READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE. https://nrc-publications.canada.ca/eng/copyright

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

NRC Publications Archive

Archives des publications du CNRC

This publication could be one of several versions: author’s original, accepted manuscript or the publisher’s version. / La version de cette publication peut être l’une des suivantes : la version prépublication de l’auteur, la version acceptée du manuscrit ou la version de l’éditeur.

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at

The Thermal and air leakage performance of residential walls

Brown, W. C.; Schwartz, N. V.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site

LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

NRC Publications Record / Notice d'Archives des publications de CNRC:

https://nrc-publications.canada.ca/eng/view/object/?id=3bff4f11-a7f4-4990-a3bf-3266dbb04192 https://publications-cnrc.canada.ca/fra/voir/objet/?id=3bff4f11-a7f4-4990-a3bf-3266dbb04192S e r

TH1

-~ 2 1 d

National Research

Conseil natlonal

no. 1527

19

Councll Canada

de recherches Canada

c . 2

BLDG

Institute for

lnstitut de

Research in

recherche en

-

Construction

construction

The Thermal and Air Leakage

Performance of Residential Walls

by W.C. Brown and N.V. Schwartz

Presented at

The Society of the Plastics Industry of Canada's

7th Annual Canadian Rigid Polyurethane Foam Conference

Huntsville, Ontario. September 1987

14p.

(IRC Paper No. 1527)

Reprinted with permission

Price $3.00

NRCC 28861

Dans le cadre tic son p g mtinn de iecherchs

snr

la pcrf~rmance de I'enwloppe du Mrimtnt eten

collahmnon avec le Rognmmc de bourses de ncherchcs SIPICNRC,I'hstitut de rechctche en consauction a nhmmcnt en-s la n!kLsadon de projets visant h Evduer la rfurmance &s murs B ossatwe de b i s des habitations au points de vuc

r

thcmiquc ct uitcs d'air,L'Cvaluation de la puformance thedque a consistt

B

mesum,B

l'aide de la chambre Bdouble atmosphk de 1'Institut. la rtsistance thermique d'Cchantillons

de

2.4 x 2.4 m sous trois tempCranves moyennes. Les essais ontp o d

sur qua= khantillons cornpartant

de

l'isolant de polyurtthane pmjet4 en place.L'Cvaluation de la performance au niveau fuim d'air a consist4 B mesurer

le taux de fuite

d'air il travers des tchantillons de 2.4 x 2.4 m sous des diffdrences de pression cornspondant B celles qui s'exercent nonnalement sur l'enveloppe du batiment. et B dCtmniner la performance saucturclle du systhe de pare-air sous des Ccarts de pression cornspondant aux charges de bowrasque.LP

performance au niveau fuites d'air a C t t CvaluCe au moyen de l'appareil de mesure des fuiss&air de l'bstitut. Les essais ont Ct6

dalids sur un khantillon comportantde

l'isolant de polyudthane projetd en place.- -

Cc document dCcrit les

n Y

- - itat desTHE THERMAL AND A I R LEAKAGE PERFORMANCE OF RESIDENTIAL WALLS

by W.C. ~ r o w n ' and N.V. Schwartz

ABSTRACT

A s p a r t of i t s c o n t i n u i n g program of r e s e a r c h on performance of t h e b u i l d i n g envelope and i n c o o p e r a t i o n w i t h t h e SPI/NRC F e l l o w s h i p Program, t h e I n s t i t u t e f o r Research i n C o n s t r u c t i o n r e c e n t l y undertook p r o j e c t s t o e v a l u a t e t h e t h e r m a l performance and a i r l e a k a g e performance of wood frame r e s i d e n t i a l w a l l s .

E v a l u a t i o n of thermal performance i n c l u d e d measurement of t h e t h e r m a l r e s i s t a n c e of 2.4 x 2.4 m t e s t specimens a t t h r e e mean t e m p e r a t u r e s . Thermal r e s i s t a n c e of t h e specimens was measured u s i n g t h e I n s t i t u t e ' s guarded h o t box a p p a r a t u s . Four specimens w i t h sprayed-in-place p o l y u r e t h a n e i n s u l a t i o n were i n c l u d e d i n t h e p r o j e c t .

E v a l u a t i o n of a i r l e a k a g e performance i n c l u d e d measurement of t h e a i r l e a k a g e r a t e t h r o u g h 2.4 x 2.4 m t e s t specimens a t p r e s s u r e d i f f e r e n c e s c o r r e s p o n d i n g t o t h o s e normally e x e r t e d on t h e b u i l d i n g e n v e l o p e , and

assessment of t h e s t r u c t u r a l performance of t h e a i r b a r r i e r system a t p r e s s u r e d i f f e r e n c e s c o r r e s p o n d i n g t o g u s t wind l o a d i n g . A i r l e a k a g e performance was e v a l u a t e d u s i n g t h e I n s t i t u t e ' s a i r l e a k a g e a p p a r a t u s . One specimen w i t h sprayed-in-place p o l y u r e t h a n e i n s u l a t i o n was i n c l u d e d i n t h e a i r l e a k a g e p r o j e c t .

T h i s paper d e s c r i b e s t h e t e s t p r o c e d u r e s used i n t h e t e s t s e r i e s and r e p o r t s on t h e i n i t i a l r e s u l t s of t h e t e s t program.

f

'

W.C. Brown i s a n A s s o c i a t e Research O f f i c e r w i t h t h e I n s t i t u t e f o r R e s e a r c h i n C o n s t r u c t i o n , N a t i o n a l Research Council.

