Publisher’s version / Version de l'éditeur:

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

Paper (National Research Council of Canada. Institute for Research in

Construction), 1990

READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE. https://nrc-publications.canada.ca/eng/copyright

NRC Publications Archive Record / Notice des Archives des publications du CNRC :

https://nrc-publications.canada.ca/eng/view/object/?id=c100e6be-afd3-4c53-b679-e6745d28587a

https://publications-cnrc.canada.ca/fra/voir/objet/?id=c100e6be-afd3-4c53-b679-e6745d28587a

NRC Publications Archive

Archives des publications du CNRC

This publication could be one of several versions: author’s original, accepted manuscript or the publisher’s version. / La version de cette publication peut être l’une des suivantes : la version prépublication de l’auteur, la version acceptée du manuscrit ou la version de l’éditeur.

For the publisher’s version, please access the DOI link below./ Pour consulter la version de l’éditeur, utilisez le lien DOI ci-dessous.

https://doi.org/10.4224/40001431

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at

Fire tower tests of stair pressurization systems with mechanical

venting of the fire floor

S e r

T H 1

National Research

Conseil national

n.

'

1

1 1

Council Canada

de recherches

Canada

1 9 9 0

BLDG.

Institute for

lnstitut de

-

Research in

recherche en

Construction

construction

Fire Tower Tests of Stair Pressurization

Systems with Mechanical Venting of the

Fire Floor

by G.T. Tamura

Reprints from

ASHRAE Transactions

1990, V. 96. Pt. 2

PP. 9

(IRC Paper No. 1691)

NRC

-

CIS77I R C

L I B R A R Y

APA

25

3 1

NRCC 32361

B I B L I O T H ~ Q U E

I R C

'CNRC-

ICImTOn a test& dans une tour d'experimentation incendie de

10

&ages, des

systemes d e pressurisation de cages d'escaliers selon divers schemas

d'utilisation des portes d'escaliers, dans des conditions de non-incendie et

d'incendie, et l'etage du feu &ant ventilk

A

l'aide d'un aspirateur. Les quatre

systemes en question comportaient les moyens suivants d'elimination de la

surpression

:

elimination au moyen de la porte de sortie, 6limination A l'aide

de registres barometriques, commande par retroaction utilisant une

derivation d e ventilateur, et commande par retroaction employant un

ventilateur

A

vitesse variable. Les essais ont rev616 que l'utilisation de l'un ou

I'autre des systemes d e pressurisation des escaliers et la ventilation

mecanique de l'btage du feu emp-aient

la

fum&

d'envahir la cage d'escalier

A

condition d'ouvrir quatre portes d'escaliers.

FIRE

TOWER TESTS OF STAIR PRESSURIZATION

SYSTEMS WITH MECHANICAL VENTING

OF THE FlRE FLOOR

G.T. Tamura, P.E.

Fellow ASHRAE

ABSTRACT

Stairshaft pressurization systems under various schedules of stair door operation, nonfirelfire conditions, and the fire floor vented with an exhaust fan were investigated in a 10-story experimental fire tower. The four stairshaft pressurization systems that were tested had overpressure relief features of exit door relief, barometric damper relief, feedback control with fan bypass, and feedback control with variable-speed fan. Tests have indicated that with

any

one of the stair pressurization systems on and with mechanical venting of the fire floor, the stairshat? was kept smoke free with four stair doors open.INTRODUCTION

For all tests, the door-opening sequence was the same

as the one used during the Phase 3 tests when the fire floor was vented with exterior wall vents (Tamura 1990b), i.e., stair doors on the exit floor, fire floor, one above the fire floor, and one of the upper floors opened sequentially. For all pressurization systems, the supply air was injected inside the stairshaft on floors 1, 3, 5, 7, and 10. The stairshaft pressurization systems were tested under the following schedules:

Nonfire Tests with Stairshaft Pressurization and Mechanical Venting of the Second Floor:

1. No doors ooen

2. Stair doors open on Floors 1 and 2 -

-

3. Stair doors open on Floors 1. 2. and 3An ASHRAE research project was undertaken to 4. Stair doors open on Floors 1; 2; 3, and 8. evaluate- the petformanc~

of

stair pressurizationsystems

withFire Teso Wirh Stairohan Pressurkation and MxhanicaI overpresJure control. The

Rrst

phaseot

the project involvedVenting (he Second Flmr:

a literature revim (Tamura 1989) and the second phase

lnvokred field evaluation

of

stairshaft pressurization systems 1. At a fire temperature of8 4 W

(450°C) and with the (Tarnura 1990a). exterlor wall vents on the secondflmr

closed (intended asThe third phass i n v o w evaluating the Peflormmce of a low-temperature fire), the a w e door-opening sequence

the stair pressurization systems in

a

$0-story experimental was follmed umjl a bacmma

the swr door opening onfire tower. The resuhsm repofled in a companion Paper the second floor was observed. The stair door opening on Famufa 1 m b h indicated that, in many cases, Smoke the fire floor was decreased until backflow was prevented

bacMIw was PrWeflQd when the fire fI00r Was vented to and the d m r angle at the point & no backflow

was

noted. the outdmrs by exterior wall vents. A series of tests were Exterior wall vents on the second floor were opened for therefom planned to mamine the performance of the some of the low-temperature fire tests to determine their7 H e m s

when mmblned with mechanical venting of the fire effect on air velocities at the stair door opening on the same floor. Tlle resuhs of the tests are reported here. The four floor.stair pressurization systems that were ~nvestigaed had 2. At a fire temperature of 1200°F

