Publisher’s version / Version de l'éditeur:

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la

première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

The 15th International Conference on Pipeline Protection [Proceedings], pp. 1-8, 2003-10-01

READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE.

https://nrc-publications.canada.ca/eng/copyright

NRC Publications Archive Record / Notice des Archives des publications du CNRC :

https://nrc-publications.canada.ca/eng/view/object/?id=4c41c48f-3fc3-4d4d-b45f-b4ed576f01f3 https://publications-cnrc.canada.ca/fra/voir/objet/?id=4c41c48f-3fc3-4d4d-b45f-b4ed576f01f3

NRC Publications Archive

Archives des publications du CNRC

This publication could be one of several versions: author’s original, accepted manuscript or the publisher’s version. / La version de cette publication peut être l’une des suivantes : la version prépublication de l’auteur, la version acceptée du manuscrit ou la version de l’éditeur.

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at Modelling the effectiveness of cathodic protection in water mains Kleiner, Y.; Rajani, B. B.

Modelling the effectiveness of cathodic protection in water mains

Kleiner, Y.; Rajani, B.

NRCC-46763

A version of this document is published in / Une version de ce document se trouve dans: 15th International Conference on Pipeline Protection, Aachen, Germany,

Oct. 29-31, 2003, pp. 1-8

Modelling the effectiveness of cathodic protection in water

mains

Yehuda Kleiner and Balvant Rajani

National Research Council of Canada, Institute for Research in Construction

Abstract

The effectiveness of cathodic protection (CP) in water mains can ultimately be expressed in terms of economic benefits obtained as a result of reduction in breakage frequency and deferral of pipe replacement. Modelling this effectiveness can be challenging because breakage frequency in water mains can be affected by several factors, both static (pipe size, material, soil type, etc.) and dynamic (climate, CP practices, etc.).

In this paper we present an approach that was developed at the Institute for Research in Construction of the National Research Council of Canada, in collaboration with 12 Canadian water utilities from Quebéc, Ontario, Saskatchewan and Alberta. Breakage patterns, before and after implementation of CP, are statistically analysed. Contributing factors such as pipe and soil characteristics, climatic changes and the type of CP (retrofit or hotspot) are explicitly considered. Once the parameters of these breakage patterns are extracted, a thorough economic analysis can be performed.

1. INTRODUCTION

In many cities, metallic water mains deteriorate as a consequence of aggressive soil conditions, use of dissimilar metals, stray electric currents due to electrical grounding or other sources of currents. These conditions encourage external corrosion pits in ductile iron (DI) and steel pipes or formation of graphitised zones in cast iron (CI) pipes. Under extreme conditions, corrosion can impact pipe integrity at quite an early stage of its life. Cathodic protection (CP) of metallic water mains is a mitigative measure that has been implemented in many cities in recent years to reduce premature breaks and leaks in water distribution networks. The effectiveness of CP can therefore be expressed in terms of the economic benefits obtained as a result of reduction in breakage frequency and deferral of pipe replacement.

Modelling the reduction of water main breaks due to CP is challenging because breakage frequency in water mains can be affected by several factor, both static (pipe size, material, soil type, etc.) and dynamic (climate, CP practices, etc.). This paper describes methods to assess the performance of cathodic protection programs implemented by water utilities. These methods should assist water utilities to optimise the implementation and scheduling of future CP programs.

2. MULTI-COVARIATE MODEL FOR PIPE BREAKAGE PREDICTION

Breakage patterns in water mains can be affected by many factors. Pipe material and size, soil type, installation practices, etc. are considered static factors because they do not vary with time. Climatic conditions (temperatures, precipitation) as well as operational practices (CP, pressure regimes) are considered dynamic factors because they change (or can change) over time. Kleiner and Rajani (2000, 2002) proposed a generalised form of an exponential model that included multiple covariates, which can be time-dependent.

t x a t N x e x N( )= ( t0) ⋅ (1)

where t = time elapsed from year of reference to; xt = row vector of time-dependent covariates prevailing at time t; N(xt) = number of breaks at time t (resulting from xt); a = column vector of parameters corresponding to covariates x; and

0 t

x = vector of baseline x

values at year of reference to.

