O

pen

A

rchive

T

OULOUSE

A

rchive

O

uverte (

OATAO

)

OATAO is an open access repository that collects the work of Toulouse researchers and

makes it freely available over the web where possible.

This is an author-deposited version published in :

http://oatao.univ-toulouse.fr/

Eprints ID : 17719

To link to this article :

DOI: 10.1016/j.cep.2016.07.010

URL :

http://doi.org/10.1016/j.cep.2016.07.010

To cite this version :

Anxionnaz-Minvielle, Zoé and Tochon, Patrice

and Couturier, Raphael and Magallon, Clément and Théron, Felicie

and Cabassud, Michel and Gourdon, Christophe Implementation of

‘chaotic’ advection for viscous fluids in heat exchanger/reactors.

(2016) Chemical Engineering and Processing: Process

Intensification, 113. pp. 118-127. ISSN 0255-2701

Any correspondence concerning this service should be sent to the repository

administrator:

staff-oatao@listes-diff.inp-toulouse.fr

Implementation

of

‘chaotic’

advection

for

viscous

fluids

in

heat

exchanger/reactors

Z.

Anxionnaz-Minvielle

a,*

,

P.

Tochon

a,

R.

Couturier

a,

C.

Magallon

a,

F.

Théron

b,

M.

Cabassud

b,

C.

Gourdon

baCEA,LITEN,DTBH,17ruedesMartyrs38054Grenoble,France

bUniversityofToulouse,LaboratoiredeGénieChimiqueUMR5503CNRS/INPT/UPS,31432Toulouse,France

Keywords: Heatexchanger/reactor Chaoticadvection Viscousfluids Continuousmode Processintensification Split-And-Recombinepattern ABSTRACT

Whenviscousfluidsareinvolved,laminarhydraulicconditionsandheatandmasstransferintensification are conflicting phenomena. A channel geometry based on Split-And-Recombine (SAR) patterns is experimentally investigated. The principle implements the Baker’s transformation and ‘chaotic’ structuresaregeneratedtopromoteheatandmasstransfer.Thisworkassessestheenergyefficiency ofdifferentheatexchanger/reactorsintegratingtheseSARpatterns.

Theheattransfercapacityisassessedandcomparedwiththeenergyconsumptionofeachmock-up.It issensitivetothecoolingmodeandtothenumberofSARpatternsperlengthunitaswell.

Thecontinuousoxidationof sodium thiosulfatewithhydrogenperoxide hasbeenimplemented. Conversionsupto99%arereachedaccordingtotheutilityfluidtemperatureandtheresidencetime.

Finally,thewholeperformancesoftheSARgeometriesarecomparedtoaplate-typeheatexchanger/ reactorwithacorrugatedpattern.Themoreviscousthefluid,themoretheenergyefficiencyoftheSAR designincreasescomparedtothecorrugateddesignbecauseofthebalancebetweenadvectionand diffusionmechanisms.TheinterestintermsofenergyefficiencyinworkingwithSARheatexchanger/ reactorappearsfromReynoldsnumbersbelow50.

1.Introduction

Among the technologies promoting process intensification

[1,2],heat-exchanger/reactor(HEXreactor)isapromisingone[3].

This device combines the benefits of a large heat transfer

performanceandaplug-flowregimeallowinganintensiveradial

mixing,asaresultofthespecificdesignofprocesschannels[4–9].

These geometries generate instabilities even in laminar flow

regime(50<Re<2000).Howevermostofthestudieshavebeen

carriedoutwithinviscidfluidsandtheintensificationof

perform-anceswhenthefluidviscosityincreasescomesattheexpenseof

pumpingcosts.Processesoffoodindustry,intermediatechemistry

likesiliconesorpolymers,... involveviscousfluidsandastudy,

carriedoutintheframeoftheindustrialnetworkEUROPIC[10],

pointedoutthatheatandmasstransfersinviscousmediaareone

ofthemainindustrialconcern.Intheverylaminarflowregime,

precludingturbulenceasamixingmechanism,mixingbydiffusion

canbeefficientprovidedthatthecontactareaissufficient.Thiscan

beachievedwithsystemsbasedonmulti-laminationmechanism

and baker’s transformation [11,12]. These have been proposed

especiallyinthecontextofmicrofluidics[13–16].Inmicrofluidic

devices,thetypicalchanneldimensionsandflowratesaresolow

that all flow is laminar (Re!0.1) and turbulence cannot be

achieved.Diffusionisalsotooslowtobeeffectiverequiringtoo

longchannellengths.Theimplementationofviscousfluidstreams

in HEX reactor and the typical millimetre dimensions of the

channel cross-section lead to similarconclusions. However,by

applyingaseriesof Baker’stransformationsindedicated

three-dimensionalmixingelements,namedSplit-And-Recombine(SAR)

patterns,therequiredchannellengthcanbereducedexponentially

with thenumber of mixing patterns.The involved separation/

stackingmechanismslieontheBaker’stransformationprinciple.

Two fluid streams are combined, split out-of-plane, rotated in

oppositedirectionsandrecombinedasillustratedwithFig.1.Then,

a 2-strips domainbecomes 2nalternatingstrips afternmixing

patterns.

*Correspondingauthor.

E-mailaddress:zoe.minvielle@cea.fr(Z. Anxionnaz-Minvielle).

