an author's

https://oatao.univ-toulouse.fr/26942

https://doi.org/10.1016/j.ijmecsci.2019.105370

Sánchez Camargo, César Moisés and Hor, Anis and Mabru, Catherine A robust inverse analysis method for

elastoplastic behavior identification using the true geometry modeling of Berkovich indenter. (2020) International

Journal of Mechanical Sciences, 171. 105370. ISSN 0020-7403

A

robust

inverse

analysis

method

for

elastoplastic

behavior

identification

using

the

true

geometry

modeling

of

Berkovich

indenter

Cesar-Moises

Sanchez-Camargo

∗,

Anis

Hor

,

Catherine

Mabru

Institut Clément Ader (ICA), Université de Toulouse, CNRS, ISAE-SUPAERO, UPS, INSA, Mines-Albi, 3 rue Caroline Aigle, 31400 Toulouse, France

Keywords: Nanoindentation Finite element modeling Inverse analysis Friction effect

a

b

s

t

r

a

c

t

Theparametersdescribingtheelastoplasticbehaviorofthe316Lausteniticstainlesssteelareidentifiedthrough inverseanalysisbasedonfiniteelementmodelingoftheBerkovichnanoindentationtest.Thetruegeometryof theBerkovichindenterisintroducedinaxisymmetricand3Dfiniteelementmodelsusingexperimental nanoin-dentationdataobtainedbyadaptingthecalibrationmethodproposedbyOliverandPharr[1].Then,usingthese trueindentershapemodels,theelastoplasticparametersofthe316Lareestimatedwithhighaccuracycompared totheparametersobtainedfromtensiletestidentification.Theindentationcurvewascorrectlydescribedbythe numericalmodelforalltheanalyzedindentationdepths,evenforindentationsinferiorto100nm,whichisa challengeuntiltoday.The3Dindentermodelproducesaresidualimprintveryclosetotheexperimental indenta-tionmark.Thefrictionanalysisbetweentheindenterandthesamplesurfacerevealssmallchangesinthesurface deformation,introducinganincreaseonthehardness,whichdisappearsastheindentationdepthdecreases. Thesestudiesdemonstratethatthemostimportantaspectintheelastoplasticparameteridentificationisthe correctrepresentationoftheindentergeometryinthefiniteelementmodel.

1. Introduction

Indentationisapopularmethodforevaluatingelastic-plastic prop-ertiesofmaterialsandstructures,includingelasticmodulus,hardness andyieldstrength[2,3].Severalresearchstudieshaveusedthistestto analyzework-hardening,residualstress[4],andfracturetoughness[5], etc.,thesepropertiesareimplicitlyrelatedwithindentationresponse. Thislocalizedtestcanalsobeappliedtomeasurethepropertiesof indi-vidualphasesaswellasglobalpropertiesofcompositematerials, coat-ingsandmultilayers[6,7].Sinceitrequiresmuchlesseffortonsample preparationthanothertechniques, itis inparticularusefulforsmall materialstructuresandbiologicalmaterials(includinglivingtissues). Duetotheinvolvedfinitelocaldeformationandnonlinearcontact con-ditions,numericalmodelingofindentationisavaluabletoolto under-standofthelinkbetweenindentationdataandmaterialproperties,and tocorrelatetheindentationresultswithmaterialparameters.Then,an inverseanalysiscanbecarriedouttoidentifythesematerialproperties fromindentationtests.

Theelastoplasticcharacterizationofmetalsbynanoindentationtest remainsoneofthebiggestchallengesinthemicro-characterization do-main[8,9,10].Themethodsofelastoplasticcharacterizationby nanoin-dentationtestcanprovideaccesstothemechanicalbehavior[11]at multiplescalesandinconditionswheretheconventional methodsof mechanicalcharacterization(e.g.tensiletest)aredifficultor

impossi-∗ Correspondingauthor.

E-mailaddress:cmoises.sanchez@gmail.com(C.-M.Sanchez-Camargo).

bletoapply,e.g.multi-layerssystems,functionalizedsurfacesamong others.Theadvantageoftheuseofthenanoindentationtechniqueis thatitisabletomechanicallytestvolumesofmatterinthemicroscale, producingexperimentaldataofhighaccuracy.

Thenanoindentationtestproducestwomainpiecesofinformation: theresidualimprintandtheloading-unloadingcurve(referredalsoas nanoindentationcurve).Theparametersdescribingtheresidualimprint andthenanoindentationcurveare:hmisthemaximumdisplacementof theindentermeasuredfromthefreesurface,hcisthedepthtothe

con-tactpoint;hsisthedistancefromthecontactpointtothefreesurface,

A(z)isthecrosssectionareaoftheindenteratthecontactpoint,Pmis

thepeakindentationload,Sistheslopeoftheunloadingbranchofthe nanoindentationcurve,andhfisthelastpointofcontactbetweenthe

indenterandthetestedsurface.

Actually,severalmethodsofestimationoftheelasticmodulusand thehardnessofthetestedsurfaceareavailable[12,13].Thesemethods purelyelasticarebasedonlyontheunloadingstageofthe nanoinden-tationtest(Fig.1)[14].Inthecaseoftheelastoplasticcharacterization, twomaintypesofapproacheshavebeendevelopedsincetheapparition of thenanoindentationtest:theanalyticalinversemethods[9,10,11]

andthenumericalinverseanalysis[8,15].

Ingeneralterms,theanalyticalmethodsarebasedonthe hypoth-esisofarepresentativestrainassociatedwiththegeometryofthe in-denter[16],i.e.thestraininducedinthesurfaceisindependentofthe

Fig.1. (a)Schemaoftheindentation,and(b)typical corre-spondingnanoindentationcurve.

