Publisher’s version / Version de l'éditeur:

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la

première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

Internal Report (National Research Council of Canada. Institute for Research in

Construction), 2000-10-01

READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE.

https://nrc-publications.canada.ca/eng/copyright

NRC Publications Archive Record / Notice des Archives des publications du CNRC :

https://nrc-publications.canada.ca/eng/view/object/?id=83399da7-0d4b-4833-ab95-9648d3132066

https://publications-cnrc.canada.ca/fra/voir/objet/?id=83399da7-0d4b-4833-ab95-9648d3132066

NRC Publications Archive

Archives des publications du CNRC

For the publisher’s version, please access the DOI link below./ Pour consulter la version de l’éditeur, utilisez le lien DOI ci-dessous.

https://doi.org/10.4224/20378489

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at

Wind uplift resistance data of TPO roofing systems with new seaming

concepts

S e r

I TH1 National Research Conseil national Council Canada de recherches Canada

R 4 i i 7 I n o .

617

I

c.2

I

IR(Z

I

Institute for lnstitut de

Research recherche

in Construction en construction

Wind Uplift Resistance Data of

TPO

Roofing Systems with New Seaming

Concepts

G. Xu and A. Baskaran

Internal Report No. IRC-IR

817

Executive Summary

Developments of new field application technologies and tools in mechanically attached

Single Ply Roofs (SPR) have led to new seaming concepts. Conventionally, these

seams have an overlap of

5"with the fastener placed 1.5" from the edge of the under

sheet, and

3.5from the edge of the overlapping sheet. The portion of the seam beyond

the fastener row is welded with hot air such that a waterproof top surface is obtained.

The width of the welded portion varied between 1.5" and 1.75". This application is

termed as One Side Weld (OSW). Genflex Roofing Systems approached NRC' with a

concept of Double Side Weld (DSW). In the DSW, the fasteners are placed at the seam

middle and hot air welding is performed simultaneously on both sides of the fastener

row.

To investigate the DSW system performance under dynamic conditions and to compare

with those of the OSW systems, several investigations were completed. The

measurements were made in the Dynamic Roofing Facility (DRF) of the National

Research Council of Canada. More information about the DRF' s features was

documented by Baskaran and Lei (1997)'. For these investigations, SIGDERS dynamic

test protocol was used. Details of the test protocol were documented by Baskaran and

Nabhan (2000)~.

Ten experiments using five different systems were completed. Figures

1to 5 provide

isometric views of the used components in these systems whereas Tables 1 to

5group

component details and their nominal physical and mechanical properties. Figures

6to

10 show the layout of the sensors that were instrumented to quantify the system

response. Tables 6 and 7 summarize the statistics for the tested system response. By

following a common format as shown in Figure 11, Appendix 1 archive the system

response by means of the time history plots.

These data can be used to document a good practice guide for wind resistance of roofs

with flexible membrane. In addition, one can use these data to develop analytical tool to

forecast system rating.

'

Authors acknowledge GenFlex Roofing Systems for support. Authors also appreciate David Scott of GenFlex Roofing Systems and William Lei of NRC for the system installations.*

Baskaran, A. and Lei, W. (1997), "A New Facility for Dynamic Wind Performance Evaluation of Roofing Systems: Proceedings of the Fourth International Symposium on Roofing Technology, NRCA/NIST,Washington, D.C., U.S.A., pp. 168-179.

3 Baskaran, A and F. Nabhan, (ZOOO), "Standard Test Method for the Dynamic Wind Upliff Resistance of

Mechanically Attached Membrane Roofing Systems'; Internal Repofi IRC-IR 699, National Research Council, Canada.

