Publisher’s version / Version de l'éditeur:

Building Research, 1, pp. 10-15, 1964-06-01

READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE.

https://nrc-publications.canada.ca/eng/copyright

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

NRC Publications Archive

Archives des publications du CNRC

This publication could be one of several versions: author’s original, accepted manuscript or the publisher’s version. / La version de cette publication peut être l’une des suivantes : la version prépublication de l’auteur, la version acceptée du manuscrit ou la version de l’éditeur.

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at

Cement-lime mortars

Ritchie, T.; Davison, J. I.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

NRC Publications Record / Notice d'Archives des publications de CNRC:

https://nrc-publications.canada.ca/eng/view/object/?id=f73ce7c3-bf8e-4bfa-bd12-ec5b9e092ca6

https://publications-cnrc.canada.ca/fra/voir/objet/?id=f73ce7c3-bf8e-4bfa-bd12-ec5b9e092ca6

Ser

TH],

N21t2

no. l-83

e . 2

BI,mi

t g { o ' 6

N R C A O 3 53646435

NRnorunl Reseencn

CouNcl-CANADA

D I V I S I O N OF BUILDING RESEARCH

THOMAS RITCHIE and J. MN

DAVISON

National Research Council of Canada

A N A I - Y Z E D

D I V I S I O N O F

T E C H N I C A L P A P E R N O . 1 A 3 O F T H E

B U I L D I N G R E S E A R C H

Reprinted

from BUILDING RESEARCH,

Morch-April 1964

@ Building Reseorch

Institufe, lnc. 1964

Cement-Lime Mortars

OTTAWA

J U N E 1 9 6 4

C E N T S

Eutldlngfleseamh

uln-lpn 1964

t 0

Cement-Lime

Mortars

Mn*t rMpoRTANr pRopERrrrs of masonry, particu-larly strength and weather resistance, are afiected to a considerable degree by the type of mortar used. One type, generally known as cementlime mortar, is used extensively in North America and Europe for all types of unit masonry construction. This paper will review the development of this type of mortar and discuss the influence of certain of its properties on the strength, durability, and weather resistance of unit masonry.

Masonry mortar is prepared by mixing sand, water, and a cementitious material. In cement-lime mortars the cementitious material is a mixture of lime and port-land cement. The proportion of lime to portport-land cement may vary over a wide range in cement-lime mortars but generally it is not less than 2O% oI the volume of the cementitious material in the mortar. The proportion of cementitious material to sand also may vary in ce-ment-lime mortars but generally it lies between l:2la and l:3 by volume of cementitious material to sand. Specification and Code Requirements

The current specification for masonry mortar of the American Society for Testing and Materials (l) de-scribes five masonry mortars, designated as types M, S, N, O, and K. According to this specification a par-ticular mortar may be classified as one of the five types either on the basis of its compressive strength or on the basis of its composition. Cement-lime mortars are in-cluded in the specification, in the range of compositions from relatively high in content of lime (80/o lime: 20ef cement by volume) to relatively low content (20/o lime: 80/o cement). The ranges in proportions of lime to cement for the various types of cement-lime mortars in the specification are given in Table l.

The only other requirement for mortar in the ASTM specification, a requirement applicable to mortars of all t1pes, is that the water retention value shall not be less than 70. The significance of this property of mor-tars will be discussed later.

A useful link between the ASTM specification for mortar and building code requirements for masonry has been established. The morta ':. described in the specification are referred to in the American Standard Building Code Requirements for Masonry (?), and also, with slight modifications, in the National Building Code of Canada (8). These codes set out permissible

com-pressive stresses in unit masonry in relation to the type of mortar being used and the type and strength of unit. and in addition set limitations on the use of various types of mortar in relation to the type and function of the masonry.