Time-dependent covariates (or “explanatory variables”) can be pipe age, temperature, soil moisture, number of effective CP anodes, etc. Parameters N

( )

xt0 and a can be found byregression. Note that the model in equation (1) does not deal directly with static factors, rather it pre-supposes that the data can be partitioned into groups of pipes that are homogeneous with respect to their static conditions (i.e., equation (1) should be applied to a population comprising water mains of a certain material, size, vintage, etc.).

Kleiner and Rajani (2002) show how climatic conditions can be considered in this model. They defined freezing index (FI) and rain deficit (RD) as surrogate measures for the severity of cold winter and soil moisture respectively. Subsequently FI and RD were input into Model (1) to capture their effect on the breakage rates over an extended period of time. The following sections will describe how CP can be considered as well.

3. HOTSPOT CATHODIC PROTECTION (HS CP)

Hotspot cathodic protection is the practice of opportunistically installing a protective (sacrificial) anode at the location of a pipe repair. These anodes are installed typically without any monitoring and stay in the ground until total depletion, usually without replacement. A hotspot CP anode is assumed to provide full protection, starting at a certain amount of time (time lag) after installation, throughout its life to depletion. Because HS CP anodes are placed opportunistically at breakage locations, their location along a water main is assumed to be random. The HS CP covariate is taken as the number of active anodes per unit length of pipe in a given group of water mains, multiplied by an effectiveness factor. It is assumed that once a HS CP program is in effect, each and every breakage event is followed by the installation of a CP anode at the breakage location. The HS CP covariate is

thus dependent both on the total length of the water mains and the number of breaks in previous years. A detailed account of how the HS CP covariate is calculated is provided in Kleiner and Rajani (2003).

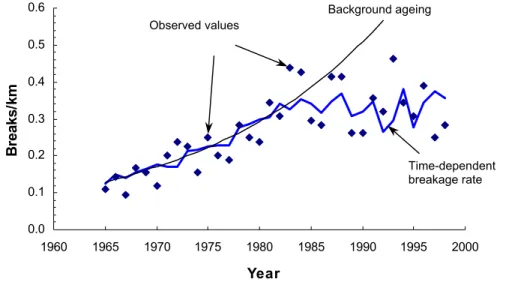

Figure 1 illustrates an example based on 84 km of cast iron pipes in a South-western Ontario utility, which started an on-going HS CP program in 1979. For the HS anodes, the life expectancy and time lag were assumed to be 15 years and 1 year, respectively. Note the background-ageing curve, which provides an indication of the breakage rate without the HS CP program. 0.0 0.1 0.2 0.3 0.4 0.5 0.6 1960 1965 1970 1975 1980 1985 1990 1995 2000 Year B rea ks /k m Time-dependent breakage rate Background ageing Observed values

Figure 1. Breakage rates modelling with time-dependent factors including HS CP

4. RETROFIT CATHODIC PROTECTION (RETROFIT CP)

Retrofit CP refers to the practice of systematically protecting existing pipes with galvanic cathodic protection. This can be done by attaching an anode to each pipe segment (if the pipe is electrically discontinuous, or through a bank of anodes in a single anode bed if the pipe is considered electrically continuous. Based on observations, it was assumed that typical pattern of breakage rates comprises three phases: (1) Before CP retrofit breakage rate grows nearly exponentially. (2) After retrofitting there is a transition period in which breakage rate drops. This is because the pipe is likely to have some deteriorated parts with imminent breaks, which are delayed by the CP. (3) Once the protected pipe is “purged” of these imminent breaks the breakage rate will continue to rise but at a much slower rate than without CP (provided that retrofit anodes are continually monitored and replaced upon depletion). A detailed account of how the retrofit CP covariate is calculated is provided in Kleiner and Rajani (2003).

Figure 2 shows how actual breakage data from a group of pipes in a Southern Ontario municipality fit into this pattern (adjusted coefficient of determination is 0.87). Note that Figure 2 does not reflect breakage rate along a real time line, rather breakage rates are plotted as an offset relative to the year of retrofit. Furthermore, there are insufficient data to clearly indicate breakage rate growth in the post-retrofit phase.

Post- retrofit Pre-retrofit 3 years transition Total bre aks

Years before (-) and after (+) retrofit

15 5 -5 -15 0 -25 20 40 60 80 100 120 140 160

Figure 2. Breakage pattern before and after retrofit (80 km CI and DI, 100-300 mm).

