Publisher’s version / Version de l'éditeur:

Technical Translation (National Research Council of Canada), 1960

READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE. https://nrc-publications.canada.ca/eng/copyright

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

NRC Publications Archive

Archives des publications du CNRC

For the publisher’s version, please access the DOI link below./ Pour consulter la version de l’éditeur, utilisez le lien DOI ci-dessous.

https://doi.org/10.4224/20386655

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at

Compacted Snow Road. III. Field Tests and Practical Applications Leijonhufvud, A. C:Son

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site

LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

NRC Publications Record / Notice d'Archives des publications de CNRC: https://nrc-publications.canada.ca/eng/view/object/?id=76683657-6f10-4b06-814c-72278f6d6f08 https://publications-cnrc.canada.ca/fra/voir/objet/?id=76683657-6f10-4b06-814c-72278f6d6f08

Although snow roads are of economic interest in Canada, particularly to its pulp and paper industry, there is as yet very little published information on their construction and performance which is generally available in English to engineers.

As one contribution toward solving this problem the National Research Council, through its Associate Committee on Soil and Snow Mechanics, is cooperating with Professor Seheult of the University of New

Brunswick, on a project to evaluate current practice in the construction and use of snow roads in Canada and other countries of the world. One of the first steps has been to translate into English the more pertinent publications available on the subject.

Sweden, through experiment and field practice has gained much valuable experience on the construc-tion of snow roads. This translation, published with the permission of the author, is the fourth of a

series of reports to be translated which describe this Swedish experience. The Division of Building Research records its appreciation of the translation by Mr. H.A.G. Nathan.

Ottawa,

September 1960

R.F. Legget, Director

Title:

Author: Reference:

NATIONAL RESEARCH COUNCIL OF CANADA Technlcal Translation 909

The compacted snow road. III. Field tests and

practical applications

(Den snopackade vagen. III. Faltforsok och

praktiskt tillamping) A. C:son Leijonhufvud

Svenska sォッァウカセイ、ウヲッイ・ョゥョァ・ョウ Tidskrift, (4): 337-394, 1955. (SDA* Meddelande no. 56)

Translator: H.A.G. Nathan, Translations Section, N.R.C. Library

SDA

=

Forestry Society and Royal Domain Adm1nistration, Research SectionSnow compaction has been studied by the SDA since 1950, partly by field tests on a minor scale in or near Lycksele and partly by logging operations on a larger scale, using wheeled tractors and horses for haulage on compacted snow roads in Vasterbotten and the southern parts of Norrbotten in Northern Sweden.

The results have previously been published in this periodical -Eriksson, R. The compacted Snow Road. I. Properties of Snow, 1954

(NRC TT-849); Ager, B.H:son. The Compacted Snow Road. II.

cャゥセ。エゥ」 Considerations, 1955 (NRC TT-816).**

Since the final report on the experiments to date is now

being published (later studies of horse-drawn timber transports on compacted snow roads will perhaps still be dealt with) the SOA wishes to express its thanks to forestry officer Ture Rylander

(chief forester with Nordmalings aョァウセァウ AB) and to forestry officer P.O. Lofstrand (administrator with Mo och Oomsjo AB) and their coworkers for their valuable assistance in the study of large-scale logging operations on compacted snow roads.

Valuable ideas for both the planning of the experiments and the study of the meteorological part of the investigations were received through the courtesy of Professor Olof Tamm at the Kungl. Skogshogskolan (Royal Forestry College), Professor H. Kohler of

Uppsala University, L. Raab, B. Rodhe, B. Samuelson and E. Schmacke, all of Sweden's Meteorological and Hydrological Institute. The

•

**

Published as no. 56 in the series "Meddelanden ヲイセ Foreningen Skogsarbetens och Kungl. Oomanstyrelsens Arbetsstudieavdeluing

(SOA)".

-Part I published as no. 52 and -Part II as no. 54 in the SOA Meddelande series which like no. 56 may be obtained from SOA, Flemminggatan 37, Stockholm K.

-4-SDA wishes to express its thanks to all these as well.

The field tests in 1954-55 were conducted by B. H:son Ager of the SDA.

I. Introduction

No doubt, the idea of compacting snow in order to obtain a better traffic foundation is extremely old. Roads were probably compacted in a primitive way long before they were ploughed with simple wooden ploughs. Even today this original method is applied for occasional hauling in districts with particularly severe snow conditions. The snow is thus merely compressed, i.e., one simply "drives on top of it" in the mountain districts of Northern Sweden when hauling hay from the outlying fields or wood from the forest. To plough a road across the moors of the field or over extensive

swamps for such brief and relatively light haulage would require a greater effort than necessary. Moreover, a road ploughed in such a way would be swept by drifting snow even before it was ready. Under these circumstances, therefore, even the simplest of compac-tion methods constitutes a racompac-tional solucompac-tion.

However, such a road is not economic when large-scale logging operations in a forest region are involved. Roads made by merely compressing the snow always tend to become soft and slushy. They are so narrow, moreover, that trucks overturn easily, unless great care is taken to drive them in the old ruts. This may prove very difficult after a snowfall.

When the interest in a more rational hauling technique became more widespread it was only natural that this type of road, which is too primitive for ordinary driving, should be studied in greater detail. Propaganda was made for ploughed roads having low roadways, which would harden rapidly as a result of frost and would thus

provide a better foundation for the driving of large trucks. The first snowploughs were homemade, clumsy pointed ploughs of wood. They certainly moved some of the snow off the road but also left a great deal on 'it. Immediately after the ploughing the

road had a typical V-shaped section. Most of the snow was ploughed away in the middle of the road, where the horse walked, but a

great deal of snow was left in the ruts.

The introduction of the modern well-designed road plough of steel plate during the 1930's meant a revolution in road mainten-ance. With the use of these ploughs roads could be opened in relatively deep snow and then gradually widened and smoothed.

With the aid of water tanks and track graders the frozen rut road, i.e., the road best qualified of all the temporary roads, was then obtained. For a number of years this type of road was quite common

in Norrbotten and Vasterbotten wherever large-scale haulage of timber by horse-drawn vehicles was required. In Norrbotten,

particularly the Domanverket and the former Munksunde AB devoted a great deal of work to this type of road. Under identical grading conditions this road permits the haulage of greater loads than any other type of rutted road. However, its construction and main-tenance is quite costly. This road must be well graded and cut out to a considerable width. Particularly in districts with a great deal of snow the maintenance costs are considerable. If the road is to function as intended, not only must it be ploughed after each snowfall but it must also be watered and ruts must be cut.

In

winters with heavy snowfalls this will involve considerable expense.Although an ordinary ploughed road does not require as costly a maintenance as one with frozen ruts, it is quite evident that ploughed roads are less suitable in districts where the snow is normally quite deep and in swampy areas where the wind causes the cold snow to drift. The deeply ploughed road acts as a dike,

accumulating the drifting snow and thus making it difficult to drive over. In order to protect the road to some extent large swamps

should be by-passed as far as possible and the road should be kept preferably within a forest or within narrow swamps. An attempt should be made to protect roads across swamps against drifting snow by building them along dOW;Dward edges where the forest provides protection at least on one side, or by providing some kind of

-6-temporary protection.

It is obvious that the by-passing of swamps in order to reduce the maintenance costs will considerably increase the cost of con-struction, since for working on wooded ground the latter is higher than over swampy ground, where, in favourable cases, special con-structive measures may be dispensed with altogether. By-passing swamps usually increases the road length considerably. This in turn increases the cost of transportation. The installation of snow fences may prove very costly in the end and is not always effective either.

