EcoGRAFI

2nd International Conference on Bio-based Building Materials & 1st Conference on ECOlogical valorisation of GRAnular and FIbrous materials June 21th - 23th 2017

Presented as poster Clermont-Ferrand, France

DEVELOPMENT OF BIO-BASED INSULATION MATERIALS FOR THE

IMPROVEMENT OF THERMAL COMFORT OF HOUSING IN BURKINA FASO

J. Carranco1, M. Palumbo2, A. M. Lacasta1

1Universitat Politècnica de Catalunya, Barcelona School of Building Construction, Av. Doctor Marañon 44, 08028 Barcelona, Spain

2Dept. de Engenharia Civil, Universidade Federal Fluminense, R. Passo da Pátria 156, Niteroi, RJ, Brasil

Abstract

Burkina Faso is located in the heart of Africa, where the average temperature during the dry season is about 40 °C. The 75% of the population is located in rural areas but, in the last years, there is a big migratory flow to the cities, in an irregular process of urban expansion where most of the houses are made with walls of concrete blocks and metal sheet roofs, generating a big lack of thermal comfort and habitability conditions. The main objective of this project is to develop a thermal insulation material, with low environmental impact, which could contribute to improve the living conditions in this new urban area of Burkina Faso. To this end, biomaterials locally available, in particular wastes or byproducts of agricultural industry have been used. Several formulations, based on peanut shells and sorghum canes and agglutinated with different kind of binders, have been investigated by evaluating properties as thermal conductivity, mechanical strength and fire reaction. The obtained insulation composites exhibited low thermal conductivity values and acceptable mechanical and fire reaction properties. Thus, according to the results, the material seems to be a promising renewable and locally manufactured product suitable for application in developing countries.

Keywords:

Bio based insulations, peanut shells, sorghum canes, thermal conductivity, fire reaction

1 INTRODUCTION

The use of thermal insulation materials made of renewable and locally available materials can contribute to the reduction of the environmental impacts of the building sector (Palumbo et al. 2014). This approach can be particularly relevant in developing countries where agricultural and industrial by-products are usually largely available (Asdrubali et al., 2015). The present research project was born from the institutional cooperation between the Polytechnic University of Catalonia and the Laafi Spain Organization, the activities of which are based in Burkina Faso.

The current living conditions in Burkina Faso are somewhat difficult for most of the population in the suburban settlements, where most of the population is concentrated. Most of the buildings there are built on cement block walls and sheet metal roofing which, considering the climatic conditions typical of the region, represents a great disadvantage in terms of thermal comfort.

The initial purpose of the research was to contribute in exploring and making available alternative strategies for the improvement of the living conditions in Burkina

Faso while seeking usefulness for organic waste generated by the agro-food industry in the country. Specifically, three natural materials were analysed: peanut shells, sorghum canes and Néré (Parkia-biglobosa) pod shells. The objective was to use these by-products for the development of thermal insulating materials that could be produced and replicated with low technology on site.

Peanuts are widely cultivated in Burkna Faso. Most of the production is shelled before selling and thus, large quantities of shells remain, which are not being exploited at the present. Some previous experiences exist on the use of peanut shells in building applications. Batalla et al. (2005) analysed the feasibility of making medium-density particleboards from milled peanut shells. Gatani et al. developed panels of both whole and crushed peanut shells, agglomerated with organic or inorganic matrices. They found that the addition of peanut shells in cement blends allows for the obtaining of low density panels that can be used in lightweight and non-bearing systems (Gatani et al., 2010). The authors also analysed the influence of particle size, shapes and their combination on the mechanical properties of compact panels bound with polyurethane resin (Gatani et al. 2014). Mgbemene et al (2014) produced