Table I

DESIGNATION OF CEMENT.LIME MORTARS ON THE BASIS OF COMPOSITION

Designation of Mortar

Parts by Volume of Aggregate, Measured Portland Hydrated Lime in a Damp, Loose

Cement or Lime Putty Condition

I I I I I Yt over r/+ lo Y.z over r/t to lr/+ over lY+ to 2Y'z over 2r/z to 4

for all mortars not less than 2r/+ nor more than 3 times the sum of the volumes of cement and lime

Sourcer ASTM Speification C-2?0. Influence ol Composition

Important properties of mortars are workability and water retentivity in the plastic state and compressive strength and bond strength in the hardened state. It has been noted that water retentivity and compressive strength values are included in specification require-ments for mortar. Workability, water retentivity, and bond strength are dependent variables.

Workability, a property of mortar difficult to define and measure, may be described as that property which determines the ability of the mortar to flow readily, under the influence of the trowel. into all the cracks and crevices of the surface of a unit, thus assuring the intimate contact between units and mortar which is necessar)r for maximum extent and strength of bond. In the field the mason assesses workability by the feel of the mortar on his trowel and by how easily bricks may be bedded in the mortar.

The ability of the mortar to retain satisfactory worka-bility during the brick-laying operation appears to be related to its water retentivity. a measure of the ability

THOMAS RITCHIE and J. MN

DAVISON,

n"-search Officers, Division of Building Ren"-search, National Ren"-search Council of Cenada, M S N

o

Kof mortar to retain its plasticity when in contact with an absorbent unit, the suction of which tends to draw water from the mortar, thus reducing its plasticity and affecting the bonding of unit to mortar. In a study of moisture losses from mortars to clay bricks it was found that these losses were sufficiently high during initial stages of contact between brick and mortar to reduce appreciably the workability of the mortar and hence its bonding ability, prior to completion of the brick-laying operation (3). The loss of moisture from mortar to an absorbent unit decreased as the water retentivity of the mortar increased.

Workability, water retentivity, and compressive strength of cementlime mortars can be varied over wide ranges by changing the proportions of cement and lime in the mortar.

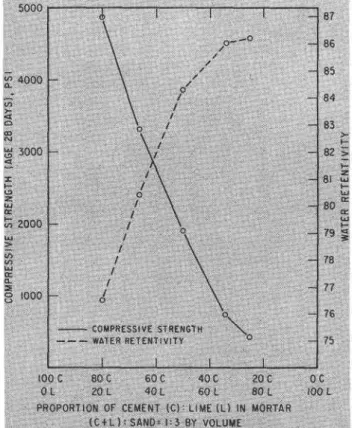

Cement contributes strength to cement-lime mortar but, as noted previously, it also contributes toward poor workability or harshness, low water retentivity, and rapid stifiening. Lime, on the other hand, contributes little strength to cementJime mortars but it is generally a material of high plasticity which adds to the workabil-ity of the mortar and increases the water retentivworkabil-ity. Variations in water retentivity and compressive strength of cement-lime mortars resulting from changes in pro-portions of cement and lime in the mix are illustrated in Figure L Mixtures were prepared of cement, lime, and sand representing mortar types M, S, N, O, and K and the compressive strength after 28 days and the water retentivity were determined. These properties have been plotted in Figure I in relation to the propor-tion of cement and lime in the mortar. In these particu-lar tests the lime was a drv hvdrate. The use of a

Figure 1. Relation betueen noftar composition, cotnpressioe strength, and water retenrioity.

more plastic lime such as might have been obtained from the slaking of a quicklime probably would have resulted in a higher water retention value for the same proportion of lime. In cement-lime mortars it is seen that, as the proportion of lime is increased, the com-pressive strength decreases, but at the same time the water retention value of the mortar is increased.

Figure I illustrates a difficulty that arises in the selec-tion of cement-lime mortars, namely, that the improve-ment of one property of the mortar usually can be ob-tained only at the expense of another. If, for example, it is considered desirable to obtain greater strength in the mortar (to increase its durability and the strength of the masonry), the proportion of cement may be in-creased, but this is usually accompanied by a lowering of water retentivity which may have an adverse efrect on the bonding between unit and mortar and therefore on the weather resistance of the masonry,