Therefore, it is obvious that in the very extensive regions in the interior of Norrland and the highest parts of Dalarna and

Varmland where snow conditions are normally troublesome and the country is boggy to a high degree, the need for other road main-tenance methods was urgent.

One such method was the result of the introduction of the crawler tractor into forest regions.

As early as the nineteen エキ・セエゥ・ウ the first tests were made with them. However, it was not until the nineteen thirties that they were successfully used in practical operation while their great snow-clearing capacity was exploited at the same time.

Where trucks had been unable to keep the rOads open, this was now achieved by the relatively light tractors. At present they are being used increasingly for reopening roads for both motor traffic and horse-drawn traffic after heavy snowfalls.

However, from the snow-clearing capacity of the crawler

tractor it became evident also that this tractor would move through deep snow with great ease and would compact it at the same time.

Thus the old discredited country road had suddenly come into its own again and had become an efficient road, i.e., the compacted snow road, suitable for haulage even on a large scale.

The first experiment, or at least one of the ftrst experiments, with this road was made during the winter 1938-39 at Nordmalings

kョァウセァウ AB a few (Swedish) miles from the coast in the parish of

hauled by the above company over compacted snow roads within Vasterbotten's Lappmark each year, except for a few years during

the war. The experiments of the first few years have definitely shown that all the timber can be hauled under very difficult snow conditions by means of the methods which have been applied at

<:> 0

Nordmalings Angsags AB. The company considers the method foolproof and every year it employs a medium heavy crawler tractor for hauling large quantities of timber on the so-called Stottingfjallet, a

region of extremely unfavourable snow conditions. Other companies in Norrland and Dalarna, e.g. Domenverket have also used this type of road during the past few years.

In 1950, in cooperation with Nordmalin3s セョァウセァウ AB, the SDA experimented with the hauling of timber by horse-drawn vehicles over compacted snow roads. Since this experiment proved to be successful, it was repeated by the Lycksele administration of the Mo and Domsjo Company, where during the past few years a great deal of timber was hauled by horse-drawn vehicles over compacted snow roads. In cooperation with the Domanverket in the Pite& region, the SDA carried out a comparative experiment during the winter 1952-53 with crawler tractors on compacted snow roads and wheeled tractors on ploughed roads. A similar experiment was finally carried out during the winter 1954-55 in association with the Lycksele

administration of the Mo and Domsho AB.

In Aktuell Information No. 30 (Leijonhufvud,

A.

C:son, 1950*) a brief account is given of tractor driving on compacted snow roads. Since additional knowledge about the road in actual operation with different vehicles has been obtained and since a number of experi-ments with different compaction methods were carried out from1950 to 1955 at the SDA Experimental Station at Lycksele, it was thought appropriate to report on the whole question in greater detail •

-8-A summary of both the physical ーィ・ョッュセョセ associated with the different methods of treating snow covers and th@ experiments to measure the hardness of snow by various means haR been published (Eriksson, R., 1954). Finally, on the basis of the experiments in 1955, an account was given of the effect of climatic factors on snow compaction (Ager, B. H:son, 1955). In the present report the results obtained from field tests and their application in practice are discussed. However, this is preceded by a discussion of the

snow compaction terminology and a report on experience in snow compaction in other countries.

II. Terminology ComEaqt) on , Banking and TamRing

The roads described in the present paper are intended as temporary roads for hauling timber, i.e., the moving of timber between places where it is stored by lumbermen at motor roads, water courses, railway stations, etc. However, the haulage of timber, if it takes place by truck (in the exceptional case by wheeled tractor) may also be continued directly as a long-distance transport.

Compaction. Although in Swedish the term "packning"

(i.e., compacting) is not entirely staisfactory (an appreciable increase in the hardness of a snow mass may also be obtained by

mixing the snow (Eriksson, R., 1954», it has been generally adopted and should therefore be retained, all the more so since the

corresponding term snow compaction is employed in the English language literature. The term snow compaction implies that snow is treated with various implements until it forms a better founda-tion for the haulage and storage of timber, etc. In practice this frequently means that an existing snow layer, which may be of

considerable thickness, is still further compressed in a different way, so that its top surface will be lower than the surrounding snow cover immediately after each such procedure.

1. Bottom-compacted roads (for motor and wheeled tractors) 2. Surface-compacted roads (for crawler tractor and

horse-drawn traffic).

As the name suggests bottom-compacted roads are -compacted

directly after the first snowfall and are then sUbjected to further treatment after each subsequent snowfall. By this means they

usually become so hard throughout that they stand up to loads pulled by trucks and wheeled tractors.

Surface-compacted roads are not compacted until the snow depth is considerable, frequently not before the snow has attained a

depth of 40 cm. The roads are then processed intensely by dragging or rolling after a snowfall. Particularly during heavy traffic the road becomes very hard on the surface but it is much softer in the deeper layers. This type of road costs considerably less to lay out, to keep open and to maintain. It stands up to lOads drawn by crawler tractor and horse.

During cold winters with moderate snow depth and during sustain-ed traffic the hardness of the surface may sometimes extend to a

considerable depth. It may also be converted into a bottom-compacted road by completely ripping it up from the bottom and then recompact-ing it.

However, the fact that owing to small snow depth, heavy traffio and climatic influences surface-compacted roads can attain the same hardness throughout as bottom-compacted roads,or that they can be converted into bottom-compacted roads by direct ュ・。ウオイ・セ should not affect the principle on which this classification is based, namely

the step to open up the road.

For practical reasons, hauling roads, which are short as a rule and which constitute the remotest branches of a road system, are of course constructed in a simpler way than the surface-compacted roads, assuming that they are subjected to horse-drawn and crawler tractor-drawn traffic. Samset (1951) designated them as "bottom-compacted roads" because of the fact that the compacted layer consists of a bottom under each tractor rut. For practical reasons it may be unnecessary to drag or roll these roads, which perhaps can be used

-10-only for a few days. However, fundamentally they do not differ from the surface-compacted roads but are merely a practical modi-fication of them. Banking and compacting are two different methods.

b。ョォゥョセ is frequently applied when a ploughed founaation road

trav-erses a lake or sometimes a swamp. The purpose of banking is to

keep the road open in layers of snow drifts at level with or higher than the surrounding snow cover so that the drifting snow can blow off the road. A method of banking a road across a lake is described below.

The snow cover on the lake usually depresses the ice. A rut is then ploughed across the lake and care is taken that the snow mixed with water is pushed to one side. On the way back a

second rut is, ploughed next to this ploughed bank with the intention of pushing the snow towards it. The bank thus increases in width and height. After this mixture of wet and dry snow freezes over, the surface is smoothed down with a drag. Finally the road is finished with brushwood and is watered. This bank is at least at the same level as the surrounding snow cover right from the begin-ning. Banking is costly and is normally used only for building a short section of a road. Banking should now be replaced by snow compaction, which renders equally good service. If the traversing of a lake by a heavy crawler tractor causes concern, which usually

is justified·, compaction may be carried out with a "weasel" or similar vehicle or with a horse-drawn vehicle.

Tamping implies that snow which has fallen on unfrozen ground is trampled down to a relatively thin snow cover towards the

underlying wet ground surface. Formerly this was done by foot but it is now done with the aid of a weasel, crawler tractor or similar vehicle. The result usually is snow permeated with water which may even melt, if the ground temperature is sufficiently high. However, this step is usually taken only after the first frost so that the

• SDA report Litt V 30, Isbildning och 1sars barighet (Ice forma-tion and bearing capacity of ice). This report may be obtained from the SDA.

snow permeated with water freezes rapidly to ice. The ground

surface, which had previously been insulsted by the layer of loose snow radiates heat which is dr9.wn off through the ice cover. As a result, the ground temperature decreases, first on the surface, but as the cold continues the temperature also decreases deeper in the ground so that the ground freezes.