r

Top sheet

Welded portion

Fasteners

8

plates

Bottom sheet

Polyiso Insulation

Steel deck

One Side Hot

Air Weld

4-318"P

!+ci

Top sheet

Welded portion

Fastener

& batten strip

Bottom sheet

Polyiso Insulation

Steel deck

Double Side Weld

4-318"I----_-L.l

Figore 2: System 2 -Double S~de Weld with Metal Batten Strips

Top sheet

Welded portion

12" olc

-

Fastener & batten strip

Bottom sheet

Polyiso Insulation

Steel deck

Side-view

Double Side Weld

4-318"j-

Top sheet

Welded portion

Fastener

&

batten strip

Bottom sheet

Polyiso Insulation

Steel deck

Double Side Weld

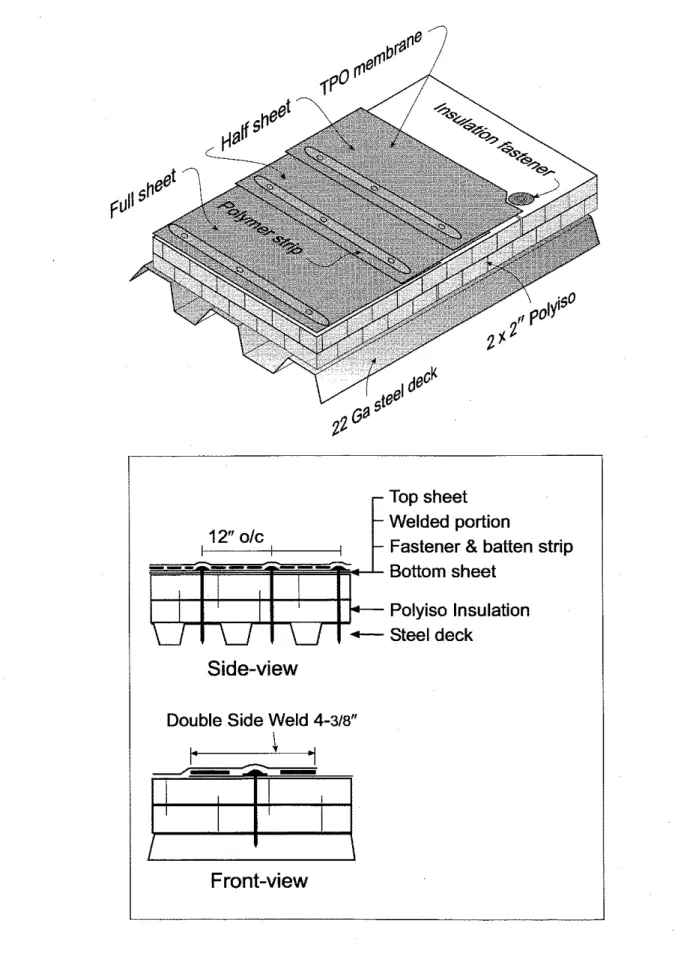

4-318''Figure 4 : System 4

-

System 3 with Full and Half Sheets LayoutTop sheet

Welded portion

12" olc

Fasteners

& plates

Bottom sheet

Polyiso Insulation

Steel deck

I

One Side Hot Air Weld

4-318"

i

,

Page 8 of 71

Table 1: System 1

-

Nominal physical and mechanical properties of the components (One Side Weld with Spot Fasteners)/

TypeI

Profiled metal sheeting 22-gaugeThickness

1

0.030 (0.76 mm)Depth

1

1.5" (38 mm)Flllte Snacinn

1

59" (150 mmb.

-E---... I . - - ...-,Fastener Pullout as per ANSIISPRI FX-1-1996*

1

470 lbf (21 20 N)I VirWest Steel I

lnsulation

Type

/

Polyiso ( E ' N R G ' Y ~ ~ )Dimension

/

2 boards of 4' x 8' (1218 mm x 2436 mm) xCompressive Strength as per ASTM D l 621 -94- Source AirNapor BarrierlRetarders

I

None used 2" thick (50.8 mrnj 18.8 psi (1 30 kPa) Johns Manville Insulation Attachmentf

i

embrane Fastener Plate Fastening Pattern SourceAssembled 5" (128 mm) screws & plates 3" (77 mm) plastic lock plate