medium-density particleboards using maize cobs, rice husks, and peanut shells and studied their feasibility for use as internal partition wall claddings in residential buildings. They used a natural-based adhesive made from acacia mimosa tannin extract and hexamine. Sorghum is an indigenous crop to Africa and is the fifth most cultivated cereal crop worldwide. Sorghum (Sorghum bicolor) stalks are formed by an inner parenchymal tissue (pith) and a fibrous tissue (bark) in approximately equal quantities (Billa 1997). The pith is characterized by its very low density, high porosity and low thermal conductivity, which makes it suitable to be used for thermal insulation (Asdrubali 2015). There are many examples of applications of corn pith (which is, morphemically very similar to sorghum pith) currently in different stages of development. Palumbo et al. (2015, 2016) have recently developed insulation rigid boards based on corn pith agglutinated with sodium alginate, which is natural binder obtained from algae. The development of green adhesives based on tannins is currently a subject of broad interest because of their potential as substitute of petrol-based chemicals (Bertaud etal., 2012). Tannins are additives extracted from many plants, fruit and seeds that contain polyphenols. The use of tannins from Néré is a common practice in the traditional construction in West Africa, where these are used to increase durability of earthen finishes (Banakinao et al., 2016). It has been found that tannins react with clays improving the strength and creep behaviour of clay-sand mixtures (Sorgho et al. 2014)

In this paper, several formulations made with peanut shells and sorghum stalks are analyzed. Different kind of binders have been considered, being one of them the extractive obtained from Néré pods.

2 CURRENT CONSTRUCTION IN BURKINA FASO.

The climate of the region is subtropical. It consists of three distinct seasons: a cold season from November to February, with temperatures ranging between 27 and 32ºC, never lower than 15ºC and without rainfalls; a warm season from March to June, with temperatures exceeding 40ºC; and a rainy season, typically comprising the months from June to October. The pluviometric regime in the latter is quite severe, with heavy rains usually accompanied by strong winds loaded with sand particles. The temperature is maintained above 30 ° C.

The diverse variability of traditional constructions existing in Burkina Faso incorporate strategies such as high thermal inertia as a response to the extreme weather conditions described. Traditional roofs were mainly of two types: flat roofs made with clay or thatched roofs.

Currently, the metal sheet roof has replaced these kinds of roofs, especially in urban areas which, since the 90’s, are experiencing a rapid growth due to an extensive migration from the rural areas. Metal sheet roof has the advantage of being easy to implement and to maintain and durable, but has a poor thermal and acoustic performance which compromises indoor comfort.

In a house subject to the climatic conditions of Burkina Faso to avoid the entrance of heat in the form of direct or indirect radiation is paramount to guarantee the thermal comfort. However, with a thin sheet of

conductive material such as metals this is difficult to achieve.

Commonly, metal sheet roof consists on a thin foil of steel about 2.5 mm thick coated with a layer of zinc (galvanizing process) supported on wood rafters. The foil can be corrugated, wavy or trapezoidal, which confers rigidity to the element.

When solar radiation hits the roof, depending on the surface properties of the element (reflectance, absorptivity, emissivity) part of the energy in the form of solar radiation (short wave) is reflected and the rest is absorbed. Steel has a high thermal conductivity and, given the thinness of the sheet, the element does not have enough mass to accumulate the absorbed heat, therefore, the heat flows almost instantly to the interior environment. The internal surface temperature that can reach the roof of a house with the roof exposed to the external solar radiation can exceed the temperature of the air by several degrees. This situation certainly affects the comfort conditions inside the enclosure. The incorporation of ceiling thermal insulation boards is proposed to improve this situation.

3 MATERIALS AND COMPOSITES

3.1 Agricultural by-products.

The two agricultural by-products used to formulate the thermal insulations were peanut shells and sorghum stalks. Peanut shells were obtained from the hulling plant of Mercoguadiana, in Montijo, Spain. They were crushed and sieved to give fractions of particles of 2, 1, 0.5 and <0.5 mm. The chemical composition of the peanut shell, reported in literature, is presented in Table 1.

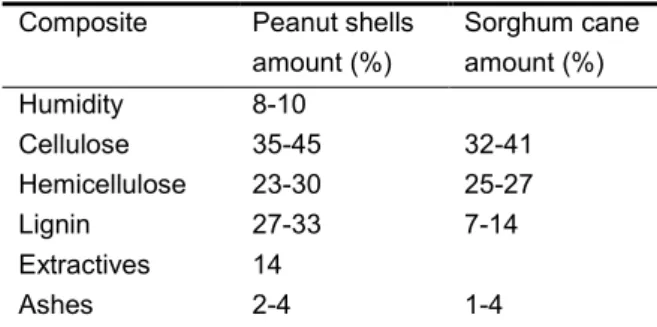

Table 1. Chemical composition of peanut shells and sorghum canes reported by Gatani (2010) and

Serna-Saldívar (1995) respectively.