On roads over solid ground no tamping is required. In swampy regions tamping may have to be resorted to when roads extend over long stretches of swamp. A tamped surface never makes a roadway except perhaps for a short tine, but it may form the foundation for a road ploughed after continuous snowfalls.

Since snow quite often falls on frozen ground, tamping is a

very 」ッュセッョ method where a ploughed road is to be used. As a

matter of fact, a compacted snow road can be obtained by trampling the snow down by foot. This method may naturally by used as well as many other methods in order to compact even a relatively thick snow cover, but this is of no practical importance in the woods, where tamping is applied for a different purpose, as stated above.

It may be mentioned in passing that during the winter in Lappmark and in many other areas with a great deal of snow, compacted snow' roads are produced by the trampling method in most farm yards

between the main building and the little house with the heart over the door - wherever these small outbuildings are still in use. Owing to the daily (and perhaps nightly) walks a compacted snow road is created just by trampling. The road lies over the surface of the snow and care must be taken not to step off it. The snow may have a depth of almost one metre, but on the road itself it may be as hard and firm as a highway. However, without wanting to question the importance of such a road, it must be emphasized that

it is wholly and entirely a "local" phenomenon. III. Experience in Other Countries

During the past few years more modern types of compacted snow roads have been used in Finland and Norway.

-12-over compacted snow roads during the winter of 1951. Ferguson "track wheel" tractors were used for compaction and haulage. The front wheels of these tractors had been replaced by tractor skids of the Forest Research Department. Tractor drags of this department were also used for the maintenance of the roads. The experiments showed that by this means the large number of track-wheel tractors could be better utilized during the winter.

In Finland, Metsateho (1953) carried out experiments with compacted snow roads for horse-drawn traffic in 1952 and 1953. Track-wheel tractors were used chiefly for keeping the roads open and drags and rollers· chiefly for maintenance.

In Canada compacted snow roads are used for driving to some extent in regions where the snow is normally of considerable depth. Relatively simple types of these roads have also been used for the transport of essential goods, personnel, etc., to remote mines in the interior of the country. They are kept open by crawler tractors and are used for crawler tractors, horses, track-wheel tractors and motor cars, depending on the quality of the road. These roads are maintained with the aid of medium heavy drags and large rollers, frequently made of steel plate.

In recent years military circles in the U.S.A. and canada have shown

an

interest in the compaction and snow-covered runways on remote air fields with limited staff in regions where snow cond1-t10ns are part1cularly diff1cult (Taylor, A., SIPRE Report No. 13, 1953**). Drags, harrows, rollers and some sort of combination machine are used to process the snow here. Compact10n starts 1mmed1ately after the f1rst snowfall and 1s then repeated after each heavy snowfall. The runways thus obtained are sufficiently hard to be used by l1ght aeroplanes, depending of course on the1ntensity of the treatment. The snow 1s usually compacted alongs1de the permanent runways. Th1s has the advantage that the latter are

•

••

SDA report L1tt S 18:2, Snopackad vag f8r hasttransport (Compacted snow roads .for haulage by horse-drawn vehicles). Th1s report may be obtained from the SDA •

not damaged by the tractor tracks or harrows, and in spring the traffic may be shifted to the permanent runways more rapidly, since the latter become almost entirely bare just about the time when the compacted runways are breaking up.

The advantage of compacting snow instead of ploughing it away is that there are no snow walls to be cleared away. As a matter of fact, an airfield must be cleared within a few hours after a snowfall and this can only be achieved by snow compaction, since it requires two steps to plough the snow away and this takes too much time.

In view of the ever-increasing strategic importance of the northern Arctic regions it is understandable that extensive snow

research is being carried out at present in the U.S.A. and Canada as well as in Russia and the snow-compaction experiments were based on this research.

According to Putkisto (1953), compacted snOw roads are exten-sively used in Russia. However, very little interest in them has been expressed during the past few years in the leading Russian forestry periodical Lesnaia Promyshlennost '• Ordinary ice roads

and, a few years ago at least, ice roads for the single-track sledges which were quite common in Russia at that time have apparently

attracted great interest. However, large sections of the Russian forest regions have a climate which should be very suitable for compacted snow roads.

In Switzerland this type of road is used occasionally but, as far as known, not for timber transports. Centuries ago the Swiss peasants had devised the following method of crossing the Alps to obtain their supply of Italian Wines:

First a single horse broke a trail. Then mOre horses followed this pathway, and finally came a horse pulling an empty sleigh with loose chains dragging beneath its bunks. A few days later the

enitre train followed along with the empty casks from the previous year's supply. By the time they reached their objective and returned with their sleighs heavily loaded with full casks of wine, their

-14.-which would have been impossible at any other time of the year was thus accomplished with ease.

Finally, it should be added that very extensive snow research is carried out in Switzerland, with particular reference to the danger of avalanches (Eriksson, R., 1954).

IV. Measures to Increase the b・。イゥョセ。ー。」ゥエク ッヲセキ

It is a know fact that snow hardens with time. If left undis-turbed, new snow compresses, shrinks and "settles" both at low

temperatures and at the relatively high temperatures experienced during thaws. This is dependent upon the physical processes taking place 'in a snow cover (Eriksson, R., 1954). However, this natural compaction in a snow cover usually is unimportant. Different

climatic influences may have a stronger effect. For example, strong winds may impart considerable hardness to a snow cover and periods of cold weather alternating with snow may increase the hardness of snow by forming a crust which may acquire a considerable thickness by late キゥョエ・セN

However, if the snow is to be used as a traffic foundation or as a storage place for timber, steps must be taken to increase the snow's bearing capacity within a short time.

All these measures aim at strengthening the bonds between the snow particles or between complexes of snow crystals within which the bonds had already been strengthened before. This may be

accomplished chiefly in the following three ways:

(1) By expelling the air from the snow, whereby the snow particles are brought into contact with one another to a greater extent than before and the conditions for strengthening the bonds between them are increased.

(2) By breaking up the snow particles. Many points of contact are provided by this means as well, thus increasing the possibility of bonding between the snow particles.

(3) By mixing snow layers of different temperatures and snow consistencies, primarily at low air temperatures.

cッューイ・ウbャセョ of the snow from the surface is brought about by both expulsion of the air from the snow within the compressed

zone and crushing the snow particles to some extent here. However, all this has a very superficial effect even at fiarly high pressures.

If a snow surface is subjected to a pressure of 10 kg/cm2

, this

pressure decreases to 0.5 kg at a depth of 30 cm (SIPRE 13).

In a snow cover of great thickness the differences in tempera-ture may be considerable. Not only is the temperature in the

layers closest to the ground usually high throughout the winter but it also is relatively constant (Ager, B. H:son, 1955). It is

far from unusual that snow falls on unfrozen ground, which thus becomes well insulated against the low air temperatures. Even though the ground may freeze on the surface, the temperature in

the lower layers will be relatively high. On the surface conditions are different. The surface is intensely affected by the air

temperature. The snow surface, moreover, reflects up to 90 percent of the sensible heat it admits during the day while at the same time (night and day) it loses heat by long-wave radiation

(Bergeron, T., 1955).

Since the upper layers of a snow cover insulate its lower layers from the air, tpe mixing of the surface layers and bottom layers of a fairly deep snow cover is equivalent to mixing snow of different temperatures. This temperature difference is particularly marked at low air temperatures. However, as distinguished from a superficial compression of snow, a mixing of snow layers works through the entire mass of snow or to the point that mixing can be brought about.

