Publisher’s version / Version de l'éditeur:

Concrete International, 21, 8, pp. 86-89, 1999-08-01

READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE. https://nrc-publications.canada.ca/eng/copyright

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

NRC Publications Archive

Archives des publications du CNRC

This publication could be one of several versions: author’s original, accepted manuscript or the publisher’s version. / La version de cette publication peut être l’une des suivantes : la version prépublication de l’auteur, la version acceptée du manuscrit ou la version de l’éditeur.

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at

Why engineers need materials science

Beaudoin, J. J.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

NRC Publications Record / Notice d'Archives des publications de CNRC:

https://nrc-publications.canada.ca/eng/view/object/?id=26002be5-f5d1-4d68-947a-74c171de6791 https://publications-cnrc.canada.ca/fra/voir/objet/?id=26002be5-f5d1-4d68-947a-74c171de6791http://www.nrc-cnrc.gc.ca/irc

Why e ngine e rs ne e d m a t e ria ls sc ie nc e

N R C C - 4 3 1 0 8

B e a u d o i n , J . J .

A u g u s t 1 9 9 9

A version of this document is published in / Une version de ce document se trouve dans:

Concrete International,

21, (8), pp. 86-89, August 01, 1999

The material in this document is covered by the provisions of the Copyright Act, by Canadian laws, policies, regulations and international agreements. Such provisions serve to identify the information source and, in specific instances, to prohibit reproduction of materials without written permission. For more information visit http://laws.justice.gc.ca/en/showtdm/cs/C-42

Les renseignements dans ce document sont protégés par la Loi sur le droit d'auteur, par les lois, les politiques et les règlements du Canada et des accords internationaux. Ces dispositions permettent d'identifier la source de l'information et, dans certains cas, d'interdire la copie de documents sans permission écrite. Pour obtenir de plus amples renseignements : http://lois.justice.gc.ca/fr/showtdm/cs/C-42

HO \ () !

Understanding

エセ・

ュZセAゥ[オ」セイイA

of

ェッョセイ・セ

H H " " .,C

oncrete is a multiphase composite materiaL The prop erties, behavior, and perfonnance of portland cement-based concretes are dependent on the nature of the binding material in the composite, The "glue" that provides structural integrity to concrete (Le., hydrated cement paste) is itself a multicomponent composite on a microscale. The primary constituent of hardened cement paste is the calcium silicate hydrate phase, often-denoted as C-S-H (calcium sili-cate hydrate).The structure of C-S-H (CaO セ C; Si02 セ S; H

20 セ H)

at the nanolevel (molecular level) is relevant to its behavior and the ultimate impact on the perfonnance of concrete.

Itis emphasized that although there is no definitive proof of any specific structure of C-S-H at the nanolevel there is substantial indirect evidence. Relationships between suggested nanostructure ofthe C-S-H, microstructure of the

cement paste, and engineering properties can provide

a basis for understanding the utility of concrete materials

as structural elements exposed to a wide variety of environ-mental conditions.

This article presents arguments as to why knowledge of the nanostructure and microstructure of hydrated cement binders should matter. It is intended to demonstrate that a

materials science approach, as well as teaching concrete

ma-terials science in civil engineering curricula, is of

signifi-cant value. The subtopics and examples chosen are

subjec-tive; they are taken from the author's research experience

during the past 25 years. They are, however, selected to il-lustrate a potentially valuable connection between materials science, engineering philosophy, and design, with possibly

a wider range of options open to civil engineers.

Nanostructure-engineering properties and the role of water

The interaction of water and hydrated cement paste has been

extensivelystudied.1-3The scanning water sorption isothenns

for hydrated cement paste (mass and length change; see Fig. I) exhibit massive primary and secondary hysteresis analogous to the sorption behavior of layered silicates. The implications of the isothenn characteristics have been dis-cussed in detail elsewhere' The complete hysteresis over the full range of partial pressures does suggest that processes other than those attributed to adsorption take place. Itwas

concluded that intercalation processes were operative, i.e.,

some of the water was associated with the C-S-H structure

86

and not reversibly sorbed. This implies that the C-S-H and its engineering characteristics .are changed by the presence of water. This is a structural change and not merely the ef-fect of a change in state of the pore water.

