetothe material’svolume,butdrasticallyincreasetheirpartialvolumewhen becomingattachedtothegraphiteinterface.Effectively,thegraphite nodulesgrowbyvolumeexpansion,pushingthesurrounding austen-iteshelltotheoutside.Ifweweretoneglectthedisplacementofthe fcc-latticeandtherelatedsolutetransportinthesimulation,wewould findallslowdiffusingelementspilingupinfrontofthegraphite inter-face.Thiswouldfalsifythesegregationprofilesandleadtotransition kineticsordersofmagnitudelowerthaninrealityasdemonstratedon theexampleofaternaryFe-C-Sialloy[8].Notethatexpansion-induced mattertransportisnotlimitedtosolidification,butalsooccursbycreep processesinsolid-state.Acomprehensivemodellingofsolidandfluid mechanicsduringmicrostructureevolutionofamulticomponentalloy wouldclearlyexceedthepossibilitiesoftoday’scomputation,especially asthemechanicalprocessesoccuronatime-scalemuchfasterthan dif-fusion.Becauseoftheelevatedtemperaturesduringprocessing,itis rea-sonabletoassumethatanytemporarystressisimmediatelyrelaxed.The newVol-MMPFapproachallowsarealisticpredictionofphasevolumes, transformationkineticsandmulticomponentmicrosegregationbasedon theassumptionthatlocalstraingradientsinliquidorsolidphasesare immediatelyhomogenizedbyinternalmatterfluxes.

Themodelaccountsforthefactthatthelocalmolarvolumemay changeasaconsequenceofphasetransition,solutediffusionorcooling. Thephase-specificmolarvolumes⇀ναareevaluatedfromthedatabaseas

functionofcompositionandtemperature.Withinthediffuseinterfacial regions,wedefinethelocalmolarvolume𝜈molastheweightedsumof theindividualphase-specificmolarvolumes𝜈𝛼:

𝑣mol(𝐱,t)=∑α[𝜙α(𝐱,t)𝑣α(𝐱α,T)]. (16) Tohomogenizethelocalvolumechangesandcontinuouslyrecover astress-freesimulationdomain,internalmolarfluxesjmolarecalculated basedonarelaxationapproachonatimescalemuchfasterthan diffu-sionandgrowth(Δ𝜏 ≪Δt).

𝐣mol(𝐱,τ)=ν−1

mol(𝐱)MV𝛁

[

nmol(𝐱, τ)νmol(𝐱)], (17) nmol(𝐱,τ +Δτ) =nmol(𝐱,τ)+𝛁⋅ jmol(𝐱,τ), (18)

Notethattheterm(nmol⋅𝜈mol)isameasureforlocalstrain.The mat-terfluxesjmolbecomezerowhennomoregradientsinlocalstrainexist. Astherelaxationisassumedtobeinstantaneous,therelaxation coef-ficientMVcanbedefinedasanumericalparameteradjustedfor

com-putationalefficiencyandthelocal molarvolume𝜈mol ismodelledas temporaryconstant.Therelaxationequationissolvediterativelyatthe endofeachphase-fieldtimestepΔtuntilahomogeneouslydistributed volumeisrecovered,i.e.untilthemeangradient∇(nmol𝜈mol)hasfallen

belowanumericallynegligiblelimit,herespecifiedas 10−5%ofthemeanvalueofn

mol𝜈mol.SimultaneouslytoEq.(18),

thelocalcompositionvectorfieldisrecalculatedineachiterationstep Δ𝜏toaccountfortheexpansion-relatedsolutefluxes:

⇀ χ(𝐱, τ +Δτ)=n−1mol(𝐱,τ+Δτ)(⇀χ(𝐱,τ)nmol(𝐱,τ)+𝛁⋅ [⇀ χ(𝐱,τ)𝐣mol(𝐱,τ) ]) (19) 5. Phase-fieldsimulations

Phase-fieldsimulationswereperformedforthevariousprocess con-ditionsreferringtothecastingsamplesM4,M8,M10andM13described inSection2.ThenominalcompositionindicatedinSection2wasused (wC=3.66,wSi=1.97,wMn=0.18andwMg=0.048inweight-%).