Composite Peanut shells Sorghum cane amount (%) amount (%) Humidity 8-10 Cellulose 35-45 32-41 Hemicellulose 23-30 25-27 Lignin 27-33 7-14 Extractives 14 Ashes 2-4 1-4

The sorghum stalks used in this work came from Burkina Faso and were delivered by the Laafi Spain Association. The pith and the bark were used together or separately. The separation was performed manually. The material was crushed and sieved to classify it into different particle sizes. The levels of cellulose, hemicellulose and lignin from sorghum cane are shown in Table 1. The data indicate that sorghum cane is less lignified than peanut husk.

3.2 Binders

Composite materials have been developed with the agricultural by-products previously described and both organic and inorganic binders. The inorganic matrices used were lime and earth, and the organic ones were fish glue, bone glue and extract of Néré pots.

Fish glue is animal originated glue, produced from the skin, thorns, cartilages and swimming bladders of various kinds of fish. It is a type of strong adhesive,

although of slow drying. Usually is applied in combination with humectants such as honey or glycerin, with the aim of increasing its shelf life. The fish glue used is the commercial product Kremer, which was applied in liquid form, in a 45% solution in water The glue was used directly in the formulations, dissolved in distilled water at various concentrations, without the addition of any humectant.

Bones glue, also known as strong glue, is mainly obtained from horns and cattle hooves. It is a glue that tends to be stronger than the fish glue one, and It is used in carpentry and fine arts. The glue used was supplied in the form of light brown beads. These beads were swelled in distilled water (50% by weight) and heated to the water bath. The obtained glue was mixed with the aggregates without the addition of any other product.

The extract of Néré was obtained from the crushed Néré pods. This extract consists mainly of tannins (Sorgho et al. 2014) with agglutinant capacity. The extraction was done by adapting the traditional procedures used in Burkina Faso: the crushed pods were introduced into water and allowed to macerate exposed to solar radiation for 24 hours. The water was then filtered with the extractive and allowed to dry. The solid residue formed crystals which were triturated into a powder and dissolved in water again to obtain the glue. Some variations were tested on the extraction process, in order to optimize it.

Earth and lime were the inorganic matrices used. The earth was provided by the Laafi Spain Association and came from a land near the city of Ouagadougou, in Burkina Faso. The lime used was an aerated lime paste, classified as CL-90 according to standard UNE-EN 459/1.

3.3 Composites

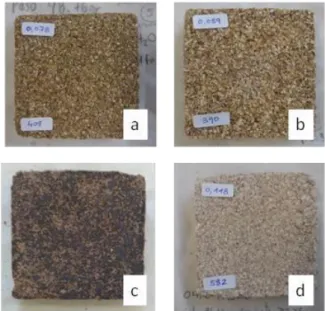

During the experimental process, many different composites made of peanut shells and sorghum stalks and the different described binders were considered. Some examples are shown in Figure 1.

Figure 1. Specimens made with peanut shells binded with fish glue (a), bones glue (b),néré extract (c) and

lime (d).

In order to select only feasible formulations, a three-point scoring system was established to evaluate cohesion:

(1) Bad cohesion, the sample is broken easily

(2) Medium cohesion, the sample remains cohesive, but is weak and / or disintegrates superficially upon contact and handling.

(3) Good cohesion, the sample remains cohesive, does not disintegrate and has a more solid appearance.

Only formulations with good cohesion were considered acceptable (see details in tables 3-4).

4 EXPERIMENTAL METHODS

4.1 Thermal properties

The thermal conductivity () of the samples was determined with a Quickline-30 Electronic Thermal Properties Analyzer (based on ASTM D5930 standard) using a surface probe. Such equipment is based on the analysis of the transient temperature response of the material to heat flow variations induced by electrical heating using a resistor heater having direct thermal contact with the surface of the sample. Prior to the test, the specimens were dried for 48 hours in an oven at 40oC and then allowed to cool under ambient conditions for about 30 minutes.