Fig.2. AtomicForceMicroscopy(AFM)capturesofBerkovich indenters:(a)wornindenterwithtipradiusof1200nmand (b)newindenterwithtipradiusof500nm.

indentationdepth.Usingadimensionalanalysis[17],andfiniteelement modeling,a vastamount of workshas beenpublished, forinstance, amongthemostrelevant,thosepresentedin[18,19,20,21,22,47–50]. Suchmethodsarebasedonfiniteelementsimulationsofawiderange ofelastoplasticparameterstodeterminethecoefficientsofthe dimen-sionlessfunctions.These methodsweredevelopedusingthe microin-dentationonarangeof1<hm≤20𝜇m,where,accordingtothe

au-thors,thedefectsanddeviationsontheindentercanbeneglected.In thenanoindentationscale,i.e.0<hm≤200nm[23,24],thewearand thedeviationsontheindentertiparenotnegligible.Theeffectsofthese deviationsonindentershapeareconfirmedbyDaoetal.[19],where theyobservedinfiniteelementsimulationsthatavariationof2° onthe halfangleofaconicalindenterresultsin15−20%variationsinthe

P−hloadingcurvature.

Since, in nanoindentation,the effectsof thewearand deviations onthetipmustbetakenintoaccountonfiniteelementsimulationsa methodtoreproducethephysicalindentergeometryinthefinite ele-mentmodelisrequired.Ingeneraltwoapproachesrelatedtothis is-suecanbefoundintheliterature:i)themodelingoftheindenterasa sphero-conicalrevolutionshape[25,26,27,28,29]andii)themodeling oftheindenterfromacloudofpointsgathered withanatomicforce microscope[30,31].Aremarkableexampleofthefirstapproachwas proposedbyPelletieretal.[25].Theprincipleofthismethodconsists inthedescriptionoftheBerkovichindenterbasedontheuseofthe func-tionareaproposedbyOliveretal.[1],whichrelatesthecrosssection areaof theindenter tothedistancemeasuredfromitstip.Fromthis functionareaanequivalentfunctionareadescribingasphero-conical indenterisderived.Thelimitationofthisapproachisthattheindenter issphero-conical; thereforetheresidualimprintcannotbe compared withtheexperimentalresidualimprintofaBerkovichindenter.

Themostrelevantworkfoundforthesecondapproachwasproposed byKrieretal.[30].TheauthorscapturedtheBerkovichindenter ge-ometrywithanAtomicForceMicroscopy(AFM) andthenintroduce thetruegeometryin thefiniteelementmodel. Theirmethodis able toreproducequitewell indentationsdowntohm =40nm.However theimplementationofthemethodisachallengeforseveralreasons,in particularthecorrectionoftheAFMcloudofpoints.Inthisworkthe

authorsstatedthatthebluntingtipdefectaffectstheload-displacement curve,especiallytheloadingphase,andalsotheelastic–plasticstress andstrainfieldsbeneaththeindenter.Theyhighlightedthatthiseffect ontheelastic–plasticstrainfieldisarealandphysicaleffectthat can-notbeavoidedandlimitedbyananalyticalmodel[30].Thisstatement isverifiedthroughAFMcapturesofthetwoBerkovichindenters avail-ableforthepresentresearch(Fig.2),whichexhibitdeviationsonthe selectedoperativerange.Butalsotheartefactsthatmustbecorrected ifthecaptureisusedtoreproducetheindentergeometryinthefinite elementmodelarevisible.

Althoughthestudiescitedaboveaddresstheproblematicassociated withthedescriptionofthephysicalBerkovichindenter,itdoesnotexist, accordingtoourpresentknowledge,areliableandeffectivemethod tointroducethetrueindentergeometryon thefiniteelement model allowingthecorrectrepresentationofindentationsonstrainhardening solidsintheinterval0<hm≤500nm.Theobjectiveofthispaperisto

providesuchmethodandevaluatethefollowingaspects:

1 Theabilityoftheproposedmethodtocorrectlydescribetheshapeof theBerkovichindenterinbothaxisymmetricand3Dfiniteelement models.

2 Theaccuracyoftheelastoplasticparametersidentificationusingthe inverseanalysisbasedonthefiniteelementmodelincludingthetrue indentergeometry.

3 Numericaleffectsofthefrictionanditsroleinthenanoindentation simulation.

2. Experimentalstudy

Thematerialusedinthisresearchisthesingle-phaseaustenitic stain-lesssteelAISI316L[32].Themicrostructureiscomposedofequiaxed grainswithamultitudeoftwinning(Fig.3a).Thegrainsizeisbetween 10and40𝜇m.Thecrystallographicstructureofthisausteniticphaseis Face-CenteredCubic(FCC).Theelectronbackscatterdiffraction(EBSD) mapshowninFig.3bhighlightsanon-texturedmaterial.

Themechanicalbehaviorofthe316Lwascharacterizedbyuniaxial tensiletest[33].TheYoung’smodulusobtainedwiththistensiletestis

Fig.3. (a)Microstructureand(b)textureof316Lstainless steel.

Fig.4. Truestress-truestraincurveof316Lstainlesssteel.

method(Fig.4),accordingtotheconstitutiveequation[19]:

𝝈 =𝝈𝒚 ( 1+ 𝑬 𝝈𝒚𝜺𝒑 )𝒏 (1)

where𝝈yrepresentstheyieldstressandnthehardeningexponent.The

valuesofyieldstressandhardeningexponentidentifiedfromthe ten-siletest,usinganoffsetof0.2%plasticstrain,wereconsideredasthe referencevaluesoftheelastoplasticparametersandwereusedasa com-parisoninthefollowingtoassesstheaccuracyoftheanalysisproposed inthispaper:𝝈y=409MPaandn=0.231

2.1. Surfaceoptimizationfornanoindentationexperiments

Ananoindentationspecimenwasmachinedinacubeof2cmside fromthe316Lsameroundbarstockthatwasusedfortensiletest.In order toensureasurfacerepresentativeofthebulkmaterial, thetop layerofthemachinedsurfacewasremovedgraduallyfollowingthis it-erativeprocedure:firstly,theinitialheightofthesamplewasmeasured. Then,mechanicalgrindingusingSiCpaperswasdownto1200gritand thefinalheighthasbeenre-determinedagain.Then,five nanoinden-tationsusingPm =50mNwereconducted.Finally,theheightof the pile-upfromAFMcapturesoftheresidualimprintwasestimated.Once thepropertiesmeasured(i.e.hmandpile-up)becameconsistent,the

sur-facewaspolishedusingadiamondsolutionof1𝜇m,andfinishedwith vibratorypolishingusingcolloidalsilicaduringeighthourswithonly sampleweight[34].Thevariationsinthemeasuresofhm (Fig.5(a))

andtheheightofthepile-up(Fig.5(b))duringtheprocedurerevealed thatthemachiningprocessinducedagradientofproperties,extending througha250𝜇mlayerfromthefreesurfaceofthesample.