Sim-ulationsstartatthemomentwhenallcavitieswerefilledwithmelt. Thetemperatureevolutionwasimposedtofollowthemeasured cool-ingcurvesT4,T8,T10,andT13depictedinFig.1fromT≈1230°C downtoT≈752°C,i.e. totheonsetof theeutectoidtransformation. Theinitialvolumeofthecubiccalculationdomainwas(200µm)3and

thenumericalgridspacingΔx=2µm.Tochecktheinfluenceofthe nu-mericaldiscretization,sampleM13whichexhibitedthefineststructure - andhencewasmostcritical– wasadditionallyrunwithasmallergrid spacingofΔx=1µm.Thiscomparativesimulationconfirmedthatthe changedresolutionhadno visibleeffecton theresulting segregation profiles.

All simulationsstarted from pure liquidphase. Asthe alloy was slightlyhypoeutectic,primaryaustenitenucleatedpriortographiteat about1175°Candthengrewdendritically.Below1161.5°C graphite nodules started to nucleate andgrow from the melt with spherical morphology. Afterbecoming encapsulatedeitherby primary austen-iteorbynewlynucleatedeutecticaustenite,thenodulescontinuedto growdrivenbycarbondiffusionthroughtheausteniteshell.Somenew graphitenodulesnucleatedduringfurthercooling.Table2givesa char-acterizationofthesimulatedgraphitedistribution,namelythegraphite fraction,themeandiameterofthenodulesattheendofthesimulation, thenodulenumberwithinthecalculationvolumeandthecorresponding noduledensity.Thehighestnumberofnoduleswasobtainedinsample

M13.Fig.4bshowsthetimeandtemperatureofnucleationeventsfor thissampleandFig.6illustratesthemicrostructureevolutionduringthe variousstagesofnucleationandgrowth.Solidificationwashere com-pletedataboutTS≈1117°C,whileintheslowestsolidifyingsample

M4,solidificationendedatTS≈1140°C.Thefinalstageofthe simula-tionwasgovernedbysolid-statetransformationwithgraphitedirectly growingfromaustenite.Allsimulationswerestoppedat752°C,i.e.the eutectoidtransformationwasnotmodelled.

Volumechangewasconsideredduringallsimulations.Asexpected, primarygrowthofausteniteresultedinlocalcontraction,whilegrowth ofgraphitecausedlocalexpansionandhencereducedtheoverall shrink-age.Thetotalvolumeofthehypoeutecticalloycontinuouslydecreased dominatedbythermalshrinkage.Theeffectivevolumechangeresulting fromthebalanceofexpansion,contraction,andthermalshrinkagewas about−5%frompouringuntilstartofeutectoidtransformation.Note thatinthepresentsimulations,thetotalnumberofmoleshasbeenkept constantandneitherliquidfeedingnorporeformationwasconsidered. Ageneralproblemofstudyingtheimpactofcoolingtimeand nod-uledensityonmicrosegregationbasedonexperimentaldataisthatboth parametersdonotvaryindependentlyinpractice.Slowercooling im-plicitlyresultsinreducednucleationundercoolingandhenceina re-ducednoduledensity.Ontheotherhand,achangeinnucleationdensity willalterthelatentheatreleaseandthustheeutecticundercooling.In contrasttoexperiments,Vol-MMPF-simulationsenableanindependent variationofbothparametersbyexplicitadjustmentoftheseeddensity function. Tostudytheseparateeffectof coolingandnodule density, twovariationsoftheexperimentalprocessconditionsweresimulated: Variation1(V1)combinesthenodulecountfromsampleM13withthe coolingfrom sampleM10andVariation2(V2)combinesthecooling fromsampleM13withthenodulecountfromsampleM10.