Mixing by itself probably does not result in a considerable increase in hardness. This increase is brought about by physical processes, which normally take place within the snow cover,i.e., primarily by sublimation. However, mixing enhances the effect of these processes and prevents, or at any rate retards, the formation of depth hoar in the lower layers and thus contributes to the

-16-In the experiments in Lycksele which were carried out to increase the bearing capacity of a snow cover by means of various methods (Eriksson, R., 1954) it was found that mixing and screening the snow increased its hardness. Thus, measurements 24 hours after screening showed a hardness of approximately 1.5 kg/cm2 and those 24 hours after mixing showed a hardness of slightly more than

1 kg/cm2• In neither of these cases was the snow subjected to any pressure.

On the other hand, the air had been expelled from the snow mass to some extent and the snow crystals had been crushed. This was probably due more to the screening than to the mixing.

As mentioned above, a snow cover exposed to superificial compression may attain considerable hardness, but the latter decreases rapidly with depth and the lower layers are virtually unchanged. In these layers, processes which have an unfavourable effect on the hardness and which are related to the aging of snow are then initiated. For example, the material undergoes transforma-tion resulting in the formatransforma-tion of depth hoar in the deeper layers, which are not affected by the compaction. It may be expected that compaction retards this transformation, at any rate as long as the compaction is effective (Eriksson, R., 1954). This depth hoar obviously forms a very poor foundation for a road. However,

experience to date has definitely shown that timber can be hauled by crawler tractors on roads, Where hardness in the deeper layers, was insignificant at any rate at the beginning, but it was also found that timber can be hauled by Wheeled vehicles on such roads in periods of severe cold as long as the temperature does not increase above approximately -lOoe. At higher temperatures roads which are hard not only on the surface but also in depth are

required.

v.

Snow ・ッュセ」エゥッョ Experiments in LyckseleSince experiments had shown that by simple means a depth

effect could be obtained in a snow cover which prevents or at least slows down and retards the formation of depth hoar, a number of

experiments were carried out in 1955 in Lycksele with three principal objectives:

(1) Firstly, to investigate whether by means of an economical method it would be possible to construct a compacted snow road which could be used for hauling timber by wheeled vehicles under normal climatic conditions in Central and Northern Norrland.

The heavy increase in the number of wheeled tractors during recent years made such an objective a matter of urgency. Of course, it was also hoped that by a simultaneous study of the meteorological conditions (cf. below) some indication might be obtained as to

whether a possibly useful method might be applied under other climatic conditions.

(2) Secondly, to investigate whether the agricultural imple-ments generally used by small farmers could be utilized for the construction or improvement of compacted snow roads. If necessary, attempts were also to be made to design simple, inexpensive imple-ments for this purpose, bearing in mind roads for horse-drawn traffic

in particular. By using a tractor in conjunction with an implement it was also intended to investigate whether the time required by tractors for compaction could thus be reduced.

That a compacted snow road for horse-drawn traffic can be

constructed with the aid of tractors and be maintained by drags and rollers pUlled by horses had been shown by earlier full-scale

experiments. The need for improving the methods of constructing and maintaining snow roads for horse-drawn traffic is dictated by the need for keeping horses competitive with tractors on compacted snow roads as well.

(3) Thirdly, to obtain more information concerning the depend-ence of freezing and bearing capacity on meteorological conditions. Finally, it was also hoped that as a result of these experiments greater knowledge of the physical properties of snow compacted in various ways could be obtained. Ager previously (1955) gave an account of the importance of the meteorological conditions. At the

same time he gave a description of measuring instruments, apparatus and snow-classification methods as well as methods of measuring the specific pressure (hardness).

-18-Only the hardness measurements are discussed here. A brief description of the density determination is also given.

A so-called Proctor needle was used for measuring the hardness of specific pressure (Eriksson, R., 1954; Ager, B. H:son, 1955). Previous calibration of this instrument showed that the bearing strength of a plate did not increase at the same rate as the plate size but that for ordinary compacted snow roads the maximum pressure per unit surface at which fracture occurs decreases with increasing load area; i.e., a large plate produces a lower pressure (expressed in kg/cm2

) than a smaller plate on one and the same foundation.

Since the experimental foundation for this assumption was considered inadequate, a new and more extensive calibration was carried out, which gave a slightly different result.

The variation is relatively great. There is no tendency towards displacement with respect to two adjacent plates at varying plate size. Therefore, an average ratio of 1.20 was used here (the exact value obtained is 1.202

±

0.099).Plate 32 16 8 4 2 1 0.5 0.25

1955 Ratio 1.00 QセRP 1.44 1.73 2.07 2.48 (2098) (3.58)

1951 Ratio 1.00 1.14 1.21 1.43 1.78 2.21 2.85

Note: The values in parentheses have been extrapolated.

In order to eliminate the influence of plate size on the mea-sured hardness values, all the meamea-sured values were reduced to the level of plate 32 with the aid of the 1955 series.

Example: As a mean of 25 measurements with plate 2, 20.2 kg is obtained, i.e., 10.1 kg/cm2 and, reduced to plate 32, 4.88 kg/cm2

• As a rule, 25 measurements were made in each case. An analysis of the variation in the values thus obtained shows that on the

average the mean error was approximately 5 percent of the mean value for the 25 measurements. It was also found that the mean error

increased with decreasing plate size.

It is impossible to say whether the Proctor needle is the best means of determining the hardness of snow. The Proctor needle is easy to handle and seems to provide acceptable results for this type of measurement. Another method of measurement which was tested was

a great deal more time consuming without giving reliable results. However, in the study of the test data it is reasonable to attach greater importance to the ratios than to the absolute values for the measured hardness.

The density of the surface layers of the road is determined in the following way. The cylindrical test piece (1 in Fig. 1). which had a capacity of 1 litre, was pressed down into the surface layer of the road until the inner edge of the test piece extended a few centimetres below the roadway. With the aid of the sheets (2) the cylinder was cut clean at both ends and emptied into the

drum (3). As a rule two or three samples were taken and placed in the same drum (3) .• They were then weighed on a scale (4). which is graduated in five milligrams. Lack of time did not permit a large number of tests. However. as a rule. four tests should be taken.

The grain size was determined with the aid of a magnifying glass (5) and a board (6) fitted with a black velvet cloth as well as a sliding millimetre scale.

VI. Experiments with ComRacted Snow Roads Intended lor Hauling Timber by Horse-Drawn vセィゥ」ャ・ウ

In SIPRE 13 an account is given of the way in which snow is compacted in North America so that it can stand up to heavy wheeled traffic or serve as runways for aeroplanes. Compaction must be carried out right after the first snowfall or even while the snow is falling if the snowfall is of long duration. Therefore. the snow depth should not be allowed to increase beyond 10 cm before compaction begins. Heavy steel rollers and drags pulled by medium heavy tractors are used for compaction. The treatment is repeated after each successive snowfall. If for some reason this intensive

treatment cannot be carried out and if the compacted snow layer does not stand up to the traffic. the entire roadway must be ripped up from the bottom and subjected to repeated harrowing, rolling and dragging. Special machines are sometimes used to rip up the

-20-The traffic on these snow roads, which are built up from the ground, i.e., bottom-compacted snow roads; increases the hardness. The latter also increases because of the movement of water vapour

from the small partlcles to the large ones (a process which takes place also in a compacted snow layer, although at a slower rate

than in an undisturbed layer). This gives rise to increased bonding but also is the beginning of a gradual formation of a granular type, called depth hoar, in the lower layers. Finally, as a result of this change due to aging a hard layer may be on top of an ever-growing layer of loose depth hoar. In heavy traffic it may occur that the hard surface cannot stand up to it without the supporting layer breaking apart. In this case, too, the road must be ripped up from the bottom and treated in the above way (SIPRE 13).