The strength and extent of the bond between masonry units and mortar depends on several factors, two of the most important being the rate of water absorption or suction of the unit and the type of mortar used. The relationship between these factors was studied in great detail at the National Bureau of Standards in the United States, and the results of this study were reported in 1934 (9). In this work various types of bricks and mortars were combined, and the tensile bond strength and other properties of the masonry were determined in relation to the properties of the bricks and mortars. The relationship of tensile bond strength, brick suction, and mortar composition is shown in Figure 2, repro-duced from Palmer and Parsons (9). When a particu-lar mortar is used with bricks of various suctions, as the suction increases, the bond strength increases to a maximum value and then decreases. It was noticed in the NBS study that strength of bond did not necessarily correspond to extent of bond and that the latter property was greatly affected by the water retentivity of the mor-tar. Even if the strength of bond of a mortar of high water retentivity was not of a particularly high order, the extent of bond was much more complete than that

Figure 2. Relation betueen brick su.ctian and snength ol bond in tension.

hlSlUhmdr

um-rpn 196l

Bulldlngfleseamlr

uen-lpn 1964T2

of a mortar o{ lower water retentivity. The actual con-tact area between brick and mortar for some combina-tions was less than 25% of. the area of the brick. This contact area increased with increasing water retentivity of the mortar. Relatively high bond strength, therefore, may be achieved with something less than maximum extent of bond, but the latter is essential if rain pene-tration at the brick-mortar interface is to be prevented. Cornpressiae and Flexural Strength

Tests of the strength of thousands of walls and piers, many of them of cement-lime mortars, have been de-scribed in the literature. These studies. which were undertaken to determine the influence of various factors on the strength of the masonry, have been concerned mainly with compressive strength. However, several studies have also been made of the flexural, shear, and impact strength of masonry. These investigations, usually concerned with brick masonry, have shown that many factors govern the strength of masonry. Although certain properties of mortar influence the strength, other factors are also of great importance, such as the strength and other properties of the brick, the conditions of con-struction and curing of the masonry, its age when tested, the size and shape of the sample of masonry, and the conditions of loading.

Two properties of mortar are of particular interest in relation to the strength of masonry. The first is the compressive strength of the mortar, which would be expected to have an important influence when masonry is loaded in compression. The second property of mor-tar that is especially important in connection with the flexural strength of masonry is the ability of the mortar to establish a strong and complete bond with the ma-sonry unit.

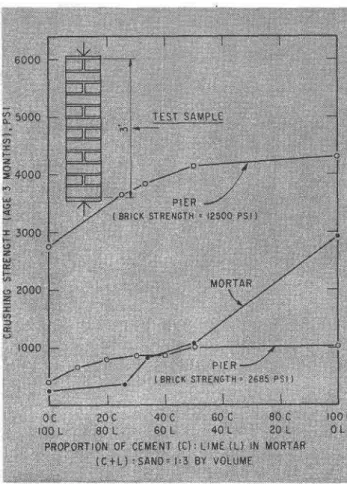

The compressive strength of masonry mortar, which is usually measured by crushing small cubes of the mortar, depends on its composition, age, curing condi-tions, and other factors, and may range as shown in Figure 2 from a value of a few hundred pounds per square inch for a high-lime mortar to a value of over 4000 psi for a high-cement mortar. Variation in the strength of mortar which results from change in the cement-lime ratio, however, does not result in propor-tional variation in the compressive strength of brick-work. This is illustrated by Figure 3, which was derived from the results of one of many series of tests made at the Building Research Station of Great Britain (3). In these tests piers 9 in. square and 3 ft high were con-structed of mortars which covered a range of propor, tions from straight lime mortar to straight gement mortar. Two bricks were used, one of which was rela-tively low in compressive strength (2685 psi) and an-other which was relatively high in strength (12,500 psi). The compressive strength of the piers made of these bricks, and also the compressive strength of the mortar used in the piers, has been plotted in relation to the proportion of cement and lime in the mortar.

It is seen that variation in the strength of the mortar did not proportionally change the strength of the

ma-sonry. With the brick of low strength, the compressive strength of the piers increased slightly as the proportion o{ cemeht in the mortar was increased up to equal proportions of cement and lime; further substitution of cement for lime, however, which greatly increased the strength of the mortar, resulted in no significant in-crease in the strength of the piers. For the piers built of the high-strength brick, there was a more marked influence of the strength of the mortar on the strength of the pier but, as before, an increase in the proportion of cement beyond equal proportions of cement and lime did not produce significant increase in the strength of the brickwork.