6. Numericalmicrosegregationanalysis

Asdirectsimulationresults,3Ddistributionmapsofthesolute ele-mentsweregivenoutatspecifiedtimesteps.Fig.7showsthe3D dis-tributionofthesubstitutionalelementsSiandMnevaluatedfor sam-plesM10andM13attheendofsimulation.Notethatallcompositions wereconvertedtoweightfraction.Toenableaquantitativecomparison withbothexperimentalresultsandScheilprediction,the3Dmapswere furtherprocessedintocharacteristic1Dprofiles.Concentrations belong-ingtotheausteniteregionwerefilteredbytheconstraintthatthelocal phase-fieldvalueofausteniteexceedsthecriticalvalueof𝜙α=0.5.In accordancewiththeprocessingoftheexperimentaldatadescribedin Section2,theconcentrationofthesoluteelementsweresorted inde-pendentlyfromeachother-accountingfortheirsegregation behaviour-andplottedversusthenormalizedcumulativedistributionofvalue num-bers.Fig.8showsthesegregationprofilesofSiandMn,andFig.9the profilesofMgandcarbonforsamplesM4,M8,M10andM13.Allcurves refertoatemperatureof752°C.Carbondistributionsareadditionally shownforT=1117°C.Furthermore,selected2DsectionsoftheSi distri-butionatdifferenttimesduringsolidificationaregiveninFig.10,and Fig.11showsa2Dsectionofthefinalcarbonconcentrationfieldfor simulationsM13,V1,V2andM10incomparison.Allnumericalresults arediscussedinthefollowingsectiontogetherwiththeexperimental data.

7. Combineddiscussionofexperimentalandnumericalresults 7.1. Microsegregationofsubstitutionalelements

Forafirstqualitativevalidation,thenumericallypredicted3D dis-tributionmapsofSiandMndepictedinFig.7werecomparedtothe experimentallyevaluated2DmapsinFig.2.Bothshowsimilar segrega-tionpatternswithlowestSicontentsandhighestMncontentsinthe re-gionsoflastsolidification.Animportantresultofthemultidimensional

Table2

Characterizationofsimulatedvolumefraction,size,numberandnumberdensity.

Sample Volume fraction Mean diameter d V Nodule number Density N V [mm −3 ]

M04 0.100 0.088 2 250

M08 0.100 0.046 12 1500

M10 0.099 0.039 20 2500

M13 0.097 0.028 60 7500

Fig. 6. Phase-field simulation of the mi-crostructureevolutioninsampleM13during coolingfromT=1230°CtoT=752°C.

Fig.7. Simulateddistributionsofsiliconandmanganesefor sam-plesM10andM13atT=752°C.

analysisisthattheextremevaluescorrespondingtotheendof solidifi-cationareunevenlyspreadalongtheintercellularboundariesatascale whichcanbemuchlargerthanthenodulespacing.Theobserved im-poverishmentofthegraphitizingelementintheresidualmeltcombined withthesimultaneousenrichmentofthecementitestabilizerprincipally promotescementiteandcarbideformationinthelaststagesof solidifi-cation,whichwashoweverfoundtobeuncriticalunderthegiven con-ditions.Onlyverysmallamountsofcementiteweredetectedinsome sampleswithfractionbelow0.5%.Aninterestingdetailobservedinthe

3DsimulationsisthattheSicontentofaustenitestillincreasesduring primarypro-eutecticgrowth,despitethefactthepartitioncoefficientof Siisgreaterthanone(Fig.10).Thisatypicalsegregationbehaviourwas reportedbefore[28]andcanbeexplainedbythestrongcomposition andtemperaturedependencyofthepartitioncoefficient.After nucle-ationof graphite,theSicontentof austenitestartstodecrease. Con-sequently,highestvaluesinthemultidimensionalSidistributionmap markthemomentoffirsteutecticprecipitationasillustratedbythe2D sectionsinFig.10.The3DdistributionmapsofMg(notdepictedhere)

Fig.8.SimulatedsegregationcurvesofsiliconandmanganeseforsamplesM4,M8,M10andM13atT=752°CincomparisonwithTC-Scheilcalculations.

Fig.9. SimulatedsegregationcurvesofmagnesiumandcarbonforsamplesM4,M8,M10andM13atT=752°C(andadditionallyatT=1117°Cforcarbon).

Fig.10. 2-DsectioncutfromPF-simulation.The sili-concontentinausteniteincreasesduringpro-eutectic solidification,butdecreasesduringeutecticgrowth.

werefoundtobequalitativelycomparabletothoseofMn,showing low-estvaluesinthedendrite’scentreandhighestvaluesinthelastsolidified regions.MgsegregationandassociatedprecipitationofMg-compounds areknowntohaveasignificantimpactonthegraphitemorphology. Whetherthiseffectisdominatedbymodificationofkinetics,interfacial energiesornucleationandtowhichextenttheinterplaywithoxygen

andsulphurplaysaroleisstillunclearandshallbethesubjectofafuture study.