N.V. Schwartz i s SPI/NRC Research Fellow a t t h e I n s t i t u t e f o r Research i n C o n s t r u c t i o n , N a t i o n a l Research Council.

INTRODUCTION

The I n s t i t u t e f o r Research i n C o n s t r u c t i o n (IRC) i s engaged i n r e s e a r c h on performance of t h e b u i l d i n g e n v e l o p e w i t h r e g a r d t o c l i m a t i c f a c t o r s such a s h e a t , m o i s t u r e and a i r . Research p r o j e c t o b j e c t i v e s range from

d e t e r m i n a t i o n of fundamental p r i n c i p l e s of b u i l d i n g s c i e n c e t o e v a l u a t i o n of in-use performance of b u i l d i n g envelope systems. Funding f o r t h e m a j o r i t y of t h e p r o j e c t s i s from p u b l i c s o u r c e s , a l t h o u g h a n i n c r e a s i n g number of p r o j e c t s a r e b e i n g funded by i n d u s t r y .

The S o c i e t y of t h e P l a s t i c s I n d u s t r y ( S P I ) has funded a F e l l o w s h i p p o s i t i o n a t IRC. The r e s e a r c h u n d e r t a k e n by t h e SPI/NRC F e l l o w aims t o e s t a b l i s h procedures f o r a s s e s s i n g t h e value-in-use of r e s i d e n t i a l t h e r m a l i n s u l a t i o n m a t e r i a l s and systems. These would i n c l u d e m a t e r i a l s such a s p o l y u r e t h a n e , p o l y s t y r e n e and g l a s s f i b r e i n s u l a t i o n s .

I n s u p p o r t of both t h e I R C r e s e a r c h program and t h e SPI/NRC F e l l o w s h i p program, I R C undertook p r o j e c t s t o e v a l u a t e t h e t h e r m a l performance and a i r l e a k a g e performance of r e s i d e n t i a l w a l l s . The o b j e c t i v e s

were:

a ) t o produce measured v a l u e s of performance;

b ) t o a s s e s s t h e a c c u r a c y of a v a i l a b l e p r e d i c t i o n models.

The m a j o r i t y of t h e specimens i n t h e t h e r m a l performance p r o j e c t were i n s u l a t e d w i t h g l a s s f i b r e i n s u l a t i o n i n t h e s t u d s p a c e . The e f f e c t of i n s u l a t i n g s h e a t h i n g , s t u d d e p t h and s t u d s p a c i n g were examined i n t h e

p r o j e c t . Four wood frame specimens c o n t a i n i n g sprayed-in-place p o l y u r e t h a n e i n s u l a t i o n were i n c l u d e d i n t h e t e s t program. T h i s paper r e p o r t s on t h e r e s u l t s from t h e p o l y u r e t h a n e specimens a n d , f o r comparison, f o u r g l a s s f i b r e i n s u l a t e d specimens.

The m a j o r i t y of t h e specimens i n t h e a i r l e a k a g e performance p r o j e c t used wood s t u d f r a m i n g a s t h e main s t r u c t u r a l element. One wood frame specimen c o n t a i n i n g sprayed-in-place p o l y u r e t h a n e i n s u l a t i o n on f i b e r b o a r d s h e a t h i n g was i n c l u d e d i n t h e t e s t program. T e s t r e s u l t s from t h i s specimen a r e r e p o r t e d i n t h i s paper. S i n c e t h e r e i s no s t a n d a r d t e s t procedure t o e v a l u a t e t h e a i r l e a k a g e performance of w a l l s , a procedure developed by I R C was used f o r t h i s purpose.

THERMAL PERFORMANCE

I n an e v a l u a t i o n of t h e r m a l performance, t h e primary c o n c e r n i s

assessment of h e a t t r a n s f e r due t o t e m p e r a t u r e g r a d i e n t . This i n c l u d e s h e a t t r a n s f e r by c o n d u c t i o n , r a d i a t i o n and c o n v e c t i v e a i r flow. It d o e s not i n c l u d e h e a t t r a n s f e r due t o vapour movement, which i s d r i v e n by vapour p r e s s u r e g r a d i e n t , o r a i r l e a k a g e , which is d r i v e n by a i r p r e s s u r e g r a d i e n t . Thermal r e s i s t a n c e is t h e s t a n d a r d measure of t h e e f f e c t i v e n e s s of a s y s t e m a t c o n t r o l l i n g h e a t t r a n s f e r due t o t e m p e r a t u r e g r a d i e n t .

A s e c o n d a r y concern i n a n e v a l u a t i o n of t h e r m a l performance i s

assessment of s u r f a c e t e m p e r a t u r e performance. T h i s i s i m p o r t a n t because of i t s e f f e c t on c o n d e n s a t i o n . I n g e n e r a l , wood frame w a l l s do n o t p r e s e n t problems w i t h s u r f a c e t e m p e r a t u r e i f t h e s t u d s p a c e i s f i l l e d w i t h i n s u l a t i o n and t h e vapour and a i r t i g h t n e s s c o n t r o l p l a n e s a r e a t t h e i n t e r i o r s u r f a c e .