As noted previously, when unit masonry is subjected to lateral loading, an important property of mortar which influences the transverse strength of the masonry is the adhesion or bond of the mortar to the unit. It has been pointed out that "In transverse tests of walls with the usual horizontal courses, initial cracking almost invariably results from a breakdown of the brick-mortar bond rather than from tensile failure of the mortar or bricks," (3) or as expressed in another way, "The source of transverse strength in a masonry assem-blage is the bond at the interface between the brick and the mortar." (6)

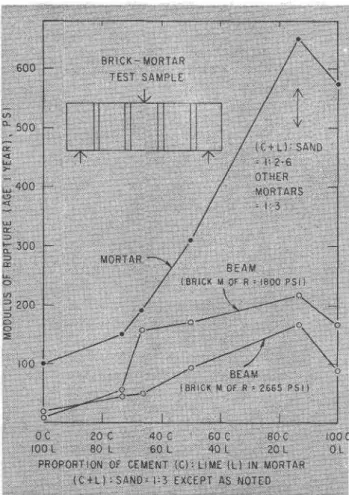

The flexural strength of cementlime mortars, like compressive strength, varies over a wide range of values depending on the proportions of cement and lime in the mix. In measurements of the transverse strength of mortars (9), the mortars were used to construct

brick-Figure 3, Mortar compositioit anil strength in relation to strength ol brickuork.

mortar assemblages consisting of five bricks laid one the water retentivity and extent of bond, thereby facili-

Suildlngfleseamlr

over the other, which were subsequently tested as abeam for transverse strength. The results of one series of the tests are shown in Figure 4. The flexural strength (modulus of rupture) of mortar alone and of brick beams made of two difierent bricks is plotted in rela-tion to the proporrela-tion of cement and lime in the mortar. It is clearly seen that the flexural strength of the brick-mortar beam is much less than that of the brick-mortar alone, indicating the weakening effect of the brick-mortar interface.

Durability and Vearher Resistance

The two major causes of decay of masonry materials are frost and salt crystallization. No damage from either cause can occur without water. The durability of mortar in a masonry wall will therefore depend not only on the materials used but on factors that influence the moisture content of the wall, i.e., the severity of its exposure to the weather and its ability to resist rain penetration. Rain penetration of masonry occurs mainly at the interface between the masonry unit and the mortar. Durability of mortar, generally the least dur-able part of masonry construction, can therefore be enhanced by creating conditions conducive to the maxi-mum extent of bond between units and mortar.

When considering the durability of cement-lime mor-tars, two conflicting factors are apparent. Increasing the cement content results in higher strength and greater resistance to deterioration of the mortar but reduces

Figure 4. Transoerse strength oJ mortm and, brickwork.

tating rain penetration and ultimate deterioration of the masonry. There is abundant evidence, provided by numerous very old masonry buildings along the Atlantic Coast of North America, an area of severe weather ex-posure, that the weakest mortar of all, lime and sand, is amply durable if the construction of the masonry was carried out in summer weather and the mortar was not {rozen at an early age, and if the subsequent condi-tions of exposure were favorable and the masonry walls well protected. In the modern design of buildings, how-ever, and their all-season construction, it has been found desirable, particularly in winter work, to employ relatively rich cement-lime mortars to provide sufficient early strength of the mortar to resist damage from frost and to provide durability in the mortar itself when exposed to severe weathering conditions later. This again may mean that, in increasing the cement content of the mortar, the desirable properties of a high degree of workability and water retentivity are to some extent sacrificed to better another property-durability of the mortar.