Aquantitativevalidationofthenumericalsimulationresultswas en-abledbyprocessingthemulti-dimensionaldataintocharacteristic1D profiles.Incontrasttosimpleline-scans,theseprofilesarenot subjec-tivelybiasedandensureastatisticalrepresentationof thewhole

mi-Fig.11. Carbondistributionfromindependentvariationofprocessparametersa)sampleM13,b)variantV1withreducedcooling,c)variantV2withdecreased nodulecount,d)sampleM10withreducedcoolinganddecreasednodulecountcombined.

crosegregationspectrumdistributedoverdifferentlengthscales. Exper-imentallyandnumericallyevaluatedprofiles(Fig.3vsFig.8)ofboth SiandMnshowgoodagreementexceptfordeviationwithinthefirst 20%ofthedistributionwhicharemostprobablyrelatedtothephysical noisegenerallyassociatedwithEDXmeasurements[34].The experi-mentalvalidationconfirmsthatthenewVol-MMPFapproachproduces realisticresultswithouttheneedforparameterfitting.Theonly parame-terwhichwascalibratedisthenoduledensitywhichhoweverobviously hasnosignificanteffectonthecharacteristic1Dprofilesofthe substi-tutionalelements.

Indeed,themoststrikingresultofthemicrosegregationanalysisis thatthecharacteristicprofilesofnoneof thesubstitutionalelements (Figs.3,8,9a)exhibitanysignificantdifferenceforthesamplesM4,M8, M10andM13processedundersignificantlydifferingcoolingconditions Theseresultsgoagainstthestillwidelyacceptedtheorythat microseg-regationincastironstronglydependsoncoolingrate[12,13,30,31], butfindssupportinthedifficultyofascertainingthisstatementin prac-ticalstudies[14,26,28,29].Thepresentstudygoesbeyondthe previ-ousstudies,demonstratingthatvariationoftheprocesstimesranging from20minto25handrelatedchangeinnoduledensityfromapprox. 0.4⋅1012to7.6⋅1012m−3shownosignificantimpactonthe

character-istic1Dsegregationcurves.Independentvariationofcoolingcondition andnoduledensityin simulationsV1andV2revealedaslightly en-hanced,howeverstillnegligibleimpact.Itishoweverimportanttonote thatthisstatementonlyholdsforthecharacteristic1Dconcentration profiles,whichdonotaccountforspatialaspects.Whilethestatistical distributionremainunaffected,themultidimensionaldistribution pat-ternsconsiderablyalterwithchangingprocessconsideration.The3D distributionmaps(Fig.7)generallyrevealincreasedspatial concentra-tiongradientsforhighernodule densities,becausetheconcentration variationoccursoverreducedsegregationlengths.Incontrasttoclassic 1Dmodels,thenewVol-MMPFmodelcanprovidethesemore compre-hensivelocalinformation.

7.2. Microsegregationofcarbon

Inadditiontothemicrosegregationofthesubstitutionalelements, alsotheredistributionofcarbonwaspredictedbytheVol-MMPFmodel. Ascarbonisinterstitiallydissolvedinaustenite,itsdiffusioncoefficient isstillrelativehighat1175°C(3.7·10−10 m2s−1),butdecreases

dur-ingcoolingto752°Cbytwoordersofmagnitude.Duringtheeutectic transformation,carboncontinuouslydiffusesfromtheliquid/austenite interfacetothegraphite/austeniteinterface.Nevertheless,theresidual

meltbecomesmoreandmoreenrichedincarbonandthehighest car-bonconcentrationsinausteniteareobtainedatthepointoflast solidi-fication.Fig.9showsthatthecarbonconcentrationprofilesofallfour samplesarestillclosetoeachotherattheendofsolidification.During subsequentcoolingtoeutectoidtemperatureallcurvesaresignificantly shifteddownwardbecauseofthecontinuousdecreaseofcarbon concen-trationatthegraphite-austeniteinterfaceandresultingdiffusionfluxes towardsthegraphitenodules.Atthefinaltemperatureof 752°C,the maximumcarbonvaluesrevealaclearimpactoftheprocessconditions, whiletheminimumvalueisidenticalforallsamples.Thehighestcarbon concentrationisobtainedinthefastestsolidifyingsampleM13,clearly followedbyM10.However,theprofilesofM08andM04hardlydiffer, whichcanbeexplainedbythefactthattheimpactofincreasedcooling timeanddecreasednoduledensitycompensateeachother,i.e. increas-ingdiffusiontimeiscompensatedbylongerdiffusiondistances.