(650%)

and with the overpressure relief features of exkl door relief, barometric exterior wall vents open (intended as a high-temperaturedamper refief, feedback control with fan bypass, and fire), the above door-opening sequence was followed until

feedback control with variable-speed fan. a backflow at the stair door opening on the second floor

TEST PROCEDURE

was observed. The stair door was again gradually closed and the door angle at the point of no backflow was noted.All tests were conducted in a 10-story experimental fire

tower located near Ottawa, Ontario. The details of the Pressure differences across stair doors were measured

experimental fire t m r equipped with various overpressure with a diaphragm-t~ P magnetic reluctance pressure relief features mi described In a companion

paper

Varnura

transducer, and the supply air rates for stairshaft 1 ggob). A" exhauff fan having a of 1 9 . ~ ~ 1 d m pressurization were measured at the flow-measuring station. 0.50 in.af

water (9 rn31sax

125 Pa) and a variabie-spnd Temperatures were measured with chromel-alumel drive w r e located ontop

of the return air shaft roof lwei. thermocouples. The average air velocities at the stair door The rsturn air shaftwas

arranged

to serve as a smoke owning on the second floor during nonfire tests were exhaust shaft. All shutters. to the return air shaft wereclosed

measured by carrying out a 21-Point hot-wire ~~emOmeter except for the one on the second floor (fire floor), which traverse. They were averaged to obtain the average air served as an exhaust opening with an area of 5.25 ft2 (0.49 velocity. Smoke backfl0w during the fire tests wasm2). determined with smoke sticks at the stair door opening on

George T. Tamura is Senior Research Officer in the Building Performance Section of the Institute for Research in Constructlonl National Research Council Canada, Onawa

THIS PREPRINT IS FOR DISCUSSION PURPOSESONLY, FOR INCLUSION IN ASHRAE TRANSACTIONS 1990. V. 96. Pt. 2. Not to be re~rlntedln In part w~thout wr~nen permusson of the Amer~can Soc~ety of Heating. Refr~gerattng and AlrCond~tlmlng Engineers. Inc

.

1791 Tullle Circle- NE. Atlanta. GA 30329 Opln'Ons' flndlngs, conclus~ons. or recommendations expressed In thls paper are those of the author@) and do not necessarll~ reflect the vlewsOf ASHRAEthe second floor. Carbon dioxide concentrations in the tower were measured with nondlspersFre infrard gas anatyzers.

The t&s with mechanical venting

ot

the

second flmr and those with both mectlanicd veniing and stairshaftpressurization were conducted under summer conditions only,

RESULTS AND DISCUSSION

Mechanical Exhaust of the Fire Floor

Tests of the stairshaft pressurization systems have indicated that venting of the fire floor by opening the exterior wall vents on the second floor increased the air veloclies at

the stair door opening (Tamura 1990b). Relieving pressures on the second floor by means of mechanical venting

is

therefore expected to improve the performance of stair pressurization syaems.Tests wars conducted inajally to evaluate the pefformance of mechanical venting alone without

stair

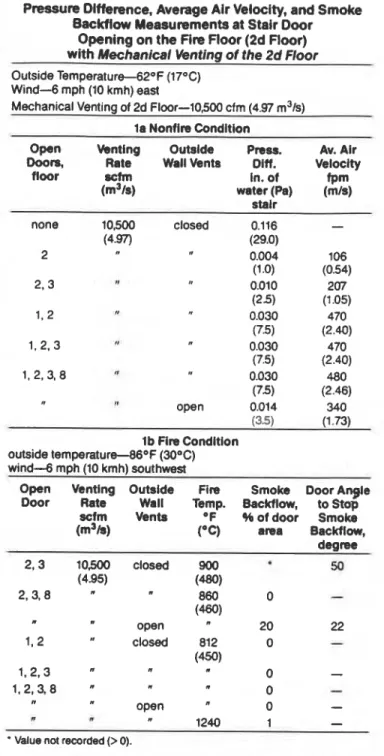

pressurization. The results of tests are given in Tables l aand I b. The

S

6cond floor was exhausted at a fate of 10,500 d m (4.97 mIs).

With all stair doors closed, the pressure d#ersnce across the stair door on the second flmr was0.116 in. d water (29 Pa). When the stair door on the

smxnd floor was opened, the average air velocity at the stair dmr was

1M

fpm (0.54 d s ) . When the stair doors on floors 1, 2, 3, end 8 were opened, the average air vefocrty increased to480

fpm

(2.44 d s ) but then decreased to 340 fprn (1.73 mls) when the exterior wall vents on the second floor wereopened

as

well, to simulate broken windows.Tabla l b shows that with a low-temperature fire and outside wall

rents

closed, smoke backflow occurred when the stair doorson

Rmrs 2 and 3 were opened. R was prevented when the stair doof an the eighth floor wasalso

opened, but It recurred when the outside wall vents were opened. When the stair door on the fitst floor was

also

opened under thb condition, smoke backflow was prevented. When the fire tempersture was then increased toI24W (G'PC), smoke backftcw was marginal. For the last two cases, the corresponding average air velocrty for the nonfire condition was 340 Ipm (1.73 mls) and the pressure difference across the stair door opening was 0.014 in.

of

water (3.5 Pa).