AveryefficientmixingisachievedbydiffusionandSchönfeld

etal.[13]evenproposedasanoutlooktousesimilarSARstructures

toimproveheattransferinminiheatexchangers.Theinfluenceof

chaotic advection on heat transfer has been numerically and

experimentallyinvestigated[17–21].Resultsina singlechannel

arepromising.

TheinterestofHEXreactorsistheclosecontrolofthereaction

temperature.Theveryshortcharacteristiclengthsbetweenboth

theprocessandtheutilitystreamsareofparamountimportance.

Withthree-dimensionalSARstructures,characteristicdimensions

are quite different from ‘classical’ two-dimensional patterns

(plate-typeHEXreactor)andheattransfermightbeaffected.

ThustoinvestigatetherelevanceofimplementingSARpatterns

ina HEXreactordevice,performanceindicatorsbesides mixing

havetobeassessed.Theyaccountfor heattransferand energy

consumption.Theobjectiveistopromoteheatandmasstransfer

eveninviscousconditions.

For that purpose, we experimentally characterized three

stainlesssteelmock-ups"assembledbydiffusionbonding. Two

differentflowpatternsaccordingtothenumberofSARstructures

areconsidered.Theirdesignscomefrom[14,15].

For oneofthesegeometries,two coolingsystemshavebeen

investigated, external cooling Plates "isothermal wall- and

integrated cooling tubes. For each mock-up, the 3mm square

cross-sectionchannelsarearound3.5mlong.Then,acasestudyin

reactiveconditionsisimplementedwiththecontinuousoxidation

ofsodiumthiosulfatewithhydrogenperoxide.Finally,thewhole

performancesoftheSARgeometrieshavebeencomparedwiththe

onesofacorrugatedpatternplate-typeheatexchanger/reactor[6].

2.Heat-exchangerreactordesignandintegration

2.1.SARpatterns

ThreeSARpatterns,basedonthedesignsof[14,15]havebeen

considered. Fig. 2 depicts four patterns of each considered

geometry.

The square cross-sections of the channels are 3#3mm2

correspondingtoanequivalenthydraulicdiameterof3mm.The

Reynoldsnumberassessmentisbasedonthishydraulicdiameter

andonthefluidvelocityattheinletoftheprocesschannel,i.e.

upstreamthefirstfluidstreamseparation.Thisreferenceistaken

since the inlet flowrate is a major process parameter for the

industrialapplication.

TwochannellengthscanbedefinedintheSARgeometries.We

considerthedeveloped length,Ldevand thetotallength,L. The

former corresponds tothe distance travelled by a single fluid

particle between the inlet and the outlet of the HEX reactor.

Whereas the latter corresponds to the sum of every stream

branches,i.e.thetotalfluidvolumedividedbythecrosssection.

PatternsSAR-1andSAR-2areverysimilar.Thedifferencestems

fromthepatterndimensiononthez-axiswhen fluidstreamis

split.IncomparisonwithSAR-2,theSAR-1patternisexpandedto

allowtheinsertionofcross-flowcoolingtubes(seeSection2.2).

SAR-3patternislesscomplexthanSAR-1andSAR-2patterns.It

makeseasieritsmanufacturing.It includes3bendsperpattern

versus6bendsperpatterninbothSAR-1andSAR-2geometries.

2.2.HEXreactorintegrationandmanufacturing

ThethreeSARgeometriesareintegratedinrespectivelythree

wholeHEXreactorprototypes.TomanufacturetheHEXreactors,

theSARchannelisfirstdividedinseverallayerswhicharethen

transposedincorrespondingplatesasdepictedinFig.3.

The HEX reactors are made of one process plate including

severalrowsofSARpatternsinseriesandsensorconnectionsat

eachendoftherows(seeFig.4b).

ThestratificationstepdepictedinFig.3 isduplicatedonthe

platetoobtaintherequirednumberofrows(seeFig.4a).Laser

machiningisusedandplatesarethenstackedintoacontainer.The

assembling process is based on diffusion bonding (High

Nomenclature

A [m2]heatexchangearea

Cp [Jkg"1K"1]thermalcapacity

dh [m]hydraulicdiameter

Fp [kgh"1]processflowrate

Fu [kgh"1]utilityflowrate

L [m]totallengthoftheprocesschannel

Ldev [m]developedlengthoftheprocesschannel

_ni [mols"1]initialmolar

flowrate

Ploss [W]thermalloss

Pth [W]thermalpower

Preaction [W]heatofreaction

Pe [-]pecletnumber(=RePr)

Pr [-]prandtlnumber

Re [-]reynoldsnumber

T [K]temperature

u [ms"1]

fluidvelocity

U [Wm"2K"1]globalheattransfer

coefficient

V [m3]volumeof

fluid

Greekletters

D

Hr [kJmol"1]enthalpyofreactionD

P [Pa]pressuredrope

[Wm"3]energydissipationrateL

[-]darcycoefficientl

[Wm"1K"1]thermalconductivitym

[Pas]viscosityr

[kgm"3]densityx

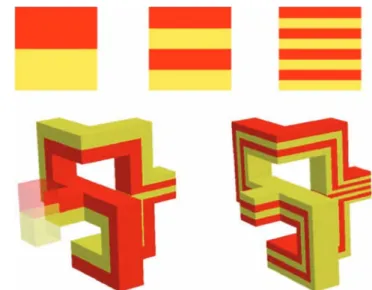

[%]conversionrateFig.1.Illustrationofa3Dmixingpattern.Top:Cross-sectionillustratingtheBaker’s transformationaftertwoiterations.Bottom:sketchofmixingactionsaftertwo elements[11].

temperatureIsostaticPressing–HIP–assembling,[22]).Thefinal

prototypeismadeofstainlesssteel.