The 2D sections depicted in Fig. 11 give further insight into the fundamental segregation mechanisms. Fig. 11a correspond to simulation M13. Minimal carbon concentrations are located at the graphite/austeniteinterfaceandmaximalconcentrationsinplaceswith largestdistancetoagraphitenodule.Fig.11bshowsthesamesection forsimulationV1wherereducedcoolingwasassumed.Theincreased diffusiontimehereresultsinahomogenizationoftheprofileandthus adecreaseofthemaximalvalues.Theminimalvalues-determinedby thelocalequilibriumconditionattheinterface-donotchange.A re-ducednoduledensity,incontrast,resultsinlongerdiffusiondistances andthusinhighermaximumconcentrationsasshowninFig.11c. Com-binationofbothvariationsinsampleM10(Fig.11d)resultsinpartial compensation.Inthisspecificcase,theeffectofthecoolingchangewas foundtoslightlydominate,whichhowevercannotbegeneralizedand maydependonthespecificcastingconditions.

8. ComparisontoScheilpredictions

ScheilcomputationswereperformedwiththeThermo-CalcScheil module[21]basedonthesamethermodynamicdatabaseasusedfor theVol-MMPFsimulations.TheTC-modelaccountsformulticomponent interdependencieswithcarbondefinedasfast-diffuser,i.e.withinfinite diffusivity.Figs.8–10showthattheTCScheilpredictionsare-forall so-luteelementsbutcarbon-almostidenticaltothesimulateddistribution curvesandhencealsoingoodagreementwiththeexperimentaldata. Thisresultisbyfarnottrivialtakingintoaccountthedifferentways thesecurveswereobtained.Thestatistic1Dcurvesweregeneratedfrom post-mortemdata,i.e.bysortingtheconcentrationdataofthefinal3D

structureinprogressiveorder.Scheilconcentrations,incontrast,are lo-calequilibriumvaluescontinuouslyevaluatedduringsolidificationand originallyfunctionoffractionsolid,butherecorrelatedtothe cumula-tivedistribution,i.e.adimensionlessranknumberwhichindicatesthe relativepositioningofaspecificconcentrationwithinthespectrumofall occurringconcentrations.Acorrelationbetweencumulativedistribution andsolidfractionisonlyreasonableprovidedthatallconcentrationsare unambiguouslyascendingordescendingwithtime.ThisholdsforMn andMg,butnot strictlyforSi,which exhibitsanatypical temporar-ilyincreaseduringpro-eutecticgrowthasdiscussedin Section7.1.A changingcurveprogressiongenerallyrequiresadifferentsortingofthe simulationdatae.g.withrespecttoaleadingelementoraweightedrank number[7].Asaconsequenceofthesimplifiedsorting,weobservea small,howeveralmostnegligible,deviationfromScheilintheveryfirst partofthesimulateddistributioncurveinFig.8.

Furthermore,cumulativedistributionscan onlybe relatedto frac-tionsolidvaluesprovidedthatlocalconcentrationsatthesolid/liquid interfacearesimplyfrozeninduringsolidificationandnotfurther af-fectedbyback-diffusion.Thisseemstobeareasonableassumptionfor allsubstitutionalelements,asthesubstitutionaldiffusioncoefficientsin austeniteevaluatedfromthemobilitydatabasewerefoundtobemore thanfourorderslowercomparedtothediffusioncoefficientof intersti-tialcarbon,whichcontrolstheeutectictransition.Nevertheless, back-diffusionplaysanimportantroleduringtheverylaststageof solidifi-cation.Here,theexponentiallyevolvingconcentrationgradientscause non-negligibleconcentrationfluxeswhicheventuallydeterminetheend ofsolidification.Duetotheinherentneglectofback-diffusion,Scheil predictionscantheoreticallyneverreach100%solidandthe concen-trationsasymptoticallyapproachinfinityorzero.Inthepresentstudy, Scheilcomputationswerestoppedat99%fractionsolid.

