Publisher’s version / Version de l'éditeur:

Materials Research and Standards, 5, 10, pp. 510-515, 1965-12-01

READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE. https://nrc-publications.canada.ca/eng/copyright

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la

première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

NRC Publications Archive

Archives des publications du CNRC

This publication could be one of several versions: author’s original, accepted manuscript or the publisher’s version. / La version de cette publication peut être l’une des suivantes : la version prépublication de l’auteur, la version acceptée du manuscrit ou la version de l’éditeur.

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at

An unsoundness test for limes without cement

Ramachandran, V. S.; Feldman, R. F.; Sereda, P. J.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

NRC Publications Record / Notice d'Archives des publications de CNRC:

https://nrc-publications.canada.ca/eng/view/object/?id=59c5695a-e3cf-4d6d-97f8-e8c4101136d7 https://publications-cnrc.canada.ca/fra/voir/objet/?id=59c5695a-e3cf-4d6d-97f8-e8c4101136d7Author~zed Reprint from the Copyrighted Moterrols Research 6 Standards, Vol. 5, No. 10, October 1965

Published by the American Society for Testing and Materials, Philadelphia 3, Pa.

An Unsoundness Test for Limes Without Cement

By V. S. .RAMACHANDRAN, R. F. FELDMAN, and P. J. SEREDA

The authors first used compacts to test soundness in an investigation of plaster bulging reported in the December,

1964,

issue ofMR&S

( " ~ e l a ~ e d Hydration in White-Coat Plas- ter"). The method was so promising that it has been developed as a test of unsoundness in limes.and thc ASTL\I St:uidard for H y d r ~ ~ t c d Liine for ;\lasonry I'urposes, C 207 - 49. Othcr sta~idards linliting AIgO arc Rcfs. [ I ] ' and [ 2 ] ) . A limitation on thc perccwtagc of ~inllydrated oxide could be criticized 011 thc grounds th:it this mount by itself

nlay riot coinl~lctcly rcprcsent, the expansion ill practice. HCIICCI, :L direct deternlinatiorl of thc po- tcntial exl)atisivc nature ol' the liinc is preferred for studying unsouudncss.

Onc met hod of dct crininirig 1 he liability to cx- p t ~ ~ ~ s i o n , described in Britisl~ specification BSS 890- 1940, is know11 :LS thc 1,c Chatclier test. I n it mor-

t:us arc forrued with 3 : 1 : 12 proportio~~s of hydrated lime, por(l:u~tl cc~nenl, ; I I I ~ s t : ~ ~ ~ d a r d snrid. After

setlirig for 18 hr they arc steamed for 3 hr arid the c x ~ ~ a ~ i s i o n is mcasurcd. Thc permissible limit is 10 1nn1 i l l :L 1,e Chatclier mold. The XSTAlI Method

for I'hysical Tcsl,ing of Quicklime ; ~ n d Hydrated

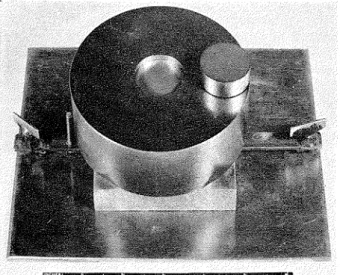

Fig. 1 -Mold assembly.

, l l l l , , l i l l l l l I I 1 l ~ l 1 , , 1 , , , , 1 1 1 1 1 1 1 1 1 1 1 , , , , , , , , , , , ~ 1 . 1 1 , . 1 1 1 , 1 1 , 1 ~ 1 , 1 1 1 1 1 1 l l l i l l l l l l l l l l l l l l l ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ l l l i l 1 I I I I I I 1 I I ~ I 1 1 1 1 1 1 1 1 1 1 1 1 1 1 ~ ~ l i 1 l l i l l l l l l l ~ i l ~ l l ~ ~ ~ l ~ l l 1 l l l l i i l ~ 1

or inortar c:ui C ~ U S C failure because of excessive expan-

s i o n : ~ ~ aresul~of post-hydrat io11 of ~llagrlesiunl oxidc in the form of periclasc. ;\lagncsium oxidc constitutes a considerablc proportio~~ of burn1 dolonlitic limestone, :u~d if the linle is hard burnt a1 tempcraturcs abovc about 1100 C, the pcriclase nlay rcquire illany ycars to hydrate in tllc prescricc of ~noisturc. An urisound lime is one that c:iuses cxpansion and disruption when used as a constituent of a building material. The inagnitude of the cxp:~nsion is indicated by all ab- solulc volunle ch:inge of 117.2 per cent when onc ntolc ol magncsiuln hydroxide ( A ~ l g ( o H ) ~ ) is fornlcd from onc lnoIc of magnesium oxide (14gO).