Themeanvalueofhmwas 820nmonthestabilized surface,and

860nmonthepolishedsurface(Fig.6(a)).Theresidualimprintonthe polished surfacerevealedthe influenceof the crystallographic char-acteristics of theindented point in theform of asymmetric pile-ups (Fig.6(b)).

The prepared surface was inspected by X-ray diffraction using sin2𝜓 method to analyze the residual stress state [35], finding 𝜎11 = 12∓8MPa and 𝜎22 = −15∓11MPa. The surface can thus be considered as free from internal stresses. The microstructural-crystallographiccharacteristicsweredeterminedthroughEBSD analy-sis.ThetreatmentoftheEBSDdata[36]revealedadistortionless mi-crostructurefreeofpre-hardening,withanintragranularmisorientation rangingfrom0° to4° atthecenterofthegrains(Fig.7(a)).Theroughness oftheworkingsurfacewasestimatedfromAFMcaptures(Fig.7(b));it wasgloballyRa=4nmandlocallyRa=1.4nm.ThelocalvalueofRa wasusedtodefinetheminimumvalidvalueofhmonthissurface,which

Fig.5. Surfaceoptimizationprocedure:(a)evolutionofhm

and(b)evolutionoftheheightofthepile-upasafunctionof theremovedlayer(affectedbymachining).

Fig.6. Effectsofpolishing:(a)evolutionofhmand(b)residual

imprintofthepolishedsurface.

Fig.7. Surface stateof the polishedsurface:(a) crystallo-graphicmisorientationstateand(b)roughnessstate.

Table1

Finalsurfaceproperties.

Roughness

Crystallographic misorientation

(pre-hardening) Residual stresses R a = 4 nm less than 5° 𝜎11 ≈ 0 MPa/ 𝜎22 ≈ 0 MPa

isofabout28nm,i.e.20timesRa[24].Thepropertiesofthesurfaceat

theendofthepreparationprocedurearelistedinTable1.

2.2. Nanoindentationexperiments

Oncetheworkingsurfacewasprepared,thenanoindentation exper-imentswereoptimizedandconductedonthepolishedsurface.Allthe nanoindentationexperimentswereconductedusingthewornBerkovich indenteroftipradiusr=1200nm(Fig.2(a))inloadcontrolledmode atroomtemperatureonaNHT2commercialnanoindenterfromAnton Paarinstruments.Theoptimumloading/unloadingratewasdetermined experimentally on the optimized working surface. Series of nanoin-dentationexperimentswereconductedusingaconstantloadingforce

Pm=10mNandvaryingtheloadingrate.Thetotalindentationwork

(Wt,Eq.(11))constantuntilavalueofloadingratenearto25mN/min,

afterthisvalue,Wtincreaselinearly(Fig.8(a)).Thereforewe consid-eredthatusingloadingrateslowerthan25mN/minallowsneglecting thetimedependenteffects(e.g.indentationcreep)forPm=10mN.

Onthesmallerscale,thetimedependenteffectscanbeobservedin thefirststageoftheloadingnanoindentationcurve(Pmbetween0and

0.5mN),whereloadingratesgreaterthan6mN/minintroduceaslight increaseintheloadingcurve(Fig.8(b)).Finallyusingtheloadingrate closeto6mN/minallowsobtainingcomparableindentationcurvesfor differentindentationloadingvalues.Thevaluesofloading/unloading rateusedinthisstudy(Table2)wereselectedrespectingthisrule,and consideringtheacquisitionfrequencytohavesimilarquantity experi-mentalpoints(i.e.usinglowerloadingratesforthesmallerPm).

Basedon thisinformation,theexperimentalprotocolwasdefined (Table2).ThistablealsopresentsthehmproducedbytheselectedPm.

Table2

Experimentalprotocolforindentationtestsusingthe wornBerkovichindenter.

P m ( mN ) h m ( nm ) Loading / unloading rate ( mN / min )

0.3 25 0.5

1 68 1

3 150 3

10 330 6

15 420 6

Themaximumhmisinferiorto500nm,asrequiredforthepresentstudy,

andtheminimumhmisgreaterthan20nm,whichisvalidwithrespect

tothelocalroughnessoftheworkingsurface(Fig.7(b)).

Atotalofninenanoindentationswereappliedforeachofthefive peakloadslistedintheTable2,spacedenoughtoavoidinterferences. Accordingtotheliterature[24],theindentationmustbespacedatleast threetimesthediameteroftheimprintmark.Inthisstudyweuseda spacingoftentimesthediameteroftheresidualimprint.Fromeach groupofnineindentationstheP−hcurvessharingthesameloading pathwereselected(Fig.9(a)),andanAFMcaptureoftheirrespective residualimprintswastaken(Fig.9(b)).

3. Numericalmethod

3.1. Finiteelementmodelingofthespecimen

Allthesimulationsinthispaperwereconductedincontrolled dis-placementappliedtotheindenter.Thespecimenwasmodeled asan axisymmetricbodyandasafull3Dmodel[37]usingtheimplicit non-lineargeometryFEalgorithminAbaqus[38].

Firstly,theaxisymmetricmodelwasoptimizedthroughamesh re-finement convergence analysis, using a fixed hm = 500nm, a rigid

cone equivalent to a perfect Berkovich indenter [39], a frictionless contact,andtheelastoplasticparametersoftheEq.(1):E=180GPa,

𝜎y =148MPa, n=0.278[40].Theiterativeprocedurewasapplied

Fig.8. Analysisofnanoindentationtimedependenteffectson 316L:(a)effectsofloadingrateonWtand(b)effectsofloading

rateonthefirstportionoftheloadingnanoindentationcurve.

Fig. 9. Nanoindentation experiments using the worn Berkovichindenter:(a)P−hcurvesand(b)residualimprints associatedtoeachP−hcurve.

