Publisher’s version / Version de l'éditeur:

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la

première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

Research Paper (National Research Council of Canada. Division of Building

Research); no. DBR-RP-539, 1972-10-01

READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE. https://nrc-publications.canada.ca/eng/copyright

NRC Publications Archive Record / Notice des Archives des publications du CNRC :

https://nrc-publications.canada.ca/eng/view/object/?id=3ff7febc-ee8a-49ab-a8e5-aa6f0c271cf5 https://publications-cnrc.canada.ca/fra/voir/objet/?id=3ff7febc-ee8a-49ab-a8e5-aa6f0c271cf5

NRC Publications Archive

Archives des publications du CNRC

This publication could be one of several versions: author’s original, accepted manuscript or the publisher’s version. / La version de cette publication peut être l’une des suivantes : la version prépublication de l’auteur, la version acceptée du manuscrit ou la version de l’éditeur.

For the publisher’s version, please access the DOI link below./ Pour consulter la version de l’éditeur, utilisez le lien DOI ci-dessous.

https://doi.org/10.4224/40001662

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at

Fire endurance of selected concrete masonry walls

Ser TH1 I N21r2

no.

539

c. 2BLDG

A @ > 4 k ~ Z E D

NATIONAL RESEARCH COUNCIL OF CANADA

CONSEIL NATIONAL DE RECHERCHES DU CANADA

FIRE ENDURANCE OF SELECTED CONCRETE

MASONRY WALLS

by

L.W. Allen and T.Z. Harmathy

Reprinted from

Journal, American Concrete Institute September 1972

p. 562 - 568

Research Paper No.

539

of the

Division of Building Research

OTTAWA October 1972

LA RESISTANCE AU FEU DE CERTAINS MURS DE

MACONNERIE EN BETON

SOMMAIRE

On a soumis'a des essais de re'sistance au feu des murs constituis de quarante-quatre diffe'rents genres d'ele'ments de ma~onnerie en be'ton. Trois formules semi-empiriques ont servi exprirner la risistance au feu de ces murs en fonction de trois variables ge/ome'triques et de deux proprie'te's thermiques qui caractirisent la forme et le matkiau des kliments de ma~onnerie constitutifs. Un exemple num&ique montre l'application des formules.

TlTLE

NO. 69-51

A N A L Y Z E D

Fire Endurance

of

Selected Concrete

Masonry Walls

By

L. W. ALLEN and T. Z. HARMATHYWalls made from 44 different types of concrete

ma"nr'Z

units were sub'ected t o fire endurance tests. T ree semiempiricaI

formulas were used t o ex- press the fire endurance o f these walls as a func- tion o f three geometric variables and two thermal properties which characterize the shape and ma- terial o f the constituent masonry units. A nu- merical example i s included t o show the application o f the formulas.Keywords: a g g r e g a t e s : a u t o c l a v i n g : c o n c r e t e blocks; con- cretes: e x p a n d e d clay a g g r e g a t e s ; e x p a n d e d shale a g g r e - gates: e x p a n d e d slag aggregates; f i r e resistance: f i r e tests: l i g h t w e i g h t a g g r e g a t e concretes: masonry walls; moisture c o n t e n t ; p u m i c e ; research: sand-gravel concrete; silica f l o u r : t h e r m a l properties; walls.

DURING

THE PAST FEW years 71 fire endurancetests have been performed on walls made from 44 different types of concrete masonry units of overall nominal thicknesses ranging from 4 to 10 in. (10.2 to 25.4 cm). The test program was de- signed to develop information on the fire endur- ance of masonry units supposedly representative, with respect to materials and dimensions, of those currently being produced by Canadian manufac- turers.

The fire test series was supplemented by a com- prehensive investigation of the thermal charac- teristics of the various concretes to provide suf- ficient background information to analyze the experimental fire endurance data. Although de- tails of the fire tests and the supplementary in- vestigations have been or soon will be reported sufficient information is included

here to make the material presented in this paper understandable without extensive preparatory reading. A regression analysis of the results of this fire test series will be published e1sewhere.t

CONCRETES USED

The test program covered both normal and lightweight materials. The aggregates in the nor- mal weight concretes consisted of fine and coarse fractions of either siliceous or calcareous gravel.' Maximum aggregate size was 3/8 in.