Bccause cxpansiorl is related to the anlount of un- hydrated magnesiun~ oxide resent, thc 1lgO content in hydrated lime is linlitcd to 8 pcr cent in some sl>ecifications (for exaillple the ASTAI Standard for Sj~ccial Finishing F1ydr:ited Lime, C 206-49,

V. 5. RAMACHANDRAN received a B.S. from Mysore University, an M.S. in physical chemistry from the Banaras Hindu University, and a

Ph.D. from the Calcutta University of India. From 1949 to 1956 he

was engaged in research on electrical conductivity in gases and on

catalysis. He joined the Central Building Research lnstitute of India

in 1956. Since 1956 he has been working in clay mineralogy and

lime, gypsum, and cement chemistry. From 1962 to 1964 he worked

at the Division of Building Research, National Research Council, Canada, returning to the Central Building Research lnstitute of India.

R. F. FELDMAN was granted his M.A.Sc. by Toronto University in 1959

and has since been employed at the National Research Council. He has been engaged in research on many physical and chemical phenomena related to materials, their formation, and their deteriora-

tion. He has also been involved in a basic study of sorption and

length changes on various building materials.

PETER J. SEREDA rece~ved his M.S. in chemical engineering from the

University o f Alberta. From 1944 to 1948 he worked a t the Atomic

Energy of Canada, Ltd., at Chalk River. He joined the Division of

Building Research, National Research Council, Canada in 1948. He

has been engaged in research on corrosion, electrostatic hazards, and properties of building materials. He has been an active member of

ASTM Committee B-3 and also represents the National Research

Council on Committees C-1 1 and E-1.

' The italic ~ ~ u r r ~ h e r s in br:~clrets refer to the list of references

al)gended to this pager. ,,,,,,,,,,,ll,,,,,ll,ll,l,llll,,,,,ll,,11111111,111,,11111,,,,,,,,,ili, ,,, ,,,,, ililil,llllllllllllll ill,l ,,,,,,~,,,,,,,,,,,11111,1IIIIIIIIIIIIIlllillllllllllIliiiilllllllllllil1~111111111i111

510 Materials Research & Standards

-

Linlc (C 110-38) does iiot nletlsu1.c exp:ulsion, bul includes sleailli~~g for 3 1lr ru1d testing the s p c c i ~ n e ~ ~ s For faults. Although t,hc LC Chatclicr test may dc- tect urlsoundiiess C : L U S C ~ by h:~rd-bllrnt liinc, it is llot

sevcrc cilough to clctcct the uusound~~ess C : L I I S C ~ by

periclase that is oltcri found ill clolonlitic liincs. A much niorc scvcrc tcit 11:~s bccil suggcstcd by Wclls a i d his co-iv0rkc1.s [ S ] . They c:~rricd out, systeillntic :~utoclnvc tcyl iilg ol' v:~rious t yl)cs ol I ~ I I I C

gaged with ceinclit. -1 tcch~lic~uc I'or I ) ~ ' c I ) ; L I * ~ I L ~ , ( ~ r -

ing, and autoclaviilg 1 by 1 by 10-ill. c,cine~lt-linlc bars W:LS dcvc1ol)ccl. The csl)a~~sioiis mcrc mcas-

ured by propol.tioni~lg :L m i s t ~ u c ol ccn~cut limc = 1 : 1

by ~veight :~ild s~1b~c(111elltly autoclnvillg to 295 psi for 3 hr. A maxi~num (~x1)ailsioli OF 1 per cent w:~s suggested for a linlc to bc acccl)tablc. Various other workers have al)l,lied this mcthod for testing limes [ & I S ] . The autoclave tcstiilg of limes lllixed with ceme~lt, though a uscful mcthocl for determining the potential cupai~sion char:~ct cr~st ics of limes, has disadvantages. T h c exl~arlsion of the ccmcnt-lime inixturc 111:~y not rcflecl thc cxl~nl~hio~l of liille alo~lc, as i t also depends on thc t y l x ol cenlcilt uqecl. Solne- tinles a lime ~ v i t h excessive cxl)ansioil c:iuses \\-:~rping and disintegratioll of the sl~ecinlcil. The :~dequacy of 1 per eelit exp~zilsioil hay also been qucstioiled on the premise that calciunl llyd~.oside might cxlxl~ld by about 1 1x1. c e ~ l t

[dl.