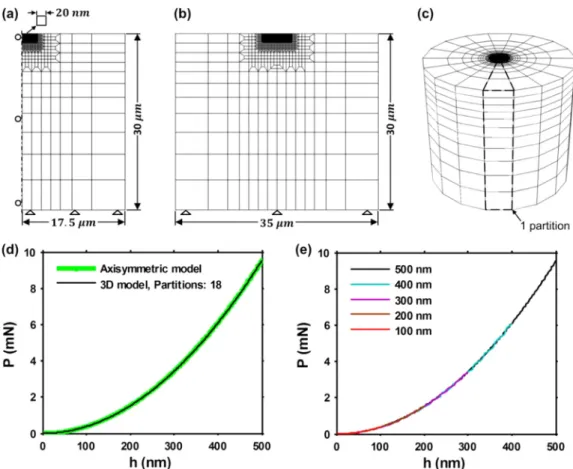

Oncetheoptimummeshandsizeofthespecimenwasfoundforthe axisymmetricmodel(Fig.10(a)),thecharacteristicsoftheaxisymmetric modelwerereplicatedonthe3Dmodel(Fig.10(b)).Then,themesh densityofthe3Dmodelwasincreasedbyaddingpartitions(Fig.10(c)), untiltheloadingcurvesofthe3Dandtheaxisymmetricmodelswere equivalents(Fig.10(d)).

Finallybothmodelswereparametrized,usingasmasterparameter

hm:thereforethesamemodelwassuitablefor theanalysisofalarge rangeofhm,ensuringsimilarcontactconditions(Fig.10(e)).

3.2. Finiteelementmodelingoftheindenter

Theproposed methodis basedontheuseofseveralvaluesofthe sectionareaAoftheindenterandtheircorrespondingvaluesofz,i.e.

A(z),withztheneutralaxisoftheindenter(Fig.11).ThevaluesofAare usedtodefinethepointsofthegeneratrixatthecorrespondingzvalues. Then,thegeneratrixisrotatedaroundthezaxisfollowingacircular directrixtoobtainaconicalindenter(Fig.11(a)).Inthecaseofa3D indenter,thegeneratrixismovedalongastraightdirectrixtogenerate onewalloftheindenter.Then,usingacircularpatterntheotherthree wallsaregeneratedandtrimmedontheintersections(Fig.11(b)).The stepsrequiredtoobtainthegeneratrixforbothindentersareexplained below.

Forsimplicity,theexplanationofthemethodisbasedonthe assump-tionofaperfectBerkovichindenter(Fig.11).Consideringtheareaofthe circularsectionofacone,theassociatedradiusisgivenbytheequation:

𝐫(𝐳)= √

𝐀(𝐳)

𝝅 (2)

wherer(z)isthegeneratrixintheaxisymmetricfiniteelementmodel (Fig.11(a)).

Movingtothe3Dindenter,thesectionoftheindenterhasashape ofanequilateraltriangle(Fig.11(b)).Thelengthof eachsideofthe

triangleisgivenbytheequation:

𝑎(𝑧)= √

𝐴(𝑧)√4 3

(3)

Then,theperpendiculardistancefromtheaxisoftheindentertothe sideofthetriangleiscomputedfrom:

𝑐(𝑧)= 𝑎(𝑧) 2 tan

(

30◦) (4)

Inthiscasec(z)isthegeneratrixofthewall,anda(z)isthe direc-trix.Introducingtheindenteronthefiniteelementmodelrequiresthe valuesofAalongtheaxiszoftheindenter.Awell-knownrelationisthe BerkovichfunctionareaA(z)=24.5z2[1].Usingthisrelationonthe

proposedprocedureaperfectBerkovichindenterisgenerated,whichis characterizedbyanangle𝜃 =70.3° inthecaseofanaxisymmetric in-denter(Fig.11(a)),orbyanangle𝛼 =65.3° inthecaseofa3Dindenter (Fig.11(b)).

Sincetheobjectiveis tointroducethetrue indentergeometryon thefiniteelementmodel,itisrequiredtoestimateAatseveralpoints ofthezaxisofthephysicalindenter.Thisproblemwassolvedafew decadesagobyOliverandPharr[1].Theprincipleofthismethodisto estimateAatagivencontactdepth,hc,throughtheindentationona

well-knownmaterial(Fig.1).Ontheirworktheyproposedtousethe fusedquartzasindentedmaterialwiththeelasticconstantsEs=72GPa

and𝜈s=0.17;andadiamondBerkovichindenterwiththeelastic

con-stantsEi=1141GPaand𝜈i=0.07.

Firstly,Aiscalculatedusingtherelation:

𝑆= 𝑑𝑃 𝑑ℎ = 2 √ 𝜋𝐸𝑟 √ 𝐴 (5)

whereSisthecontactstiffness,computedattheinitialportionofthe unloadingdata(Fig.1),andthereducedmodulus,Er,iscomputedusing

Fig.10. Nanoindentationfiniteelementmodeling:(a)axisymmetricmodel(b)sectionofthe3Dmodel(c)partitioningofthe3Dmodel,(d)equivalencebetween the3Dandtheaxisymmetricmodeland(e)loadingcurvesproducedbytheparametrizedmodelsonawiderangeofhm.

Table3

Experimentalprotocolforindentationsonfusedquartz.

Indentation numbers Peak load (mN)

Loading/unloading rate (mN/min) Oliver and Pharr [1] 1–10 0.1 0.6 11–20 0.3 1.8 21–30 1 6 31–40 3 18 41–50 10 60 51–60 20 120 Extension 61–70 40 240 71–80 60 360 81–90 80 480 therelation: 1 𝐸𝑟 =1−𝜈𝑠 2 𝐸𝑠 +1−𝜈𝑖 2 𝐸𝑖 (6) where𝜈sandEsaretheelasticconstantsforthespecimen,and𝜈iandEi

arethesameparametersfortheindenter. Then,hciscomputedfromtheequation:

ℎ𝑐=ℎ𝑚−ℎ𝑠 (7)

wherehsisthedeflectionofthesurfaceoutsidethecontactarea(Fig.1),

whichiscomputedfromtheequation:

ℎ𝑠=𝜋2(𝜋 −2)𝑃𝑆𝑚 (8)

Onthisstudy,themethodofOliverandPharr[1]wasusedunder threeconsiderations:1)hcis equivalenttoz,2) theoriginal

nanoin-dentationprotocolusedonthefusedquartz(Table3),wasextendedto estimatethevalueofAforacorrespondingvalueofz=500nm,and

3)theelasticconstantsoftheBerkovichindenterandthefusedquartz werethesamethatthoseproposedbyOliverandPharr[1];both,the di-amondBerkovichindenterandthestandardizedsampleoffusedquartz wereobtainedfromthemanufactureroftheNHT2nanoindenter.The indentersgeneratedwiththeproposedprocedurearereferredastrue indenters.