Twocoolingconfigurationshavebeenconsidered.Thefirstone

assumesisothermalwalltemperature. Theprocessplate(SAR-2

andSAR-3)issandwichedbetweentwocoolingplates.Thesecond

cooling configuration involvescross-flow coolingtubes directly

integratedthroughtheSARpatterns(SAR-1).Fig.5illustrates

SAR-1andSAR-3integration.

Thefinalprototypesarearound185mmlongand90mmwidth.

ThegeometricalcharacteristicsarelistedinTable1.

2.3.Corrugatedpattern

TheperformancesofthepreviousSARpatternsarecompared

withaclassical2Dcorrugatedonewhichdesignisbasedontheone

studiedby[5,6].Themanufacturingprocessofthe2DHEXreactor

isthesameandthecoolingsystemisbasedonisothermalwalls

(withcoolingplates).Thesquarecross-sectionofthecorrugated

channelis2#4mm2andthehydraulicdiameteris2.67mm.The

channelis2.2mlongincluding103bends(90$)perlengthunit.The

corrugatedchannelisshowninFig.6.

3.Thermalandhydraulicinvestigations

ToassesstheHEXreactorsperformances,thestudiedReynolds

number rangesfrom0.1 to10,000.Waterand twosolutions of

glycerolintowater(70%w.and90%w.ofglycerol)areused.

3.1.Pressuredrop

3.1.1.Experimentalset-upandprocedure

Pressuredropsaremeasuredwithadifferentialpressuresensor

betweentheinletandtheoutletoftheHEXreactors.Tocovera

widerangeof Reynoldsnumber,distilled water,ethylene glycol

andtwosolutionsofglycerolareused(70%w.and90%w.).The

tests are implemented in isothermalconditions and the mean

physico-chemicalpropertiesofthefluidsarelistedinTable2.Since

thetemperatureismeasuredduringthepressuredrop

measure-ments,boththeviscosityandthedensityareassessedattheexact

testtemperature.

FrompressuredropmeasurementstheDarcycoefficient,

L

,isassessedaccordingtothefollowingexpression:

L

¼ 2&D

P&dhr

&Ldev&u2ð1Þ

AndtheReynoldsnumberisdefinedas:

Re ¼

r

&um

&dh ð2ÞwhereLdevisthedevelopedlengthoftheprocesschannel,anduthe

processfluidvelocity.TheSARgeometriesaredesignedsuchasthe

pressuredropsineachfluidbranchareequal.Moreover,sincea

fluid particle flows successively through the inlet zone (flow

velocity, u), a split branch (flow velocity, u/2), a stream

Fig.2.SARpatterns.ThereddottedlinesdelimitoneSARpattern.(Forinterpretationofthereferencestocolorinthisfigurelegend,thereaderisreferredtothewebversionof thisarticle.)

Fig.3. StratificationoftheSAR-2patternforthemanufacturingprocess.

recombinationzone(flowvelocity,u),asplitbranch(flowvelocity,

u/2),... Wedecidedtoconsiderthedevelopedlengthtoassess

theDarcycoefficientintheSARgeometries.

3.1.2.Resultsanddiscussion

Fig. 7 showstheevolution of theDarcycoefficientwiththe

ReynoldsnumberinboththeSARandthecorrugatedchannels.

Nomajordiscontinuityisobservedbetweentheglycerol0.7w.

curve(Reynoldsnumberfrom5to90)andtheglycerol0.9w.one

(Reynoldsnumberfrom0.1to3).Whateverthegeometry,alinear

sharpdecreaseisobservedasforstraighttubes(

L

)64/Re)inthelaminarflowregime.Aweakdecreaseoftheslopecanbenoticed

onFig.7whereasReynoldsnumberisfarbelowtheclassicalflow

regime transition around Re=2300 for straight channel. To

illustrate this low Reynolds number flow regime transition,

Fig.8showstheevolutionoftheDarcycoefficientintheSAR-1

channelonawiderReynoldsnumberrange.

AsobservedinFig.7,thelinearsharpdecreaseismeasuredfor

Reynoldsnumberrangingfrom10toaround100.Above100,the

transitionalzoneseemstoappearandfinallyamoderateslopeis

observedforhigherReynoldsnumbers.Thesetrendsaresimilarto

straightchannelsexceptthatthetransitionalzoneinourgeometry

isaroundRe=100ratherthanRe=2300.Flowinstabilitiesabove

these Reynolds number may certainly promote turbulence-like

vortices. This is interestingto promote heat and mass transfer

intensificationwhileworkingwithlowReynoldsnumbers.Similar

trendshavebeenobservedbyTheronetal.[6]inthecorrugated

channel.

InthelowReynoldsnumberzone,Fig.7showsdiscrepancies

betweentheSARpatterns.LossesintheSAR-3geometryarehigher

thaninSAR-1andSAR-2geometries(uptox2).Thismaybedueto

thenumberofpatternsperdevelopedlengthunitwhichisaround

50%higherinSAR-3thaninSAR-1and2(39.5vs25patterns/Ldev).