It is obvious that roads which should be rolled and dragged before the snow attains a depth of 10 em, must be well graded. However, such treatment involves considerable expense in other respects as well.

Therefore, an investigation of whether a somewhat simplified method might not be sufficient for the ordinary wheeled tractor motor transports under the climatic conditions existing in Northern and Central Norrland and in other places in Sweden which are similar

in this respect was considered urgent. 1. Test Roads

In the vicinity of the SDA experimental station Lycksele three test roads were set up and were intended to be used as follows.

Test イッ。セ was to be compacted after the first snOWfall and then maintained by compacting and processing after each snowfall, using the Canadian methods but simpler implements. This road was compacted with a Cletrac OC 3.

セ・ウエ road.2 was not to be compacted until the snow had attained a depth of 40 or 50 cm and was then to be maintained as thoroughly as test road 1. Test road 2 was intended for determining whether

roads compacted at a greater snow depth would stand up to as heavy traffic as the bottom-compacted snow roads.

Open ground exposed towards the west Pine forest, approximately 60 years old Open ground, reforestation area

Pine forest, approximately 60 years old Young pine forest

Fairly old mixed woods

Test road 3 was constructed when the experiment with test road 2 failed because of intense thawing (cf. below). The former was thus merely replaced by the latter. Test road 2 differed from test road 3 in that the former had an ice-like bottom layer and that a light weasel-type tractor was used for its compaction, whereas the latter had no such ice layer and a Cletrac OC 3 was used for compaction.

It had been intended to reinforce test road 2 (a surface-compacted road) by ripping it up and recompacting it. However,

for the above reason this experiment was transferred to test road 3.

セウエ road 1 Length: 800 m Section:

o

+ 00 - I + 50I

+ 50 -V

+ 30 V + 30 - V + 60 V + 60 - VI + 75 VI + 75 - VII + 25 VII + 25 - VIII + 00 UpgradesSection Mean upgrade Max. upgrade

...

%

m%

mo

+ 00 - 0 + 75 7.0 75 11.0 7II + 44 - III + 48 7.5 1M 11.5 13

The first compaction was carried out in November 1954 at a

snow depth of approximately 15 em, whereupon the road was recompacted three times during November and December, using a Cletrac OC 3 with no implements. In each case the tractor made three trips, compacting the entire width of the road.* However, this was only 2.5 m, which

*

By trip is meant driving to and fro during the compaction or maintenance of the road. During the haUlage of timber there was no driving without load and therefore the term trip then refers to driving with a load.

-22-1s too narrow for an actual road. Nevertheless thls small road w1dth cannot have affected the result.

The effect of thls type of treatment was 1ncreased conslder-ably by a perlod of lntense thaw followed by severe cold. Th1s also had an adverse effect on the experlment.

At the end of January one trlp was made on the road wlth a Cletrac and a loaded wooden roller. On February 1st drlvlng wlth a wheeled tractor began. The rear wheel of the Ferguson tractor, whlch was used for th1s purpose, had been f1tted wlth chalns. The tractor pulled a haullng devlce carrylng a load of 160 cu ft. On even ground the road held but the tractor was unable to cllmb grades. It got stuck and dug ltself lnto the road.

The rear wheels of the tractor were then fltted wlth Troeng tracks lnstaad of chalns. However, the tracks skldded agalnst the foundation and the wheels. When one of the two tract10n flanges on each track was lengthened and the tracks were fltted with tract10n studs on the tlre s1de the tracks operated perfectly.

Whlle these changes were belng made, 25 - 35 cm of snow fell on the road. On February 18th at a temperature of -26°C the road Was rolled to and fro wlth a Ferguson tractor fltted wlth lmproved Troeng tracks. The road was agaln rolled to and fro the followlng day ata temperature of -17°C and was dragged to and fro on

February 23rd at a temperature of -13°C.

Between February 19th and March 1st dlfferent haullng devlces were tested. From March 1st up to and lncludlng April 6th the road was subjected to an average of 3.5 trlps per day. Durlng March the mean value for the max1mum dally temperatures was -45°C and the mean values for the mlnlmum dally temperatures was -18.7°C. From

Aprl1 1st to Apr11 6th the correspondlng values were - 0.8°C and -18.1oC.

The hlghest temperatures were measured on March 15th, l.e., a maxlmum of +3°C and a mlnlmum of -6°C. The surface layer of the road broke down under a welght represented by 130 cu ft of tlmber whereupon the road was lmmedlately dragged. The lowest temperature, 1.e., -28°C, was measured' on March 22nd. The road Was dragged

Open ground exposed towards the west Pine forest, approximately 60 years old Open, level ground

Pine forest, approximately 60 years old six times in all during the driving period, one trip each time.

The device on which the timber was hauled had an average area of 9,500 cm2

• At a load of 90 cu ft the specific pressure was

0.2 kg/cm2 and at a load of 200 cu ft it was 0.42 kg/cm2 assuming

that the weight of the hauling device was 200 kg and that of the timber 19 kg/cu ft (cf. Section VI, 4, "Calculation of tractional resistance in the test roads").

The changes in the size of the load during the driving period are evident from Fig. 2.

Throughout the time of timber haulage the surface hardness in test road 1 exceeded the maximum value obtained by measurements With the Proctor needle, i.e., 45 kg/cm2 for a 0.25 disc.

Test road 2 Length: 525 m Section:

o

+ 00 - II + 10 II + 10 - III + 10 I I I + 10 - I I I + 50 III + 50 - V + 25 UpgradesSection Mean upgrade Max. upgrade

,

%

m%

mo

+ 5 - 0 + 66 8.0 61 14.0 5II + 15 - II + 45 4.0 30 5.5 20

III + 75 - IV + 25 4.0 50 5.0 25

The road was compacted on December 14th, 1954, at a snow depth of 45 em with a Cletrac OC 3. As mentioned above, there was a

severe thaw in December followed by a period of intense eold. This made the road very hard and less suitable for the type of test road that had been intended here. Therefore, it was decided to repeat the experiment, that is to say, to wait until the snow cover on the road had once more attained a thickness of 40 cm and then to

MRセM

affect the result. However, there was no alternative, since it was impossible to construct an entirely new test road within reason able distance from the other experiments which had been planned and prepared.

On February 9th, when the snow had attained a depth of 40 or 50 cm, i.e., that of the old roadway, the road was finally recom-pacted. Depth hoar had already begun to form in the bottom layer

of loose snow. The temperature was -9°C on that day. This time

the compaction was carried out with the Doman weasel, which had been designed by Chief Forestry Officer I. Jonsson (Fig. 13). This tractor has almost the same specific track pressure as the standard weasel, just over 0.1 kg/cm 2• The compaction was carried out in

two trips.

On February 18th (at a temperature of -26°C) the road was rolled to and fro with a wheeled Ferguson tractor fitted with improved

Troeng tracks. Compared with test road 1, which was rolled simul-taneously, road 2 was weaker and the tractor got stuck and dug itself into the road, where the upgrade was 12 percent. Other parts of the road, also proved to be weak and only a stretch of 200 metres could be rolled effectively. The next day a load of 90 cu ft pulled by

the above tractor was driven back and forth twice over this stretch. On February 23rd (temperature -17°C) the entire road was

dragged and the following day, at approximately the same temperature, one trip with a load was made over the road. Where, at an upgrade of 12 percent, the road made a relatively abrupt curve, the tractor wheels dug themselves in and, as a result, the tractor got stuck. The additional traction required by the tractor to pull the load through the difficult curve evidently put too much strain on the road. After this the tractor detoured in order to avoid the curve.

On February 25th (temperature _7°C) the new stretch was compacted in two trips with the Doman weasel and on February 28th

(temperature _6°C) the entire road was dragged in one trip. This was repeated on March 4th (temperature _2°C). On that day a load of 90 cu ft was driven over the road once.