4.2 Pyrolysis Combustion Flow Calorimeter

Small-scale flammability tests for aggregates and binders were carried out on a Fire Testing Technology Pyrolysis Combustion Flow Calorimetre (PCFC). The heating rate at the pyrolyser was set to 60oC/min up to a maximum temperature of 750oC. Products from the anaerobic thermal degradation completed in a nitrogen atmosphere were mixed with a 20 cm3/min stream of oxygen prior to entering the combustion furnace at 900 oC. The Heat Release Rate (HRR) was determined from the oxygen consumption. Total heat release (HR) was calculated as the integral of the HRR over the complete time of the test. Once the test finished, the loss of mass was determined.

4.3 Fire reaction test

A radiator device described in the Spanish Standard UNE 23.725-90 was employed to measure the ignition time and the degree of extinguishability of combustion. Samples of surface 80 x 80 mm and variable thickness were placed on a metallic grid 3 cm below a heat source of 500 W, which was removed and replaced after each ignition and extinction, respectively. The most important parameters determined were the time of the first ignition and the number of ignitions and the average value of flame duration during the 5 minutes of assay.

4.4 Mechanical test

An adaptation of a Michaelis double-lever machine was performed in order to evaluate the tensile strength of the samples. That involved the construction and assembly of a tooling suitable to contain the “8-shaped” specimens showed in Figure 2, which were cast in moulds to have a neck of area of 645 mm2. This tool was connected to a press for mechanical tests with a high sensitivity load cell. The test consists in separating the upper and lower clips of the clamp at a speed of 1.8 millimeters per minute, until the moment when the specimen breaks.

5 RESULTS

5.1 Thermal properties

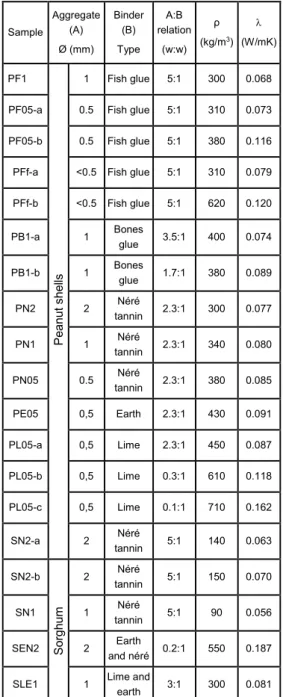

Table 2 summarizes the density and the thermal conductivity obtained for the different formulations.

Figure 2. “8-shaped” specimens (left) used for the mechanical test evaluation (right).

Table 2. Formulations and results for density and thermal properties. Sample Aggregate (A) Ø (mm) Binder (B) Type A:B relation (w:w) ρ (kg/m3) (W/mK) PF1 P e a n u t s h e lls 1 Fish glue 5:1 300 0.068

PF05-a 0.5 Fish glue 5:1 310 0.073

PF05-b 0.5 Fish glue 5:1 380 0.116

PFf-a <0.5 Fish glue 5:1 310 0.079

PFf-b <0.5 Fish glue 5:1 620 0.120 PB1-a 1 Bones glue 3.5:1 400 0.074 PB1-b 1 Bones glue 1.7:1 380 0.089 PN2 2 Néré tannin 2.3:1 300 0.077 PN1 1 Néré tannin 2.3:1 340 0.080 PN05 0.5 Néré tannin 2.3:1 380 0.085 PE05 0,5 Earth 2.3:1 430 0.091 PL05-a 0,5 Lime 2.3:1 450 0.087 PL05-b 0,5 Lime 0.3:1 610 0.118 PL05-c 0,5 Lime 0.1:1 710 0.162 SN2-a 2 Néré tannin 5:1 140 0.063 SN2-b S o rg h u m 2 Néré tannin 5:1 150 0.070 SN1 1 Néré tannin 5:1 90 0.056 SEN2 2 Earth and néré 0.2:1 550 0.187

SLE1 1 Lime and

earth 3:1 300 0.081

The density of each formulation was calculated based on weight and dimensions. For this purpose, 80 x 80 x 20 mm specimens were prepared for each of the formulations. After drying at 40 °C for 48 h, the samples were weighed on a scale and measured with a caliper. The thermal properties were evaluated using the equipment described in section 4.1.