*Harmathy, T. Z., and Allen, L. W.. "Thermal Properties of

Selected Concrete Masonry Units" (to be published).

+Williams-Leir G . and Allen L W "Prediction of Fire En- durance of ~oricret'e Masonry' ~ a l 1 s " f r o m Correlations of 94 Fire Tests" (to be published).

T. Z. H a r m a t h y has been a research o f f i c e r with t h e Fire Section, Division o f Building Research, N a t i o n a l Re- search C o u n c i l o f C a n a d a . O t t a w a , since 1958. H e o b t a i n e d a d e g r e e i n mechanical engineering f r o m t h e Budapest U n i - versity o f Technology i n 1946, a n d a D o c t o r o f Engineering d e g r e e f r o m t h e Vienna University o f Technology in 1967. Dr. H a r m a t h y ' s c u r r e n t research includes i n v e s t i g a t i n g t h e physical properties o f b u i l d i n g materials a t e l e v a t e d t e m - peratures a n d t h e b e h a v i o r o f b u i l d i n g elements i n f i r e . The a u t h o r o f numerous t e c h n i c a l papers, currently, he is a m e m b e r o f A C I C o m m i t t e e 216, Fire Resistance a n d Fire Protection o f Structures.

A C I m e m b e r L. W. A l l e n is manager, M a t e r i a l s Engineer- i n g Services, Professional Services Division, W a r n o c k H e r s e y I n t e r n a t i o n a l Ltd.. Toronto, O n t a r i o , C a n a d a . Prior t o his present position, M r . A l l e n was concrete producers' fellow a t t h e Fire Section, Division o f Building Research, N a t i o n a l Research C o u n c i l o f C a n a d a , O t t a w a . f r o m 1967 t o 1971. H e o b t a i n e d a BS d e g r e e i n c i v i l engineering i n 1966 a n d a M S d e g r e e i n civil engineering i n 1967, b o t h f r o m t h e University o f W i n d s o r . M r . A l l e n ' s p a r t a n d research i n - v o l v e d i n v e s t i g a t i o n i n t o t h e thermal p r o p e r t i e s o f concrete a t e l e v a t e d temperatures a n d t h e behavior o f concrete masonry units exposed t o fire. H e is a registered profes- sional engineer i n t h e p r o v i n c e o f O n t a r i o .

ACI JOURNAL

1

SEPTEMBER

1972

In the lightweight masonry units, four types of aggregate were used: l fine and coarse fractions

of expanded shale; fine and coarse fractions of expanded slag; fine and medium fractions of ex- panded clay; and fine fraction of pumice.

In some lightweight concretes the fine frac- tions of lightweight aggregates were replaced by natural sand in 10 or 20 percent by volume of the total amount of aggregate.'

Some of the normal weight and lightweight ma- terials were autoclaved;, in these concretes part of the cement was replaced by silica flour.

In Table 1 typical values of the thermal proper- ties of the concretes are given at room tempera- ture. The variation of these properties at elevated temperatures will be reported elsewhere. The val- ues are generally in line with those reported by Harmathy,3 with one important difference. While Harmathy assumed that the aggregates were physicochemically more or less stable constituents of concretes, thermogravimetric studies performed on the siliceous and calcareous aggregates used in the normal weight masonry units indicated sub- stantial weight losses associated with decomposi- tion reactions.

GEOMETRY OF MASONRY UNITS

Approximately 40 percent of the 4 and 6 in'. (10.2 and 15.2 cm) walls were made from solid masonry units. Hollow units were used in the re- mainder of the 4 and 6 in. walls and in all 8 and 10 in. (20.3 and 25.4 cm) walls.