PRESSURE DIFFERENCE ACROSS STAIR DOOR. Pa

AIRRATE-17 &i 0 A C.4 UEOW(ICAL#HAUST RATE

-

10500 cbn (407 d h ) W m.4

6 LMEH)-

STAIR OPEN2

5ONIFIDmmFLooR

n 0 A 0 1PRESSURE DIFFERENCE ACROSS STAIR DOOR. INCH OF WATER

TABLE 1

Pressure Difference, Average Air Velocity, and Smoke Backflow Measurements at Stair Door

Opening on the Fire Floor (2d Floor) with Mechanical Wbnting of the 2d Floor

Outside Temperature--62OF (17%) Wind-6 mph (10 kmh) east

Mechanical Venting of 2d Floor-10,500 cfm (4.97 m3/s) l a Nontire Condition

Open Venting Outslde Press. Av. Air Rate WaliVents Din.

-

uhn Velocity floor in. of fPm (m3/s) water (Pa) (mls) stalr none 2 2,3 1.2 1.2,3 1,2,3,8 closed 0.116 (29.0) 0.004 (1 .O) 0.010 (2.5) 0.030 (7.5) - lb Fire Conditlon outside temperat~re-46~F (30°C) wind--6 mph (10 kmh) southwestOpen Venting Outslde Fire Smoke Door A y l e Door Rate Wall Temp. Backflow, to Stop

scfm Vents OF $6 of door Smoke (m3/s) (*C) area Backflow, dearee 10,500 closed (4.95) I open closed open w

Value not recorded (> 0).

Tests have lndlcated that the average air velocity at the stair door increased as more stair docrrs were opened and decreased when the exterior wall vents were opened. This

effe-3 is opposite to that with stair pressurization; the

average air velocw decreased as stair doors were opened and increased when the exterior wall veMs were

opened.

It appearedthal

the two operationscan complemem

each other. Tests were conducted to investigate the performanceof the combined operation of stair pressurization with

rnechanlcal venting of the second floor. They were conducted lor the summer condition

only.

Mechanical Venting of the Second Floor and

Stairshaft Pressurization System with Exit Door

Relief

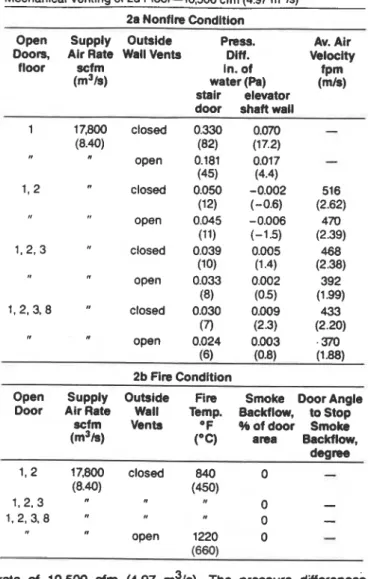

Figure 1 Pressure difference measurements with Nonflre Conditlon Pressure differences across the stair mechanical venting of second floor and s&& doors under nonfire conditions are shown in Figure 1. The pre~owization system with exit door relief, stairshaft wf3 pressurized with a supply air rate of 17.800

TABLE 2

Pressure Difference, Average Air Velocity, and Smoke

Backflow Measurements

ai

Stair Door Opening on the Fire Floor (2d Floor) of Staimhaft Pressurization System with ExitDoor Relief and Mechanical Venting of the 2d Floor Outside Temperature--73OF (23°C)

Wind-7.5 mph (12 kmh) south

Mechanical Venting of 2d Floor-10,500 cfrn (4.97 m3/s) 2a Nonflre Condition

Open Supply Outside Press. Av. Air Doors, Air Rate Wall Vents Dlff. Velocity

floor scfm in. of

(m3/s) water (Pa) (mk) fpm

stair elevator door shaft wall

1 17,800 closed 0.330 0.070

-

(8.40) (82) (17.2) I open 0.181 0.017-

(45) (4.4) 1, 2 closed 0.050 -0.002 516 (12) (-0.6) (2.62) open 0.045 -0.006 470 (11) (-15) (2.39) 1,2,3 closed 0.039 0.005 468 (10) (1.4) (2.38) open 0.033 0.002 392 (8) (05) (1.99) 1,2,3,8 " closed 0.030 0.009 433 (7) (2.3) (2.20) open 0.024 0.003 ,370 (6) (0.8) (1.W

2b Fire ConditionOpen Supply Outside Fire Smoke Door Angle Door Air Rate Wall Temp. Backflow, to Stop

scfm Venta O F %of door Smoke

(m3/s) (OC) area Backflow,

degree 1, 2 17,800 closed 840 0

-

(8.40) (450) 1,2,3 0-

1. 2, 3, 8 " 0-

open 1220 0-

rate of 10,500 cfm (4.97 m3/s). The pressure differences were much greater than those with the stairshaft pressurized and with no mechanical exhaust of the second floor (Tamura 1990). Except for floors 1 and 2, the pressure differences across all doors were about 0.10 in. of water (25 Pa) with stair doors open on floors 1, 2, 3, and 8. Those on floors 1 and 2 were 0.006 and 0.020 in. of water (0.5 and 5 Pa), respectively.