Thefluidundergoesahighernumberofsplittingand

recombina-tionwhichproduceslosses.Moreover,theratiobetweenthelength

ofthebrancheswherethefluidflowswithavelocityu/2andthe

Table1

GeometricalcharacteristicsofSARHEXreactors.

SAR-1 SAR-2 SAR-3

Coolingconfiguration cross-flowcoolingtubes Coolingplates(isothermalwall) Coolingplates(isothermalwall)

Cross-section(mm2) 3#3

Hydraulicdiameter(mm) 3

Developedlength,Ldev(m) 1.9 1.7 2.1

Totallength,L(m) 3.4 2.8 3.4

Totalvolume(mL) 28.3 24.7 28.5

Numberofrowsinseries 4 4 7

Numberofpatternsperrow 12 12 12

Numberofpatternsperunitofdevelopedlength 25 29 39.5

Fig.6.PhotographofthecorrugatedchannelbeforeHIPassembling.

Table2

Physico-chemicalpropertiesofthefluidsusedforpressuredropmeasurements.

Fluid Densityr(kgm"3) Viscositym(Pas) FlowrateFp(kgh"1) Reynolds,Re

Water"Glycerol(70%weightglyc.) 1030 0.018 1.4–18.0 5.3–110.9

Water"Glycerol(90%weightglyc.) 1015 0.210 0.3–7.1 0.1–3.3

Water"Ethyleneglycol(98%weighteth.Glyc.) 1110 0.010 1.0–27.5 9.0–316.0 Fig.5. CADviewsofSAR-1(aandb)andSAR-3(c)HEXreactors.(a)ZoomofthecrossingbetweenthecoolingtubesandtheSAR-1channel.(b)Thecross-flowcoolingtubesin SAR-1HEXreactoraredepictedinred.

developed length is lower in SAR-3 than in SAR-1 and 2. The

pressuredropisdirectlyproportionaltothesquareofthevelocity

andthisalsogeneratesadditionallossesinSAR-3pattern.

TheslightdiscrepancybetweenSAR-1andSAR-2curvesmight

beexplained aswellsince SAR-1 geometryhasbeenexpanded

compared withSAR-2.ThismeansthatthelengthofoneSAR-1

patternisslightlyhigherthantheoneoftheSAR-2pattern,i.e.the

fluidundergoesalittlebitlesssplittingandrecombinationperunit

ofdevelopedlength(29vs25patterns/Ldev).

Finally,the corrugated channel generateshigher losses than

SARgeometriesinthelowReynoldsnumberrange(Re<100).The

chaoticstructuresseemtogeneratemoderatelossescomparedto

theturbulent-likestructuresofthecorrugatedgeometry.

3.2.Thermalcharacterization

3.2.1.Experimentalset-upandprocedure

The HEXreactorsareequippedwithtemperaturesensorsto

characterizethetemperatureprofilesversustheflowregime.The

temperatureismeasuredbetweentheinletandoutletofeachrow

(seeFigs.4and5).Eitheracounter-currentflow(SAR-2,SAR-3)ora

cross-flow(SAR-1,corrugatedchannel)patternisimplementedfor

the cooling stream. The intermediate temperature probes are

required to locate the temperature pinch and to avoid

under-estimatingtheheattransfercapacity.

Tocharacterizethethermal behaviouroftheHEXreactors,a

heat transfer capacity, or thermal intensification factor, UA/V

(kWK"1m"3),isassessed.Uistheglobalheattransfer

coefficient

(Wm"2K"1),Aistheheatexchangerarea(m2)andVisthevolume

offluid(m3).

InboththeSARpatternsandthe2Dcorrugatedgeometry,the

heatexchangeareacanbedefinedaccordingtovariousreferences.

Itcanrepresentthedevelopedheatexchangeareaofthe4facesof

thechannel,or aprojected area(i.e.assumingnoheattransfer

limitations in the process plate material). The 3-dimensions

characteristic of the SAR structures add an extra level of

complexityand theresultsinterms of heattransfer coefficient

(and the resultant Nusselt number) depends on the chosen

reference.It mayleadtointerpretationmistakeswhentheHEX

reactorsarecompared.

Fig.7.DarcycoefficientvsReynoldsnumber(glycerol70%andglycerol90%at25$C).

Thethermalintensificationfactoristhusdirectlyassessedfrom

temperaturemeasurementsandnoheatexchangeareareferenceis

required: U&A ¼ Pth

D

Tmlð3Þ

wherePth(W)istheexchangedpowerbetweentheprocessfluid

andthecoolingfluid:

Pth¼Fp:Cp:!Tp;in "Tp;1" ð4Þ

and

D

Tmlisthelogarithmicmeantemperature:D

Tml ¼ Tp;in "Tu;out ! " "!Tp;1 "Tu;in" ln Tp;in"Tu;out Tp;1"Tu;in # $ ð5ÞTp,inaswellasTu,inaretheinlettemperaturesofprocessand

cooling (also named utility) fluids respectively. Tp,1 is the

temperaturemeasuredatthefirsttemperaturesensorconnection.

Tu,outistheoutlettemperatureoftheutilitystream.