Wc thought that sollie of tllcsc disadvantages could be ovcrconie by climiil:~tii~g the ccment. 111 our iilrrestigatiol~ snlnll sl)ccsinlc~ls IVCI-C m:~cle by coln-

1)actiilg thc lilnc ~ ~ o ~ v c l c r . This ~nctl~ocl also rlimi- nated thc use of ~nisiiig n:\tcr.

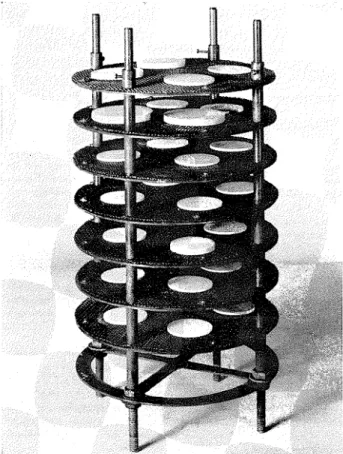

Fig. 2-The c a g e for outoclaving compacts.

Fig. 3-Measurement o f expansion.

Experimental Procedure Mixing

I n all thc cxl)erime~its only illaterials passing through a 100-mesh sievc \\-ere used for thc prepnra- tion of thc compact. hlixi~ig of the powders in various proportiolw was carricd out in an air-tight bottlc agitntcd vigorously ill :L 1)nint conditioner. Every 2 inin the bot tlc was t a k c ~ i out of t h c con- ditioner and shakcil maiiually for a fciv minutes to remove any powder sticking to tllc sidcs of thc bottle. Each mixing was continued for 15 mill. Ccment and lime for the p~.el)aratioil of bar specilllc~is were mixed in thc conditiouer contirluously for 15 min, thcrl shaken ~ n n ~ i u a l l y for 15 min.

Preparation oj' the Specirilens

Compacts with a rioillillal diameter of 1.26 in. wcrc made in a st ecl mold co~~sisting of a cylindcr and two closely fitJtiiig pistolis. T h c cylinder was mounted

vertically with thc bot toill

isto toil

1oc:~tccl ill the cylin- der a t a, co11st:~nt dcptll. For n coml)acti~lg load of 20,000 lh, n clcl)lh ofi:k

in. was chosen. This wasm e : ~ s u ~ w l \\-it,h a dcl)th gwgc wit11 :L r:Lilge of

4

in.and :L sensitivity of 0.0003 ill. The pistoil a t thc

bottonl could be loivcrcd or raised by scrcivs in the sul)porting f r a n c (Fig. 1).

The powder nras placed i l l the Inold by tanlpiiig

with the cdgc of a spatula ag:~iiist the edge of thc cyli~~cler while esccss poivdcr rcn1:liucd heaped ovcr the mold. Tamping was done with equally spaced strokes in two directions pe~'l)e~idiculnr to each other. Exccss powder was t,hen scraped off lcvel with tlic top of the cylindcr. Tlle bottolll ~ ~ i s t o ~ l , with the specimen 011 it, was loiirercd and the top piston

placed in the cylinder; thc :~ssembly was then rllountcd on a testing machiilc and loaded to the desired pressure. Loads up to 100,000 lb mere uscd, although nlost of thc exl~erimellts mere carried out wit11 specimens coml)>~cted a t 20,000 lb. T h c load was released and thc top piston pushed out with thc compact, rcsting 011 thc top of the bottom piston.

Cement-lime bars were preparcd according to thc nlethod described by Wells and his collaborators [ S ] .