In contrast to Scheil computations, Vol-MMPF simulations com-prehensively addressthe solid-state process. A critical questionwas whethertheconcentrationprofilesbuiltupinausteniteduring solidi-ficationwouldbecomepartiallyhomogenizedbydiffusionduringthe subsequentcoolingto752°C.Thiswasexpectedtobemostlikelyfor sampleM4,exposedtothelongestcoolingtime(25h),butfoundnot tobethecaseforany ofthesubstitutionalelements. Onlycarbonis stronglyaffectedbyfinitesolid-phasediffusionandcanthereforenot bepredictedbytheScheilmodel.Itisnoteworthythatdespitethe as-sumptionofinfinitediffusivityintheScheilmodel,thecarboncontent doesnothomogenizeinausteniteduethemulticomponent interdepen-dencyofitsdiffusionpotentialwiththeslowdiffusingelements.

Goodmatchingbetweenstatisticalpost-mortemdataandScheil pre-dictionsfurthermorerequiresthatthemicrosegregationisnotaffected bythecontinuinggrowthof thegraphitenodulesaftersolidification. Sincegraphiteformscompletelyfromcarbon,allotherelementshave tobetransportedoutoftheevolvinginterfacialregions.Thistransportis howeverinducedbyvolumeexpansionandhence,thesubstitutional el-ementsmovetogetherwiththedisplacedFe-lattice,thusonlychanging theirlocalposition,butnottheircharacteristicprofiles.Infact,the sta-tistical1DprofilesofSi,MnandMgevaluatedattheendofsimulation (752°C)showednovisibledeviationfromthoseevaluatedattheend ofsolidification(1117°C).Moreover,theseprofileswerefoundingood agreementwiththeexperimentalprofilesevaluatedatroom tempera-ture,i.e.aftertheeutectoidtransformationhastakenplace.Thisfinding supportsthehypothesisthattheeutectoidstructureinheritsthe substi-tutionalsolutecontentoftheas-solidifiedausteniticstructure[19].It isemphasizedthatthisonlyholdsforsubstitutionalelements,butnot forcarbon,whoseconcentrationsprofilestronglychangesduringsolid statetransitionandcompletelydeviatesfromScheilprediction(Fig.9). Most revealing is to recall that the TC-Scheil computations are merelybasedonthermodynamicdataand-incontrasttotheVol-MMPF simulations-donotconsideranyprocessconditions.Nevertheless, sta-tisticalconcentrationprofilesevaluatedfromsimulationswithstrongly varyingcoolingandnucleationconditionsrevealnosignificant devia-tionfromScheilpredictions.Thissupportsthefindingthatthe

concen-trationstatisticsofsubstitutionalelementsareindependentofany pro-cessspecificconditions.Non-negligibledeviationfromScheilprediction mayonlybeexpectedwhenextremelylongprocesstimesarecombined withveryhighnoduledensities.

Altogether,itcanbesummarizedthatthestatisticalconcentration distributionofsubstitutionalelementsinductilecastironcanreliably bepredictedbytheTC-Scheilmodelprovidedthatmatterisconserved. Thebenefitsofthispredictionarehoweverlimitedbythefactthat nei-ther corresponding carbon concentrationsnorinformation aboutthe spatialdistributionofthesoluteelementsisprovided.Incomparison, thenewVol-MMPFmodeliscomputationallymoreexpensive,but pro-videscomprehensive3Ddistributionmapsforallsolutesasfunctionof time,whichisessentialtostudylocaleffectse.g.ongraphite degenera-tionorcarbideformation.

9. Conclusions

Microsegregationinhypoeutecticductilecastironwasstudiedfor thefirst timein3Dspace basedon anovelvolumetric multicompo-nentmulti-phase-field(Vol-MMPF)approach.TheCalphad-based simu-lationsweresuccessfullyvalidatedforarepresentativeFe-C-Si-Mg-Mn alloybyasimultaneousexperimentalstudy.Thecombinednumerical andexperimental microsegregationanalysisconfirms theassumption thatthestatistical distributionofsubstitutional elementsinthefinal microstructureissimplyinheritedfromtheas-solidifiedstructureand notsignificantlyaffectedbyon-goinggraphitegrowthordiffusionin solid-state.Againstthecommonviewthatmicrosegregationisstrongly affectedbyprocessconditions,onlythecharacteristicprofilesof inter-stitialcarbonrevealedasensitivitytovaryingcoolingandnucleation conditions,whilecharacteristic1Dprofilesofsubstitutionalelements hardlydifferedfromeachotherorfromTC-Scheilpredictions.In con-trasttothemerelystatistical1Dprofiles,thecomplex3Ddistribution patternsandlocalchemicalgradients,however,considerablyalterwith varying nodule density. Thenew Vol-MMPFmodel can provide this morecomprehensiveinformationandcontributetoabetter understand-ingandcontroloftheinterplaybetweenmicrosegregationandstructure evolutionincastironalloys.