Finally,9valuesofA(z)werecomputedusingtheextendedmethod ofOliverandPhar[1]indentingonfusedquartz(Fig.12),tocovera maximumz=500nm.

ThephysicalBerkovichindenterwasintroducedinthefiniteelement modelapplyingthisprocedurethroughPythonscriptsinAbaqus,in sep-aratemodelsintheformofaxisymmetric(Fig.13(a))and3D(Fig.13(b)) indenters,respectively.TheexperimentalpointsA(z)weredirectlyused togeneratetheindentergeometriesaddinganinitialpointintheorigin. Nofittingprocedurewasincludedtocreatethegeneratrixofthe inden-ters.Theaxisymmetricmodel(Fig.13(a)),ispresentedintheformof aconeusingthevisualizationcapabilitiesofAbaqus.The3Dindenter (Fig.13(b)),isafull3DrepresentationofthephysicalBerkovichused intheexperiments.

Oncethecharacteristicsofthespecimenandtheprocedureto gen-eratetheindenterwereestablished,thenextstepistodefinethe inter-actionbehaviorbetweenthesurfacesoftheindenterandthespecimen.

3.3. Indenter-specimencontactmodeling

Theinteractionbetweentheindenterandthespecimenwasdefined inAbaqusStandardusingthemaster-slaveconfiguration[38].The mas-tersurfacewastheexternalsurfaceoftheindenter,andtheslavesurface wastheexternaltopsurfaceofthespecimen.Theinteractionbetween theindenterandthespecimenwasanalyzedintwoways:1)in friction-lesscontact,and2)withfrictioncontact.Thefrictionwasintroduced in the modelusing the formulationof Coulombincludedin Abaqus

Fig.11. Geometricspecificationsoftheindenters:(a)conical indenterand(b)3Dindenter.

Fig.12. Experimentalpointsobtainedfromindentationonfusedquartzusing thewornBerkovichindenter.

[38]. Thisformulationassumesthatthere isnorelativemovementif theequivalentfrictionalstressgivenby

𝜏𝑒𝑞= √ 𝜏2 1+𝜏 2 2 (9)

isinferiortothecriticalstress,𝜏crit,whichisproportionaltothecontact

pressure,p,intheform:

𝜏𝑐𝑟𝑖𝑡=𝜇𝑝 (10)

Thefrictioncoefficient,𝜇,isafunctionofthecontactpressure,p, thesliprate,theaveragetemperature,andtheaveragefieldvariables atthecontactpoint.If𝜏crit=𝜏eq,slipoccurs.Inthisstudythefrictionis

consideredisotropic.Thedirectionoftheslipandthefrictionalstressis coincident.

3.4. Optimizationprocedureforelastoplasticparametersidentification

TheLevenberg-Marquardt[41]optimizationalgorithmwasusedto determinetheelastoplasticbehaviorparameters.Theobjectivefunction proposedisformulatedusingbothloadingandunloadingbranchesof theP−hcurve(Fig.1).

Fromtheloadingcurvethetotalindentationwork,Wt,isobtained

withtheexpression:

𝑊𝑡= ℎ𝑚

∫

0 𝑃𝑑ℎ

(11) whichisusedtodefinethefirstcomponentoftheobjectivefunctionin theform:

𝑓𝑡=𝑊𝑡𝑛

−𝑊𝑡𝑒

𝑊𝑡𝑒 (12)

whereWtn isthetotalindentationworkobtainedfromthesimulated

loadingcurve,andWteisthetotalindentationworkobtainedfromthe experimentalloadingcurve.

Usingtheunloadingcurve,theelasticindentationwork,We,is

ob-tainedthrough: 𝑊𝑒= ℎ𝑚 ∫ ℎ𝑓𝑃𝑑ℎ (13)

whichisusedtodefinethesecondcomponentoftheobjectivefunction intheform:

𝑓𝑒=𝑊𝑒𝑛

−𝑊𝑒𝑒

𝑊𝑒𝑒 (14)

whereWenistheelasticindentationworkobtainedfromthesimulated

unloadingcurve,andWeeistheelasticindentationworkobtainedfrom theexperimentalunloadingcurve.

UsingtheEqs.(12)and(14),theobjectivefunctionforthewhole

P−hcurveisassembledintheform:

𝑓(𝛽) 𝑚𝑖𝑛= [ 𝑓𝑡 𝑓𝑒 ] (15) where𝛽 representsthesetofelastoplasticparameters.Finally,the mini-mizationoftheobjectivefunctionisachievedusingthealgorithmshown intheFig.14.

Thealgorithmusedinthisworkwassetwithasteptoleranceand functiontoleranceof10−14.Changesinresidualswassetwithavalue

of10−6,andthenumberofiterationswassetasinfinite.

Fig.13. Berkovichindentermodeling:(a)generatrixofthe axisymmetricindenterand(b)generatrixofthe3Dindenter.

Fig.14. Optimizationalgorithmusedfortheelastoplasticparameter estima-tion.