Table 2a gives the pressure difference and the average air velocity at the open stair door on the second floor during the door-opening test with the exterior wall vents on the second floor closed and open (simulating broken windows) and under nonfire conditions. With the exterior wall vents closed, the pressure differences across the open stair door on the second floor varied from 0.030 to 0.050 in. of water

f7

to 12 Pa); with them open, they varied from 0.024 to 0.045 in. of water (6 to 11 Pa). The average air velociies varied from 433 to 516 fpm (2.20 to 2.62 m/s) with the exterior wall vents closed as compared to 370 to 470 fpm (1.88 to 2.39 mls) with them open. These average air velocities are considsrably greater than those with stair pressurization systems alone.Fire Condition Table 2b gives the results of the fire tests. There was no smoke backflow at fire temperatures of 840°F (450°C) with the exterior wall vents closed or 1220°F

PRESSURE DIFFERENCE ACROSS STAIR WOR. Pa -25 STlRSHAFIswPLY AIR MTE

-

15,m dn 8 UECHAMCALDMAlsl ~E-10500da 7 (497 mlh) C rn o u r S l D E ~ P . 7 5 F p 4 ~ 1 I I WfND 6.0 mph (10 brim) EAST 1 I -0.1 0.0 0.1 0 2 0.3 0.4PRESSURE DIFFERENCE ACROSS STAIR DOOR, INCH OF WATER

ngum 2 Pressure difference measurements with mechanical venting of second floor and stair pressurization system with barometric damper relief, nonfire condition

(660°C) with the exterior wall vents open when doors on floors 1, 2, 3, and 8 were open. The minimum average air velocities during the nonfire tests that prevented smoke backflow were 392 fprn (1.99 mls) for the low-temperature fire with stair doors open on floors 1, 2, and 3 and the second floor wall vents closed and 370 fpm (1.88 mls) for the high-temperature fire with stair doors open on floors 1, 2, 3, and 8 and the second floor wall vents open.

Mechanical Venting of the Second ~ l o d / and

Stairshaft Pressurization System with Barometric

Damper Relief

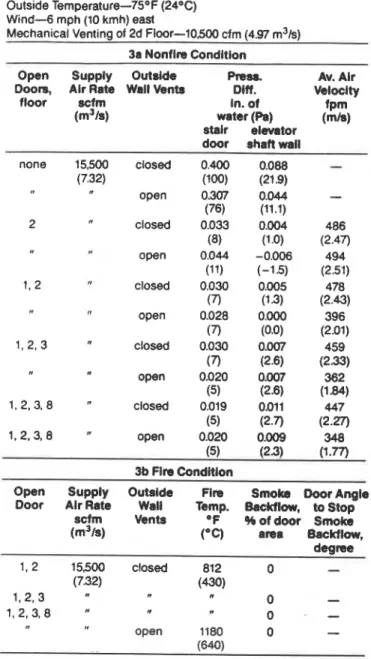

Nonfire Condition Pressure differences ross the stair doors under nonfire conditions are shown in

?

igure 2. The second floor was exhausted at a rate of 10,500 cfm (4.97 m3/s). The supply air rate fo stairshaft pressurization was5

set at 15,500 cfm (7.32 m Is) to prevent the pressure difference across the stair door on the second floor from exceeding 0.40 in. of water (100 Pa) with all stair doors closed. Except for floors 1 and 2, the pressure differences across the doors were about 0.05 to 0.10 in. of water (12 to 25 Pa) when stair doors on floors 1, 2, 3, and 8 were opened. Those on floors 1 and 2 were about 0.010 and 0.015 in. of water (2 and 4 Pa), respectively. Because of the reduced supply air rate, these pressure differences were lower than those for the previous case for a stair pressurization system with exit door relief when the stair doors were opened (Tamura 1990).Table 3a gives the pressure differences and the average air velocities at the open stair door on the second floor during the door-opening test with the exterior wall vents on the second floor closed

and

open. The tests were conducted under nonfire conditions. With the exterior wall vents closed, the pressure differences across the open e i r door on the second floor varied from 0.019 to 0.033 In. of water (5 to 8 Pa); with them open, they varied from 0.020 to 0.044 in. of water (5 to 11 Pa). The average air velocities varied from 447 to 486 fpm (2.27 to 2.47 m/s) with the exterior wall vents closed as compared to 348 to 494 fpm (1.77 to 2.51 m/s) with them open. The above values are slightly lower than those for the previous case with exit door relief.Fire Condition Table 3b gives the results of the f~re tests. There was no smoke backflow at fire temperatures of 81 0°F (430°C) and 1 180°F (640°C) when doors on floors 1,

TABLE 3

Pressure Difference, Average Air Velocity, and Smoke Backflow Measurements at Stair Door Opening on the Fire Floor (2d Floor) of Stairshaft Pressurization System with

Barometric Damper Relief and Mechanlcal Yenting of the 2d Floor

Outside Temperature-7S°F (24"C) Wind--6 rnph (10 kmh) east

Mechanical Venting of 2d Floor-10,500 cfrn (4.97 m3/s)