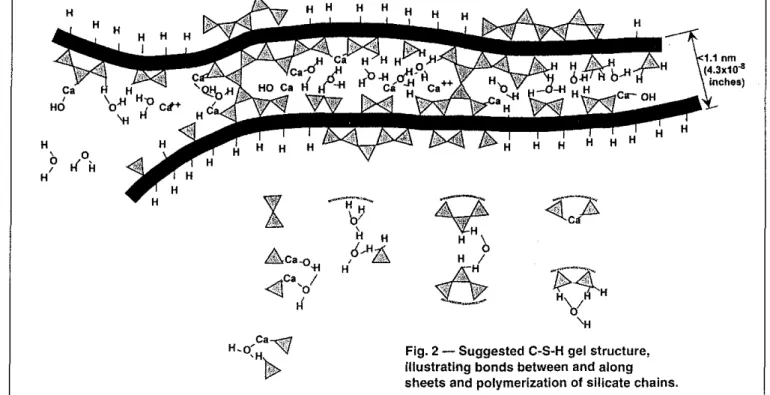

Feldman and Sereda in 19705described a nanostructural

layered silicate model for C-S-H, later refined by Feldman in 19816(Fig. 2). This model accounts for variable CoS ratio

products (observe the missing bridging tetrahedra) and pre-sents several bonding possibilities. The exit and entry ofwater (interlayer regions) is used to explain up to a two-fold in-crease in stiffness on wetting and drying (Fig. 3)7 The intcrregions of the layers contribute significantly to stiffen-ing in the humidity range, 50 to 100 percent relative humid-ity (RH) and loss of stiffness at low humidities.

The opposite behavior is observed for strength, i.e., strength usually decreases at humidities above 50 percent RH. The strength decrease is attributed to attenuation ofSi-O-Si bonds

in presence of water.

The importance of these observations lies in engineering

design. Civil engineering students who appreciate the con-sequence of relative humidity on stiffness and strength, for example, may bring to their practice a better understanding of problems related to cracking phenomena and potential

solutions. 18

A

0.7 16./ f

0.6 14 0.5 12 00.4

0 0 10 0-

)( セ-

)(セ

8 0.3 ...I::J

<l <l 6 0.24

- Primary absorption curve- Primary desorption curve

- Ascending curve 0.1

2 - Deeending cu",.

o

20 40 60 0 20 40 60 80 100p/pox100

Fig. 1 - Scanning water sorption isotherms (mass and

length change) for hydrated cement paste.

H H H

"},,nm

,01> H (4.3x10-8 inches) Cor- OH H H H H H H H H H H H Hセ」NMッ

-H c. I セ '0If

I

o

Ii

Ii H H"

,

HFig. 2 - Suggested C-S-H gel structure, illustrating bonds between and along

sheets and polymerization of silicate chains.

known that pore coarsening can occur on drying) facilitating the ingress of aggressive fluids and accelerating deleterious processes.

The length change isotherm for hardened cement paste is

also indicative of the influence of various admixtures on

volume stability. Shrinkage of cement paste containing li-gnosulfonate admixtures in the range 100 to 50 percent RH can be significantly larger than a control paste containing no admixture.' Subsequent shrinkage between 50 and II per-cent RH is similar for the pastes with and without ture. This suggests that the dispersing effect of the admix-ture on the C-S-H product is negated at humidities below 50 percent RH.

Microstructure-porosity, crystallinity,

and strength

It is well known that an increase in porosity generally re-sults in a decrease in strength of porous bodies.10This is true

for the hydrated portland cement system. This discussion will focus on the intrinsic aspects of cement pastes as many of the arguments are generic to concrete behavior. A com-prehensive treatment ofthe effect of porosity on the strength of concrete is provided elsewhere.11

There is no unique strength-porosity relationship for all cement systems. A characteristic of autoclaved cement sys-tems is that they exhibit very low strength at high porosities and very high strength at low porosities relative to normally hydrated cement systems. The dense crystalline hydrates present at low porosities are well bonded as the particles are in very close proximity to each other. The opposite is true at higher porosities as the dense crystallites are weakly bonded. It was concluded that, in practical applications, an optimum mixture of dense crystallites and poorly crystalline material gives maximum performance.