4. Resultsanddiscussion

4.1. Thetrueindentergeometrymodelling

Fortheinvestigatedindenter height,i.e. 0nm<z ≤500nm,the profileofthetrueaxisymmetricindenter(Fig.15(a)),looksmorelike aparabola thana sphero-conicalindenterasstatedbysomeauthors

[25,26,27,28,29].Infact,theprofileofthetrueindenterneverexhibits aparallelismwithrespect totheperfectindenter(70.3°).Thisfound helpstoexplainwhythepolynomialformofthefunctionareausedby OliverandPharr[1]isabletodescribetheBerkovichindenterwithhigh precisionregardlessaphysicalmeaning.Anothermethodtodetermine thefunctionarea,includingaphysicalmeaning,wasproposedby Lou-betetal.[42].Thismethodreliesontheestimationoftheheightofa roundedportion(thetipdefect),connectedtoaperfectindenter.The3D indentermodeledwiththemethodproposedinthispapercannotbe

de-scribedusingthisassumption,becausethesectionsofthetrueindenter arecurved(Fig.15(b)).

Inaddition,thecloudofpointsgatheredbytheAtomicForce Mi-croscopy(AFM) wasdirectly used forcomparisons, founding thatat leastoneofthethreesectionsobtainedfromtheAFMcaptureofthe Berkovichtipispartiallysimilartothesectionofthetrueindenter, ex-hibitingarelationwiththephysicalindenter.

4.2. Elastoplasticparametersidentification

Thethreeelastoplasticparametersofthe316Lconstitutivemodel described in Eq. (1) were estimated from each experimental P − h

curveobtainedwiththeindentationsusingthewornBerkovich inden-ter(Fig.9(a))andtheparameteridentificationroutine(Fig.14).Both perfectandtrueindentermodelswereusedintheaxisymmetricmodels, assumingfrictionlesscontact(𝜇 =0inEq.(10)).Theestimated param-eterswereplottedasafunctionofthemaximumindentationdepthin

Fig.16,andthevaluesoftheparametersobtainedbytensiletestwere includedasreference.

Thethreeelastoplasticparametersobtainedwiththeperfect inden-termodelincreasewithrespecttothereference(tensile)valuewhen

hmdecreases.Fortheminimumvalueofhm,theerrorinthehardening

exponentreaches%err=166i.e.n=0.61,whichisoutoftherangefor

metals[19];theerrorintheyieldstressreaches%err=370andisalso

outoftheparametricrangeofmetals[19].

However,theelasticmodulusandthehardeningexponentestimated withthetrueindentermodelexhibitaconstanttrendnearthe refer-ence. Thehardeningexponentandtheelasticmodulus havea mean error%err=3.7and%err=17.8respectivelycomparedtothereference.

Theerrorintheyieldstressonthemaximumvalueofhmis%err=21.6.

This errorincreaseswiththedecreaseof hmtoreach%err=72.9.In theliterature,theincrease oftheyieldstrengthwiththedecreaseof

hm,reflectedonthehardness,isreferredasindentationsizeeffect(ISE)

[43,44,45].WesupposethattheISEisalreadypresentinthemaximum

hminvestigated,andthatiswhythevalueoftheelasticlimitisgreater

thanthevaluefoundbytensiletest.Thisfindingopenthepossibilities tonewexperimental-numericalstudiesoftheISE,besidestheexisting formulationsbasedonthehardnesse.g.themethodofGaoetal.[44].

Inaddition,theparameter identificationconductedwiththe per-fectindentermodelwasclosetotheknown(reference)solutionforthe indentationcorrespondingtothegreaterhm.Thiseffectcanbeeasily observedintheP−hcurves,wherethesimulationoftheshallow in-dentationexhibitsagreatdifferencewithrespecttotheexperimental curve(Fig.17(a)),whileinthedeepestindentationthedifference be-tweenthemisreduced(Fig.17(b)). Nevertheless,theparameter esti-mationperformedusingthetrueindentergeometryshowedpowerful

Fig.16. Elastoplasticparametersevolutioninfunctionofhm.

Fig.17. Comparisonbetweenthetrueindenterandthe per-fectindenterP−hcurvesin(a)shallowand(b)deep inden-tations.

Fig.18. Comparisonbetweentheexperimentalresidualimprintprofileandthe numericalresidualimprintprofileobtainedwiththe3Dmodel.

capabilitiesofthismodeltofaithfullyreproducetheexperimentalcurve fordeepandshallowindentations(Fig.17(a)and(b)).

Finally,thesectionoftheresidualimprintproducedbythe3Dtrue indentermodelwithPm=15mN,fortherespectivedetermined

elasto-plasticparameters, isvery closeatleast tooneof thethreesections obtainedexperimentally(Fig.18).Thisgreatresemblancealsoconfirms thattheoptimizationroutineconvergedtothecorrectsolutioninthis case.

4.3. Frictionanalysis

Theparameteridentificationroutinewasexecutedtwotimes sepa-ratelyusingthefrictioncoefficients𝜇 =0.1and𝜇 =0.2respectively, foreachinvestigatedexperimentalindentationonthe316L.The start-ingpointoftheroutinewasthelastsetofparametersdeterminedwith

thefrictionlessconfiguration of eachparameter identification execu-tion.Thetrueindenterfiniteelementmodelwasused.Inallcases,after afewiterationstheroutinestoppedbecausethechangesinthecurve werenegligible(Fig.19(a)and(b)),inconsequencethechangesinthe valueoftheparameterswerealsonegligible.Therefore,theeffectofthe investigatedfrictioncoefficients(𝜇 =0; 𝜇 =0.1; 𝜇 =0.2)were evalu-atedusingthedeterminedelastoplasticparametersfortheexperimental

Pm=15mN.Theresidualimprintshowedadecreaseoftheheightofthe pile-up(until31nmfor𝜇 =0.2),comparedtothefrictionlesscontact (Fig.19(c)),revealingsmallvariationsinthecontactarea.

Basedonthisevidence,thehardness,H=Pm/A(hc)[1],was com-putedfortheexperimentalP−hcurveswithPm=3mN, Pm=10mN

andPm=15mNusingtheAFMcapturesoftheircorresponding

resid-ualimprints.Inthecaseofthenumericalmodels,A(hc)wasdetermined athm.Theresultswereplottedinfunctionofhm(Fig.20).Theresults

showanincreaseofHwiththedecreaseofhm.Fortheindentations

in-feriortohm=200nm,theeffectsofthefrictionarereduced,i.e.the

changesinthecontactareaarenegligible.Forindentationssuperiorto

hm=200nm,theexperimentalHisclosetothesimulationusing

fric-tionlesscontact,andtheincreasewhen𝜇 = 0.2induces%err=19.6,

meaningadifferenceofHabout490MPa.