3a Nonfire Condition

Open Supply Outside Press. Av. Air

Doors, Air Rate Wall Venta Olff. Velocity

floor scfm ln. of

(m3 is) water (Pa) (mk) fpm

stair elevator door shaft wall

-- none 15,500 closed 0.400 0.088

-

(7.32) (100) (21.9) open 0.307 0.044-

(76) (11.1) 2 closed 0.033 0.004 486 (8) (1.0) (2.47) open 0.044 -0.006 494 (11) (-15) (2.51) 1 , 2 closed 0.030 0.005 478 (7) (1.3) (2.43) n open 0.028 0.000 396 (7) (0.0) (2.01) 1, 2, 3 closed 0.030 0.007 459 (7) (2.6) (2.33) open 0.020 0.007 362 (5) (2.6) (1.84) 1,2,3,8 " Closed 0.019 0.011 447 (5) (2.7) (2.27) 1.2.3.8 " open 0.020 0.009 348 (5) (2.3) (1.77) 3b Flre ConditionOpen Supply Outside Fire Smoke Door Angk Door Alr Rate Wall Temp. Backflow, to Stop

scfm Vents O F %of door Smoke

(m3W (*C) area Backt~ow, d c g m 1, 2 15500 Closed 812 0

-

(7.32) (430) 1,2,3 n 0-

1,2,3,8 " " 0-

,

open 1180 0-

(640)2, 3, and 8 were open. The minimum average

air

velocities during the nonfire tests that prevented smoke backflow were 362 fprn (1.84 m/s) for the low-temperature fire with stair doors open on floors 1, 2, and 3 and the second floor wall vents open and 348 fprn (1.77 m/s) for the high-temperature fire with stair doors open on floors 1, 2, 3, and 8 and the second floor wall vents open.Mechanlcal Venting of the Second Floor and

Stairshaft Pressurlzatlon Systems with Fan Bypass

and with Variable-Speed Fan

Nonflre Condition Pressure differences across the stair doors under nonfire conditions are shown

in

Figure 3. The pressure difference across the stair door on the fifth floor was controlled at 0.130 in. of water (32 Pa). The pressure differences above the third floor remained at about this value for all door-opening tests. The pressure differences were about 0.005 to 0.030 in. of water (1 to 7 Pa) for the first floorPRESSURE DIFFERENCE ACROSS STAIR DOOR, Pa

LEGEND

'

'

STAlAOOORSWENON WRY

IM)lXl€O AJRR41E

PRESSURE DIFFERENCE ACROSS STAIR DOOR.

INCH OF WATER

figure 3 Pressure difference measurements with mechanical venting of second floor and stair pressurization system with fan bypass, nonfire condition

and 0.020 to 0.032 in. of water (5 to 8 Pa) for the second' floor.

Table 4a gives the pressure differences and the average air velocities at the open stair door on the second floor during the door-opening test with the exterior wall vents on

the

second

floor closed and open. The tests wereconducted under nonfire conditions. With the exterior wall vents closed, the pressure differences across the open stair door on the second floor varied from 0.035 to 0.058 ifl. of water (9 to 14 Pa); with them open, they varied from 0.034 to 0.053 in.

of

water (8 to 13 Pa). The average air velocities varied from 478 to 588 fprn (2.43 to 2.99 m/s) with the exterior wall vents closed as compared to 443 to 539 fprn (225 to 274 m/s) with them open. The values of pressure diierences and average air velocities are greater than those of exit door relief with mechanical venting.Fire Condttion Table 4b gives the results of the fire tests. There was no smoke backflow at fire temperatures of

8404

(450°C) and 1200°F (650°C) when doors on floors 1,2, 3, and 8 were opened. The minimum average air velocities during the nonfire tests that prevented smoke backflow were 478 fprn (2.43 m/s) for the low-temperature fire with stair d mopen on floors 1, 2, 3, and 8 and the second floor wall vents closed and 480 fprn (280 d s ) for the hlgh-temperature fire with stair doors open on floors 1, 2, 3, and 8 and the second floor wall vents open.

The results for the stair pressurization system with variable-speed drive fan are similar to those of fan bypass; they are given in Figure 4 and Tables 5a and 5b.

Smoke Concentration Patterns

In addition to pressure differences, C 0 2 concentrations were measured throughout the tower during fire tests. Concentrations of C02 as a surrogate indicator of smoke can be expressed

as a

percentage of the concentration in the bum area of the second floor. Froma

consideration ofsmoke

obscuration, an area is assumed to be reasonablysafe if it

is

not contaminated to an extent greater than 1% of thatIn

the vicln'qof

the burn area (McGuire et al. 1970).Table 6 gives the smoke concentration patterns caused by fire at steady-state conditions and without stair pressuriiation

or

mechanical venting. Under the summer condition, with the exlerior wall vents on the second floor open and a fire temperature of 840°F (450"C), the smoke concentrations exceeded the 1% level in the stairshaft, elevator shaft, service shaft, and floor spaces. TheTABLE 4

Pressure Difference, Average Air Velocity, and Smoke Backflow Measurements at Stair Door Opening on the Fire

floor (2d Floor) of Stairshaft Pressurization System with An Bypass and Mechanical Venting of the 2d Floor

Outside Temperature-73OF (23OC) Wind-5 mph (8 kmh) southwest

Mechanical Venting of 2d Floor-10,500 cfm (4.97 m3/s)

