Publisher’s version / Version de l'éditeur:

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

Research Paper (National Research Council of Canada. Division of Building

Research); no. DBR-RP-367, 1968-06-01

READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE.

https://nrc-publications.canada.ca/eng/copyright

NRC Publications Archive Record / Notice des Archives des publications du CNRC :

https://nrc-publications.canada.ca/eng/view/object/?id=0ee355ab-e821-45fb-9dcd-8bcbace4ac6b https://publications-cnrc.canada.ca/fra/voir/objet/?id=0ee355ab-e821-45fb-9dcd-8bcbace4ac6b

NRC Publications Archive

Archives des publications du CNRC

This publication could be one of several versions: author’s original, accepted manuscript or the publisher’s version. / La version de cette publication peut être l’une des suivantes : la version prépublication de l’auteur, la version acceptée du manuscrit ou la version de l’éditeur.

For the publisher’s version, please access the DOI link below./ Pour consulter la version de l’éditeur, utilisez le lien DOI ci-dessous.

https://doi.org/10.4224/40001508

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at

Thermal decomposition products of polyethylene

Thernlal Deconlpositiorl Products of Polyethylene"'

YOSHlO 'I'SUCI-IIYAI. alld ICIIiUO SUl\/IIf, Naliot~ul 12esea1~cl~ Cour~cil, Diuis-ior~ o j Buildir~y Research,

Otlawa, Car~udu

Synopsis

J)eco~iipositio~i producls of polymcrs Ilave bccn detcr~iiilicd by ~iii~liy i~ivestigz~tors, but the results are often coliflictilig because of difficulties in analyzing a large number of products. A compreheiisivc aiialysis of the volatile thermal decompositioii products of high-density polyethylene has been made with the latest techliiques ill gas chromatog- raphy. The formation of products is explained on the basis of free-radical mechanism. The predominailt process in the formation of volatiles appears to be intramolecular transfer of radicals, in which isomerization by a coiling mechanism plays an important rolc in determining the relative quantities of each product.

ICnowledge of decomposition products could be used for elucidatirig thc mechanism of thermal decomposition of polymers. Decomposition prod- ucts of polymers have been determined by n~arly investigators, but their experimental results often conflict concerning the nature and quantities of different components produced. This discrepancy is due mainly to difficul- ties in analyzing the products. Otller reasons are differences in polymer samples and in experimental methods of decomposition.

Madorsky' determined thermal decomposition products of polyethylene by mass spectrometry. Owing to difficulties in tlie analysis of a large number of components present in small quantities, isomers of olefins were not separated. These data, therefore, are not very satisfactory as a basis for proposing a mechanism. Moiseev e t al.233 used gas chromatography for the separation of decomposition products; the chromatograms presented indicate that the separation of compoi~ents was riot as good as one could obtain with the newest techniques in gas chromatography. Rapid progress has been made in the field of gas chromatography in the past decade, with vast improvements in techniques both of separating and of identifying the components of a mixture. Moiseev2 explained the formation of volatile thermal decomposition products of almost linear polymers by assuming intramolecular transfer of radicals or isomerization. He predicted the quantities of different volatile products that should be formed and com- *This paper is published with the approval of the Director of thc Divisioii of Building ltcsearch, National Research Council, Canada.

tResearch Ofiicer, Fire ltescarch Scction, I_)ivisio~~ of Buildii~g llcscarch, Satiollal ltcscarch Council, Canada.

416 Y. TSUCIIIYA AND K. SUM1

pared them with experimental data. The influcnce of isomerization by a coiling mechanism on the formation of different ail~ounts of various products

W:LS not considered.

The purpose of this investigation was to obtain more completc and reliable information on the volatile thermal decomposition products of poly- ethylene than havc been obtained in the past. Gas chromatogl.nphy was used for dcternlining decon1positioi1 products with hydrocarbons of up to Cg.

EXPERIMENTAL

A comn~erci:~lly av~~ilable sample of high-dcnsity ~olyethylcne was uscd in this study; its properties arc give11 in Tnblc I .

TABLE I

Properties of IIigh-Density Polyethylene Samplc Appearance: white, translucent, solid Density: 0.962 g . / ~ m . ~ .