As expected, samples made with sorghum pith have lower density and lower thermal conductivity that those made with peanut shells. In general thermal conductivity is higher for higher density of the samples, as can be observed in Figure 3.

Figure 3. Thermal conductivity versus density for peanut shells (blue diamonds) and sorghum pith (red

squares) formulations.

5.2 Pyrolysis Combustion Flow Calorimeter

Small samples of peanut shell and sorghum pith were tested with the PCFC technique. In this kind of microcalorimeter, the sample is heated in an inert atmosphere at a constant rate. The gases resulting from the pyrolysis are progressively mixed with a stream of oxygen and completely combusted at the combustion furnace. The measured heat release rate (HRR) curves, obtained from the oxygen consumption, are shown in Fig. 4. The two materials present the characteristic shape of lignocellulosic materials, with a main peak around 320-350oC which is related to cellulose and hemicelluloses and a tail relate with lignin and other extractives. However, the maximum of the peak is lower for the sorghum pith. The total heat release (HR) is 23.7 kJ/g for peanut shells and 11.0 kJ/g for the sorghum pith. Therefore, in case of fire, sorghum-based materials would have a lower contribution, releasing less energy during their combustion.

Figure.4. Heat release rate curves for peanut shells (red line) and sorghum pith (blue line)

The organic binders used in this work have been also tested in the PCFC. Results are shown in Figure 5.

0,04 0,06 0,08 0,1 0,12 0,14 0,16 0,18 0 200 400 600 800 (W /m 2K) (kg/m3) 0 50 100 150 200 250 300 0 100 200 300 400 500 600

HR

R

(W

/g

)

Temperature (°C)

Fish glue and bones glue have a similar behavior, whereas néré tannins present a very low HRR value.

Figure.5. Heat release rate curves for the organic binders: fish glue (red line), bones glue (black line) and

néré tannins (blue line).

5.3 Fire reaction test

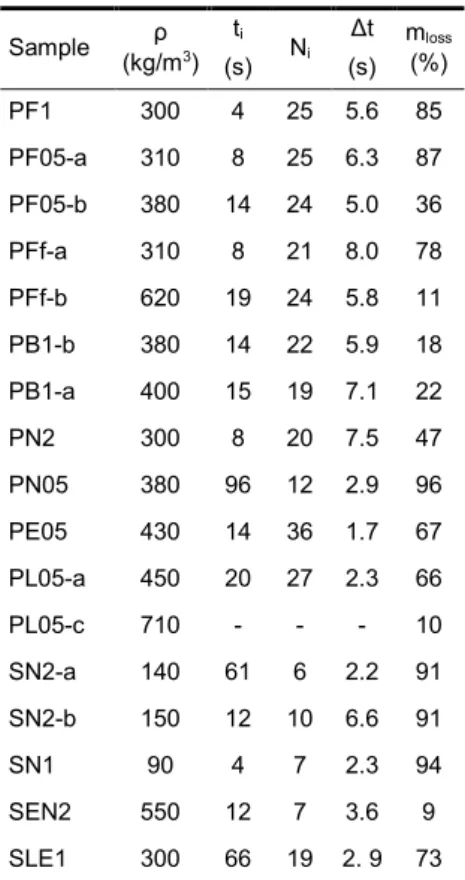

The results of the exposure of the samples to the radiator described in section 4.3 are summarized in Table 3. The main parameters are: the time of the first ignition (ti), the number of ignitions along the 5 minutes of essay (Ni), the duration of the flame (t) and the mass loss after and before the test. A better fire behavior corresponds to longer ti, smaller Ni and smaller t values.

Figure. 6. Specimen before and after the fire test.

In general, all the specimens tested have a relatively good fire performance since, although ignition occurs in all cases (with the exception of sample PL05-c which did not ignite), the flame extinguishes quickly as soon as the radiator is removed.