4 fasteners per board Olympic Membrane

I_

I ype Width ThicknessTensile property as per ASTM D 751-98 (Grab)*

Attachment

TPO

74 718" (1 910 mm) 45 mil (1 .l mm)

MD XD

Breaking strength, kN (Ibf) 1.3(293) 1.1 (248)

Elongation at Max. load, % 29 29

-

Type Fastener" Plate

Fastener Row Spacing Fastener Spacing Slippage Control

Mechanical fasteners with plates 5" (128 mm) Genfast #15

2 38" (61 mm) Dia. metal plate

70

in"

(1 790 mm) 12" (305 mm) Yes Seam Type Seaming Weld ConditionHot air welding

Overlap: 4 38" (1 11 mm) Type: One Side Weld

Good Weld Cold Weld

Temperature: 950 'F (510

'

C

) 500 'F (260 'C )Speed: 7.9' Irnin(2.4m/min) 11.8'/min(3.6m/rnin)

Weight: 1 weight (6 lbs) 1 weight (6 lbs)

Table 2: System 2

-

Nominal physical and mechanical properties of the components (Double Side Weld with Metal Batten Strips)Type Thickness

Depth

Flute Spacing

Fastener Pullout as per ANSIISPRI FX-1-1996'

Sn, WPP

Insulation Attachment

Profiled metal sheettng 22-gauge 0.030" (0.76 mm)

1 . 5 (38 mm) 5 . 9 (150 mm)

470 lbf (2120 N)

VirwD~t S ~ D D ~

Compressive Strength as per ASTM D l 621 -94* Source 2" thick (50.8 mm) ' 18.8 psi (130 kPa) Johns Manville AirNapor BarrierlRetarders

I

None used Type Fastener Plate Fastening Pattern SourceMechanical fasteners with plates

Assembled 5 (128 mm) screws & plates 3 (77 mm) plastic lock plate

4 fasteners per board Olympic Membrane

.

. . -. .-

.--

.-

. .-

.-

. .., ;enfast #15 (XHD) -- :, u.u41" (1.20 mm)thi_ck- --. . . - Type Width ThicknessTensile property

as

per ASTM D 751-98 (Grab)'Membrane Attachment f u irz (1790 mm) 12" (305 mm)

.

, TPO 74 718" wide (1910 rnm) 45 mil (1 .l mm) MD XD Breaking strength, kN (lbf) 1.3(293) 1.1 (248)Elongation at Max. load, % 29 29

Type Fastener* Plate

Fastener Row Spacing Fastener Spacing Slippage Control

Seam

Metal batten strin and fasteners

I

5 (1 28 mm) C

1

"

wid€ ^ ^"--

. .-8,-

yes

I

Type

I

Hot air weldingSeaming

I

Overlap: 4 318" (11 1 rnm)I

Weld ConditionT e: Double Side Weld

Good Weld Cold Weld

Temperature: 950

V

(510 % ) 801 *F (427 'C ) Speed: 6.5'1rnin (2 mlmin) 9.8'lmin (3 mlmin) Weight: 1 weight (10 lbs.) 2 weight (2x10 lbs.)L

I

I

Position: in normal position inner side* NRC test results

Table 3: System 3

-

Nominal physical and mechanical properties of the components (Double Side Weld with Polymer Batten StripsJThickness

1

0.030 (0.76 mm) Depth -. - .1

1.5 (38 mm) ' i" (1 52 mm) i85 lbf (3050 N) Flute Spacing 16Fastener Pullout as per ANSIISPRI FX-1-1996-

16

Snl ~ r c e I

,

r

3anam SteelI

Insulation

Type

I

Polyiso (E'NRG'Y2IM)Dimension

1

2 boards of 4' x 8' (1218 mm x 2436 rnm) xzal fasteners with plates

28 mm) screws & plates

Plate

1

3" (77 mm) plastic lock plateFastening Pattern

/

4 fasteners per boardSnl l r ~ p I nltnnnir

Compressive Strength as per ASTM D l 621 -94* Source AirNapor Barriermetardew None used 2" thick (50.8 mm)' 18.8 psi (1 30 kPa) Johns Manville Membrane Type

/

TPOWidth

1

74 718" (1910mm) wide sheets, Lot # 30144,colorBreaking strength, kN (Ibf) 1.3(293) 1.1 (248)

Elongation at Max. load, % 29 29

Thickness

1

45 mil ( I . l mm)Membrane Attachment

Tensile property as per ASTM D 751-98 (Grab)

'

--- - -

-,

-nd fasteners1

MD XD Type Fastener*.