3.2.2.Resultsanddiscussion

Fig.9displays theheattransfercapacityasa functionofthe

ReynoldsnumberforthethreeSARheatexchanger/reactors.

ThebehaviourofthethreeSARgeometriesisclearlydistinct.

Thehighratioofsplittingandrecombinationperunitoflengthof

SAR-3geometry(+50%comparedwithSAR-1andSAR-2

geome-tries) seems clearly to favour heat transfer. Despite a small

differencebetweenthenumberofpatternperunit oflengthin

SAR-1andSAR-2geometries,respectively25pattern/Ldevand29

pattern/Ldev,anincreaseoftheheattransfercapacityupto30%is

measuredinSAR-2 heat exchangerreactor.To integratethe 22

cooling tubes through the SAR-1 channel in a cross-flow

configuration,theirdiameterislimited(2mm).Becauseofhigh

pressuredrops,thislimitstheutilityflowrate.Thecontributionof

theutilitystreamthermalresistancemaybenolongernegligiblein

the global heat transfer assessment as it is for the plate-type

cooling(SAR-2configuration).Asaconsequence,theincreaseof

theprocessflowrateinSAR-1channeldoesnotcontributedirectly

totheincreaseoftheheattransfercapacity.Thisemphasizesthe

differencebetweenSAR-1andSAR-2geometries,especiallywhen

theReynoldsnumberincreasesaboveRe=200.

AboveRe=150,theslope oftheSAR-3curvediminishesand

heattransfercapacityofSAR-2configurationbecomeshigher.For

suchReynoldsnumber,advectionmaybecomethemostdominant

phenomena(overdiffusion)andtheflowismainlygovernedby

secondaryandDeanvortices.Heattransferthendependsonthe

numberof90$bendsperunitofdevelopedlengthwhichishigher

intheSAR-2patternthanintheSAR-3one(respectively173bends/

mvs118bends/m).

Fig.10illustratestheeffectoffluidviscosity.Theheattransfer

capacityisplottedasafunctionoftheReynoldsnumberforamore

viscousfluid(Pr)200).

ItisconsistentwithresultsdisplayedinFig.9belowRe=150.

ForlowReynoldsnumber,advectionisnomorethedominantflow

mechanism and a balance is made between advection and

diffusion. As a consequence, the number of SAR patterns/Ldev

influencestheheattransfercapacity.

3.2.3.Comparisonwiththe2Dcorrugatedgeometry

Fig.11comparestheheattransfercapacityofeachHEXreactor

(bothSARgeometriesand2Dcorrugatedone)asafunctionofthe

energydissipationrate

e

(Wm"3).Thisparameterrepresentstherequiredpumpingpowerandisdefinedas:

e

¼Fp:D

Pr

:V ð6ÞAbove 1000Wm"3, the heat transfer capacity of the 2D

corrugated channel is clearly higher than the one of the SAR

geometries.It corresponds toReynoldsnumber around100. As

observedin Fig.9,theflowis governedbyadvectionandDean

vorticesallowtheintensificationofheattransferwhilegenerating

moderatefrictionlosses.

Below 1000Wm"3, heat transfer capacities are similar in

functionoftheenergydissipationratewhatevertheflowpattern.

This is an interesting result considering both mixing and heat

transfercapacity.Indeed,Ghanemelal.[23]showedthattheSAR

geometries promote mixing when compared to 2D corrugated

geometryandFig.11showsthatheattransferinSARpatternscan

competewithcorrugatedchannelperformances.Wecanconclude

thattheyaregoodcandidateforchemicalsynthesis

implementa-tionwithviscousfluids.

The Fig.12 illustrates the effect of Prandtl number on the

thermalandhydraulicperformancesofthestructuredflows.The

exchangedthermalpowertothepumpingpowerratioisplotted.It

isfunctionofthegeometry,thePrandtlnumberandtheReynolds

number.

Fig.12 showsthatwhateverthegeometryandthefluid,the

Pth/

e

ratiodecreaseswhen theReynoldsnumberincreases.Thismeans that the heat transfer intensification regarding energy

saving ismoresignificantatlowerflow regime.WhenSAR and

corrugatedgeometriesarecompared,twobehavioursareobserved

dependingonthePrandtlnumber.ForlowPrandtlnumber(water),

thepowerratioishigherinthecorrugatedchannelthanintheSAR

patterns(x2)whereasforhighPrandtlnumbers(glycerol70%w.)

powerratiosaresimilar.Inourcase,theincreaseinPrandtlnumber

favours the diffusion effect vs advection. As a consequence,

advectionwhich appearsas thepredominantphenomenon and

seemstogovernthewaterflow(lowPrandtlnumber)favoursthe

powerratiointhe2DcorrugatedgeometrycomparedwiththeSAR

ones.Whentheviscosityincreases,thebalancebetweenadvection

anddiffusioneffectsisshiftedandtheSARmechanismseemsto

becomeinterestingoveradvection.SAR-3patternshowsalower

powerratiothanothergeometries.Thisisconsistentwithresults

displayedinFigs.7and9,thehigherheattransfercapacity(see

Fig.9)doesnotcompensatethehigherpressuredrop(seeFig.7).

4.Implementationofacasestudy"exothermalreaction

4.1.Theoxidationreaction

Basedonthepromisingresultsofthethermalcharacterization,

anexothermicreactionisimplementedintheSAR-1HEXreactor.