Thermal T e s t P r o c e d u r e

The t h e r m a l performance t e s t s were performed i n t h e F u l l S c a l e Thermal T e s t F a c i l i t y of I R C . This f a c i l i t y conforms, i n g e n e r a l , t o t h a t

s t a n d a r d i z e d by ASTM C236

-

S t a n d a r d T e s t Method f o r S t e a d y - S t a t e Thermal Performance of B u i l d i n g Assemblies by Means of a Guarded Hot Box (ASTM 1986a). It c o n s i s t s of a c o l d chamber ( t e s t t e m p e r a t u r e s between 0°C and -40°C), a m e t e r i n g box ( t e s t t e m p e r a t u r e s between 15OC and 25OC), and a chamber t h a t s e r v e s a s t h e t h e r m a l guard f o r t h e m e t e r i n g box. The m e t e r i n g box, w i t h a 2.4 x 2.4 m t e s t a r e a , measures t h e h e a t f l o w through a 2.4 x 2.4 m t e s t specimen. Thermocouples a r e used t o measure a v e r a g e warm and c o l d s u r f a c e t e m p e r a t u r e s . Specimen t h e r m a l r e s i s t a n c e i s c a l c u l a t e d from t h e measured t e m p e r a t u r e d i f f e r e n c e and h e a t flow.Because t h e r m a l r e s i s t a n c e of i n s u l a t i n g m a t e r i a l s v a r i e s w i t h mean t e m p e r a t u r e , specimen t h e r m a l r e s i s t a n c e was measured a t t h r e e mean

t e m p e r a t u r e s . These measurements were perfokmed w i t h

a

meterf-ng box t e m p e r a t u r e of a p p r o x i m a t e l y 2I0C and c o l d chamber t e m p e r a t u r e s ofa p p r o x i m a t e l y -7OC, -21°C and -35OC. A mean t e m p e r a t u r e of 0°C was chosen a s t h e b a s i s f o r comparing t h e r m a l r e s i s t a n c e f o r d i f f e r e n t specimens. T h i s v a l u e was determined from a l e a s t s q u a r e s l i n e a r f i t t o t h e t h r e e measured v a l u e s of thermal r e s i s t a n c e .

Thermal P r e d i c t i o n Models

Two s i m p l i f i e d h e a t t r a n s f e r models a r e g e n e r a l l y used t o p r e d i c t t h e t h e r m a l r e s i s t a n c e of wood frame walls. The f i r s t i s r e f e r r e d t o a s t h e " p a r a l l e l " model, while t h e second is r e f e r r e d t o a s t h e " s e r i e s - p a r a l l e l " model (ASHRAE 1985). The " p a r a l l e l " model assumes t h a t t h e r e is no l a t e r a l h e a t flow between p a t h s and t h e a v e r a g e t h e r m a l r e s i s t a n c e of t h e assembly i s t h e a r e a weighted a v e r a g e of t h e t h e r m a l r e s i s t a n c e of t h e i n d i v i d u a l p a t h s . The " s e r i e s - p a r a l l e l " model assumes t h a t t h e r e i s p e r f e c t l a t e r a l h e a t f l o w between p a t h s and t h e a v e r a g e t h e r m a l r e s i s t a n c e of t h e assembly i s t h e sum of t h e t h e r m a l r e s i s t a n c e s of t h e i n d i v i d u a l l a y e r s . Thermal r e s i s t a n c e of

l a y e r s w i t h m u l t i p l e p a t h s i s c a l c u l a t e d u s i n g t h e " p a r a l l e l " model. ASHRAE n o t e s t h a t t h e a c t u a l t h e r m a l r e s i s t a n c e of an assembly w i l l f a l l between t h e v a l u e s c a l c u l a t e d by t h e two models.

Thermal T e s t Specimens

The t h e r m a l performance t e s t specimens were wood frame w a l l s e c t i o n s c o n s t r u c t e d of 38 mm x 89 mm p i n e s t u d s l o c a t e d on 406 mm c e n t e r s . Half w i d t h s t u d s , 19 mm t h i c k , were i n s t a l l e d a t t h e s i d e s of t h e specimens, which were c o n s t r u c t e d w i t h a double t o p p l a t e and s i n g l e bottom p l a t e . An i n s i d e f i n i s h of p a i n t e d 12 mm gypsum board was i n s t a l l e d on t h e specimens. T h i s was s e a l e d a t a l l j o i n t s t o p r e v e n t a i r l e a k a g e through t h e specimens. Each of t h e

t h e r m a l t e s t specimens had a d i f f e r e n t combination of s t u d s p a c e i n s u l a t i o n , e x t e r i o r s h e a t h i n g and e x t e r i o r c l a d d i n g . These d e t a i l s a r e l i s t e d i n

Table 1.

The g l a s s f i b r e i n s u l a t e d specimens ( 1 t o 3 ) used t h e same

s t u d / i n s u l a t i o n system; t h a t i s , specimens 2 a , 2b and 3 were c o n s t r u c t e d by modifying t h e e x t e r i o r of specimen 1. The p o l y u r e t h a n e i n s u l a t e d specimens

( 4 t o 7 ) were c o n s t r u c t e d on f o u r s e p a r a t e s t u d frames. Specimens 4 and 5 were foamed by one o p e r a t o r , w h i l e specimens 6 and 7 were foamed by a second o p e r a t o r . The same c h e m i c a l s were u s e d f o r t h e s t a n d a r d d e n s i t y foams i n specimens 4 , 5 and 6 , w h i l e d i f f e r e n t c h e m i c a l s were used f o r t h e low d e n s i t y foam of specimen 7. The same equipment was u s e d t o foam a l l f o u r specimens. Both o p e r a t o r s were i n s t r u c t e d * t o foam t o a d e p t h of 75 mm. However, i n a l l c a s e s t h e foam exceeded t h e d e p t h of t h e s t u d s a t p o i n t s and some trimming was r e q u i r e d . A f t e r trimming e x c e s s foam back t o t h e f a c e of t h e s t u d s , t h e

a v e r a g e t h i c k n e s s of foam i n t h e specimens v a r i e d from a low of 71.4 mm (specimen 4 ) t o a h i g h of 85.5 mm (specimen 7 ) .