The initial diamcter of t,hc colllpilct was taken as the average of thrce liilcs drawn across tlic clinmctcr of thc compact in India ink. The lillcs werc distillet

ever1 after :lutoclavi~~g. Compacts were placed in a cage ivit,ll seven c o m l ~ a r l ~ n ~ c i ~ t s of co1)pcr gauac. Eacll s c r c c ~ ~ could s a ~ t , four coi111)ac:ts (Fig. 2). The cage nT:ls tlle~i pl:~cccl ill a. st:l~ldard :~utoclavc used for studyirlg the uilsourldl~ess of cements. Steam pressure was nlaii~taii~ed a t 295 psi for

X

hr, urlless otherwise stated. The autoclave was cooled, and the compacts were dried overnight over nlagnesiu~n perchlornte.The average incre:lsc i l l the diameter of the speci-

mens a t the three lines was measured wit,h a dial micrometer wit11 1- to 2-in. range (Fig. 3). The conlpact was mounted or1 a stainless steel platform situated below the anvils. The height of the platform could be adjusted. The pressure exerted on the anvil coililected to the dial mas negligible, so that a very small pressure on the compact made the pointer on the dial move to zero position without deforining the edges of the compact. The microm- eter had a scilsitivity of 0.0001 ill.

The thickness of the conlpscts was measured with a micrometer gage to an :lccur:Lcy of 0.0001 in. and each value was the average of four determinations on the same specimeil. The expansions :Ire ex- pressed as percentage linear espaiisioii along the diameter or the thickness or by volumetric expansion calculated from the diameter and thickness.

The expansions of the lime-ceme~it bars were determined by the length compamtor for lower lime contents and by calipers for higher lime contents. Analysis

Chemical arialysis of the hydrated dolomitic lime before aiid after autoclavi~lg mas carried out by the standard method. The carbon dioxide content was

-. 0 0 - - - - 4 I I I I I 10 20 39 40 50 60 70 80 5 H y d r a l e d D o l o m i t i c L i m e 1M 90 8 0 7 0 60 5 0 40 30 20 10 0 5 C a l c i u m H y d r o x i d e C O M P O S I T I O N OF THE C O M P A C T

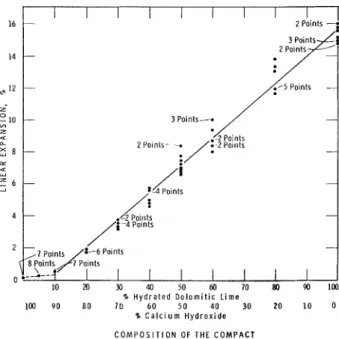

Fig. 4-Effect of composition of compact on expansion in autoclave; correlation coefficient is 0.97, equation of the line is y = 0 . 1 7 ~ -

1.34.

estinlntcd by absorl)tion i l l barium hydroxide in a

closccl systc111. The calcium l~yclros~clc (&(OH)?) co11te110 n . : ~ h ebl i111:lt ('(1 1)y ~ s i r : t c t i i ~ g it with :ill

:~1coI~ol-glyccrir~e ~nixture ;lild stal~dardiziilg with ammonium acetate. Tlle total loss of (OH) hom Ca- (OH)? 2nd hlg(OIl)2 was calculated by heating the m:~teri:~l a t 520 C for 5 hr. 11s aluiniilum oxide (AI2O3), silica (SiOn), aiid ferric oxide (Fe2O3) are negligible, the total u11hydi~:ltecl A[gO could be calculated from the above values.

The perceiitage iric~.casc in weight of a compact is calculated with rerlxct to the weight of the com- pact dried over magriesiuin perchlorate for 24 hr. The properties of so-called inert substarloes under autoclnvc treatment, iiarncly &(OH),, calcium car- bonate ( C R C O ~ ) , and 31g(OI-I)P, were studied by usirig cl~emic:~lly pure coml)ounds.

Results and Discussion

Aut,oclavc cxl)n~lsiori rcsults for compacts contaiil- ing precipit:~ted calcimn hydroxide, hydrated dolo- mitic lime (DLH), DLR-calcium hydroxide, aiid DLH-cement mixtures \\-ere studied. C:llciunl hy- droxide was used as the diluent because it showecl very little autoclave cxpansio~~, in the order of 0.1 to 0.2 per cent. Any reactio~l between calciuill hy- droxide and other coi~stituents of hydrated lime is not probable under the co~iclitions studied. I n ad- dition, hydrated lime itself contairis :I ~ n a j o r pro-

portion of ct~lciuill hydroxide, which does not con- tribute to the autoclave expar~sion value to a signifi- cant extent. Calcium hydroxide compacts well.