On March 5th driving was continued and three trips were made. However, an annoying downslip made the haulage difficult on the

section of road which had been recompacted on February 25th (temperature _7°C). The road was then repaired and dragged on March 8th when a load of 90 cu ft of timber was driven back and forth six times.

During the time from March 8th to March 15th a load was driven the same number of trips as that on test road 1. The size of the load was also the same (cf. Fig. 3). On March 15th (maximum

temperature +3°C, minimum temperature -6°C) all the roads broke

down. Driving took place in the afternoon. The roads became slushy as the result of エィセ high temperature and were then dragged in one

trip.

The breakdown was not due to the high temperature alone but to some extent also to the warm weather during the 24 hours directly preceding March 15th, especially during the preceding night.

From March 16th up to and including April 6th driving and dragging coincided with that on test road 1. It should also be noted that the tractor kept sliding down and getting stuck on

March 30th (temperature -4°C). Probably this was due to the rela-tively high temperature accompanied by strong winds (maximum 6.2 m/ second) and low relative humidity of the air during the preceding 24 hours. This mild weather partially dissolved the surface layer of the road. Of course, the considerable increase in traction

required to overcome the upgrade and the fact that the bottom layers under the road, which had been surface-compacted with the Doman

weasel were relatively loose, were contributing factors. Test Road 3

Sections: Open ground exposed towards the west

Upgrades: Maximum upgrade 1.9%, 10 m

On January 26th at a temperature of _6°C セョ、 a snOw depth of approximately 40 cm this road was compacted with a Cletrac OC 3 in

1

22 trips. The following day at 5 a.m. when the air temperature was high (_4°C) the road was rolled to and fro once.

-26-During the period from January 27th to February 18th, from 25 to 35 em of snow fell on the road. After the Ferguson tractor had been fitted with improved tイッセョァ tracks the セ。、 was rolled in one trip on February 18th. Subsequently, up to and including

March 25th this road was treated in the same way as test road 1 (cf. Test Road 1 and Fig. 2).

On March 26th, at -3°C, 40 metres of the road were ripped up with an ordinary disc harrow pulled by a Ferguson tractor. Loading produced a working depth of approximately 25 em. The road was

recompacted with the Ferguson tractor + roller + so-called mOdified drag (cf. below) and was then left undisturbed till March 28th.

During the time ヲセュ March 28th to April 6th the road was treated and driven on in the same way as test road 1 (cf. Fig. 2). 2. Comparison of the Hardness of Ripped-Up and Not Ripped-Up Roads

By ripping up a portion of a road it was intended to investigate whether improved bearing capacity could be imparted to a surface-compacted road by ripping it up then rolling and dragging it as opposed to the" conventional method of treatment in Sweden.

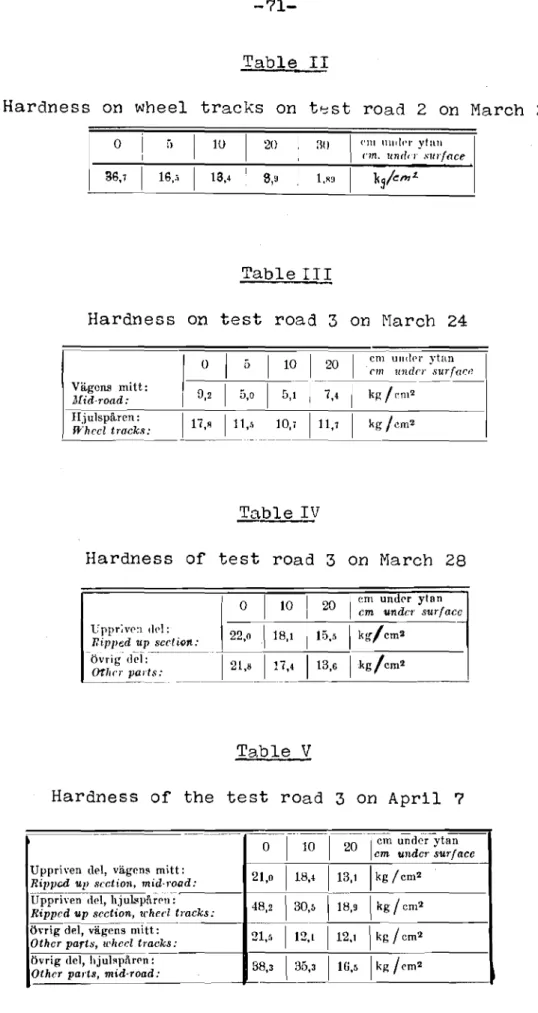

On February 19th (the day after the rolling) the following

hardnesses were measured in the road surface of test road 3: in the middle of the road: 4.43 kg/cm2 in the ruts made by the wheels:

6.65 kg/cm2•

On March 24th the hardness was measured on and in the roadway. On March 28th, two days after the road had been ripped up and compacted, the hardness of the road portion thus treated but not yet sUbjected to traffic was compared with the portion of the road which had been subjected only to normal traffic and normal dragging.

On April 7th the hardness was measured at the same points after the road had been subjected to traffic in the way evident from

Fig. 2.

The greatest caution must be exercised in comparing these

values, particularly with respect to the hardness below the surface. A road which is subjected to traffic during a period with snowfalls obtains a more or less hard layer. For example, a very hard,

1ce-like layer can form on the surface of a road, which is subjected to traffic for a lengthy period during which no snow falls,

particularly if - as was the case here - the temperature is high during the day and very low during the night. When Gnow finally falls the old surface will lie in a snow layer which either did not yet attain the same hardness as the result of traffic or was not exposed to the same extent to the noonday sun alternating with

the cold of the night. If the hardness measurements concern a hard layer in one case and a looser one in the other, the comparison may be misleading.

It should also be pointed out that the "middle of the road" and the "ruts" at·say 10 em depth need not lie on the same previous

road surface. This shows that a comparison of the hardness in the middle of the road with that in the wheel ruts can also be

mis-leading.

Probably, both the high value of 35.3 kg/cm2 for the hardness

in the wheel rut at a depth of 10 em in the "other part" and the relatively low.value of 12.1 kg/cm2 for the hardness in the middle

of the road are due to such an inequality in the points of measurement.

The surface measurements should provide a safer means of comparison. However, the surface hardness is so great here that it approaches the limit of the Proctor needle's applicability.

Therefore, the values scatter considerably, for which reason caution should also be exercised when making the comparison here.

Even if the recorded appreciable increase in the surface

hardness of the wheel rut and the increase of 2.4 kg at a depth of 20 em were reliable, the relatively costly ripping-up procedure with subsequent rolling and dragging could scarcely be justified, especially if the hardness value for the untreated portion of the road may be considered fully satisfactory for wheeled traffic when the upgrade is not too steep. This step may possibly be justified where an additional increase in the hardness is required locally as for example, on a steep grade, where the road for one reason or another is キ・セォ・イ than elsewhere or where the turning of a vehicle

-28-has made a hole.

The fact that the increase in hardness is greater throughout in the wheel ruts than in the centre of the road may indicate that the increase in hardness was caused, to some extent, by the traffic on the road between the time when it was ripped up on March 26th and the measurement on April 7th.

A comparison of the road hardnesses on March 24th and April 7th is interesting. The temperature conditions on these days and in the 24-hour period before each of these days were very much alike.

Even if, as indicated above, the values for the hardness at a depth of 10 em are not completely reliable - the increase of

230 percent is perhaps too great and that of 137 percent too small -the comparison shows that -the hardness increased most substantially during the two weeks in question when the road was not treated at all but was subjected to fairly heavy traffic. Thus, the increase was due only to the traffic and to climatic influences.