4a Nonflre Condition

Open Supply Outside Press. Av. Air

Doors, Alr Rate Wall Vents Diff. Veloclty

floor scfm In. of

(m3/s) water (Pa) fpm

stair elevator (mls) door shaft wall

none 1700 closed 0.248 0.052

-

(0.80) (62) (12.9) 1700 open 0.146 0.004-

(0.80) (36) (1.0) 2 14.160 Closed 0.058 -0.010 588 (6.68) (14) (-2.5) (2.99) 13.650 open 0.053 -0.011 539 (6.40) (13) (-2.7) (2.74) 1. 2 15,690 closed 0.045 -0.008 476 (7.40) (11) (-2.1) (2.42) 15.690 open 0.038 -0.008 443 (7.40) (91) (-1.9) (2.25) 1, 2, 3 17.430 closed 0.038 -0.002 484 (8.22) (9) (-0.4) (2.46) 17,050 open 0.031 -0.004 450 (8.05) (8) (-11) (2.26) 1, 2, 3. 8 24.700 closed 0.035 0.011 478 (1 1.66) (9) (2.7) (2.43) 24,420 open 0.034 0.012 480 (11 52) (8) (3.0) (2.45) 4b Fire ConditionOpen Supply Outside Fire Smoke Door Angle

Door Air Rate Wall Temp. Backflow, to Stop

sctm Vents 'F %of door Smoke

(m31s) (OC) area Backflow,

degree

2 14,480 closed 840 0

-

(6.98) (450)29,000 open 1200 0

-

(13.69) (650)concentrations in the stairshafts varied from 6% on the second floor to 9% on the tenth floor. When the stair door on the second floor was opened, the concentrations in the stairshaft increased greatly, from 70% on the second floor to 66% on the tenth floor.

Smoke concentrations with mechanical venting of the second floor and the second floor wall vents closed are given in Table 7. With all stair

doors

closed, smoke concentrations were zero everywhere except for the fire floor. When stair doors were opened on the first and secondfloors, smoke concentrations everywhere In the tower were well above the critical level except in the stairshaft at the first floor level; this was also the case, but with somewhat lower values, when the stair door on the third floor was also opened. Although smoke backflow was prevented at the open stair door on the second floor (Table lb), smoke spread from the elevator and setvice shafts into floor spaces

TABLE 5

Pressure Difference, Aveage Air Velocity, and Smoke Backflow Measurements at Stair Door Opening on the Fire

Floor (2d Floor) of Stairshaff Pressurization System with Variable-Speed A n and Mechanical

Venting of the 2d Floor

Outside Temperature--80°F (n°C) Wind-6 mph (10 kmh) south

Mechanical Venting of 2d Floor-10.500 cfm (4.97 m3/s)

Sa Nontire Condition

Open Supply Outside Press. Av. Air

Doors, Air Rate Wall Vents Dlff. Velocity

floor sctm in. of fPm

(m3/s) water (Pa) (m/S)

stair elevator door shaft wall

none 3150 closed 0.325 0.057

-

(1 .87) (81) (14.2) none 3150 open 0.183 0.007-

(1.87) (45) (1.8) 2 14.660 0.060 -0.008 624 (6.92) (15) (-2.1) (3.17) 14,660 open 0.058 -0.014 540 (6.92) (14) (-3.4) (2.75) 1, 2 15,830 closed 0.056 -0.005 504 (7.47) (14) (-1.3) (2.56) 15,830 open 0.042 -0.010 453 (7.471 (10) (-2.6) (2.30) 1, 2, 3 17,900 Closed 0.046 -0.002 484 (a451 (11) (-0.6) (2.46) 17,400 open 0.040 -0.008 464 (8.21) (10) (-1.9) (2.36) 1, 2.3. 8 24,900 closed 0.043 0.016 464 (11.75) (10) (4.1) (2.36) 25,000 open 0.038 0.012 433 (11 8) (9) (2.9) (2.20) Sb Fire ConditlonOpen Supply Cutside Fire smoke\ Door Angle

Door Air Rate Wail Temp. Backflow, to Stop

scfm Vents OF %of door Smoke

(m3/s) (OC) area Backflow,

dearee - - - 2 14.480 closed 812 0

-

(6.w (450) 1,2 16,900 (I I 0-

(8.00) 1,2.3 19.460 w 0-

(9.18) 1,2,3.8 24450 a 0-

(13.43) " 29,000 open 1200 0-

(13.69) (650)and from there into the stairshaft. Opening the stair door on the second floor increased the pressure on the second floor to such an extent that fire pressure was no longer suppressed, allowing smoke to flow into elevator and stairshafts. A greater exhaust rate may have prevented this from happening.

Table 8 gives smoke concentration patterns of the stair pressurization system ith exit door relief

3

at a supply air rate of 17,800cfm (8.40

m Is). With no other stair doors open. the stairshaft was smoke free. When the stair door on the second floor was opened, however, smoke concentrations in the stairshaft at the first and second floor levels were 5% and 6%, respectively. When the exterior wall vents of the second floor were opened as well, the smoke concentrations in the stairshaft were reduced to zero. These results agreewith those of the observation of smoke backflow during the fire tests.