DeclarationofCompetingInterest

Theauthorsdeclarethattheyhavenoknowncompetingfinancial interestsorpersonalrelationshipsthatcouldhaveappearedtoinfluence theworkreportedinthispaper.

Acknowledgement

TheauthorsliketothankAlexandreFreulonforsamplepreparation, YannickThébaultforperformingEDXmeasurements,andtheGerman FederalMinistryforEconomicAffairsandEnergyforpartialfundingof theworkintheframeoftheresearchprojectDiWaGussGJS.

References

[1]J. Eiken , B. Böttger , I. Steinbach , Multiphase-field approach for multicomponent alloys with extrapolation scheme for numerical application, Phys. Rev. E 73 (2006) 066122 .

[2]J. Eiken , A Phase-Field Model for Technical Alloy Solidification, Shaker Verlag, 2010 ISBN 978-3-8322-9010-8 .

[3] MICRESS multicomponent multi-phase-field software, www.micress.de , pre-release version 6.350, 2018.

[4]B. Böttger , M. Apel , J. Eiken , P. Schaffnit , I. Steinbach , Phase ‐Field simulation of solidification and solid ‐state transformations in multicomponent steels, Steel Res. Int. 79 (8) (2008) 608–616 .

[5]Y. Shen , S. Yang , J. Liu , H. Liu , R. Zhang , H. Xu , Y. He , Study on micro segregation of high alloy Fe–Mn–C–Al steel, Steel Res. Int. 90 (5) (2019) 1800546 .

[6]J. Eiken , M. Apel , S.M. Liang , R. Schmid-Fetzer , Impact of P and Sr on solidification sequence and morphology of hypoeutectic Al–Si alloys: combined thermodynamic computation and phase-field simulation, Acta Mater. 98 (2015) 152–163 .

[7]K. Grätz , J. Eiken , R. Schmid-Fetzer , Methods of segregation analysis applied to simulated multicomponent multiphase microstructures, Int. J. Mater. Res. 105 (2) (2014) 130–138 .

[8] J. Eiken , B. Böttger , A multi-phase-field approach for solidification with non-neg- ligible volumetric expansion–application to graphite growth in nodular cast iron, Trans. Indian Inst. Met. 71 (11) (2018) 2725–2729 .

[9] P.C. Liu , C.R. Loper , Segregation of certain elements in cast irons, AFS Trans. 92 (1984) 289–295 .

[10]A. Kagawa , T. Okamoto , Partition of alloying elements on eutectic solidification of cast iron, MRS Proc. 34 (1984) 201 .

[11]N.K. Datta , N.N. Engel , Electron microprobe study of the distribution of Si, Cu, Ni, Mn, Mo, and Cr in ductile iron, AFS Trans. 83 (1976) 431–436 .

[12]A. Owhadi , J. Hedjazi , P. Davami , M. Fazli , J.M. Shabestari , Microsegregation of manganese and silicon in high manganese ductile iron, Mater. Sci. Technol. Lond. 13 (10) (1997) 813–817 .

[13]S. Pietrowski , G. Gumienny , Microsegregation in nodular cast iron with carbides, Arch. Found. Eng. 12 (4) (2012) 127–134 .

[14]J. Charbonnier , J.C. Margerie , Contribution to the study of microsegregation in Fe-C casting alloys, Mem. Sci. Rev. Met. 64 (1967) 345–357 .

[15]B. Pustal , B.A. Bührig-Polaczek , Physico-chemical causes of the formation of chunky graphite in austenitic ductile iron, Acta Mater. 124 (2017) 137–142 .

[16]M.J. Lalich , C.R. Loper , Effects of pearlite promoting elements on the kinetics of the eutectoid transformation in ductile cast irons, AFS Trans. 81 (1973) 217–228 .