5. IMPACT OF CP ON LIFE-CYCLE COSTS OF WATER MAINS

Cathodic protection can impact the life-cycle costs of water mains in two ways. First, by reducing the breakage rate, CP will reduce the operational costs including direct, indirect and social costs that are typically associated with pipe breakage. Second, by slowing pipe deterioration, CP will enable to defer its renewal (rehabilitation or replacement), creating further cost savings.

The total life-cycle costs of a water main, including CP can be expressed by equation (2) for HS CP and equation (3) for retrofit CP

∫

− − + + ⋅ ⋅ ⋅ = T rt t HS b rT r e C C N x e dt C T C 0 ) ( ) ( ) ( (2)where Cr = cost to replace a unit length of pipe ($/km); r = equivalent continuous discount rate; T = the year at which the pipe is replaced (time elapsed from the present); Cb = cost of a single water main breakage, including direct, indirect and social costs;

CHS = cost of a hotspot anode; N(xt) = number of breaks per unit length as defined in equation (1) including CP covariates (km-1 year-1); and t = integration variable.

⋅ + ⋅ + ⋅ + + + ⋅ =

∫

∫

∫

∫

+ + − − − − − − − ret ret tr ret ret tr ret ret ret T T t T T t T rt t rt t rt t b T T T t r ret rT rT r dt e x N dt e x N dt e x N C dt e C e e C T C 0 ) ( ) ( ) ( ) ( ) ( (3)Where Tret = year of pipe retrofit (time elapsed from present); Cret = annualized cost of pipe retrofit ($/km/year); and ttr = transition period (years).

6. CASE STUDIES

6.1. Life-cycle Costs with HS CP

The following is a case study comprising 341 km of cast iron water mains in an Eastern Ontario municipality. These water mains include pipes of diameters ranging from 150 to 300 mm, installed between 1960 and 1969. The water utility started an on-going hotspot cathodic protection (HS CP) program in 1990, whereby in each maintenance event when a pipe is exposed, an anode is installed on the exposed section. The HS CP anodes were assumed to provide effective protection for 20 years. The multivariate model was applied to 29 years (1972-2000) of breakage rate data. Because rain deficit (RD) has shown to have an insignificant impact on breakage rate variations, the only time-dependant factors considered were freezing index (FI) and HS CP. Figure 3 illustrates how the model fitted the observed breakage rates with an adjusted coefficient of determination of 0.7.

0.0 0.1 0.1 0.2 0.2 0.3 0.3 0.4 1970 1975 1980 1985 1990 1995 2000 2005 Year B rea ks /k m HS CP program Background ageing

Figure 3. Breakage pattern in HS CP protected CI water mains in Eastern Ontario.

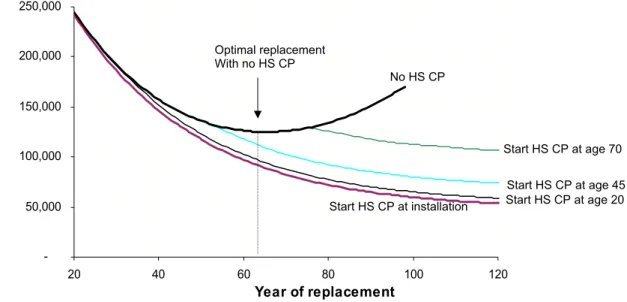

For the economic analysis, the total cost of a breakage event (including direct, indirect and social costs) was assumed to be $6,340. The average water main replacement cost was taken $400/m, and the cost of a HS CP anode was assumed to be $250. Figure 4 illustrates the resulting economic analysis. For the analysis presented here, the life-cycle costs associated with a pipe include the costs of pipe breakage, HS CP anodes and pipe replacement. Since water mains are mostly public assets, the discounting factor was taken as 3%, which is more akin to a social discount factor than to a financial one. It can be seen that the age at which the HS CP program commences has an impact on the total life cycle cost of the pipe. While there is little difference in the impact at an early age, the differences increase significantly as the pipe ages. This is because breakage rates are low at an early age, the number of HS CP anodes is small and therefore the impact on costs do not vary much between, say, starting an HS CP program at age zero or at age 20.