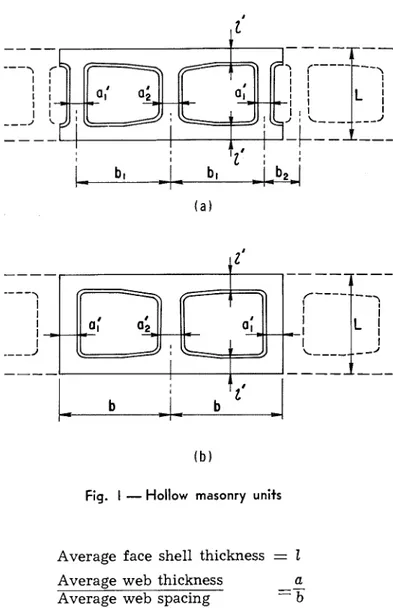

Although hollow masonry units often have com- plicated geometries, it is possible to characterize them by three basic geometric variables. These are:

Overall thickness =

L

Fig. I

-

Hollow masonry unitsAverage face shell thickness = 1 Average web thickness a Average web spacing

=%

In Fig. 1 two frequently used shapes of masonry units are shown. Because the sides of the inner cores are generally made with substantial slopes, the evaluation of 1, a,, and a' is rarely simple. InTABLE I - T H E R M A L PROPERTIES O F T H E SELECTED M A S O N R Y UNITS A T R O O M TEMPERATURE*

Siliceous Siliceous, autoclaved Type of concrete: Calcareous

1

129.8 (2.08)1

0.84 (0.0035)1

0.033 (0.0084)1

0.20 Density p. Ib per cu f t (g/cm3) Expanded shaleExpanded shale. 10 percent sand Expanded shale, 20 percent sand Expanded slag

Expanded slag, autoclaved Expanded slag, 10 percent sand Expanded slag. 20 percent sand

Thermal conductivity$ k, Btu per h r f t F (callsec cm C) 91.1 (1.46) 89.9 (1.44) 93.0 (1.49) 96,l (1.54) Pumice

Pumice, 10 percent sand Pumice, 20 percent sand

Thermal Specific diffusivity

K , sq f t per h r (cm2/sec)

Expanded clay

Expanded clay, 10 percent sand Expanded clay, 20 percent sand

*All materials were tested in oven-dry conditions. For details see Harmathy. T. 2.. and Allen, L. W., "Thermal Properties of Se- lected Concrete Masonry Units" (to be oublishedl.

87.4 (1.40) 90.5 (1.45) 94.8 (1.52)

=

+In some concretes sand was used as replacement for the indicated percentage (by volume) of the fine aggregate. $Multiply by 12 to obtain Btu per h r ft? (F per in.).

the present studies the following approximations were used:

1 = 1.11' (1)

a, = 1.15a,', etc. (2) where l', a,', etc., are dimensions measured on the side of minimum thicknesses.

The values of a and b for the shape shown in Fig. 1 (a) are obtained as:

a = (%) (2al + a z ) (3)

b ('h) (2bl

+

ba) (4)and for the shape shown in Fig. 1 (b) the average web thickness is expressed as:

a = (%) (2al

+

aa) (5) I t is usual to characterize hollow masonry units by the equivalent web thickness, a,,, which means the sum of all a,', a; along a row of masonry units, in inches per unit length, in feet, of the row. By using Eq. (2), it can be shown that:I t has been usual to study the fire endurance of concrete masonry units in relation to their equiva- lent thicknesses L,,. The equivalent thickness is the thickness that would be obtained from the same amount of material if the voids were elimi- nated from the inside of the units. The relation between L,, and the already introduced geometric variables is:

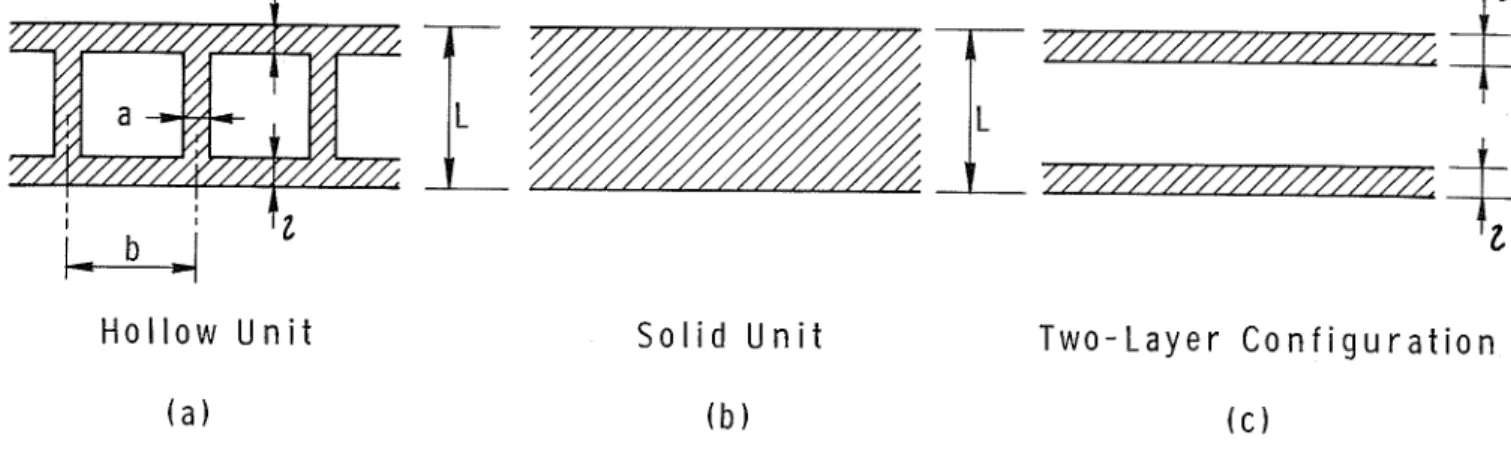

By adopting the practice of combining all three geometric variables into a single variable L,,, one tacitly assumes that, from the viewpoint of fire, only the amount of solid material between the two exterior surfaces of the masonry wall is es- sential and the geometric arrangement of the material is unimportant. Although this assumption often proved useful in correlating experimental fire endurance information, in a strict sense it is inaccurate. To explain the reasons, attention is directed to Fig 2. The upper three sketches show three walls whose equivalent thicknesses are ob- viously equal. However, owing to the additional resistance to heat flow of an air layer, the wall shown in Fig. 2(2) will exhibit higher fire en- durance than that in Fig. 2 (1)

.* For similar rea-

sons, the wall shown in Fig. 2 (3) will yield even better performance.In the lower two sketches of Fig. 2 two hollow masonry walls are compared. Both have identical overall thicknesses as well as equivalent thick- nesses, but the material between the exterior surfaces is arranged differently. I t can be shown (see "Numerical Example") that the wall having more material in the face shell, i. e., the one in Fig. 2 (5), can be expected to yield better fire per- formance than the one that has more material in the webs [see Fig. 2 (4)

1.

*Computer calculations* have clearly indicated that the gain

(7) in fire endurance resulting from the insert~on of an air gap may be as high as 10 percent.

(4

1

( 5

1

Fig. 2

-

Limitations of equivalent thickness method-

-

H o l l o w U n i t

S o l i d U n i t

lil

T w o - L a y e r C o n f i g u r a t i o n

( a )

( b

( c )

Fig. 3 -Theoretical modeling of masonry units

I t is apparent now that the practice of correlat- ing the fire endurance t , directly with L,, is not rigorously correct; it has, therefore, not been fol- lowed in these studies.

FIRE ENDURANCE TESTS

All fire tests were conducted, essentially, ac- cording to the standard ASTM E 119 procedure except that in most cases the width and height of the test specimens were much smaller than those prescribed in the ASTM standard, i. e., about 2.5 x 2.5 f t (76.2 x 76.2 cm), instead of a minimum 10 x 10 f t (304.8 x 304.8 cm)

.

Previous experience indicated that with the small scale test facilities used" the thermal fire endurance* of building ele- ments in fire can be determined with the aid of such reduced scale test specimens with fair ac- curacy.t

When the sizes of the test specimens conformed to the requirements of ASTM E 119, the specimens were tested as nonbearing walls, i. e., the edges of the specimens were restrained on all four sides against thermal expansion. No restraint was ap- plied to the reduced scale specimens.

As failure by crack formation or collapse of concrete masonry unit walls in a fire is rare, it is believed that the thermal fire endurance values derived in this series either by full scale or re- duced scale test can be, as a rule, regarded as rep- resentative of the overall fire endurance (thermal as well as structural) of walls of concrete masonry units.