To d e t e r m i n e t h e a c c u r a c y of t h e models used t o p r e d i c t w a l l t h e r m a l r e s i s t a n c e , t h e r m a l r e s i s t a n c e of samples of a l l i n s u l a t i o n used i n t h e

specimens was measured by I R C . These measurements were performed u s i n g a n

ASTM C518 h e a t flow meter a p p a r a t u s (ASTM 1986b) a t a mean t e m p e r a t d r e of 24OC. T a b l e 2 l i s t s t h e t h e r m a l r e s i s t a n c e measured f o r a l l i n s u l a t i o n used i n t h e f u l l s c a l e specimens.

T e s t samples of t h e g l a s s f i b r e i n s u l a t i o n and i n s u l a t i n g s h e a t h i n g s were s e l e c t e d from t h e m a t e r i a l u s e d i n t h e f u l l s c a l e specimens. For t h e p o l y u r e t h a n e i n s u l a t i o n , t e s t samples were s p r a y e d a t t h e same time a s t h e f u l l s c a l e specimens. Measured t h e r m a l c o n d u c t i v i t y f o r Type A and Type B p o l y u r e t h a n e was t h e same (0.017 W/(m*K)) and s l i g h t l y lower t h a n t h a t

measured f o r Type C p o l y u r e t h a n e (0.018 W/(m*K)). Thermal r e s i s t a n c e f o r t h e p o l y u r e t h a n e , which v a r i e d from a low of 4.20 m 2 * K / w t o a h i g h of 4.75 m 2 * K / w , was c a l c u l a t e d from t h e measured t h e r m a l c o n d u c t i v i t y and measured a v e r a g e t h i c k n e s s . Measurements were made on unaged foam, 21 t o 28 d a y s o l d .

Thermal T e s t R e s u l t s

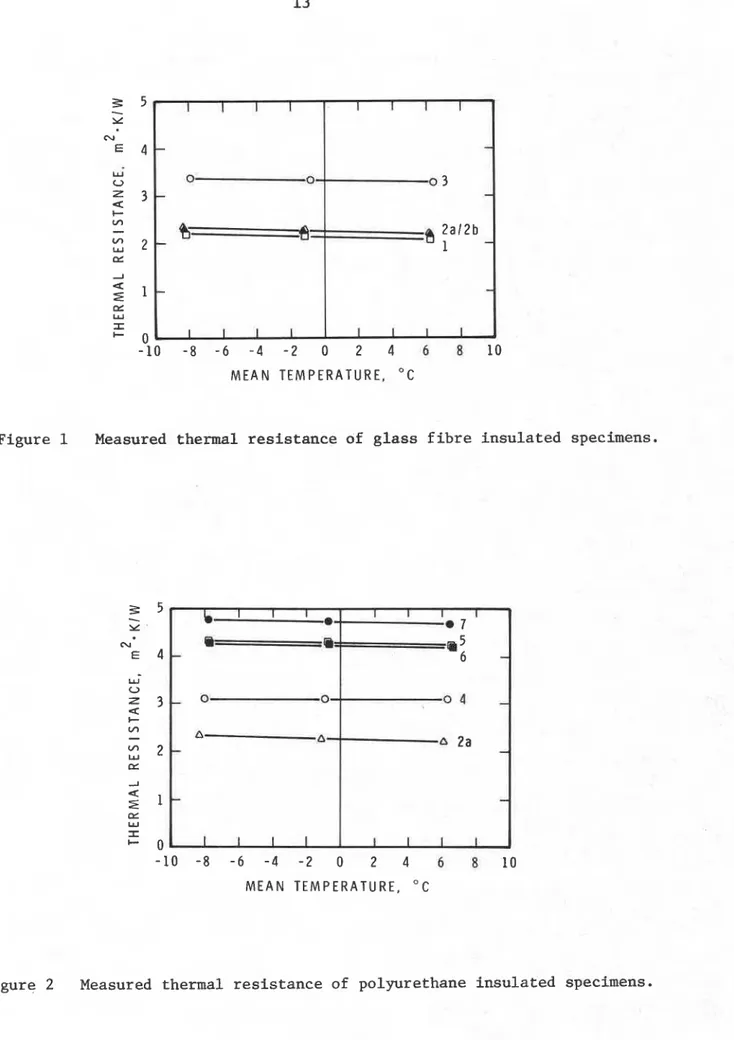

Thermal r e s i s t a n c e v a l u e s measured f o r t h e g l a s s f i b r e i n s u l a t e d specimens a r e shown i n F i g u r e 1.

The measured t h e r m a l r e s i s t a n c e f o r specimens 2a and 2b was t h e same, i n d f c a t i n g t h a t , from t h e viewpoint of t h e s e t h e r m a l t e s t s , t h e r e i s no d i f f e r e n c e between v i n y l and aluminum s i d i n g . The d i f f e r e n c e between t h e r e s u l t s from t h e s e specimens and t h a t from specimen 1 i n d i c a t e t h a t a t h e r m a l r e s i s t a n c e of 0.13 rn2*K/w was added by b o t h s i d i n g s . T h i s compares f a v o u r a b l y w i t h t h e v a l u e of 0.11 m2*K/w quoted f o r hollow-back aluminum s i d i n g i n t h e

ASHRAE Handbook of Fundamentals (ASHRAE 1985).