In order to bhr-ow more light on the importance of the ripping-up process for the strength of the road, four roads were compacted on March lOth between 6.45 and 7.15 a.m. with the Cletrac and

then rolled. At different times of the day the roads were then ripped up, using a disc harrow in each case, and then recompacted with the Cletrac and roller (U series). Simultaneously, in each

case a road was compacted with the Cletrac, harrow and roller in undisturbed snow (T series) in order to throw some light on the

importance of ripping-up by making a direct comparison with ordinary compaction.

For each test road the densities constitute a mean value from only two tests.

Although the trend is clear, the experiment has provided no reliable differences, nor has the ripping-up in this experiment produced any marked increase in hardness.

3a Profiles in the Test Roads

OWing to the aging of snow, depth hoar (or granular snow) is from time to time encountered in the deeper layers of both untreated

snow and snow that has been compacted from the surface. Eriksson (1954) mentions the formation of depth hoar at the bottom of

compacted snow roads in the Lycksela district and he describes how it originates. SIPRE 13 also deals with this phenomenon.

The presence of depth hoar obviously may seriously affect the strength of a road. However, Eriksson assumes that "by continuous compaction of a road and by processes of settlement in a road this formation of depth hoar may be avoided".

In order to determine whether depth hoar had formed in the test roads, and if so, to what extent, a number of profiles were cut in these roads.

Only in test·road 2 could depth hoar b3 noticed. However, in each case most of it was present already during compaction. This had been carried out with the Doman weasel which, like other crawler vehicles with low specific pressure on the foundation, does not

stir up the snow cover from the bottom.

In test road 3, too, depth hoar was found in the bottom layer, but the quantity was so small that it was unimportant for the bear-ing capacity of the road.

In test road 1 a certain increase in the grain size in the bottom layers was observed but no real depth hoar had formed. 4. Determination of the Tractional Resistance on the Test Roads

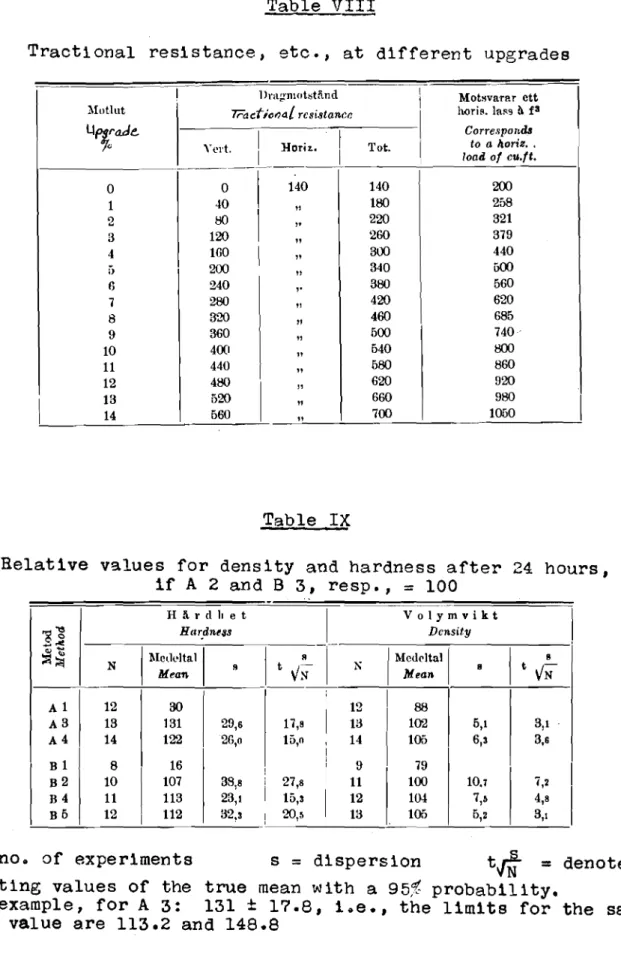

The directions of the test roads were chosen so as to include certain upgrades. The steepnesses of these were approximately the maximum that would be encountered in practice. Since the required traction increases in proportion to the increase in the angle of inclination (given equal coefficient of friction), it was thus possible to determine the stresses to which the road could be subjected without having to change the load size.

The following calculation can be made on the basis of the experiments.

The maximum load was 20 cu ft of timber. At a weight of

19 kg/eu ft the weight of ,this load is 3800 kg. The weight of the hauling device was approximately 200 kg and the total weight of

-30-load + hauling device thus approXimately 4000 kg.

An average tractional resistance of 3.5% may normally be expected on a compacted snow road over level ground·. Hence for the maximum load the tractional resistance at 00 upgrade (level

ground) should have been 140 kg.

On upgrades the tractional resistance increases with the grade percent per total weight.

The total tractional resistance and the corresponding load size on level ground were calculated for different upgrades. Since the roads stood up to a load of 200 cu ft on grades exceeding

10%, this corresponds to a tractional resistance of more than

540 kg or a load of at least 800 cu ft on level ground. A tractional resistance of 540 kg corresponds to a load of approximately 370 cu ft + hauling device on a maximum grade of 4%. Upgrades greater than this can usually be avoided.

VII. Comparison b・セキ・・ョ Di(ferent Methods of cッセー。」エゥッョ and Processing and Tests with Different Simple Implements For this purpose about ten 15 - 20 m long test roads were

compacted on a field, each representing a certain method. Compaction was carried about three times per week and new test roads were made during each compaction. In these roads the bearing capacity and temperature were then measured 10 and 20 cm below the roadway,

respectively, during 48 hours at certain intervals. During the last measurement the road profile was examined and the density in the surface layer of the road was measured.

The preliminary experimental program included a comparison between different implements (for processing the road) pulled by

crawler tractor. The following implements were used: spring

harrow, disc harrow, roller and drag. The experiments were divided into two groups •

•

The tractional resistance varies with the temperature and the hardness of the road.A. Compaction and processing in one working phase

1. Crawler tractor

2. Crawler tractor + roller

3. Crawler tractor + spring harrow + roller 4. Crawler tractor + disc harrow + roller

B. Compaction and processing in two working phases with an interval between them

1. Crawler tractor

2. Crawler tractor + drag 3. Crawler tractor + roller

4. Crawler tractor + spring harrow + roller 5. Crawler tractor + disc harrow + roller

By compaction is usually meant only the work of the tractor and by processing that of the implement. Compaction and processing in Group A was usually carried out simultaneously with the treatment in Group B in order to assure direct comparison. With respect to the interval in Group B the following principle was applied. When the air temperature was lower than -10°C compaction in Group B was carried out with the tractor alone (over the entire width of the

road), usually early in the morning. This was followed by processing with the implement approximately three hours later. When the air temperature was higher than -10°C compaction in Group B usually

took place in the evening and processing was carried out the morning after.

During the experiment forestry officers Ager and Malmberg of the SDA designed a combination implement, for which the term

"modified drag" was used. The implement was compared with the other implements in a series of tests.

In addition to the above test with different implements the

compaction work performed by different tractors was compared directly. For this purpose, a crawler tractor, a Cletrac OC 3, a track-wheel tractor and a tractor of the weasel type, i.e., the so-called

-32-1. Comparison Between Different Implements

Compaction was carried out with the Cletrac OC 3 and the

measurements were made 2, 5, 10, 24 and 48 hours after the processing. From the beginning, a road that had not been processed at all (Al and 81) was thought to be most suitable as a basic alternative in comparing the different methods. However, the surface becomes very uneven and the hardness values are very low and show great variations. Processing with the roller alone (A2, 33) was thought to be suitable as a basic alternative. It was also found that the hardness values obtained from measurement 24 hours after processing were representative for a comparison of the results from the

different methods セヲ processing.