First the iriflue~lce of the load of compaction, the thickness of comp:~cts, aiid tlle dur:ttion of autoclaviiig on the expansion characteristics of D L H compacts were determined. At compnction loads from 5000 to 100,000 lb, the :~utoclave expansion irlcrensed up lo 10,000 lb and decreased progressively to 10.3 per cent a t 100,000 lb. At stJill higher loads the com- pacts sho~vcd a tendency to warp after autoclave treatment. Lower expansion a t higher loads was the result of too i~lconlplete hydration of periclase. This was sho~vii by studyi~ig the weight gain in the compacts on autoclaviiig. A t a coillpactiorl load of 5000 lb the weight increased by 15 per cent; a t 100,000 lb the value was only 13.6 per c e ~ ~ t .

Ten compacts, varying in thickness from 0.46 to 0.223 in., were formed a t 20,000 lb and their be- havior on r~utoclave treatment JV:LS studied. The

densities of compacts of different thicknesses formed a t 20,000 lb were fairly uniform, varying from 1.59 to 1.61 g/cc. The exp:ulsiori irlcreascd with thickness initially but decreased as thickness continued to in- crease. Expa~ision along the two faces of the com- pact was urlcqual for thicknesses over 0.15 in. Lower expansion for thicker compacts is perhaps the result of incomplete hydration. A cornpact 0.046 in. thick increased in weight by 14.58 per cer~t on autoclave tre:ltineut, whereas one 0.223 in. thick increased in weight by only 13.98 per cent.

Coml~acts were autoclaved for 1, 2, 3, 4, alld 5 hr and practically all the compacts showed similar es- p:u~sion values. The weight gain measurements

I I

10 20 33 40 50 60 70 80 90 l(10

% H Y D R A T E D D O L O M I T I C L I M E I N C a l O H I Z

Fig. 5-Autoclave expansion of Ca(OH)?-DLH compacts in terms of lineor and volumetric measurements.

showed that there was no significant difference in the weight increase for the periods studied. These re- sults show t h a t almost complete hydration is effected after one hour of autoclave treatment a t 295 psi.

From these studies we concluded that a coil~paction load of 20,000 lb was suitable. At lower loads the conlpacts were not strong enough and needed greater care in handling; s t higher loads they showed a tendency to warp. The thickriess of a11 of them was kept i11 the r:ingc 0.07 to 0.08 in. An autoclave

treatment a t 295 psi for 3 hr was found to be suitable. The initial thickness of coil~nacts of a particular composition varied less than a mil and was about 0.07 in. for a D L H compact.

The initial diameter of compacts of pure D L H was lower than that of the mixtures. This indicates that, owing to the inherent nature of the constituents and particle-to-particle contact, thc DLH-Ca(OH)* mixture rebounds more after re- rnoval from the mold. The compacts were almost perfectly circular, as indicated by a negligible variation in the diameters taken along three lines. After the compacts were autoclaved, however, the diameters showed some variation in the third place, especially a t higher expansion values, so the results were calculated as averages of three diameters.

A statistical analysis of the relation between the hydrated lime content and linear expansion along the diameter has been made. Eighty-three points representing different conceritrations have been plotted in Fig. 4. A regression line is drawn for conce~ltrations from 10 to 100 per cent DLH. The correlation coefficient was found to be 0.97 and the significance level higher than 0.99. The equation of this line is y = 0.17.2: -1.34 (units as taken in the graph). The two points corrcsporiding to 0 and 5

per cent D L H do iiot [all on this line. This indi- catcs that part of the hydratcd inagnesiunl oxide inay eiitcr t11c pores wit haul, contributing t,o t,he cxpansioii. Tlic rcsults obtained by Wells arid llis collaborators [ S ] show that the curvc is not as steep a t lower conccntratioris of 14g0 as a t highcr con- ceiitmtioiis.