Softening point: 127°C.

Crystalline melting poinl: 135°C.

IIeaLdistortion temperature a t 66 psi: 88°C.

I n preliminary espcrimcnts :L ccranlic boat was used. Because of its

high hcat capacity thcre was apprccinble dclay in clcvating thc san~ple and boat to a dcsired tcrnperature. An :~luminum foil boat was therefore used in place of a ceramic boat. Thc similarity in the experimcntnl results and residue aftcr pyrolysis suggested that aluminum has no catalytic influence on this decon~positioil rcaction.

Thermal Decomposition

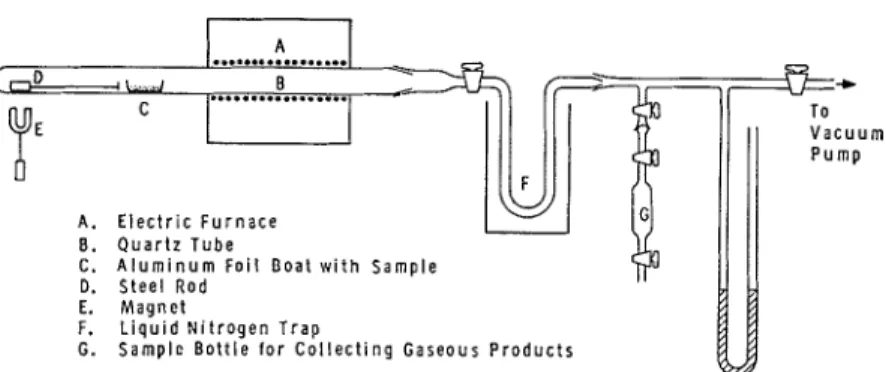

The apparatus uscd for the thermal decomposition of polyethylene is illustrated in Figure 1. A11 aluminuin foil boat containing 1 g. of sample was placed in a quartz tube, which was coniiccted to a vttcuum pump by a ground-glass joint. After thc qui~rtz tube was evacuated to 1 X 10-4 mm. Hg, the vacuum linc to the pump was closed, and the boat was pushed into the hot zone by means of :in external magnet. Thc furnacc was set a t one of the following sclected temperatures: 375, 385, 395, 405, 415, aiid 425°C. The sample was decomposed for 20 min.

Most of the volatile decomposition products wcre collected in a liquid- nitrogen trap; some condensed on the cooler parts of the quartz tube and on the tube leading to the trap. The fraction volatile a t room temperature was transferred from the trap into a flasli of lcnown volun~e by removing liquid nitrogen. The condensates in the tubes and the trap mcrc washecl with a predetermined amount of benzcne, which was known from prclimi- nary experiments to be s millor component of the decomposition products. The benzene extract and the fraction volatile a t room tcrnperature were

THERMAL DECOMPOSITION 417 A. E l e c t r i c F u r n a c e L- I 8. Q u a r t z T u b e C. A l u m i n u m F o i l B o a t w i t h S a m p l e D. S t e e l R o d E. M a g n e t F. L i a u i d N i t r o q e n T r a ~ G. ~ a m ~ ~ e B o t t l e f o r c o l l e c t i n g G a s e o u s P r o d u c t s

li

Fig. 1. Apparatus for the thermal decomposition of polyethylene.analyzed separately, and the combined amounts of the various products were recorded.

Analysis

Four different chromatographic conditions were used for the determina- tion of decomposition products. An open tubular column coated with squalane was used a t 0°C. for the analysis of gases from methane to hexane (condition 1). The same colunln was used a t 40°C. followed by a non- linear temperature rise to 140°C. for the analysis of the benzene extract (condition 2). A packed column of deactivated silica gel was used a t a temperature rise of 10 for the analysis of both gases and benzene extract (condition 3). A paclicd column having silver nitrate-diethylene glycol a s liquid phase was used for the determination of n-butane and isobutylene (%methyl propene) (condition 4). Further details of the chromatographic conditions are presented in Table 11.