[17]E.N. Pan , M.S. Lou , C.R. Loper , Effects of Cu, Sn, and Mn on the eutectoid transfor- mation of graphitic cast irons, AFS Trans. 95 (1987) 819–840 .

[18]J. Lacaze , The austenite to pearlite/ferrite transformation, ASM Handb. 1A (2017) 106–113 .

[19]A. Freulon , A.P. de Parseval , P.C. Josse , J. Bourdie , J. Lacaze , Study of the eutectoid transformation in nodular cast irons in relation to solidification microsegregation, Metall. Mater. Trans. A 74 (2016) 5362–5371 .

[20]A. Sommerfeld , B. Böttger , B. Tonn , Graphite nucleation in cast iron melts based on solidification experiments and microstructure simulation, J. Mater. Sci. Technol. 24 (3) (2008) 321–324 .

[21]M. Zhu , L. Zhang , L.H. Zhao , D.M. Stefanescu , Modeling of microstructural evolution during divorced eutectic solidification of spheroidal graphite irons, Acta Mater. 84 (2015) 413–425 .

[22]A.A. Burbelko , D. Gurgul , M. Królikowsk , M. Wróbel , Cellular automaton modeling of ductile iron density changes at the solidification time, Arch. Foundry Eng. 13 (4) (2013) 9–14 .

[23]E. Scheil , Bemerkungen zur schichtkristallbildung, Z. Metal. 34 (1942) 70–72 .

[24]R. Boeri , F. Weinberg , Microsegregation in ductile iron, AFS Trans. 97 (1989) 179–184 .

[25]R. Boeri , F. Weinberg , Microsegregation of alloying elements in cast iron, Cast Met. 6 (3) (1993) 153–158 .

[26]B. Domeij , A. Diószegi , Inferring the development of microsegregation and mi- crostructure in spheroidal and compacted graphite iron using EPMA ‐WDS, in: Pro- ceedings of the of the 6th International Conference on Solidification Processing SP, 17, 2017, pp. 455–458 .

[27] Thermo-Calc software. www.thermocalc.com .

[28]J. Lacaze , Solidification of spheroidal graphite cast irons, part III: microsegregation related effects, Acta Mater 47 (14) (1999) 3779–3792 .

[29]C. Selig , J. Lacaze , Study of microsegregation buildup during solidification of spheroidal graphite cast iron, Metall. Mater. Trans. 31B (2000) 827–836 .

[30]L. Nastac , D.M. Stefanescu , Modeling of microsegregation in sg cast iron, AFS Trans. 101 (1993) 933–938 .

[31]A. Tadesse , H. Fredriksson , H , On the solidification and structure formation during casting of large inserts in ferritic nodular cast iron, Metall. Mater. Trans. B 49 (3) (2018) 1223–1235 .

[32]A. Escobar , D. Celentano , M. Cruchaga , J. Lacaze , B. Schulz , P. Dardati , A. Parada , Experimental and numerical analysis of effect of cooling rate on thermal-microstruc- tural response of spheroidal graphite cast iron solidification, Int. J. Cast. Met. Res. 27 (3) (2014) 176–186 .

[33]S.A. Saltykow , Stereometrische Metallographie, VEB Dt. Verlag für Grundstoffind- ustrie, 1974 .

[34]J. Lacaze , P. Benigni , A. Howe , Some issues concerning experiments and models for alloy microsegregation, Adv. Eng. Mater. 5 (2003) 37–46 .

[35] TCFe8, TCS Steels/Fe-Alloys Database, version 8.0. [36] MobFe3, TCS Steels/Fe-Alloys Mobility Database, version 3.0.

[37]D. Turnbull , Theory of catalysis of nucleation by surface patches, Acta Metall 1 (1953) 8–14 .

[38]R.H. McSwain , C.E. Bates , W.D. Scott , Iron-graphite surface phenomena and their effects on iron solidification, AFS Trans. 82 (1974) 85–94 .

[39]A. Carré, B. Böttger , M. Apel , Implementation of an antitrapping current for a mul- ticomponent multiphase-field approach, J. Cryst. Growth 380 (2013) 5–13 .

[40]J. Eiken , Numerical solution of the phase-field equation with minimized discretiza- tion error, IOP Conf. Ser: Mater. Sci. Eng. 33 (2012) 012105 .