Ten scts of coinpacts coiitaining 0, 5, 10, 20, 30, 40, 50, 6'0, 80, and 100 per cent D L H in Ca(0I-I), nerc autoclavcd. E'or cach compo- sition, seven lo tcn specinlcris were chosen to providc information on the variation in the results obtained on autoclavir~g the con~pacts in different batches. Thc linear exl,arisiori rcl)rescnts tlle aver- age expansion of several specimens. The average lincar exparisioii values are very close to those ob- tained by coml~utation froill the regression line of Fig. 4. Thcrc is a definite iiicreasc in tllc linear ex- pansion as thc amourit of D L H increases. The var- iation in the rcsults of cxl~ansion is more n~srlied a t a conccntratiori of 50, 60, mid 80 pcr ccnt DLH. I n Fig. 5 the expansions along t,he diizincter and thick- ness arc plotted as fund,ions 01 D L H content. A linear* rclatioii belwccii diainctcr and per cent D L H is indicated a t coriccntrations fro111 10 to 100 per cent DLH. Thc curvc of cxl~ansion :iloiig thc thickr~ess also shows lincnrily and passcs through thc origin. At ally coriceritratiori lhcre is a definitc indication that the exl~aiision i~loiig thc thickiicss is illuch more than that along the dianlctcr; it is possiblc t h a t the particles are iilucll morc coii~l)rcssed along the thickness than along tllc diamcter [IS]. Hence, thc cxl~ansion resulting froill hydration a t the con- tact point,s nloiig the thickncss could be cxpected to bc more. Tlle accuracy of il~easurements along the thickncss is lolvcr t h a i ~ aloilg a diameter, so thc forii~er are not rccoin~ncndcd. The plot of per- centage voluil~e cspalision lollows a linear rclation up to 50 per ccnt and again bct\vccn 60 arid 100 pcr cent.

T l ~ c chcil~ical nnalysis of hydrated dolon~itic lime was approxim:~tely calculated by neglecting the small amount, of SiO,, ,11,03, 2nd 1?c2O3. Liine con-

H Y D H h T C D D O L O I ~ I I T I C L I M E . Z

Fig. 6-Autoclave expansion results for cement-lime bars and compacts.

tent determined by alcohol-glycerol extraction gave a value of 57.73 percent for Zprom Ihe COZ c1etcrn~inat,ion (lie CaCOaI colltc~lt was c : ~ l ~ ~ l a I e d to be 6.60 per cent. P'ro111 the loss of weight a t 520 C, the loss due to E120 fro111 was subtracted and the remaining quantity attributed to A'Ig(0H)z. i\'Iagnesiun~ hydroxide content was 1.03 per cent. The total urihydrated h1gO by difference was 34.64 per cent. Assuinillg this composition an autoclave treatnlent would result in an increase of 15.46 per cent in weight of the compact if all ,\IgO wcrc hydrated. Actual deternlinatioil showed that the autoclave treatment increased the weight by 14.8 to 14.9 per cent, indicating that more than 95 per cent MgO was hydrated. This figure would increase if S O z , Fe203, and A1203 wcrc also taken into account in calculating the conlpositiorl of the >LH. The com- position was also indirectly checked by determining the loss of weight in the autoclave-treated specimen when heated to 320 C. The loss was found to be about 2 per cent less than that calculated from the analysis.

Cement-DLH bars containi~ig various alnounts of DLH were autoclaved and the results plotted in Fig. 6. The expansion bears a linear relation to the composition fro111 20 to 50 per cent DLH, but for DLH contents less than 20 per cent the line is less steep. I t is possible that a t lower conce~itratiorls of DLH only a sinall amount of hydrated product is responsible for expansion. I t is also interesting to note that for any particular collcentratioll of DLH the cement-lime bar sho~vs a nlucll higher expansion than the Ca(OH)2-DLI-I compact. Results could not be obtained for cement-DLH bars containing more than 50 per cent DLH. Even those contain- ing 50 per cent DLH sho~vcd signs of weakness and cracking.

The expansion results of compacts with cement- DLH mixtures are also shown ill Fig. 6. I n general, it nlay be observed that cement-DLH compacts show a much higher expansion than the correspond- ing bars. For example, a bar containing 50 per cent DLH shows an expansion of 13.65 per cent, whereas the corresponding compact exhibits an expansion of as much as 36.25 per cent. The cement-DLH com- pacts show an approximately linear relation of ex- pansion with DLH contents fro111 20 per cent. The enormous difference between the expansions of Ca (OH)2-DLH and cement-DLH coinpacts shows that the cement-DLH interface under compacting pres- sure is different from that of Ca(OH),--DLH particles. There is every possibility of an interaction between cement and DLH particles. I t is pertinent to note that pure cement and CEL(OH)~ con~pacts exhibit autoclave expansion values of only 0.12 and 0.15 per cent, respectively. The autoclave expansion values of compacts of cement-&(OH)2, cement-CaCO3, and cement-i\~lg(OH)~ containing 50 per cent cement varied between 0.01 and 0.02 per cent.