Many of the peaks were identified by comparing retention indices with those of pure materials, n-alltanes being used as internal standards. A sub- traction technique was used for separating unsaturated from saturated hydrocarbons; this facilitated identification of some of the peaks. A tube 4 in. (10.2 cm.) long and l / 4 in. (0.G cm.) o.d., packed with equal weights of concentrated sulfuric acid and silica gel of 60 to SO mesh, was used for this purpose. When the squalane column was used (conditions 1 and 2), another method available for the identification of products was the linear leelation between boiling point and retention index. For quantitative anal- ysis areas under each peak were measured, and approximate substance correction factors4 were used.

Results

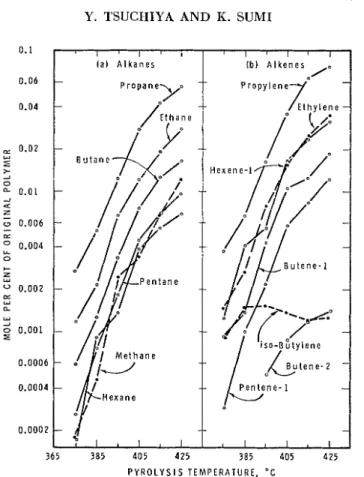

The thermal decomposition products of polyethylene found in the frac- tion volatile a t room temperature were as presented in Figure 2. They were calculated in "mole per cent of the original polymer" by considering i t to be the monomer, ethylene.

TI-IERMAL DECOMPOSLTION 419

Thirty pealts were found for hydrocarbons of

CI

to Cs when the gaseouscomponents were analyzed with a squalane column (condition 1); these data are presented in Table 111. The lower molecular weight hydrocarbons that were not separated into individual components by condition 1 were analyzed by condition 3 with deactivated silica gel. The separation of components from methane to n-butane was very good, except for propane and acetylene, which had approximately the same retentions. Results with

TAULE 111

A~l:tlysib of 1 ) ~ ~ 0 1 n ~ ~ o s i L i o r 1 Proclucts of P o l y e t l ~ y l e ~ ~ e by ~ L I I Ope11 Tub111:~r C o l ~ i ~ n r ~ Coated will1 S(l\lttla~~e

- - --

l t e t e ~ ~ t . Satd. or L)eco~npositior~ 111te11siLy Peak ir~dex'~ U I I S ~ L L ~ . protlucts b.p., '(3. of peak"

Propi~rle, propene 2-Methylpropa~le I-butene, 2-nletl~yl- propelle butane 2-butene, l m n s 2-butene, cis pcnlar~e 2-pentene, lratrs 2-perlte11e, cis I,Y-pel~lndie~~e, Irur~s (2-methyl-2- buterle j c l,S-pel~Ladic~~e, cis (4-rneLhyl-2-pe1l- tene, cis)^ 3-rnethylpe~~tt~rle 2-methyl-I-pentcne 1-hexene hexnne -0.5 S 1.0 A l , should. 3 . 7 31 2 0 . 1 W 2 6 . 0 TV 2s. 0 W 30.1 S 3 1 . 0 N W 36.1 S 35. S W, sllould. 37.0 hI 42.0 R I (38. li j" 60.8 RI 3

r

63 5 S W W W, should. M 6 8 . 8 S - -- a Here b = 0.580.b S, strong; RiI, m e t l i u ~ r ~ ; W, weak.

Y. 'I'SUCBIYA AND K. SUM1

Fig. 2. Decomposition products of polyethylene.

a subtraction technique indicated that the amount of acetylene produced mas negligible.

The hydrocarbons found in the benzene extract were mainly normal alkanes and normal 1-alltenes.

DISCUSSION

The present experin~clltal 1.esults on the thcrlnal decomposition products of polyethylene were csaminecl on the basis of a free-radical mechanism. A possible reaction scheme, in which R is a n~acron~olecule and 12' is a small n-alkane group, is shown below.

Initiation:

11-R -+ 2 R . Propagation :

R . -+ E .

+

CH2=CF12Intranlolecular transfer followed by a clecon~position reaction:

R . -+ R-CII-CI%,-R' -+ R .

+

CII,=cH-cI1,-Rt (3)TI-IERMAL DECOMPOSITION 421

Intermolecular transfer followed by a decomposition reaction:

R-CH2-R

+

R .-

R-CH-R+

R H (5)R-C~I-R

-

R-CEI=CHZ+

R . ( 6 )Termination:

R'.