The d i f f e r e n c e between t h e t h e r m a l r e s i s t a n c e measured f o r specimen 3 and t h a t measured f o r specimen 2b i n d i c a t e s t h a t a n e t t h e r m a l r e s i s t a n c e of

1.06 r n 2 * ~ / w was added by t h e Type I V p o l y s t y r e n e i n s u l a t i n g s h e a t h i n g . Assuming t h e plywood s h e a t h i n g on specimen 2b has a t h e r m a l r e s i s t a n c e of 0.11 rn2*K/w (ASHRAE 1 9 8 5 ) , a t o t a l t h e r m a l r e s i s t a n c e of 1.17 m2*K/w can be a t t r i b u t e d t o t h e s h e a t h i n g on specimen 3.

Thermal r e s i s t a n c e v a l u e s measured f o r t h e p o l y u r e t h a n e i n s u l a t e d specimens a r e shown i n F i g u r e 2.

I t was i n t e n d e d t h a t specimens 4 t o

7

have s i m i l a r q u a n t i t i e s of p o l y u r e t h a n e i n t h e s t u d s p a c e i n o r d e r t o make a d i r e c t comparison of measured t h e r m a l r e s i s t a n c e s v a l u e s . However, because of t h e v a r i a t i o n i n i n s u l a t i o n t h e r m a l r e s i s t a n c e , a d i r e c t comparison was n o t p o s s i b l e . Accurate p r e d i c t i o n models must t h e r e f o r e be u s e d t o p r o v i d e a b a s i s of comparison.To make an a c c u r a t e comparison between measured and c a l c u l a t e d t h e r m a l r e s i s t a n c e , b o t h v a l u e s must be d e t e r m i n e d a t a common mean t e m p e r a t u r e . S i n c e specimen thermal r e s i s t a n c e cannot be measured a t 24OC mean t e m p e r a t u r e and m a t e r i a l t h e r m a l r e s i s t a n c e h a s n o t been measured a t O°C mean t e m p e r a t u r e , a compromise s o l u t i o n was t o e x t r a p o l a t e t h e l i n e a r f i t of specimen t h e r m a l r e s i s t a n c e t o 24OC mean t e m p e r a t u r e . It i s r e c o g n i z e d t h a t t h i s is an i n c o m p l e t e s o l u t i o n , s i n c e t h e t h e r m a l r e s i s t a n c e of p o l y u r e t h a n e does n o t v a r y l i n e a r l y w i t h mean t e m p e r a t u r e . However, i t does p r o v i d e

a

f i r s t approximation of t h e a c c u r a c y of t h e t h e r m a l r e s i s t a n c e p r e d i c t i o n models.The comparison of measured and c a l c u l a t e d t h e r m a l r e s i s t a n c e i s shown i n F i g u r e 3. Thermal r e s i s t a n c e c a l c u l a t e d by t h e " p a r a l l e l " and

" s e r i e s - p a r a l l e l " models f o r e a c h specimen a r e shown and l a b e l e d w i t h t h e number of t h e specimen. The s o l i d l i n e i n F i g u r e 3 i s t h e l i n e of p e r f e c t agreement between measured and c a l c u l a t e d v a l u e s ; t h e dashed l i n e s e n c l o s e a n e n v e l o p e r e p r e s e n t i n g c a l c u l a t e d v a l u e s w i t h i n 10% of measured v a l u e s .

While b o t h models p r e d i c t a p p r o x i m a t e l y t h e same v a l u e f o r specimens of low t h e r m a l r e s i s t a n c e , t h e d i f f e r e n c e between t h e p r e d i c t i o n s t e n d s t o i n c r e a s e a s t h e specimen t h e r m a l r e s i s t a n c e i n c r e a s e s . I n most c a s e s t h e p r e d i c t e d v a l u e s b r a c k e t t h e measured v a l u e and, e x c e p t f o r specimen

5,

a l l p r e d i c t i o n s a r e w i t h i n 10% of t h a t determined from t h e measurements. For t h e range of t h e r m a l r e s i s t a n c e c o n s i d e r e d , t h e s i m p l e s t approach t o a morea c c u r a t e p r e d i c t i o n is t o t a k e a n a v e r a g e of t h e two v a l u e s p r e d i c t e d by t h e models. T h i s c o n c l u s i o n w i l l be checked f u r t h e r w i t h t h e a d d i t i o n of measured r e s u l t s from o t h e r r e s i d e n t i a l w a l l c o n s t r u c t i o n s . It is a l s o planned t o compare r e s u l t s a t O°C mean t e m p e r a t u r e u s i n g i n s u l a t i o n t h e r m a l r e s i s t a n c e measured a t t h a t p o i n t .