TABLE 6

Smoke Concentration Patterns Caused by Fire Smoke concentration in percent of that in the bum area of the 2d floor Exterior wall vents on the 2d floor open

Fire temperature--840OF (450°C) Outside Temperature--7g°F (26OC) Wind-7 mph (12 kmh) northwest

Floor All Stalr Doom Stair Door on

Closed 2d Floor Open

Stair Elev Floor Stair Elm Floor

(sew) (sew) 10 9 12 28 66 26 45 (39) (43) 8 8 12 25 67 24 49 (39) (43) 6 3 12 19 69 20 43 (39) (44) 3 6 16 44 67 17 50 (34) (42) 2 6 74 100 70 44 100 (83) (57) 1 2 1 4 52 17 19 (9) (26)

Note: Elev-elevator shaft Sew-service shaft

Smoke cancentraflons with mechanical venting and the

stairshaft pressurization system wlth exit door relief are given in Table 9. At a fire temperature of 8405 (450°C) and stair doors

on floors

1, 2, 3, and 8 open, the stalrshafl was kept smoke free while other areas were contaminated. At a fire temperature of 12204 (660"C), the stairshaft remained uncontaminated when stair doors on the first andsecond

floors and the exterior wall vents on the second

floor

were open.Similar results were obtalned with

combined

operation of mechanical venting of the second floor and other stairshaft pressurization systems with overpressure relief investigated in the experimental tower; smoke concentration patterns for these cases are given in Tables 10, 11, and 12 For the stair pressurization system with fan bypass (Table1 I), the stairshaft remained uncontaminated at

a

fire temperature of 1200°F (650°C) and the exterior wall vents open when stair doors were open on floors 1, 2, 3, and 8.PRESSURE DIFFERENCE ACROSS STAIR DOOR, Pa

PRESSURE DIFFERENCE ACROSS STAIR WOR.

INCH OF WATER

FIgun 4 Pressure difference measurements with

mechanical venting of second floor and stair pressurkation system with variable-speed fan, nonfire condition

Similar results would be expected for other pressurization systems, as demonstrated by the smoke backflow conditions reported in Tables 2, 3, 4, and 5.

SUMMARY

The performance of the stair pressurization systems operated together with mechanical venting of the fire floor

was investigated

in

the 10-story experimental fire tower. The following is a summary of observations:1. Mechanical venting alone of the fire fl& prevented smoke contamination of the experimental fire tower including the stairshaft. The whole tower, however, was contaminated with smoke when the stair door on the fire floor was opened; a greater venting rate may have prevented this from happening.

TABLE 7

Smoke Concentration Patterns with Mechanical Venting of the Second Floor Smoke concentration in percent of that in the burn area of the 2d floor

Fire temperat~re--840~F (450°C) Exhaust air rate--10.500 cfm (437 m3/s) Outside Temperature-7g°F (26OC) Wind--6 mph (10 kmh) southwest

Floor All Stair Doors Closed Stair Doors on Floors 1.2 Open Stair Door on Floom 1,2,3 Open

Stair Elw Floor Stalr Elev Floor Stalr Elev Floor

(WW) (sew) (Sew) 10 0 0 0 33 29 37 28 23 32 (0) (35) ( 3 ) 8 0 0 0 32 31 35 27 27 28 (0) ( 3 ) 6 0 0 0 28 26 27 25 20 18 (0) (34)

(W

3 0 0 0 10 10 11 8 19 7 (0) (1 5) (9) 2 0 0 100 5 17 100 8 90 100 (0) (5) (8) 1 0 0 0 0 20 1 0 10 0 (0) (30) (27)Note: Elev-elevator shaft Sew-servtce shaft

2. Combining mechanical venting and any one of the ACKNOWLEDGMENT . . . . . - - -. - - . .

--

--tested stair pressurization systems kept the stairshaft free of

---

The

author acknowledges the contribution of R.A

smoke during the fire tests with up to four open stair doors.

MacDanaId in

w i n g

our

teas in the expenmeml fireAlthough the remainder of the tower was contaminated with tower and in proossring

ine

test rewings: heelso

thanks smoke, the Smoke mncentrations were lower than for the nher m e m b e ~ d the National Fire Labratov who 85s18dcase of stair pressurization systems without mechanical

the ventincl.

3.-The rnlnlmum

average

alr velocity recorded at theopen stair dmr on the second floor during the nonfire tests with stair pressurization and mechanical venting of the fire floor corresponding to no smoke backflow was 348 fpm

(1.n mts). Thls was

for

the high-temperature fire with staird mopen

on

noon 1,2,

3, and 8 and second floor wall vents open. More studies on determining critical air velocities to prevent smoke backflow are required to determine the effects of fire temperature, venting, and number of open stair doors.REFERENCES

Tamura. G.T. 1989. "Stair pressurizatlon systems for

smoke

control: Design mnsiderations-RP-559. " ASHRAE Transections, Vot. 95, Part 2.Tamura,

G.T.1990a "Field tests of stair pressurization

systems with overpressure relief-RP-559." ASHRAE Transactions, Val, 96, Pan 1.

Tamura, G.T. 1990b. "Fire tower tests of stair pressurization systems with overpressure relief-RP-559." A S H M

Transactions,

Vol. 96,Part

2.TABLE 8

Smoke Concentration Patterns of Stairshaft Pressurization Systems with Exit Door Relief

Smoke concentration In percent of that in the burn area of the 2d floor Fire temperature--840°F (450°C)

Outside Temperature--75OF (24OC) Wind-15 rnph (25 krnh) northwest

Floor All Stair Doom Closed Except Firat

.