All test specimens were conditioned prior to the tests in an attempt to ensure that (according to the requirements of ASTM E 119) the moisture content, even in the dampest section of the speci- men, would not exceed the amount that brings about a 75 percent equilibrium relative humidity

a t 73 F (22.8 C). Cylindrical samples that had been removed from each specimen a few hours before the tests, were analyzed both for relative humidity and moisture content. Unfortunately, due partly to the uncertainty concerning the moisture dis- tribution and partly to experimental difficulties, major erroIs are possible in the estimation of the average moisture content of the test specimens.

ANALYSIS OF TEST RESULTS

Based on 1180 computer calculations, Harmathy4 showed that the fire endurance of hollow con- crete masonry units in dry (moistureless) condi- tion can be satisfactorily described by the following empirical equation:

1 [ a b 1-(alb)

-

+

.C20?12(8)

t l 0 %

where tlo is the fire endurance of a dry solid

masonry wall of L thickness, and t2, is the fire

endurance of a dry two-layer configuration of characteristic dimension 1. I t can be seen that Eq. (8) is based on the assumption that a hollow masonry unit can be regarded as consisting of solid and double-layer sections (see Fig. 3 ) , the relative lengths of which are a l b and (b - a) lb, respectively.

I t has also been shown4 that -clo and too can be

described by the following semiempirical rela- tions:

*Thermal fire endurance can be defined as the time a t which the averace t e m ~ e r a t u r e on one side of a test s ~ e c i m e n exceeds its i n i t i a l v a l u e by 250 F (139 C ) when the other side is exposed toLa standard fire specified by ASTM E119.

, T h e fire endurance values derived from reduced-scale tests tend to be somewhat larEer than those obtained with t h e use of full-scale tests. The discrepancies a r e however, rarely larger than the limits of reproducibility of £All scale fire test results.

and

where the thermal properties k and r, are taken at

room temperature, and the values A, B, p, q, r ,

and s can be regarded as constants for certain major groups of concretes.

By conveniently processing and plotting the ex- perimental fire endurance information, and tak- ing into consideration the semiempirical results of Reference 4, the values of these constants have been evaluated. Thus, the explicit forms of Eq. (9) and (10) are as follows:

and

It should be noted that the constants 0.205 and 0.750 are valid only if values of k, x , L, and 1 are substituted in the British units given in the Ap- pendix notation.

Some questions concerned with the accuracy of Eq. (8), (9a), and (lOa), and with the possible limits of their applicability, will be discussed in the closing section.

EFFECT OF MOISTURE

It is well known that the presence of moisture is beneficial for the fire endurance of building ele- ments. HarmathyeS7 found that the following re- lation exists between the fire endurance z, its value in a dry condition z,, and the volumetric moisture content 4:

zo2

+

to (4+

4/34 - z) - 42 = 0 (11) where/3

= 5.5 for normal weight concretes,/3

-

8.0 for lightweight concretes and the vol- umetric moisture content 4, can be calculated from the moisture content, conventionally ex- pressed as a weight fraction, as:In a newly introduced Appendix to ASTM E 119, a procedure is also described for the estimation of 4 from the equilibrium relative humidity in the dampest section of construction.

From Eq. (11) :

This equation can be used for the calculation of the fire endurance in a dry condition if the fire endurance at some moisture content is known. If on the other hand, z, is known or has been calcu- lated previously, one can express z from Eq. (11) to make it suitable for the calculation of fire en- durance at any other moisture content:

Eq. ( l l a ) was applied to the experimental fire endurance data prior to the analysis that led to the derivation of Eq. (9a) and (10a).

NUMERICAL EXAMPLE

It may be useful to illustrate the calculation procedure through a numerical example. The task is to calculate the fire endurance of a light- weight masonry wall at 7.23 percent (by volume) moisture content. The shape of the masonry units used in the wall is of the type shown in Fig. 1 (b). The following measurements have been recorded: L = 0.4687 f t (14.29 cm) ; 1' = 0.0833 ft (2.54 cm) ;

a,' = 0.0900 ft (2.74 cm) ; a,' = 0.0867 ft (2.64 cm) ; and b

=

0.6500 ft (19.81 cm).