A I R LEAKAGE PERFORMANCE

U n c o n t r o l l e d a i r l e a k a g e through r e s i d e n t i a l w a l l s c a n l e a d t o a number of problems. These i n c l u d e problems w i t h i n t e r s t i t i a l c o n d e n s a t i o n and h i g h e r t h a n n e c e s s a r y e n e r g y c o s t . I n an e v a l u a t i o n of a i r l e a k a g e performance, t h e

primary concern is assessment of a i r flow u n d e r p r e s s u r e g r a d i e n t . S t a n d a r d s f o r b u i l d i n g components (e.g. windows, d o o r s ) s p e c i f y t h a t t h e a i r f l o w r a t e a t 75 Pa be used a s t h e measure of t h e e f f e c t i v e n e s s of t h e component a t

c o n t r o l l i n g a i r leakage. However, i t i s n o t p o s s i b l e a t p r e s e n t t o s e t such a t e s t c o n d i t i o n f o r w a l l s . I n s t e a d , t h e f l o w vs p r e s s u r e d i f f e r e n c e

r e l a t i o n s h i p can be d e t e r m i n e d f o r p r e s s u r e d i f f e r e n c e s up t o 100 Pa. A s e c o n d a r y concern i n an e v a l u a t i o n of a i r l e a k a g e performance i s assessment of s t r u c t u r a l performance of t h e a i r b a r r i e r system. For a system t o be e f f e c t i v e a t c o n t r o l l i n g a i r l e a k a g e , i t must be c a p a b l e of r e s i s t i n g t h e p r e s s u r e d i f f e r e n c e s e x e r t e d on i t . These i n c l u d e p r e s s u r e d i f f e r e n c e s g e n e r a t e d by s t a c k e f f e c t and wind and, f o r some b u i l d i n g s , by mechanical v e n t i l a t i o n systems.

When c o n s i d e r i n g t h e r m a l performance, t h e e n t i r e w a l l c o n s t r u c t i o n c o n t r i b u t e s t o t h e t h e r m a l performance of t h e w a l l . However, a i r l e a k a g e performance i s b e s t provided by a p l a n e of a i r t i g h t n e s s . T h i s may be

a t t a i n e d with a s i n g l e a i r t i g h t , s t r o n g m a t e r i a l . More commonly a n a i r t i g h t m a t e r i a l must be s u p p o r t e d by a s t r u c t u r a l m a t e r i a l . The m a t e r i a l s i n t h e p l a n e of a i r t i g h t n e s s may be t h o s e which make up t h e f a b r i c of t h e b u i l d i n g (e.g. g l a s s , m e t a l p a n s ) , o r t h e y may be m a t e r i a l s added s p e c i f i c a l l y t o improve a i r t i g h t n e s s . I n a l l c a s e s , i t is i m p o r t a n t t h a t t h e v a r i o u s m a t e r i a l s i n t h e " p l a n e of a i r t i g h t n e s s " be j o i n e d w i t h s t r o n g , l e a k - f r e e j o i n t s

.

A t e s t procedure t o measure a i r f l o w under p r e s s u r e g r a d i e n t i s s t a n d a r d i z e d a s ASTM E283

-

S t a n d a r d T e s t Method f o r R a t e of A i r Leakage Through E x t e r i o r Windows, C u r t a i n Walls and Doors (ASTM 1 9 8 6 ~ ) . A t e s t procedure t o measure s t r u c t u r a l performance u n d e r p r e s s u r e g r a d i e n t i ss t a n d a r d i z e d a s ASTM E330

-

S t a n d a r d T e s t Method f o r S t r u c t u r a l Performance of E x t e r i o r Windows, C u r t a i n W a l l s , and Doors by Uniform S t a t i c A i r P r e s s u r e D i f f e r e n c e (ASTM 1986d). N e i t h e r of t h e s e p r o c e d u r e s i s d i r e c t l y a p p l i c a b l e t o t e s t i n g t h e a i r leakage of opaque w a l l s . However, t h e a p p a r a t u s s p e c i f i e d i n them can be used on f u l l s i z e w a l l specimens.A i r Leakage T e s t Procedure

The a i r leakage performance t e s t was performed i n t h e A i r Leakage T e s t F a c i l i t y of IRC. T h i s f a c i l i t y conforms, i n g e n e r a l , t o t h o s e d e s c r i b e d i n ASTM E283 and ASTM E330. It c o n s i s t s of an a i r t i g h t t e s t chamber t o which a

t e s t specimen 2.4 x 2.4 m i s clamped w i t h a n a i r t i g h t c o n n e c t i o n . P o s i t i v e and n e g a t i v e p r e s s u r e d i f f e r e n c e s a r e a p p l i e d a c r o s s t h e specimen by

p r e s s u r i z i n g o r e v a c u a t i n g t h e space between t h e back of t h e specimen and t h e chamber. A i r f l o w t h r o u g h t h e specimen i s measured w i t h l a m i n a r f l o w m e t e r s , w h i l e p r e s s u r e d i f f e r e n c e a c r o s s t h e specimen i s measured w i t h e l e c t r o n i c p r e s s u r e s e n s o r s .

The t e s t procedure c o n s i s t e d of two p a r t s . I n t h e a i r l e a k a g e p a r t , t h e a i r f l o w v s p r e s s u r e d i f f e r e n c e c u r v e was determined f o r p r e s s u r e d i f f e r e n c e s up t o 100 Pa. I n t h e s t r u c t u r a l performance p a r t , p r e s s u r e d i f f e r e n c e s of 250, 500 and 1000 Pa, s i m u l a t i n g s u s t a i n e d wind l o a d i n g , were a p p l i e d f o r one hour and p r e s s u r e d i f f e r e n c e s of 1500, 2000 and 2500 Pa, s i m u l a t i n g g u s t wind l o a d i n g , were a p p l i e d f o r t e n seconds. A f t e r e a c h of t h e s t r u c t u r a l

performance t e s t c o n d i t i o n s , t h e specimen was v i s u a l l y checked f o r s t r u c t u r a l damage and t h e a i r f l o w a t 75 Pa was measured and compared t o t h a t measured d u r i n g t h e a i r leakage t e s t . A l l p r e s s u r e c o n d i t i o n s were a p p l i e d i n both a p o s i t i v e and n e g a t i v e d i r e c t i o n .