If the hardness values obtained 24 hours after processing and the densities for the alternatives A2 and 33 are equated to 100 within each experimental series, the following mean relative values for the hardness and density are obtained for the other alternatives. Relative values of each series were used for the hardness and the

density instead of the absolute values for the following reaSons. Because of breakdown of implements, etc., no suitable alternative was available in some of the experimental series. Since the

absolute values, chiefly those concerning the hardness, vary considerably from series to series, the weather being one of the reasons, the absolute values cannot be used for direct comparison of the different methods.

Table IX provides the following information:

The untreated road has a surface hardness of only 30 percent (Al) and 16 percent (Bl) of that of the rolled road. The respective values for the density are 88 percent (Al) and 79 percent (Bl). The untreated road hardens nevertheless considerably as the depth

increases.

The drag (82) seems to provide the same surface hardness and density as the roller. It is true, the surface haroness is 7 percent higher for the drag, but this difference is not significant.

As mentioned above, エセ・ purpose of these experiments was to study the possibilities of using either conventional agricultural

implements in order to obtain a better road or implements which the drivers of horse-drawn vehicles or tractors can easily handle

themselves.

The type of drag and roller used belong to the latter class. They can certainly be made much more efficient if more money is

invested in them. This applies to the roller in particular. The

iron-plate rollers used in North America for the compaction of roads and particularly of airfields are much larger and heavier

(SIPRE 13).

For the alternative spring harrow + roller a significant difference is obtained only for the surface hardness in A4 - the increase in hardneSS, compared with A2, thus is 22 percent (±15.0) and for the density in both A4 and B4 (5 percent ±3.6 and 5 percent ±3.l, respectively).

There is no significant difference between the two harrows. For all that, the disc harrow seems to be preferable since it

(1) is sturdier

(2) does not tear up grass, shrubs, etc., in the roadway, which the spring harrow does when the snow depth is low. Because of this the road is more liable to disintegrate because of thermal radiation.

On the average, harrowing + rolling thus seems to produce an approximately 20 percent greater surface hardness and a 4 percent higher density than rolling alone. However, it seems that harrowing

is more important in late winter than in early winter. It was found that during January harrowing produced an increase in hardness of

o -

10 percent but in March it produced one of 20 - 30 percent. Probably mixing is more important during late winter, when the snow becomes considerably more coarse-grained than in early winter.However, the variation in the material is so great that this is merely a trend.

On March 9th two roads were harrowed and rolled after they had been compacted with a Cletrac OC 3 in undistrubed snow. A Lapland sleigh was pulled by h9.nd several times over one road. The sleigh had a flat bottom and carried a load of 70 kg corresponding to a pressure of approximately 0.02 kg/cm2• After 24 hours the following

-34-relative values for the surface hardness were measured:

Crawler tractor + harrow + roller 100

Crawler tractor + harrow + roller + sleigh 154

The result of this experiment gave rise to designing the mOdified drag mentioned above.

The results obtained from the experiments carried out with this mOdified drag from March 14th to March 19th, 1955, are listed in Table X. The modifed drag carried a load of 800 kg, which applied a pressure of 0.03 - 0.05 kg/cm2 on the snow foundation.

Comparison of the results obtained from the treatment with crawler tractor + roller on the one ィセョ、 and with those Obtained from the treatment with crawler tractor + roller + modified drag on the other showed that treatment by means of the latter combination on the average increased the hardness by 82 percent and the density by 11 percent.

In six experiments the work of roller + modified drag was

compared with that of roller alone. In two of the cases the harrow WaS used in addition to both alternatives. On the average the

combination roller + modified drag increased the hardness by 95.0

±

20.0 percent and the density by 9.0 ± 2.3 percent. The limits for the same mean values lie at 95.0±

46.8 percent and 9.0±

5.4per-cent, respectively. This is significant. The comparison between

crawler tractor + drag and crawler tractor + roller + modified drag represents only one experiment and therefore permits no general statement.

Since the experiments were carried out relatively late in the winter the consistency of the snow was particularly unfavourable for the type of roller used. It sank deeply into the loose snow, for which reason the compaction of the surface was relatively poor, whereas the compacting action of the modified drag chiefly affects the surface layer. Comparative hardness measurements at

different depths in roads which had been processed with the roller or roller + modified drag produced the results shown in Table XI.

The fact that the modified drag trails and thus crushes and grinds the snow particles in the surface layer may be one of the

reasons for its superiority.

Both, the good results obtained in Lycksele during the

winter 1952-53 with a manhole cover dragging behind a tractor and the experiments with drags having inclined and rounded blades (the latter were found to be superior) also point to the superiority of the modified drag (cf. SIPRE 13).

2. Importance of the Tractor's Work in the Snow and the Interval Between Compaction and Processing

During the first A series (cf. page 31) the snow depth was so small that the tractor could pull the implement in the undisturbed snow cover. Then, beginning with the sixth series, the following method was used on account of the snow depth (60 em). The road was compacted over its entire width with a crawler tractor alone, whereupon the implements were driven over the test road one by one. There was a short interval between treatments with the two imple-ments, never exceeding one hour.

In the first five A series the road was thus produced by the work of the implements alone while the work done by the tractor probably was on a minor scale under these conditions. In the subsequent A series, as in all the B series, the road was first compacted by the tractor over its entire width.

For the series A and B, in which compaction was carried out

ウエGセエ。ョ・ッオウャケL

the relation : for the alternative with the sameimplements is calculated as follows:

B 3:1

=

208 B 4:1=

130,セ セセゥ

=

226, i.e., a mean of 188 (.S:l)A 2:1 ' A 3:1 .A:l

for these directly comparable series. For all the comparable series (of which B:3 must be excluded according to the above) the following is obtained:

Series A:B: 1 2 4 ] .§

.1

....§..2-

1.Q11

II

II

1 2 5 6 7 8 10 11 12 13 14 15

In differs and the differ. -36-B'4 the first three comparisons (up to and including A;5) B from A with respect to both the tractor's work in the snow interval. In the other comparisons only the intervals

The mean values for these groups are:

Series Mean s t

..J'"N

s B:1-

B:4 187.3 3.6 12.5 A:l A:5 B:5-

B:13 125.7 5.2 11.2 A:6 A:15 ...,,_.._

...-

-._----

.-Hence with the use of the same implements the interval brought about an increase in hardness by 25.7 percent and the compaction by the tractor + the use of an interval produced an increase in

hardness of 87.3 percent compared with the treatment by the imple-ments alone. If the tractor compacts the road over its entire width and then pulls the lmplement over the test road, the increase ln hardness thus is greater by approximately 60 percent than in the case where the tractor only pulls the lmplements.

This was confirmed by a later experiment, when a road was

compacted by a wheeled Ferguson tractor fitted with "Troeng" tracks on the rear wheels.

The compaction, which Was carried out at a snow depth of 60 em, was very dlfflcult. Immedlately after the compactlon the road was

processed wlth a roller and a modifled drag pulled by a wheeled

Ferguson tractor. While processing, the tractor sllpped to the slde of the road already compacted by the wheeled tractor and thus pulled the lmplement in undlsturbed snow. Measurements on the next day gave the followlng results: ln the road compacted and subsequently processed the hardness was 11.6 kg/cm2 and ln the portlon whlch had

been processed only but not compacted lt was 4.8 kg/cm2 •

3. A Brlef Outllne of the ,Experlence Gained from Processlng of QQmpacted Snow rセ。、セ wlth Different Implements

In flfteen years of practical experlence in tractor driving and flve years of experlence ln drlvlng horse-drawn vehlcles on compacted