First 1 and ahave to be calculated. From Eq. (1) :

1 = 1.1 X 0.0833 = 0.0917 ft (2.80 cm) From Eq. (2) and (5) :

a = 1.15 X 1/2 X (2 X 0.0900

+

0.0867)= 0.1533 f t (4.67 cm)

Thus, the three basic geometric variables are as follows:

L

=

0.4687 ft (14.29 cm)1

=

0.0917 f t (2.80 cm)The equivalent thickness from Eq. (7) is: L,, = 2

x

0.0917+

0.2358 (0.4687 - 2 X 0.0917)=

0.2507 f t (7.64 cm)The masonry units were manufactured from a concrete of expanded clay aggregates, with 10 per- cent sand replacement. For this concrete the thermal property values are available from Table 1, and are as follows:

k = 0.30 Btu per h r ft F (0.0012 cal/sec cm C)

r, = 0.016 sq ft per hr (0.0041 cm2/sec)

All information is now available for the calcu- lation of the fire endurance in a dry condition.

From Eq. (9a) :

6 - 5

-

4

-

-

3-

-

-

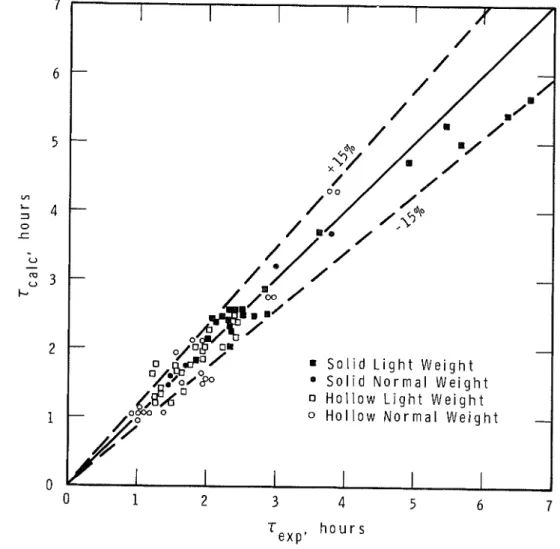

S o l i d L i g h t W e i g h t S o l i d N o r m a l W e i g h t 0 H o l l o w L i g h t W e i g h t 0 H o l l o w N o r m a l W e i g h t-

0 1 2 34

5 6 7 'exp' h o u r sFig. 4- comparison o f calculated and experimental fire endurance information on concrete masonry walls

From Eq. (10a)

= 0.7526 hr From Eq. (8) :

Finally, at a moisture content m = 0.0723 cu f t per cu ft, with

p

= 8.0 for lightweight concrete.From Eq. (llb) :

A standard fire test performed on this masonry wall yielded 1.5667 hr.

It may be of interest to find out how the fire endurance would be affected if the central web

were eliminated [see Fig. 1 (b)] and the material used in this web were used to increase the face shell thickness.* For this latter condition the following geometric variables are obtained:

L

=

0.4687 ft (14.29 cm)1

=

0.1047 f t (3.19 cm)The equivalent thickness remains unchanged;

L,, = 0.2507 ft (7.64 cm). Calculations carried out with this new set of geometric variables yield a fire endurance value T

=

1.5964 hr, 9.8 percenthigher than that obtained for the original geome- try. This finding supports the statement made in connection with Fig. 2 that the equivalent thick- ness alone is not adequate in studies concerned with the optimum design of concrete masonry walls for fire endurance.

*It is not suggested that this rearranged geometry is advan- tageous from a practical viewpoint.

DISCUSSION

In Fig. 4 experimental and theoretical fire en- durance data are compared. The calculations were performed as shown in the numerical example.

I t is not known whether Eq. (9) and (10) are strictly applicable to normal weight concretes made with chemically stable aggregates, because, as mentioned, the normal weight concretes used in the tests were all made with aggregates that underwent substantial dehydration on heating. This phenomenon may not be characteristic of all siliceous and calcareous aggregates used in other concrete masonry units.