+

R'.

-+ R'-CFI=CH2+

R'II ( 7 )R' .

+

R,'.

-+ R1-R' (8)Initiation consists of preferential scission of weak bonds caused by irregu- larities in the polymer chaiu and of random scission of ordinary C-C bonds, resulting in the production of free radicals; see reaction (I). Tile weak bonds may be due to the presence of oxygen, which forms linlts that are wealtcr than C-C bonds, or to the presence of double bonds in tlle chain, which results in wealtcr bonds in the /3 position to the clouble bonds, or t o branching, which results in wealter C--C bonds adjacent to tertiary carbons. The propagation reaction, the reverse process of polymerization, produces the monomer ethylene; see reaction (2). This reaction must compete with intm- and intermolecular radical-transfer reactions. Be- cause of intramolecular radical transfer some of the primary radicals are expected to isomerize and form secondary radicals, which are more stable. The secondary radicals should decompose t o form n-alltenes and n-alkane radicals; see reactions (3) and (4). The latter should either extract hydro- gen from the polymer chain, as by intermolecular transfer in reaction ( 5 ) ) or decompose further. The formation of short-chain n-alkenes in reaction (3) is expected to compete with the formation of short-chain n-alltane radicals in reaction (4). Some of the short-chain alkane radicals may be consumed by disproportionation, in reaction (7), or by combination, in reaction (S).

Since these involve two radicals, the quantity of volatiles produced by the reactio~ls is expected to be small.

Ethylene, which is expected from reaction (2)) was one of the major de- composition products. The quantity of ethylene found in the products increased slightly with increase in pyrolysis temperature: 10 mole-yo of vol- a t i l e ~ a t 395°C. and 11 mole-% a t 425°C. These results were in good agreement with the 9.1 mole-% obtained by Moiseev2 and the 9.6 mole-yo obtained by Bailey ancl IJiotta5 a t 415°C. but were different from the < I mole-yo reported by GrassieQnd the 4.3 mole-% obtaincd by Madorsliy and llis c o - ~ o r l t e r s . ~

The discrepa~lcies in experimental results are probably due to differences in apparatus, experi~nental procedure, and methods of analysis of the de- composition products. I n thc present investigation a relatively large amount of polynler (1 g.) was deco~nposed a t a vacuum of mm. Hg; i\!ladorslty e t aL7 decomposed smaller amounts (25 t o 50 mg.) of poly- ethylene a t a vacuum of mm. I n this study the diffusion of decompo- sition products from inside a large sample is retarded, and the products are subject to more secondary reactions. Decomposition a t mm. will also tend to increase secondary reactions, resulting in greater fragmentation.

2 4 6 8

N U M B E R O F C A R B O N S

Fig. 3. Alkrunes nrld nlkrnes p r o c l ~ ~ c e d nt, 425°C.

Thesc differences mag be responsible for thc grcater yield of monomcr in the present study.

According to reactions (3) aucl (4), normnl parafin radicals having n carbon atoms and normal I-olefins having n

+

3 carbon atoms should be produced from the same radical. The experimental results of the present investigation were in good ngreemcnt with products cxpected from these reactions. The relation between the fonnat,ion of normal alkane having n carbons and that of normal I-alkcne having n+

3 carbons may bc seen in Figure 3.The relative amounts of differcnt hydi~ocarboi~s producecl might bc dis- cussed further on the basis of the compamtivc case with \vhich transfer of radicals to the cliffcrcnt carbon atoms fakes placc. Consideration of local coiling iudicatcs that isomerizntion of >L primary carbon radical to the fifth

carboil radical shoulcl be very favorable for gcomctrical reasons. This ex- planation is in z~greemcnt wit11 thc cxpcrimcntal results. Thc amount of propanc mas thc largcst among alkanes, and that of 1-hcxene was the second largest among alkcnes. Thcse two products should be foril~ed after radical transfer to the fiflh carbon.