Theliteraturereportsamaximumincreaseof ~ 20%inthe hard-nessforcontactswithfrictioncoefficients𝜇 >0[46].Themaximum differencefoundinthiswork(%err=19.6)isconsistentwiththese ob-servations.However,forthedeeperindentationsanalyzedinthiswork, thevaluesofthehardnessobtainedusingfrictionlesscontactarecloser totheexperimentalvalues.

Mataetal.[46]observedtwoeffectsofthefrictiononthepile-up: 1)theheightofthepile-updecreaseswiththeincreaseofthefriction coefficient,and2)theindentationswithlowheightofpile-upareless sensitivetothevariationsofthefrictioncoefficient.Thetwoeffects ob-servedbyMataetal.arepresentedinthisstudy(Fig.21).Thefirstone isobservedwithindentationsofhm>300nm,whereamaximum

dif-ferenceof27.8nmontheheightofthepile-upisobservedcomparing frictionlesscontactandcontactwithfrictioncoefficient𝜇 =0.2.The secondeffectisobservedwithindentationsofhm<100nm,wherethe

Fig.19. Frictioneffects:(a)inshallowand(b)indeepindentation,ontheP−hcurves,(c)ontheresidualimprint.

Fig.20. Frictioncoefficienteffectonthesurfacehardness.

Fig.21. Effectsofthevariationsofthefrictioncoefficientonthepile-upheight.

5. Conclusion

Anewmethodologytoimprovetherepresentationofthegeometryof thephysicalBerkovichindenterinthefiniteelementmodelisproposed inthispaper.

Thisinclusionofthephysicalindenterinthefiniteelementmodel leadstoacorrectreproduction oftheexperimentalP− hcurveand

residualimprintofthetestedmaterial,providinganestimationofthe elastoplasticparameterswithsignificantlyimprovedaccuracyinthe op-erative range0<hm≤500nm. Theobservedvariationsoftheyield

stressasafunctionoftheindentationdepthopennewinsightsonthe indentationsizeeffect,which nowcanbe analyzedthrough sophisti-catednumericalmodelsonindentationswithhm<100nm.Thispaper

focusedontheanalysisofstrainhardeningsolids,howevercomplex mi-cromechanicalsystems(e.g.ultrathinlayers,nanocrystallinestructures, etc.) canbe analyzedusingtheaccuratefiniteelementmodelof the indentergeometry.

Theeffectsofthefrictioncoefficientwereobservedinthecontact interface betweentheindenter andthesamplesurfacemodifyingthe valueofthehardness,whichis ingoodagreementwithotherworks reportedintheliterature.Noeffectsofthefrictioncoefficientusedin thefiniteelementsimulationswereobservedontheP−hcurveoron theestimatedparameters.

DeclarationofCompetingInterest

None.

Acknowledgments

This workwaspartiallysupportedbytheMexicanCouncilof Sci-enceandTechnology(CONACYT).TheassistanceofDr.VictorSanchez inthereviewofthismanuscriptisgratefullyacknowledged.Wewishto acknowledgetheassistanceofMr.ThierryMartinfortheoptimum per-formanceofthenanoindenter,andthesupportofalltheISAE-SUPAERO DMSMteam.

References

[1] Oliver WC , Pharr GM . An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J Mater Res 1992;7:1564–83 .

[2] Iracheta O , Bennett C , Sun W . Characterization of material property variation across an inertia friction welded CrMoV steel component using the inverse analysis of nanoindentation data. Int J Mech Sci 2016;107:253–63 .

[3] Ben Ismail A , Rachik M , Mazeran P-E , Fafard M , Hug E . Material characterization of blanked parts in the vicinity of the cut edge using nanoindentation technique and inverse analysis. Int J Mech Sci 2009;51:899–906 .

[4] Zhu L , Xu B , Wang H , Wang C . Measurement of residual stress in quenched 1045 steel by the nanoindentation method. Mater Charact 2010;61(12):1359–62 .

[5] Romana L , Thomas P , Bilas P , Mansot JL , Aldana Aranda D . Use of nanoindentation technique for a better understanding of the fracture toughness of Strombus gigas conch shell. Mater Charact 2013;76:55–68 .

[6] Lai D , Xu J , Xie Z , Habibi D , Munroe P . Mechanical characterization of a novel nanocrystalline coating: first-principles calculations and nanoindentation. Mater Charact 2012;68:1–6 .

[7] Bouzakis K-D , Michailidis N , Hadjiyiannis S , Skordaris G , Erkens G . The effect of specimen roughness and indenter tip geometry on the determination accu- racy of thin hard coatings stress–strain laws by nanoindentation. Mater Charact 2002;49(2):149–56 .

[8] Kang J , Becker A , Sun W . Determining elastic–plastic properties from indentation data obtained from finite element simulations and experimental results. Int J Mech Sci 2012;62:34–46 .

[9] Kim M , Pandian Marimuthu K , Lee JH , Lee H . Spherical indentation method to eval- uate material properties of high-strength materials. Int J Mech Sci 2016;106:117–27 .

[10] Nguyen N-V , Kim JJ , Kim S-E . Methodology to extract constitutive equation at a strain rate level from indentation curves. Int J Mech Sci 2019;152:363–77 .

[11] Pham T-H , Kim JJ , Kim S-E . Estimating constitutive equation of structural steel using indentation. Int J Mech Sci 2015;90:151–61 .

[12] Oliver WC , Pharr GM . An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J Mater Res 1992;7(6):1564–83 .

[13] Oliver WC , Pharr GM . Measurement of hardness and elastic modulus by instru- mented indentation: advances in understanding and refinements to methodology. J Mater Res 2004;587(1):3–20 .

[14] Bulychev S , Alekhin V , Shorshorov MK , Ternovskii A . Mechanical properties of ma- terials studied from kinetic diagrams of load versus depth of impression during mi- croimpression. Strength Mater 1976;8(9):1084–9 .