The accuracy of Eq. (8), (9), and (10) and the calculation procedure can be judged from the fol- lowing findings concerning t h e average errors:

Normal weight Solid 6.9 percent units Hollow 14.0 percent Lightweight

I

Solid 7.0 percent units Hollow 8.8 percent With the exception of hollow normal weight units, the average errors seem to be quite accept- able from a practical standpoint.These findings confirm that the equations de- rived in this paper, and the calculation procedure described, are suitable for the estimation of the fire endurance of concrete masonry walls, pro- vided the thermal properties of the concretes are not too different from the values listed in Table 1.

ACKNOWLEDGMENT

The authors express their appreciation to E. 0. Por-

teous, J. E. Berndt, and D. H. Shearer for performing

the experiments and to E. W. Oracheski for his con- tribution in evaluating the test results. This paper is a contribution from the Division of Building Research, National Research Council of Canada, and is published with the approval of the Director of the Division.

REFERENCES

1. Allen, L. W., "Fire Endurance of Selected Non- Loadbearing Concrete Masonry Walls," Fire Study NO. 25, NRCC 11275, Division of Building Research, Na- tional Research Council of Canada, Ottawa, 1970.

2. Allen, L. W., "The Effect of Sand Replacement on the Fire Endurance of Lightweight Aggregate Masonry Units," Fire Study No. 26, NRCC 12112, Division of Building Research, National Research Council of Can- ada, Ottawa, 1971.

3. Harmathy, T. Z., "Thermal Properties of Concrete a t Elevated Temperatures," Journal of Materials, V. 5, No. 1, Mar. 1970, pp. 47-74.

4. Harmathy, T. Z., "Thermal Performance of Con-

crete Masonry Walls in Fire," Fire Test Performance, STP-464, American Society for Testing and Materials, Philadelphia, 1970, pp. 209-243.

5. Blanchard, J. A. C., and Harmathy, T. Z., "Small- Scale Fire Test Facilities of the National Research Council," Fire Study No. 14, NRC 8207, Division of Building Research, National Research Council of Can- ada, Ottawa, 1964.

6. Harmathy, T. Z., "Effect of Moisture on the Fire Endurance of Building Elements," Moisture of Materials in Relation to Fire Tests, STP-385, American Society for Testing and Materials, Philadelphia, 1965, p. 74.

7. Harmathy, T. Z., "Experimental Study of Moisture and Fire Endurance," Fire Technology, V. 2, 1966, pp. 52-59.

APPENDIX

-

NOTATIONa = average web thickness, ft

A = empirical constant

b = average web spacing, f t

B empirical constant

c specific heat of concrete a t room tem-

perature, Btu per l b F

k = thermal conductivity of concrete a t

room temperature, Btu per h r f t F

1 = average face shell thickness, f t

L = overall thickness, f t

m = moisture content, lb per l b

p, q, r, s = empirical constants

Greek letters

P

= empirical constantx = thermal diffusivity of concrete at room

temperature, sq f t per h r

@ = moisture content, cu f t per cu f t

P = density of concrete a t room temperature,

lb per cu ft

pul = density of water, l b per cu ft

t = fire endurance, h r

t I = fire endurance of solid wall, h r

t2 = fire endurance of two-layer configura-

tion, h r

Subscripts

e '4 = equivalent

o = in dry (moistureless) condition

1 = one-layer wall

2 = two-layer wall

Superscript

= measured .on side of minimum thickness

This p a p e r was r e c e i v e d by t h e I n s t i t u t e O c t . 18. 1971

This publication is being distributed by the Division of Building Research of the National Research Council of Canada. It should not be reproduced in whole or in part without permission of the original publisher. The Division would be glad to be of assistance in obtaining such permission.

Publications of the Division may be obtained by mailing the appropriate remittance (a Bank, Express, or Post Office Money Order, or a cheque, made payable to the Receiver General of Canada, credit NRC) to the National Research Council of Canada, Ottawa. KIA OR 6. Stamps are not acceptable.

A list of all publications of the Division is available and may be obtained from the Publications Section, Division of Building Research, National Research Council of Canada, Ottawa. KIA OR 6.