In the samples made with peanut shell, significant differences are observed depending on the type of binder, aggregate size and density. In the case of fish glue it is observed that, for a same particle size, the samples with higher density have a better behavior: higher ti and lower t. For similar density, the bigger particle sizes the lower t. The samples made with bones glue have a similar behavior than that of fish glue, but for those made with néré extraction, lime and earth, a significant improvement is observed. Also in these cases, density seems to be a relevant factor. In particular, the sample PL05-c, with a density of 700 kg/m3, did not ignite.

The samples made with sorghum presented less number of ignitions and, in average, these where of shorter duration than those observed for the samples made with peanut shells. This behavior agrees with the results obtained with the PCFC technique (Fig.4).

5.4 Mechanical test

According to the previous results, four formulations were selected to perform the mechanical test. They were: PB1-a (peanut shells with bones glue), PN2 (peanut shells with néré), PL05-a (peanut shells with

lime) and SN2 (sorghum pith with néré). For each formulation, five “8-shaped” specimens were cast (see Fig.2). Specimens were tested to reach values of the maximum limit supported for the mechanical traction described in section 4.4. Table 4 shows a summary of the average values for every formulation tested.

Table 3. Fire reaction results

Sample ρ (kg/m3) ti (s) Ni Δt (s) mloss (%) PF1 300 4 25 5.6 85 PF05-a 310 8 25 6.3 87 PF05-b 380 14 24 5.0 36 PFf-a 310 8 21 8.0 78 PFf-b 620 19 24 5.8 11 PB1-b 380 14 22 5.9 18 PB1-a 400 15 19 7.1 22 PN2 300 8 20 7.5 47 PN05 380 96 12 2.9 96 PE05 430 14 36 1.7 67 PL05-a 450 20 27 2.3 66 PL05-c 710 - - - 10 SN2-a 140 61 6 2.2 91 SN2-b 150 12 10 6.6 91 SN1 90 4 7 2.3 94 SEN2 550 12 7 3.6 9 SLE1 300 66 19 2. 9 73

Results show that the best resistance is obtained for peanut shells bound with bones glue. This result is not surprising considering that this kind of glue is commonly used for carpentry and other uses that require good cohesive strength. The second best material was based on peanut shells with néré. The other formulations showed worse results. However, the resistance obtained in all cases is enough for their use as thermal insulation material.

Table 4. Mechanical results

Code Mass (g) Load (Kg) Resistence (kg/cm2) PB1-a 18.16 12.12 2.45 PN2 18.84 2.79 0.49 PL05-a 9.14 0.38 0.09 SN2-a 11.84 0.46 0.06 6 CONCLUSIONS

This paper presents results of an ongoing research on the thermal insulation properties, fire behavior and mechanic resistance of different formulations for board based on peanut shells and sorghum pith glued by different binders.

It was found that most of the formulations tested had a low thermal conductivity, below 0.1 W/mK. However, the values obtained were higher than those of the state of the art thermal insulation materials, which generally have a thermal conductivity below 0.065 W/mK. The 0 50 100 150 0 200 400 600 H RR (W/g) Temperatura °C

thermal conductivity of the samples was more dependent on the density than on any other variable analysed. The specimens based on sorghum having a lower density, had also lower thermal conductivity. The samples made with sorghum and néré tannins where those with lowest thermal conductivity, between 0.070 and 0.055 W/mK.

Regarding the fire reaction, it was found that néré was the organic binder which presented a better behavior in case of fire. On the other hand, when peanut shells and sorghum were compared, it was found that the latter performed better.

The use of néré extract as a binder yield promising results, in particular when combined with peanut shells, indicating that further research should be done in order to further optimize the formulation of a néré based adhesive.

Then, the incorporation of a ceiling with thermal insulation boards made with the proposed material, can help to improve the described thermal comfort problems in Burkina Faso. It could be combined with some architectural design strategies, such us natural cross ventilation in the inside of the house, and an additional ventilation space or air camera between the metallic roof and the ceiling.

7 ACKNOWLEDGMENTS

The authors would like to thank Laafi organization, represented by the architect Albert Faus, whose interest in the development of materials for Burkina Faso gave rise to this research. We also thank MINECO (Spain) for the support provided under the project BIA2014-52688-R.