A i r Leakage T e s t Specimen

The a i r l e a k a g e performance t e s t specimen was a wood frame w a l l s e c t i o n c o n s t r u c t e d of 38 mm x 89

mm

p i n e s t u d s l o c a t e d on 406 mm c e n t e r s . Thespecimen was c o n s t r u c t e d w i t h a double t o p p l a t e and s i n g l e bottom p l a t e . F i b r e b o a r d s h e a t h i n g , 11 mm t h i c k , w a s i n s t a l l e d on one s i d e of t h e wood frame and a p p r o x i m a t e l y 75 mm of s t a n d a r d d e n s i t y sprayed-in-place p o l y u r e t h a n e foam i n s u l a t i o n (Type

B)

was i n s t a l l e d i n t h e s t u d space. No i n s i d e f i n i s h o r e x t e r i o r s i d i n g was i n s t a l l e d on t h e specimen.A i r Leakage T e s t R e s u l t s

The a i r l e a k a g e performance t e s t s were conducted 28 d a y s a f t e r foaming t h e specimen. The a i r f l o w v s p r e s s u r e d i f f e r e n c e c u r v e measured f o r t h e specimen i s shown i n F i g u r e 4. I n c l u d e d on t h e f i g u r e a r e t h e f l o w r a t e s measured f o r t h e specimen a t t h e s u s t a i n e d wind l o a d s t r u c t u r a l performance

t e s t .

The flow r a t e determined f o r t h e specimen a t 75 Pa p r e s s u r e d i f f e r e n c e (0.02 t / ( s * m 2 ) is c o n s i d e r a b l y l e s s t h a n t h a t measured f o r f i b r e b o a r d a l o n e (1.6 ~ / ( s * m ~ ) (Bomberg and Kumaran, 1985). The specimen showed no v i s i b l e damage d u r i n g t h e n e g a t i v e p r e s s u r e s t r u c t u r a l performance

tests

and no changet o t h e f l o w r a t e a t 75 Pa. A t 500 Pa p o s i t i v e p r e s s u r e , t h e f i b r e b o a r d showed s i g n s of b e i n g pushed o f f t h e n a i l s h o l d i n g i t t o t h e s t u d s . However, t h e r e - t e s t of t h e f l o w r a t e a t 75 Pa showed no change. No f u r t h e r v i s i b l e damage appeared d u r i n g t h e remainder of t h e p o s i t i v e p r e s s u r e s t r u c t u r a l performance t e s t and t h e r e was no change t o t h e f l o w r a t e a t 75 Pa.

CONCLUSIONS

A number of p r e l i m i n a r y c o n c l u s i o n s c a n be drawn from t h e work t o d a t e . I n g e n e r a l , both t h e " p a r a l l e l " and l ' s e r i e s - p a r a l l e l " models of h e a t t r a n s f e r can be used t o p r e d i c t t h e r m a l r e s i s t a n c e of r e s i d e n t i a l w a l l s t o w i t h i n 10% of measured v a l u e s . A more a c c u r a t e p r e d i c t i o n i s o b t a i n e d from an a v e r a g e of t h e v a l u e s p r e d i c t e d by t h e two models. While an e x i s t i n g s t a n d a r d t e s t

procedure can be used t o a s s e s s t h e r m a l performance, t h e r e is need f o r a s t a n d a r d t e s t procedure t o a s s e s s a i r l e a k a g e performance. Such a p r o c e d u r e , c u r r e n t l y under development a t I R C , h a s been used t o show t h a t unaged

p o l y u r e t h a n e foam can improve t h e a i r l e a k a g e performance of a wood frame specimen s h e a t h e d w i t h f i b r e b o a r d .

Work on both t h e t h e r m a l performance p r o j e c t and t h e a i r l e a k a g e

performance p r o j e c t is c o n t i n u i n g . For t h e t h e r m a l performance p r o j e c t , i t i s planned t o measure t h e performance of s e v e r a l more r e s i d e n t i a l w a l l

c o n s t r u c t i o n s . These i n c l u d e specimens c o n s t r u c t e d w i t h 38 x 140 mm s t u d s and specimens r e p r e s e n t i n g d e s i g n s t y p i c a l of t h o s e used i n t h e R2000 program. A l l of t h e measured r e s u l t s w i l l b e u s e d t o f u r t h e r a s s e s s t h e a c c u r a c y of t h e p r e d i c t i o n models.

For t h e a i r l e a k a g e performance p r o j e c t , i t i s planned t o c o n t i n u e t o a s s e s s t h e s u i t a b i l i t y of t h e a i r b a r r i e r t e s t procedure by a p p l y i n g i t t o a number of r e s i d e n t i a l a i r b a r r i e r systems. The t e s t procedure w i l l a l s o be a d a p t e d t o i n c l u d e t h e t e s t i n g of a i r b a r r i e r system j o i n t s .

i

To a s s e s s t h e e f f e c t of f i e l d c o n d i t i o n s on t h e performance of

p o l y u r e t h a n e specimens, t h r e e of t h e t h e r m a l specimens ( 4 , 6 and

7)

and t h e.-

a i r leakage specimen w i l l be i n s t a l l e d i n an e x t e r i o r w a l l a t IRC. The

specimens w i l l be l e f t i n p l a c e o v e r t h e w i n t e r and r e t e s t e d i n t h e s p r i n g t o d e t e r m i n e i f t h e i r performance h a s changed.