Mortar Composition and Cracking

The composition of mortar used in masonry construc-tion has an important influence on the occurrence of cracking in the masonry. In concrete brick masonry, for example, the use of a cement-lime mortar high in cement content is considerdbly more likely to result in cracking of the masonry than would be the case if a high-lime mortar was used (2). The reason for this is that concrete bricks are subject to drying shrinkage after they are placed in the wall. A high-lime mortar is usually able to accommodate the movement of the bricks as they dry, but generally this is not possible when a more rigid and strong high-cement mortar is used. The result is vertical cracks in the brickwork. The same situation applies to sand-lime bricks. If con-crete arrd sand-iime bricks are unusually low in drying shrinkage, it may be possible to lay them in a cement-lime mortar of equal parts of cement and cement-lime (l:l:5 or l:l:6) without the development of cracking taking place, but it is considered wise to make use of a mix h i g h e r i n l i m e ( I : 2 : 8 o r l : 2 : 9 o f c e m e n t : l i m e : s a n d ) to give greater protection against cracking (2).

Clay bricks do not shrink on drying to the same extent as concrete and sand-lime bricks; clay brick masonry, therefore, is not affected by drying shrinkage of the bricks. Clay bricks, however, undergo long-term expansion due to hydration of certain materials present in them, and recent studies of this property of clay bricks (5) have shown that such expansion may cause severe cracking of walls. In order to minimize the dam. age that might result from moisture expansion of bricks it has been suggested that lime-rich mortars be used, presumably on the basis that such mortars can accom-modate the expansion of the bricks more readily than stronger, more rigid, cement-rich mortars.

Experience with tall masonry chimneys has also dem-onstrated the important influence which mortar exerts

u.ln.epn 1964

IIHhGt$l

urn-irPn 1964

l4

on the cracking of masonry. Severe cracking of these chimneys has occurred when strong (high-cement) mor-tar has been used, such masonry being too rigid to stand the normal stresses and those imposed by tempera-ture difrerences. High-lime mortars, however, such as l:2:9 cement:lime:sand, appear to provide sufficient resiliency in the brickwork of tall chimneys to greatly reduce the danger of cracking.

Conclusions

Observations of the performance of masonry of cement-lime mortars in actual structures, as well as laboratory studies of the properties of masonry in rela-tion to the composirela-tion of the mortar, have been made by several organizations interested in various types of masonry construction. These have led to recommenda-tions for the use of certain mortars with particular kinds of units under various conditions of use, a summary of which is presented in Table 2. Detailed discussion of the basis for most of the recommendations may be found in the literature sources cited in the table.

Cement-lime mortars are extensively used in North America and Europe for the construction of all types of brick, block, and stone masonry. Certain deficiencies in the traditional mortar of unit masonry eenstmstiqn-lime-sand mortar-led to the introduction of cement-sand mortars which, in turn, because of difficulties in their use, were replaced by cement-lime mortars. Cement-lime mortar therefore iepresents a compromise, an at-tempt to take advantage of the desirable properties of the two types of mortar-lime-sand and cement-sand.

The properties of cement-lime mortars vary over a wide range, depending mainly on the proportions of cement and lime in the mix. Illustrations have been given of the efiects of changing the proportions of eement and lime on the strength and working qualities of the mortar, which in turn have an influence on the properties of the masonry. Unfortunately, if it is de-sired to better a certain pfoperty of mortar by changing the proportions of cement and lime, this usually can only be done at the expense of another property. The selection of a cement-lime mortar for particular condi-tions of use therefore involves a compromise.

Table 2

RECOMMENDED CEMENT.LIME MORTARS Type of Masonry Unit Ratio of Cement to Lime in Mortarr Equivalent ASTM Type Source of

Recommendation2 Remarks on Us€

Clay brick or Clay tile l : Y + lzt/z to lY* I:Vt to 2\6 lz2 l : l

M For masonry below grade snd in contact with earth.

For general use in exposed masonry above grade.

For general interior use.

External walls, moderate exposure, spring and summer construction.

External walls, severe exposure conditions, all season construction.

Internal walls and partitions, spring and summer construction.

Internal walls and partitions, autumn and winter construction.

External walls, moderate exposure, spring and summer construction.

I 2

o

o

( l : 2 o ' { t , s( r : 2

o'l r 'z

l : 2o

K No

o

2 2 2 2 2l : l External walls, severe erposure conditions, all geason construction.

Internd walls, spring and summer construc-tion.