ThisistheoxidationofsodiumthiosulfateNa2S2O3byhydrogen

peroxideH2O2:

2Na2S2O3+4H2O2!Na2S3O6+Na2SO4+4H2O

Thisreactionoccursinhomogeneousliquidphase,is

irrevers-ible,fastanditsreactionheatis

D

Hr="586.2kJmol"1.Sinceitistemperature sensitive, i.e. the conversionrate depends on the

Fig.10. HeattransfercapacityvsReynoldsnumber(glycerol90%weight"Pr)200).

operatingtemperature,thisreactionisanidealcandidateforcase

study[4,24–28].

4.2.Experimentalset-up

The implemented experimental set-up and procedure are

similartotheonesdescribedbyTheronetal.[6].Theoxidation

reactioninvolvestwoaqueoussolutionsofsodiumthiosulfateand

hydrogenperoxideasreactants.Toavoidtoohightemperatures

insidethereactorincaseofanadiabaticrisethetwosolutionsare

bothpreparedinorder toreach9%inmass ofeach reactantin

water. Two operating temperatures, controlled by the utility

streamtemperature,aretested: 40 and50$C.For these

experi-mentsthereactoristhermallyinsulatedthankstoapolystyrene

jacket.

TheoperatingconditionsarelistedinTable3.

Theconversionrate

x

inthereactorisdeducedfromthereactorthermalbalancebetweentheprocessandutilityinletsandoutlets

atsteadystate.Theconversionisthuscalculatedasfollows:

x

¼Ploss þFp:Cpp: Tp;out "Tp;in!

" þFu:Cpu: Tu;out "Tu;in

! "

Preaction ð11Þ

where

FpandFuarethemassflowrateinrespectivelytheprocessand

theutilitychannels

Preactionisthetotalheatofreaction:

Preaction ¼ _ni:

D

Hr ð12Þwhere _ni is the initial molar flowrate of the limiting reactant

(Na2S2O3).

Plossistheheatloss.Itismeasuredfrompreliminaryunreactive

tests.Boththeprocessandtheutilitylinesarefedwithwateratthe

temperatures and flowrates targetedfor thereactiontests. The

heatlossesareassessedwhensteadystateisreached.

4.3.Resultsanddiscussion

ThemeasuredconversionratesaregiveninTable3 foreach

experiment.

As expected the conversion rate increases when increasing

eithertheresidencetimeinthereactororthetemperatureofthe

utilitystream.Itisinterestingtonotethatautilitytemperature

below40$CalmostinhibitsthereactionintheHEXreactor.Asa

consequencetheminimalutilitytemperatureof40$Callowsthe

initiationofthereactionandthenthecontrolofthetemperature

riseduetothereactionexothermicity.

TheFig.13showstheconversionprofileversustimeobtained

fromtheGrauetal.[29]kineticlawandtheexperimentaldatafor

boththe2DcorrugatedHEXreactor(see[6],T=42.9$C)andthe

SAR-1one(T=47.5$C).

At fixed utility inlet temperature the different flowrates

experimentallytested enabletocompare theconversiontothe

kineticdata reportedintheliterature at differentstagesof the

reaction.

TheexperimentaldatadisplayedinFig.13areobtainedwitha

utilitytemperatureequalto40$C.Theequilibriumtemperatureat

theprocessoutletishigherintheSAR-1HEXreactor(47.5$C)than

inthecorrugatedone(42.9$C).Thisis consistentwiththeheat

transfer characterisation (see Fig. 10) which showed that for

inviscidfluidheattransfercapacityofthecorrugatedgeometryis

higher.

TheFig.13showsthatforbothconversionratesof88and94%

thekineticmodelresultsfitwellwiththeexperimentaldatasince

thediscrepancyislowerthan6%.Ahigherdiscrepancy (15%)is

Fig.12.ThermalexchangedpowertopumpingpowerratiovsReynoldsnumber(glycerol70%weight"Pr)40andwater"Pr)7).

Table3

Operatingconditionsoftheoxidationtests.

No.exp. Processside Utilityside Conversionrate(%)

FH2O2(kgh"1) FNa2S2O3(kgh"1) Reynoldsnumber Residencetime(s) Tutility($C)

1 1.7 3.4 472 20 40 94

2 2.4 4.8 667 14 40 88

3 3.4 6.8 944 10 40 59

obtainedatthelowresidencetime.Theprofileofconversionvs

time obtained from Grau et al. data [29] assumes a constant

temperature.HoweverintheSARHEXreactor,whentheresidence

timedecreases,i.e.whentheflowrateincreases,thetemperature

profile along the SAR channel is less uniform than for longer

residencetimes.Almost0.5m,i.e.aquarteroftheprocesschannel

developedlength,isrequiredtoheatthereactantuptothedesired

temperature(40$C).Inthispartofthechannel,thetemperatureis

thustoolowtoinitiatethereaction.Asaconsequencetheeffective

residencetime during which reactantsareconverted is shorter

than the theoretical one reported in Fig.13 (Fp/V=10s). This

explainswhythediscrepancybetweentheconversionpredicted

fromGrauetal.kinetics[29]andthemeasuredonemayincrease

whentheflowrateincreases.