Stair Door on 2d floor Open Stair Door on 2d Floor OpenFloor Outside Wall Vents Open

Stalr Efev moor Stair Elm Floor Stalr Elev €loor

(Sew) ( s e w (94 . 10 0 2 11 0 22 24 0 27 17 (24) 8 0 (40) (26) 2 9 0 22 20 0 27 12 (24) 6 (41 0 (27Y\ 0 6 0 23 19 0 29 12 (23) 3 0 1 28 0 (43) 25 44 (29) 0 27 (23) 36 2 0 45 100 6 (40) 54 100 0 (24) 30 100 1 0 (47) 0 0 5 (60) 12 13 0 (54) 11 10 (0) (12) (8)

Note: Elev-elevator shaft Sew-sewtce shaft

TABLE 9

Smoke Concentration Patterns with Stairshaft Pressurization System with Exit Door Relief and Mechanical Venting of the Second Floor

Smoke concentration in percent of that in the burn area of the 2d floor Supply air rate-1800 d m (8.40 m31sk

Exhaust air rate--10.500 cfm (4.97 rn Is)

Outside Temperature-77OF (25OC) Wind--6 rnph (10 kmh) south

Floor Stair Door on Floor 1 Open Stair Doom on Floors 1,2,3,8 Open Stair Door on Floom 1,2 Open Fim 840°F (450°C) 840°F (450°C) 1220°F (660°C)

Outside Wall Vents Open

Stair Elm Floor Stalr Elw floor Sblr Elm Roor

10 0 0 0 0 16 20 0 13 13 I 8 0 0 0 0 10 20 0 3 0 6 0 0 0 0 15 17 0 11 2 1 3 0 0 0 0 5 0 0 6 0 2 0 0 100 0 7 100 0 13 100 1 0 0 0 0 5 0 0 13 1

TABLE 10

Smoke Concentration Patterns wlth Stairahaft Pressurization Svstem with Barometric Damber Rellef

and Mechanical Venting of the second Floor r 8

Smoke concentration in percent of that in the burn area of the 2d floor Supply air rate-15.500 cfm (7.32 m3k)

Exhaust air rate--10.500 cfm (4.97 m3k) Outside Temperature-73OF (23OC) Wind-5 mph (8 kmh) southwest

Floor Stalr Door on Floor 2 Open Stair Doom on Room 1,2,3,8 Open Stalr Door on Room 1.2

Fire 840°F (4SOoC) 840°F (4S0°C) 1180°F (S40°C)

Outslde Wall b n t a Open

Stalr Elev Floor Stalr E l w Floor Stair E l w Floor

(Sew) (Sew) 4-w) 0 8 10 12 0 17 21 0 12 25 (0) (1 8) (1) 8 0 13 11 0 11

-

0 15 15 (0) (0) (0) 6 0 2 0 0 17 24 0 8 24 (0) (0) (0) 3 0 0 7 0 11 0 0 7 3 (0) (0) (0) 2 0 0 100 0 16 100 0 9 100 (0) (0) (0) 1 0 0 0 0 17 3 0 10 2Note: Elev-elevator shaft Sew-service shaft

TABLE 11

Smoke Concentration Pahems with Stairshaft Pressurization System wlth Fan Bypass and Mechanical Venting of the Second floor

Smoke concentration in percent of that in the bum area of the 2d floor

-

Outside Temperature-n°F (2S°C) Wind--6 mph (10 kmh) south

floor Stalr Door on Floor 1 Clo#d Stair Door on Floom 1.2.3.8 O w n . . .

.

Strlr Dooron

Floon 1,2,3,8 Open840°F (450°C) 120O0F (S50°C)

Outride Wall VenU Open

Stair E l w Floor Stalr E l w Floor Stair E l w Floor

(sew) (sew) (Sew)

. .

2 0 57 100 0 17 100 0 3 100

1 0 (0) 0 0 0 15 (1 5 0 (0) 6 2

Note: Elev-elevator shaft Sew-service shaft

TABLE 12

Smoke Concentration Patterns with Stairshaft Pressurization System with Variable-Speed Fan and Mechanical Ventlng of the ~ e c o n d ~ l o o r

Smoke concentration in percent of that in the burn area of the 2d floor Outside Temperature--80°F (27OC)

Wind--6 mph (10 kmh) south

Floor Stalr Door on Floor 2 Open Stair Doom on F l o o n 1,2,3,8 Open Stair Door on F l o o n 1,2 Open Fire 840°F (450°C) 840°F (450°C) 111O0F (600°C)

Outslde Wall Vent8 Open Stair Eiev Floor Stair Elev Floor Stair Elev Floor

(Sew) (Sef'J) (Sew)

10 0 11 27 0 11 8 0 1 6 (23) (6) 8 0 13 26 0

-

0 0 (6) 1 0 (21) (4) (4) 6 0 5 25 0 10 16 0 3 14 (1 8) (5) (3) 3 0 0 16 0 14 0 0 5 0 (5) (3) 2 0 (I6) 9 100 0 15 100 0 5 100 (0) (27) 1 0 0 0 0 19 7 0 (1 1) 7 4 (14) (5) (3)Note: Elev-elevator shaft Sew-sewice shaft