To check the efficacy of the compact technique six comn~ercially available limes, three high-calcium and three dolomitic, were tested after being com- pacted a t 20,000 lb and autoclaved at, 295 psi

for 3 hr. The three high-calcium liines showed expansions of 0.15, 0.72, and 0.98 per cent, whereas [,he hydlxtcd dolorllitic limes sllowcd cxpa~isions of 14.5, 17.0, and 18.5 per cent.

Conclusions

1. The use of compacts for testing urlsoundlless of linles has shown certain advantages: (a) This nlethod conlpletely clinlinates the use of cement and mixing water. I n the nornlal bar test cements with different autoclave expansion values give variable expansion values for the same lime. (b) The ex- pansions in colnpacts are Inore than those that can be obtained in bars with similar composition. (c) As many as 28 conlpacts can be autoclslved in a single test, whereas in the standard test only nine bars can be placed in the autoclave. (d) The com- pacts provide reasonable accuracy and reproduci- bility of results. (e) A compact requires as little as 2.5 g of material for a single expansion determina- tion.

Cf)

The total time for making conlpacts is much less than that required for the cement-lime bars because the latter require mixing, consistency testing, and curing.2. Components such as CaC03, Mg(OH),, and Ca(OH),, which are norn~ally present in lime, show negligible expansion when used separately in the form of a conlpact and hence do riot influence test results. The possibility of an interaction between hydrated dolomitic lime and components of cement in the bar tests cannot be ruled out.

3. For an unhydrated RIgO content of 8 per cent, which is the specified limit in certain specifications, the autoclave expansion of the compact would ap- proximately correspond to 2.5 per cent.

4. The compact technique offers promise for the determination of unsoundness in cements.

Acknowledgments

The authors wish to thank Messrs. L. J. O'Byrne and H. F. Slade for their assistance in recording the information.

REFERENCES

[I] Federal Speci$cation SS-L-361 for limes, hydrated for

structural purposes, Feb. 2, 1940. (A proposed amend-

ment.)

[b] Standard specifications for gypsum plastering including

requirements for lathing and furring, American Stand-

ards Association, Add-1, 1950.

[S] L. S. Wells, W. F. Clarke, and E. M. Levin, "Expansive

Characteristics of Hydrated Limes and the Development of an Autoclave Test for Soundness," Journal of Re-

search, National Bureau of Standards, Vol. 41, No. 179,

1948.

[Q] N. Stutterheim, T . L. Webb, and B. Uranovsky, De-

uelopmenls i n Research on the Burning and Hydration of Lime and I t s Use in Building, Building Research Con-

gress, London, 1951, p. 120.

[5j T. L. Webb, "Chemical Aspects of Unsoundness and

Plasticity in Building Limes," South African Industrial

Chemist, Vol. 6, No. 290, 1952.

[6] T. L. Webb and V. Sampson, "Pressure I-Iydration of Dolomitic Lime," South African Industrial Chemist, Val. 11, No. 198, 1957.

[ 7 ] F. C. Welch, "The Hydration of Magnesium Lime and

the Autoclave Test," Symposium on Lime, AS'I'M STP 40, Arn. So?. Tesling i\I:tts., 1939, p. 20.

[a] I<. Alberli, '"rhr Hydralion of 1)olomite I ~ ~ J I I C . L ~ , ' '

Tonzndu.strze-Zezt~~ny, 1-01. 75, No. 129, 1051.

[8] N. V. S. Knibbs and 13. J. Gee, Lime and Limestune,

H . L. Hall Co. Ltd., Toronto, Ont., Canud:~, 1952, p. 113.

[lo] H. R. Staley, Report on Research Work, National Lirne

Association, 1943-1944; 1944-1045.

[ I l l T. Ritchie, "Dimenzioual Changes of Masonry in

Relation to S o u ~ ~ d t ~ e s s of Bricks and Mortars," S,t/m-

posi~cln on Alosonrj! I'estin{/, STP 520, Am. Soc:. Test,ing M:tLs., 1062, p. 93.

[lB] T. R,itchie, "Effect, of Restraining Forces UII the Expau-

sion of Masonry Ivlortars," Materials 12esea1.cl~ h Stand- ards, Vol. 4, No. 15, 1964.

[IS] I-I. R. Gregory, "The Compaction of Powders," Transac-

tions oj the Institute oj Chemical Engineers, Vol. 40. No.

241, 1962.