Fig. 4 illustrates these principles. Strength contours are shown on a plot of porosity versus increasing proportion of coarse, dense, crystalline material.l ' Line A-B is typical of G E H B

c

xx

XXX)(State

Axxxxx

xxxxxxxx

Fxxx

-100

Cement pastew/c

=

0.30 FSATD. 0

Microstructure-volume stability

The length change-to-mass change relationships for cement paste that has initially been dried and subsequently wetted are indicative of the volume instability of the material8

Wetting and subsequent drying to zero mass change results in an irreversible shrinkage. The amount of this shrinkage is directly dependent on the level of humidity attained on wet-ting, suggesting that potential bonding sites are activated at higher humidity. This behavior also indicates that concrete behavior and performance can be strongly influenced by dry-ing-wetting history. This history is one of the fundamental

reasons whysome concrete is durable in a given environ-ment, and performs poorly in another. For example, it is

50

p/po x 100

Fig.3 - Simple model showing entry and exit of Interlayer water with change In modulus of elasticity.

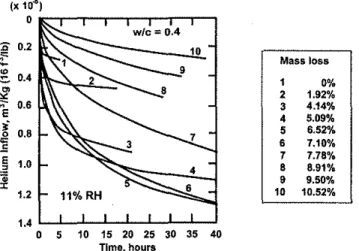

Mass loss 1 0% 2 1.92% 3 4.14% 4 5.09% 5 6,52% 6 7.10% 7 7.78%

•

8.91% 9 9.50% 10 10.52%...

2.4 w/cセ

00.3 N 2.0 00.4..

セ

60.5 セ 1.6 00.6セ

lJ 0.8,.

1.2 .6.1.0"

Nセ 0.8セ

セ 0.4 0 $&!

0 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0 w/cm 1.2 11% RHFig. 5 - Rate of diffusion of propan-2-01

intoキ。エ・イセウ。エオイ。エ・、 pastes as a function ofwlcm.

1.47) indicates that the nature ofthe length change behavior, i.e., contraction or expansion, is dependent on the C to S ratio of the C-S-HPItis apparent from these results that the use of the solvent replacement technique as a microstruc-tural probe has significant potential. Further research is re-quired before this technique can be incorporated into stan-dard test procedures.

(x10')

!l:

2.6r",--,---r-,-,,-,--,--,

セ 1.4 '-.1.--'--'--'--'--'---'--' o 5 10 15 20 25 30 35 40 Time, hoursFig. 6 - Helium Inflow versus time for cement paste at different water contents starting from the 11 percent RH condition.

The helium inflow technique is more specific to the be-havior of the C-S-H itself at the nano-leveL Cement paste specimens are preconditioned to II percent RH where there is a monolayer present on the C-S-H surfaces and pores are generally empty of bulk water. Water is removed incremen-tally from the structure and the space previously occupied by the water is filled with helium. Helium inflow versus time curves are presented in Fig. 6. The helium inflow increases as water is removed until the structure collapses and the curves begin to cross over. The ability of the helium probe to detect changes in C-S-H structure and properties such as volume and density can facilitate understanding ofengineer-ing behavior such as creep. The dryofengineer-ing-rewettofengineer-ing process actually results in an increase in solid volume as determined by the instantaneous displacement of helium.

The application of stress has an analogous effect to that of drying and wetting. Increases in solid volume have been de-tected in creep experiments.IS There is also a reduction of

helium inflow into the C-S-H as a result of sustained stress.

::0 0.2 セ

セ

0.4セ

\1:....,,"-.::::...

il

1i

0.6セ

0.8]

§ 1.0セ

s 160 50 セ 40f

30 20 10 oL --::::._---:::...J

Increasing proportion of coarse,dense, crystalline material )

Fig. 4 - Compressive strength (MPa) as a function of porosity and particle crystallinity distribution. The significance of the lines is described in the tex!.