Propylene was the most abundant volatile decomposition product. I t can be produced by two cliffercnt routes. Onc is intran~olecular radical transfer to the second carbon and subsequent deconlposition reaction; the amount of propylene forined by radical transfer to the second carbon, ho~rr- ever, is expected tjo be small for geometrical reasons. The other route involves scission of t,he C-C bond in the P position to a terminal double bond, which is formed in large amounts during decomposition. The C- C

bond in this position is known to be a wcali link of a linear hydrocarbon ~hain.~."Tllc largc amount of propylcnc is therct'ore from the terminal double bonds.

The formation of two other products, isobutylcnc and 2-butcne, may bc explai~ied in similar ways. Isobutylene can be produced from an unsatu-

rated group of the type

wliich is known to bc prcsent in p o l y ~ t h y l c n c . ~ ~ Scission of C-C boilds in the position /3 to a double bond should result in the formn1,ion of t,his hydrocarbon. Isobutylcne can also bc produced a t branchcs of polycth- ylene chaiii as a result of prcfcrcntinl :~bst~r:~ct~ioii of a hydroge~l atom attached to a tertiary carbon:

J t

I

CTI, I R.I

CFI?Scission of C-C bonds in the position /3 to a double bond should again result in the formation of isobutylcne.

2-Butene can be prodl~ced from :zn u~lsat~uratcd group of the type

R-

C H = CH-R, prcscnt in thc original polymer.'" Scission of C-C bonds in the position /3 to a double bond should rcsult in the formatio~l of 2-butenc.The logarithm of the molc percent of product increased with tempcraturc for most of the products, and t,hc slopcs of the lines wcre approximately equal (Fig. 2). Thc sole exceptlion was isobutylene, which was produced in a comparatively larger amount a t the lowest decomposition tenlperature of 375°C. Thc unsaturated group and branching, which were responsible for t,hc formation of isobutylenc, should decrease in the course of thermal dc- composit,ion, resulting in proportional decrease of this hydrocarbon in tllc products. The unsaturated group originally prcsent in the polymer and responsible for the formation of 2-butene should also decrease as dccornpo- sition proceeds. T o explain the increase of 2-butene with increase iu tcmpcrature, tllc possible formation of thc unsaturated group R - C H = C H - R during clecon~position was considcrcd. One plausible route in- volvcs a bimolccular rcnction of tjhc type suggcstcd 1 ) ~ ' Slovoklotova e t al.,lL sllown below :

CONCLUSIONS

Thc volatile thermal decoinposition products of high-density polyethylene hnvc been clctcrinincd with the use of gas ~hronlat~ography, and the presence of the main prodlicts was explained by a free-radical mechanism. Thc

4,24 Y. TSIJCZIIYA AND K. SIJMI

predominant process for the formation of volatiles appears to be intra- molecular transfer of radicals, in which local coiling plays an important role in determining the relative quantities of each product.

References

1. S. L. Madorsky, Thernzal Degradation of Organic Polymers, Interscience, New York, 1964, p. 93.

2. V. D. Moiseev, Soviet Plastics, (English transl. Dec. 1963), Dec. 1964, 6. 3. M. S. Khloplyaukina, M. B. Neiman, and V. D. Moiseev, Soviet Plastics (English transl., No. 2, 1961, 9), No. 2, 1961, 11.

4. R. Kaiser, Chromatographie in d e ~ Gasphase 111, Bibliographisches Institut, Mannheim, 1962, p. 136.

5. W. J. Bailey and C. L. Liotta, A m . Chem. Sac. Div. Polyn~er Chen~., 5,333 (1964). 6. N. Grassie, The Chemistry of High Poly~~zer Deg7.adation Processes, Butterworths,

London, 1956, p. 5.

7. S. L. Madorslcy, S. Straus, D. Tl~ompson, nnd L. IVillia~nson, J . Res., Arat. BUT.

Std., 42, 499 (1949).

8. C. E. 11. Bawn, Trans. Faraday Sac., 34, 598 (1938).

9. F. 0. Rice and E. Teller, J . Cl~em. Phl~s., 66, 489 (1938); l'bid., 7, p. 199 (1939). 10. A. Renfrew and P. Morgan, Polythene, Interscience, New York, 1960, p. 89. 11. N. A. Slovolrlotova, R4. A. Margupov, and V. A. Icargin, Vysoko~nolen~l. Soedin.,

6, 1974 (1964).

Received May 1, 1967 Revised June 26, 1967