However,theresultsobtainedinthisstudyshowreasonable

agreementwithGrauet al.[29] kineticparameterswhich have

been obtained from batch experiments, especially for long

residence time, ie low flowrates (Re=573 and 802). As a

consequence itconfirms that themixing time is not a limiting

parameterforsuchafastreaction.Moreover,sinceheattransfer

capacityintheSARHEXreactorishighenough,thereactioncanbe

implemented at higher temperature to accelerate the rate of

reactionwithoutsafetyissues.

5.Discussion/Conclusion

Thermalandhydraulicbehaviourofastructuredchaoticflow

hasbeencharacterizedinheatexchanger/reactorswithchannel

designsbasedonSplit-And-Recombinepatterns.Theprincipleis

based ontheBaker’s transformation and chaotic structuresare

generated to promote heat and mass transfer intensification.

Intensive mixing performances of such geometry have been

demonstratedinpreviousstudies[13,23]and thiswork

investi-gatedtheenergyefficiencyofaheatexchanger/reactorintegrating

theseSARpatterns.

Three stainless steel mock-ups "assembled by diffusion

bonding-havebeenexperimentallycharacterized.Twodifferent

flow patterns according to the number of SAR structures are

available.Foroneofthesegeometries,twocoolingsystemshave

beeninvestigated,externalcoolingPlates"isothermalwall-and

integrated cooling tubes. For each mock-up, the 3mm square

cross-sectionchannelsarearound3.5mlong.

The SAR based reactors have been compared with a 2D

corrugatedgeometry.Thenumberoffluidsplittingand

recombi-nation per unit of developed length is a design parameter

promotingheattransferbutalsogeneratinghigherfrictionlosses.

Itresultsinsimilarperformancesconsideringtheenergy

dissipa-tionrate.Likewise,similarheattransfercapacitiesaremeasured

betweenSAR-1 and SAR-2geometriesregardless of thecooling

system. The integrated cooling tubes system which is more

complex to implement than the sandwiched plates seems not

necessary.

Accordingtotheflowregimeabalancebetweenadvectionand

diffusion exists. The former becomes predominant for high

ReynoldsnumberorlowPrandtlnumber.Turbulent-likestructures

(likeDeanvortices)appearandgovernthetransfermechanisms.In

these flow conditions, the design parameter seems to be the

number of 90$ bends/m and thecorrugated geometry is much

moreperformant.Butwhenthefluidviscosityincreases,the

Split-And-Recombinemechanismseemstopromotethechaoticnature

oftheflow andcontributes withadvection totheheat transfer

intensification.

Considering theintensification of mixing in SAR geometries

comparedwithcorrugatedone,maintaininghighheattransferata

similarlevelthanthecorrugatedgeometryisaninterestingresult

regardingapplicationsinchemicalindustryhandlingviscousfluids

(food industry, bulk chemistry, polymers,...). Implementing

moreviscousfluidscouldpossiblyhelptocompletelydissociate

theinfluenceofadvectionversusdiffusion.

A case study with the continuous oxidation of sodium

thiosulfatewithhydrogenperoxidehasbeenstudied.Conversions

havebeenmeasuredaccordingtothecoolingfluidtemperature

andtheresidencetime.Conversionsupto99%havebeenreached

withresidencetimearound13sandconfirmedthatmixingtimeis

nota limiting parameterforsucha fastreaction.Howeverthis

reaction involves inviscid fluids (viscosity close to water) and

advectiongoverns probablythe flow.It could beinteresting to

completetheseresultswithanexothermicreactionwithviscous

media.

Finally,SARpatternscouldbecandidateforscale-upprocedure.

Whenincreasingthehydraulicdiameterabalancebetweenthe

increaseoftheDeannumber(coupledtoanincreaseofthelosses)

andtheuniformityofthemulti-laminatedfluidstreamshouldbe

thekeyissue.

References

[1]A.I.Stankiewicz,J.A.Moulijn,Processintensification:transformingchemical engineering,Chem.Eng.Prog.96(2000)22–34.

[2]A.Cybulski,J.A.Moulijn,A.I.Stankiewicz,NovelConceptsinCatalysisand ChemicalReactors:ImprovingtheEfficiencyfortheFuture,Wiley-VCH, Weinheim,2010.

[3]Z.Anxionnaz,M.Cabassud,C.Gourdon,P.Tochon,Heatexchanger/reactors (HEXreactors):conceptstechnologies:state-of-the-art,Chem.Eng.Proc.47 (2008)2029–2050.

[4]Z. Anxionnaz, M. Cabassud, C. Gourdon, P. Tochon, Transposition of an exothermicreactionfromabatchreactortoanintensifiedone,HeatTransfer Eng.31(2010)788–797.

[5]Z.Anxionnaz-Minvielle,M.Cabassud,C.Gourdon,P.Tochon,Influenceofthe meanderingchannelgeometryonthethermo-hydraulicperformancesofan intensifiedheatexchanger/reactor,Chem.Eng.Process.ProcessIntensif.73 (2013)67–80.

[6]F. Theron,Z. Anxionnaz-Minvielle, M.Cabassud, C. Gourdon, P. Tochon, Characterizationoftheperformancesofaninnovativeheat-exchanger/reactor, Chem.Eng.Process.ProcessIntensif.82(2014)30–41.