8 REFERENCES

Asdrubali, F., D'Alessandro, F., & Schiavoni, S. (2015). A review of unconventional sustainable building insulation materials. Sustainable Materials and Technologies, 4, 1-17.

Batalla L, Nuñez AJ, Marcovich NE (2005). Particleboards from peanut-shell flour. Journal of Applied Polymer Science, Vol. 97:916–923

Bertaud F, Tapin-Lingua S, Pizzi A, Navarrete P and Petit-Conil M (2012) Development of green adhesives for fibreboard manufacturing, using tannins and lignin from pulp mill residues. Cellulose chemistry and technology 46 (7-8), 449-455.

Banakinao, S., Tiem, S., Lolo, K., Koutsawa, Y., & Bedja, K. S. (2016). Dataset of the use of tannin of néré (parkia-biglobosa) as a solution for the sustainability of the soil constructions in West Africa. Data in Brief, 8, 474-483.

Billa, E., Koullas, D. P., Monties, B., & Koukios, E. G. (1997). Structure and composition of sweet sorghum stalk components. Industrial Crops and Products, 6(3), 297-

Gatani, M., Argüello, R., & Sesín, S. (2010). Effect of chemical treatments on the mechanical properties of peanut shell and cement blends. Materiales de Construcción, 60(298), 137-147.

Gatani, M., Granero, V., Medina, J. C., Fiorelli, J., Lerda, J., Sipowicz, E., & Kreiker, J. (2014). New Process for Peanut Husks Panels: Incorporation of Castor Oil Polyurethane Adhesive and Different Particle Sizes. In Key Engineering Materials (Vol. 600, pp. 452-459). Trans Tech Publications.

Mgbemene, C., Rosenkranz, A., Pichelin, F., Lehmann, M., Job, C., Kimeng, H., ... & Nduka, O. (2013). Feasibility study on the production of particleboard from maize cobs, rice husks, and groundnut shells using acacia mimosa tannin extract as the bonding adhesive. Journal of Architectural Engineering, 20(1), 04013006.

Müssig J. Industrial applications of natural fibres. In: Stevens CV (ed.) Renewable resources. Chichester: John Wiley & Sons Ltd, 2010.

Palumbo M., Navarro A., Avellaneda J., Lacasta A.M. (2014). Characterization of thermal insulation materials developed with crop wastes and natural binders in WSB14 World Sustainable Building Conference (GBC). Barcelona, 2014, pp 1–10.

Palumbo M., Formosa J., Lacasta A.M. (2015a). Thermal degradation and fire behaviour of thermal insulation materials based on food crop by-products. Constr Build Mater 79:34–39.

Palumbo M (2015b). Contribution to the development of new bio-based thermal insulation materials made from vegetal pith and natural binders: hygrothermal performance, fire reaction and mould growth resistance (2015). Doctoral dissertation, Universitat Politècnica de Catalunya.

Palumbo,M., Lacasta AM., Holcroft N, Shea A, Walker P. (2016a). Determination of hygrothermal parameters of experimental and commercial bio-based insulation materials. Construction and Building Materials, 124, 269-275.

Palumbo, M., Lacasta, A. M., Navarro, A., Giraldo, M. P., & Lesar, B. (2016b). Improvement of fire reaction and mould growth resistance of a new bio-based thermal insulation material. Construction and Building Materials.

http://dx.doi.org/10.1016/j.conbuildmat.2016.11.020 Pichelin F, Kamoun C and Pizzi A (1999) Hexamine hardener behaviour: effects on wood glueing, tannin and other wood adhesives. Holz als Roh- und Werkstoff 57.

Serna-Saldivar, S., & Rooney, L. W. (1995). Structure and chemistry of sorghum and millets. Sorghum and millets: chemistry and technology, 69-124.

Sorgho, B., Zerbo, L., Keita, I., Dembele, C., Plea, M., Sol, V., ... & Blanchart, P. (2014). Strength and creep behavior of geomaterials for building with tannin addition. Materials and structures, 47(6), 937-946.