Internal walls, autumn and winter construc-tion.

For ordinary senice.

For heavy loading, s€vere frost action. Concrete brick, concrete block, and sand-lime brick

o

K No

N M Ms

( l : 2ot{r,s

( l : lo'l r 'z

2 2 2 2 3 3 4 4 l:l to lYr l:0 to Yn r:Yt l:Y+ lo \6 pq16ps lin6st6ne or sandstone Dens€ trimestone or sandstone K l : 3 l : ll Rrtio of cmentitioue mat€rial (ment + lime) to su{ genenry lie betwen ltLla tnd l:3 by volume. 2Surca:

l. Stnctunl Glav Prcducts Instltut€. Technical Notea e Brbh awl TiIc Conctructim, No, t. Wshtngrton, D.C.: tlre Institule, 1961. 2. Building naercn Strtion of GEt Britain. DIoiar le Brickuule, BInk Cnstreti.oe ond Munw. Bulletin No. 8. London:

tbe Station, 1969.

8. Portlnd Cmeat Amictbt. Connte Mmtt Eonilbnk tG Archicects, Enginaq Brildcn. Chiecos the Associltion, 1060. ,f, CoDcrete fmnry Amiatlon of Cdifornia Cmtcta Mwta Dqign Dlonul 1966.

Relerences

l . A m e r i c a n S o c i e t y f o r T e s t i n g a n d M a t e r i a l s . T e n t a t i a e Specifications lor Mortar lor Unit Masonry. ASTM Desig-n a t i o Desig-n C 2 7 0 - 6 1 T . P h i l a d e l p h i a : t h e S o c i e t y , 1 9 6 1 . 2 . A n d r e w s , H . M o r t a r tor Brickuork, Block Construction

and. Masonry. Building Research Station of Great Britain, B u l l e t i n N o . 8 . L o n d o n : t h e S t a t i o n , 1 9 5 9 .

3. Davey, N. and Thomas, F. G. The Structural Uses ol B r i c k w o r k . l n s t i t u t i o n o f C i v i l E n g i n e e r s o f C r e a t B r i t a i n , S t r u c t u r a l a n d B u i l d i n g P a p e r N o . 2 4 . L o n d o n : t h e I n s t i -t u -t i o n , 1 9 5 0 .

4. Davison, J. L Loss of moisture lrom lresh mortars to bricks. ASTM Materiols Research and Standards, Vol. l. No. 5. p. 385-388, May 1961.

5. Hosking, J. S., and Hueber, H. Y. Dimensional Changes Due to Moisture in Bricks and Brickwork ASTM Special Technical Publication No. 320. Philadelphia: the Society,

t962.

6. Monk, C. B. Transterse Tasts ol Masonry Volls. ASTM Special Technical Publication No. 166. Philadelphia: the Society, 1954.

National Bureau of Standards. American Standard' Build'' ing Code Requirements ol Masonry. NBS Miscellaneous P u b l i c a t i o n 2 l l . W a s h i n g t o n , D . C . : U . S . G o v e r n m e n t P r i n t -ing Office, 1954.

National Research Council of Canada, Associate Committee on the National Building Code. National Building Coile ol Canada. NRC No. 5800. Ottawa: the Council, 1960. Palmer, L. A. and Parsons, D. A. A study ol the properties of'mortars and bricks and their relation to bond. tournal ol Research, National Bureau ol Standarils ol the U.S. Department ol Commerce, Vol. 12, pp. ffi9-644. l

Mr. Ritchie, who is with the Inorganic Materials Section ol the Diaision ol Building Research at Ottawo, Canad.a, is a member ol the American Society tor Testing and Materials Technical Comtnittee on Masonry Materials and the Canadian Stanilards Association. He holils the B.A. Sc. in Engineering lrom the Uniaersity ol Toronto.

Mr. Danison is at lhe Atlantic Regional Station ol the Dhtision ol Buililing Research, Halilax, Canaila. He receiaeiJ both the B.Sc. and. M.Sc. degrees in Chemistry lrom ML Allison anber' sity and, is a member ol the Chemical Insti.tute ol Canada.

7 .