Micro- and nanostructural probes

Microstructural characteristics of hydrated cement systems can be revealed through application of techniques involving counter diffusion of solvents or diffusion of helium into the materiaL"·16 The pore water in hydrated cement paste can be replaced by a counter diffusion process when samples are placed in an excess volume ofsolvent, e.g., isopropanol. The rate of diffusion into water-saturated pastes as a function of water to cementitious material ratio (w/cm) is plotted in Fig. 5.

The ratc of diffusion increases with w/em and is an indica-tor of the resistance of the material to the ingress of aggres-sive ions. Length change can also be an indicator of how the solvent is interacting with the solid. The length change for an equivalent mass change is significantly greater for low

wlem pastes reflecting the increased amount of solids per unit volume for these preparations. This suggests that length change resulting from the solvent exchange process may be considered to be affected by the total porosity of the paste system and a possible indicator of its potential durability.

Length change of water-saturated cement paste due to solvent replacement generally results in a contraction or shrinkage. However, methanol replacement results in expan-sion suggesting the possibility that some solvent is entering the layered C-S-H structure. Recent work has indicated that depending on the drying path (within the primary hysteresis region), isopropanol, methanol, and dimethyl sulfoxide sol-vents all produce large expansions. Further, anomalous length change behavior ofC-S-H preparations (C to S ratio,0.68 to nonnally hydrated portland cement. Strength increase at low porosity is accompanied by larger amounts of unhydrated cement.Itis noted that in these systems, bonds can be bro-ken and readily remade, a deduction made from the coinci-dence of strength porosity curves for compacted and paste hydrated systems.' Line C-D is typical of the hot-pressed pastes studied by Roy and co-workers." A small increase in the amount of hydrated cement can result in large increases in strength. Line E-F represents a binary cement-fly ash (50 percent fly ash by mass) product. Lines T, S, R, 0, and P represent autoclaved cement-silica systems with varying in-creasing amounts of silica.

The concept that conditions of fonnation and not compo-sition alone influence strength is also applicable to alumi-nate systems."Itis well-known that fonnation ofhydrogamet (C,AH6[A

=

Alp,; C= CaO; H=

Hpj) in hydrating cal-cium aluminate cement generally leads to low strength. This is not the case when C,AH. is formed in these systems at very low porosity. Bonding of hydrogamet crystals in close proximity to each other enhances strength.60

r---:;::::::==::::::::-""":::----,

Conclusion

Nano- and microstructural information provides insight into concrete performance. It also helps civil engineers make decisions regarding the modification of concrete mixtures

for particular applications. Civil engineers are often involved

in large projects involving significant financial investments

in concretestructures. A clearer understanding of the

prin-ciples governing service-life and engineering design can be achieved through a materials science approach to concrete

technology instruction.

Environmental effects, pore structure, transportpropcliies, and resistance of concrete to aggressive agents can only be

optimally managed through increased technical awareness.

Civil engineering curricula can be more effective ifstudcnts arc provided with materials course options that have a base in both science and engineering. Design of concrete struc-tures can be more effective if structural engineers and archi-tects are aware of the nano-, micro-, and macrobehavior of

the construction materials they employ.

References

I. Taylor. H. F. W, Cement Chemistl)!, Academic Press, 1990, pp. 475. 2. Ramachandran, V. S., Concrete Admixtures Halldbook, Noycs Publi-cations. 1984, pp. 626.

3. Ramachandran,V. S.; Feldman, R.F.;and Beaudoin, J. J., Concrete Sciellce,Heyden & Son Ltd., 1981, pp. 427.

4. Feldman, R. E, "Sorption and Length Change Isotherms of Methanol and Water on Hydrated P0l11and Cement," Fifth International SymposiuJII all the Chemistry of Cement,V. 3, 1968, pp. 53-56.

5. Feldman, R. F., and Sereda, P.J.,"A New Model for Hydratedpッイエセ

land Cement and Its Practical Implications," EngineerillgJoumal, V. 53, 1970.pp.53-59.