[7]M.Moreau,N.DiMiceliRaimondi,N.LeSauze,M.Cabassud,C.Gourdon, Pressuredropandaxialdispersioninindustrialmillistructuredheatexchange reactors,Chem.Eng.Process.ProcessIntensif.95(2015)54–62.

[8]A.Ghanem,C.Habchi,T.Lemenand,D.DellaValle,H.Peerhossaini,Mixing performancesofswirlflowandcorrugatedchannelreactors,Chem.Eng.Res. Des.92(2014)2213–2222.

[9]C.Habchi,S.Russeil,D.Bougeard,J.L.Harion,T.Lemenand,D.DellaValle,H. Peerhossaini,Enhancingheattransferinvortexgenerator-type

multifunctionalheatexchangers,App.ThermalEng.38(2012)14–25. [10]EuropeanProcessIntensificationCenter,EUROPIC,http://europic-centre.eu/,

2016(accessed02.29.2016).

[11]P. Carrière, On a three-dimensional implementation of the Baker’s transformation,Phys.Fluids19(2007)118110.

[12] F.Raynal,P.Carrière,Thedistributionoftimeofflightinthreedimensional stationarychaoticadvection,Phys.Fluids27(2015)1.4918750.

[13]F.Schönfeld,V.Hessel,C.Hofmann,Anoptimisedsplit-and-recombine micro-mixerwithuniform‘chaotic’mixing,LabChip—Miniat.Chem.Biol.4(2004) 65–69.

Fig. 13.Conversionratevs.residencetime(Tu=40$C).Comparisonofthetheoretical conversionwiththeexperimentalones.

[14]B.L.Gray,D.Jaeggi,N.J.Mourlas,B.P.vanDrieënhuizen,K.R.Williams,N.I. Maluf,G.T.A.Kovacs,Novelinterconnectiontechnologiesforintegrated microfluidicsystems,Sens.ActuatorsAPhys.77(1999)57–65.

[15]H.Chen,J.-S.Meiners,Topologicmixingonamicrofluidicchip,Appl.Phys.Lett. 84(2004)2193–2195.

[16]J.Branebjerg,P.Gravesen,J.P.Krog,C.R.Nielsen,Fastmixingbylamination, Proc.IEEEMicroElectroMech.Syst.(MEMS)(1996)441–446.

[17]M.Creyssels,S.Prigent,Y.Zhou,X.Jianjin,C.Nicot,P.Carrière,Laminarheat transferintheMLLMstaticmixer,Int.J.HeatMassTransfer81(2015)774–783. [18]A.Ghanem,T.Lemenand,D.DellaValle,H.Peerhossaini,Optimizedchaotic heatexchangerconfigurationsforprocessindustry:anumericalstudy,Proc. ASMEFluidsEng.Div.SummerMeet.(2013),InclineVillage,USA. [19]A.Mokrani,C.Castelain,H.Peerhossaini,Theeffectsofchaoticadvectionon

heattransfer,Int.J.HeatMassTransfer40(1997)3089–3104.

[20]C. Chagny, C. Castelain, H. Peerhossaini, Chaotic heat transfer for heat exchangerdesignandcomparisonwitharegularregimeforalargerangeof Reynoldsnumbers,Appl.Therm.Eng.20(2000)1615–1648.

[21]V.Kumar,S.Saini,M.Sharma,K.D.P.Nigam,Pressuredropandheattransferstudy intube-in-tubehelicalheatexchanger,Chem.Eng.Sci.61(2006)4403–4416. [22]R.Couturier,C.Bernard,J.M.Leibold,F.Vidotto,P.Tochon,Deviceforminga

chemicalreactorwithimprovedefficiency,comprisingaheatexchanging circuit,PatentnoWO2011/083163Al,2011.

[23]A.Ghanem,T.Lemenand,D.DellaValle,H.Peerhossaini,Transportphenomena inpassivelymanipulatedchaoticflows:Split-and-recombinereactors,Proc. ASMEFluidsEng.Div.SummerMeet.(2013),InclineVillage,USA.

[24]L.Prat,A.Devatine,P.Cognet,M.Cabassud,C.Gourdon,S.Elgue,F.Chopard, Performanceevaluationofanovelconcept“openplatereactor”appliedto highlyexothermicreactions,Chem.Eng.Technol.28(9)(2005)1028–1034. [25]M.D. Grau, J.M. Nougues, L. Puigjaner, Batch and semibatch reactor

performanceforanexothermicreaction,Chem.Eng.Proc.39(2000)141–148. [26]A.M.Benkouider,J.C.Buvat,J.M.Cosmao,A.Saboni,Faultdetectionin semi-batchreactorusingtheEKFandstatisticalmethod,J.LossPrev.ProcessInd.22 (2009)153–161.

[27]L.Vernieres-Hassimi,M.A.Abdelghani-Idrissi,D.Seguin,Experimentaland theoreticalsteadystatemaximumtemperaturelocalizationalongan exothermictubularreactor,OpenChem.Eng.J.2(2008)57–65.

[28]W.Benaissa,S.Elgue,N.Gabas,M.Cabassud,D.Carson,M.Demissy,Dynamic behaviourofacontinuousheatexchanger/reactorafterflowfailure,Int.J., Chem.React.Eng.6(2008).

[29]M.D. Grau, J.M. Nougues, L. Puigjaner, Batch and semibatch reactor performanceforanexothermicreaction,Chem.Eng.Proc.39(2000)141–148.