REFERENCES

ASHRAE. 1985. ASHRAE Handbook of Fundamentals, S I E d i t i o n , C h a p t e r 23.

ASTM. 1986a. ASTM C236, S t a n d a r d T e s t Method f o r S t e a d y - S t a t e Thermal

Performance of B u i l d i n g Assemblies by Means of a Guarded Hot Box. Annual Book of ASTM S t a n d a r d s , Vol. 04.06.

ASTM. 198hb. ASTM C518, S t a n d a r d T e s t Method f o r S t e a d y - S t a t e Heat F l u x Measurements and Thermal T r a n s m i s s i o n P r o p e r t i e s by Means of t h e Heat Flow Meter Apparatus. Annual Book of ASTM S t a n d a r d s , Vol. 04.06.

ASTM. 1986c. ASTM E283, S t a n d a r d T e s t Method f o r Rate of Air Leakage Through E x t e r i o r Windows, C u r t a i n Walls and Doors. Annual Book of ASTM S t a n d a r d s , Vol. 04.07.

ASTM. 1986d. ASTM E330, S t a n d a r d T e s t Method f o r S t r u c t u r a l Performance of E x t e r i o r Windows, C u r t a i n W a l l s and Doors by Uniform S t a t i c A i r P r e s s u r e D i f f e r e n c e , Vol. 04.07.

Bomberg, M. and Kumaran, M.K. 1985. A T e s t Method t o Determine A i r Flow R e s i s t a n c e of E x t e r i o r Membranes and S h e a t h i n g s . RRN 227. I n s t i t u t e f o r Research i n C o n s t r u c t i o n , N a t i o n a l Research Council of Canada.

ACKNOWLEDGMENTS

J.A. Richardson c o n s t r u c t e d and i n s t r u m e n t e d t h e t h e r m a l t e s t specimens and conducted t h e t h e r m a l t e s t s . G.F. P o i r i e r c o n s t r u c t e d and i n s t r u m e n t e d t h e a i r leakage t e s t specimen and conducted t h e a i r l e a k a g e t e s t s .

The f i n a n c i a l s u p p o r t of Canada Mortgage and Housing C o r p o r a t i o n i n t h e a i r leakage t e s t program i s acknowledged. The f i n a n c i a l s u p p o r t and comments of t h e S o c i e t y f o r t h e P l a s t i c s I n d u s t r y and t h e S t e e r i n g Committee f o r t h e SPIINRC Research F e l l o w s h i p a r e a l s o acknowledged.

This paper is a c o n t r i b u t i o n from t h e I n s t i t u t e f o r Research i n C o n s t r u c t i o n , N a t i o n a l Research C o u n c i l of Canada.

TABLE

1Thermal Performance Project

Details of Test Specimens

Specimen

No.

--

Stud Space

Exterior

Insulation

Sheathing

--Exterior

Siding

glass fibre

11plywood

Itnone

hollow back

vinyl

Type IV

polystyrene

hollow back

aluminum

std. density

PUF (Type A)

std. density

PUF (Type

B)

low density

PUF (Type

C )plywood

Type IV

polystyrene

Type

1polystyrene

Type IV

polystyrene

hollow back

vinyl

---Note: The following characteristics were common to all specimens:

a) 38

mmx

89 mmpine studs at 406 mm on center

b)

19 mmpine studs (half studs) on sides

c) double top plate and single bottom plate, all pine

TABLE 2

Thermal Performance Project

Measured Insulation Thermal Resistance

Material

Thickness

Density

R-value

Specimen

nun

kg/m

m

2 * ~ / ~ NO.stud insulation

glass fibre

batts

std. density

71.4

PUF (Type

A)

73.6

std. density

75.8

PUF (Type

B )low density

85.5

PUF (Type

C )sheathing

Type

IV

37

polystyrene

Type

=

37

polystyrene

Note: R-value of PUF (polyurethane foam) calculated from measured average

thickness of PUF in the specimen and thermal conductivity measured at

M E A N T E M P E R A T U R E , " C

Figure 1 Measured thermal resistance of glass fibre insulated specimens.

.6 - 4 - 2 0 2 4 6 8 10

M E A N T E M P E R A T U R E , " C

0 PARALLEL MODEL

-

A SERIES-PARALLEL MODEL-

-

MEASURED THERMAL RESISTANCE. m2. KIW

Figure 3 Comparison of "measured" and calculated thermal resistance.

1 . 0 t 1 I I I I I I l l I N

E I 0 NEGATIVE PRESSURE

C

A POS ITlVE PRESSURE a0 . 0 0 1 I I I 1 1 1 1 1 1 I

10 100 1000

P R E S S U R E D I F F E R E N C E . P a

T h i s paper

i s

being d i s t r i b u t e d i n r e p r i n tform by the I n s t i t u t e f o r Research i n

Construction. A l i s t of b u i l d i n g p r a c t i c e and r e s e a r c h p u b l i c a t i o n s a v a i l a b l e from t h e I n s t i t u t e

may

be obtained by w r i t i n g t o t h e P u b l i c a t i o n s S e c t i o n , I n s t i t u t e f o r Research i n C o n s t r u c t i o n , National Research C o u n c i l of Canada, O t t a w a , O n t a r i o ,KIA

0R6.

Ce document e s t d i s t r i b u g sous forme de tir6-3-part p a r