Further, in this case study HS CP can also impact the life expectancy of the pipe. The economic life expectancy of the pipe can be defined as the duration until such time when it is more economical to replace the pipe rather than continue repairing it, or in other words,

-50,000 100,000 150,000 200,000 250,000 20 40 60 80 100 120 Year of replacement D is c ount ed l if e -c y cl e c o s t ( $/ k m ) Optimal replacement With no HS CP Start HS CP at installation Start HS CP at age 45 Start HS CP at age 20 Start HS CP at age 70 No HS CP

Figure 4. Life cycle costs of water mains with HS CP

the time at which the total discounted life-cost of the pipe is a minimum. This point is depicted in Figure 4 as age 62 years for a pipe with no HS CP. However, in this case study the point of optimal replacement for pipes with HS CP is deferred to beyond 120 years of age.

6.2. Life-cycle Costs with retrofit CP

The following is a case study comprising 29 km of ductile iron water mains in a Southern Ontario municipality. These water mains include pipes of diameters ranging from 150 to 300 mm, installed between 1970 and 1979.

0.0 0.2 0.4 0.6 0.8 1.0 1.2 1.4 1.6 1970 1975 1980 1985 1990 1995 2000 Year B rea ks /k m Retrofit CP program

Average Background ageing

The water utility started to retrofit these water mains with cathodic protection in 1984, at a rate of between 1 and 5 km per year, so that by 1996 the entire group was retrofitted. The multivariate model was applied to 25 years (1972-1996) of breakage rate data. Figure 5 illustrates how the model fitted the observed breakage rates with an adjusted coefficient of determination of 0.66.

For the economic analysis, the total cost of a breakage event and water main replacement costs were assumed to be the same as before $6,340/event and $400/m, respectively. Retrofit CP was assumed to cost $35,000/km every 20 years and the discount factor was taken as 3%. Figure 6 illustrates the resulting economic analysis. It can be seen that due to the exceptionally high deterioration rate in the water mains prior to their retrofit, the economic life expectancy could be as low as 25-30 years. Again, the age at which the CP program commences has an impact on the total life cycle costs of the pipe. Because of the high deterioration rate the impact of retrofit CP on the life-cycle costs is high even if implemented at an early age. Note that the cost of retrofitting the pipe upon installation was assumed to be only $20,000/km because there was less work involved compared to retrofitting an existing pipe.

Retrofit CP appears to have significant impact on the life expectancy of the pipe as well. If implemented before 20 years of age, retrofit CP will defer the optimal replacement time to beyond 120 years. If retrofitting were to start at age 30, the optimal replacement time would be deferred for about another 60 years.

-100,000 200,000 300,000 400,000 500,000 0 20 40 60 80 100 120 Year of replacement D is count ed l if e-cy cl e c o st ( $/ km )

Start retrofit CP at age 10 Start retrofit CP at age 20 Optimal replacement

With no retrofit CP

Start retrofit CP at installation Start retrofit CP at age 30 Start retrofit CP at age 40 No retrofit CP

7. SUMMARY

A time-dependent multi-covariate break prediction approach was used to model the effects of hotspot cathodic protection and retrofit cathodic protection on the breakage rates of water mains. The cathodic protection itself is considered as a time-dependent covariate. The hotspot CP covariate varies over time depending on the number of remaining active anodes and the length of water main. The retrofit CP is treated as a step-function that alters the breakage rate pattern of water mains after its implementation.

The analysis is performed on a group of water mains that are homogeneous with respect to their historical breakage patterns. The impact of these effects on the life-cycle costs and on the economic life expectancy of water mains was modelled as well. The models show that the magnitude of this impact can depends on the time of implementation of the cathodic protection program.

If a water utility does not have adequate data, e.g., breakage rate before and after the implementation of a CP program, inferences could be made from data of other utilities with similar conditions. Caution, however, must be exercised such that inferences are applied (as much as possible) from a homogeneous group of pipes in one utility to pipes with very similar characteristics in the other utility.

REFERENCES

Kleiner, Y., and Rajani, B.B. (2000). “Considering time-dependent factors in the statistical prediction of water main breaks.” Proc. American Water Works Association Infrastructure

Conference, Baltimore.

Kleiner, Y., and Rajani, B.B. (2002).“Forecasting variations and trends in water main breaks,” Journal of Infrastructure Systems, ASCE, 8(4).

Kleiner, Y., and Rajani, B.B.(2003). “Quantifying Effectiveness of Cathodic Protection in Water Mains: Theory.” Submitted to Journal of Infrastructure Systems.