[15] Kang JJ , Becker AA , Wen W , Sun W . Extracting elastic-plastic properties from ex- perimental loading-unloading indentation curves using different optimization tech- niques. Int J Mech Sci 2018;144:102–9 .

[16] Tabor D . The hardness of solids. Review of Physics in Technology 1970;1(3):1–145 .

[17] Barenblatt GI . Scaling, self-similarity, and intermediate asymptotics: dimensional analysis and intermediate asymptotics. Cambridge University Press; 1996 .

[18] Cheng Y-T , Cheng C-M . Scaling approach to conical indentation in elastic-plastic solids with work hardening. J Appl Phys 1998;84(3):1284–91 .

[19] Dao M , v Chollacoop N , Van Vliet KJ , Venkatesh TA , Suresh S . Computational mod- eling of the forward and reverse problems in instrumented sharp indentation. Acta Mater 2001;49:3899–918 .

[20] Bucaille J-L , Stauss S , Felder E , Michler J . Determination of plastic properties of metals by instrumented indentation using different sharp indenters. Acta Mater 2003;51:1663–78 .

[21] Chollacoop N , Dao M , Suresh S . Depth-sensing instrumented indentation with dual sharp indenters. Acta Mater 2003;51(13):3713–29 .

[22] Ogasawara N , Chiba N , Chen X . Measuring the plastic properties of bulk materials by single indentation test. Scr Mater 2006;54:65–70 .

[23] ISO 14577-1:2015. Metallic materials - Instrumented indentation test for hardness and materials parameters, part 1: test method. Switzerland: Geneve; 2002 .

[24] Fischer-Cripps AC . Nanoindentation testing. Springer; 2011. p. 21–37 .

[25] Pelletier H , Krier J , Cornet A , Mille P . Limits of using bilinear stress–strain curve for finite element modeling of nanoindentation response on bulk materials. Thin Solid Films 2000;379:147–55 .

[26] Bouzakis K-D , Pappa M , Maliaris G , Michailidis N . Fast determination of parameters describing manufacturing imperfections and operation wear of nanoindenter tips. Surf Coat Technol 2013;215:218–23 .

[27] Berla LA , Allen AM , Han SM , Nix WD . A physically based model for indenter tip shape calibration for nanoindentatio. J Mater Res 2010;25(4):735–45 .

[28] Yu N , Polycarpou AA , Conry TF . Tip-radius effect in finite element model- ing of sub-50 nm shallow nanoindentation. Thin Solid Films 2004;450(2):295– 303 .

[29] Chen W , Li M , Zhang T , Cheng Y-T , Cheng C-M . Influence of indenter tip roundness on hardness behavior in nanoindentation. Mater Sci Eng 2007;445:323–7 .

[30] Krier J , Breuils J , Jacomine L , Pelletier H . Introduction of the real tip defect of Berkovich indenter to reproduce with FEM nanoindentation test at shallow penetra- tion depth. J Mater Res 2012;27(1):28–38 .

[31] Herrmann K , Hasche K , Pohlenz F , Seemann R . Characterisation of the geome- try of indenters used for the micro-and nanoindentation method. Measurement 2001;29(3):201–7 .

[32] Sapezanskaia I , Roa JJ , Fargas G , Turon-Viñas M , Mateo A . Deformation mecha- nisms induced by nanoindentation tests on a metastable austenitic stainless steel: a FIB/SIM investigation. Mater Charact 2017;131:253–60 .

[33] Davis JR . Tensile testing. ASM International; 2004 .

[34] Wang Z , Bei H , George EP , Pharr GM . Influences of surface preparation on nanoin- dentation pop-in in single-crystal Mo. Scr Mater 2011;65(6):469–72 .

[35] Basrour S , Robert L . X-ray characterization of residual stresses in electroplated nickel. Mater Sci Eng 2000;288(2):270–4 .

[36] Bachmann F , Hielscher R , Schaeben H . Texture analysis with MTEX - free and open source software toolbox. Solid State Phenom 2010;160:63–8 .

[37] Larsson P-L . Investigation of sharp contact at rigid-plastic conditions. Int J Mech Sci 2001;43:895–920 .

[38] M. Smith, ABAQUS/Standard User’s Manual, Version 6.9, Simulia, 2009. [39] Bolshakov A , Pharr GM . Influences of pileup on the measurement of mechan-

ical properties by load and depth sensing indentation techniques. J Mater Res 1998;13:1049–58 .

[40] Beghini M , Bertini L , Fontanari V . Evaluation of the stress-strain curve of metallic materials by spherical indentation. Int J Solids Struct 2006;43:2441–59 .

[41] Marquardt DW . An algorithm for least-squares estimation of nonlinear parameters. J Soc Ind Appl Math 1963;11(2):431–41 .

[42] Loubet JL , Georges JM , Marchesini O , Meille G . Vickers indentation curves of mag- nesium oxide (MgO). J Tribol 1984;106:43–8 .

[43] Swadener J , George E , Pharr G . The correlation of the indentation size effect mea- sured with indenters of various shapes. J Mech Phys Solids 2002;50(4):681–94 .

[44] Nix WD , Gao H . Indentation size effects in crystalline materials: a law for strain gradient plasticity. J Mech Phys Solids 1998;46:411–25 .

[45] Shim S , Bei H , George EP , Pharr GM . A different type of indentation size effect. Scr Mater 2008;59(10):1095–8 .

[46] Mata M , Alcala J . The role of friction on sharp indentation. J Mech Phys Solids 2004;52(1):145–65 .

[47] Cao YP , Lu J . A new method to extract the plastic properties of metal materials from an instrumented spherical indentation loading curve. Acta Mater 2004;52:4023–32 .

[48] Casals O , Alcalá J . The duality in mechanical property extractions from Vickers and Berkovich instrumented indentation experiments. Acta Mater 2005;53:3545–61 .

[49] Gao X-L , Jing XN , Subhash G . Two new expanding cavity models for inden- tation deformations of elastic strain-hardening materials. Int J Solids Struct 2006;43:2193–208 .

[50] Giannakopoulos AE , Suresh S . Determination of elastoplastic properties by instru- mented sharp indentation. Scr Mater 1999;40:1191–8 .