6. Ramachandran,V. S.; Feldman, R. E; and Beaudoin, J.1.,Concrete Science,Heyden & Son Ltd., 1981, p. 5.

7. Sereda, P.1.;Feldman, R. E; and Swenson E. G., "Effect of Sorbed Water on Some Mechanical Properties of Hydrated Portland Cement Pastes and Compacts.," Highway Research Board Report 90,1966, pp. 58-73.

8. Feldman, R. F., "Mechanism of Creep of Hydrated Portland Cement Paste," Cement alld Concrete Research, V. 2,1972, pp. 521-540.

9. Feldman, R. F., and Swenson E. G., "Volume Change on First Drying of Hydrated Portland Cement With and Without Admixtures," Cement and Concrete Research,V. 5, 1975, pp. 25-36.

10. Beaudoin, J.J., and Feldman, R. F.. "A Study of Mechanical Proper-ties of Autoclaved Calcium Silicatc Systems." Cemellt alld COl/crete Re-search,V. 5, 1975, pp. 103·118.

II. Popovics, S., Strength and Related Properlies a/Concrete: A

QUGlI-titalive Approach,Wiley, 1998, pp. 535.

12. Crenn<ln,J.M.; El-Hemaly. A. S.; and Taylor. H. F. W., "Autoclavcd Lime Quartz Materialsセ Some Factors Influcncing Strength," Cemen! and COl/crete Research, V.l 7, 1977, pp. 493-502.

13. Roy, D. M.; Gouda, G. D.; and Bobrowaky, A., "Very High Strength Cement Pastcs Prepared by Hot Pressing and Other High Pressure Tech-niques," Cemenl alld COl/crete Research. V. 2, 1972, pp. 349-366.

14. Beaudoin, J.J.• and Ramachandran, V. S., "Physicochemical Char-acteristics of Low-Porosity Cement Systems," Materials Science ofCol/-creteIII, Amer. Cel". Soc., 1992. pp. 271-318.

15. Feldman, R. E, "Diffusion Measurements in Cement Paste by Water Replacement Using Propan-2-ol," Cemellt alld Concrele Research,V. 17, 1987,pp.602-612.

16. Feldman, R. F.,"The Flow of Helium into the Interlaycr Spaces of Hydrated Portland Cement Paste." Cement and Concrete Research,V. I,

1971.pp.285-300.

17. Beaudoin,1.J., unpublished results.

18. Feldman, R. E, and Beaudoin,J. J., "Effect of Applied Stress on the Helium Inflow Characteristics of Hydraled Portland Cement," Cemellt alld Concrete ResearchV. 13,1983, pp. 470-476.

Selected for reader interest by the editors after independent expert evaluation and recommendation.

ACI member James J. Beaudoin is a principal research officer with the Institute for Research In Construction, National Research Council, Ottawa, Canada. He is the author of more than 300 research papers and three books on

concrete materials. His current research

focuses on the application of electrical methods in cement and concrete science. He is a member of ACI Committee 209, Creep and Shrinkage in Concrete.

Why not become

a

CI author?

It's tradition with CONCRETE INTERNATIONAL that our expert authors come from the ranks of our readers. You may well qualify.

It makes sense. You probably have many years of experience in concrete design and construction, and have something to write about that others will be interested in:

• A recent job your firm completed,

• A success you had with a technical problem you and your colleagues faced,

• Or, you just might have a valid opinion how important matters confronting the industry can be addressed.

What better, more accurate and knowledgeable reporter can there be than you - someone who is expert in and has been right on top of what is being published. So, let the world know about what you are involved with through the pages ofC/!

GAIN WORLDWIDE RECOGNITION FOR YOURSELF AND YOUR ORGANIZATION

Give CI a try - with an article on a topic of your choice. Call attention to the work you and your people are doing; help others facing the same or similar problems and challenges!

For more information on how to publish in CI, contact:

Bill Semioli, Editor-in-Chief& Associate PUblisher,

CONCRETE INTERNATIONAL, P.O.Box9094, Farmington Hills, MI48333,

phone (248) 848-3737,fax(248) 848-3701,e-mail BSemioli@aci-int.org