-

. .

-

,

. .

- -

. .

. . . .

-

. .

,

12" (305 mrn) . -. . -.I

Slippage ControlI

YesI

Polymer batter :!!; :

5" (128 mm) Genfast #15 (WH)

1

Ratten Strip 1" wide, 0.057" (1.45 mm) thicktener Rnw Snadnn 71) i 17" 11 741) mrnl

Seam Type Seaming

Hot air welding

Overlap: 4 318" (1 11 rnm) Type: Double Side Weld Welding Condition

Temperature: 950 'F (51 0 ' C )

Speed: 6.5'lmin (2 mlmin) Weight: 1 weight (10 lbs.) * NRC test results

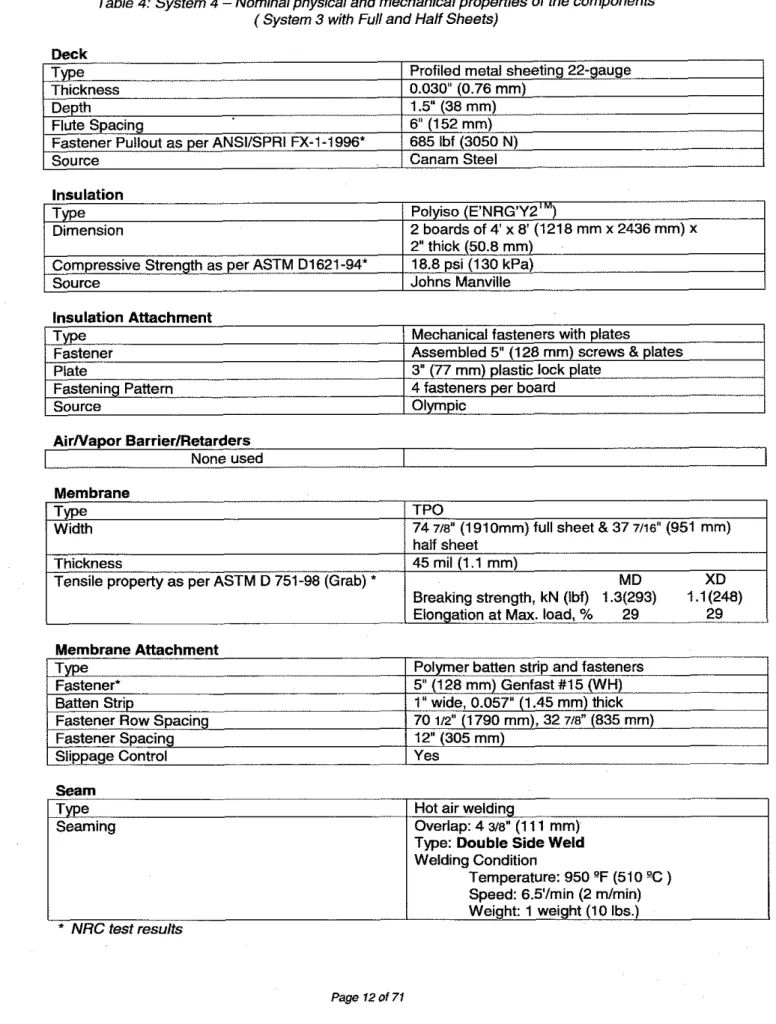

Table 4: System 4 - Nominal physical and mechanical properties of the components (System 3 with Full and Half Sheets)

Deck

Type

I

Profiled metal sheeting 22-gaugeThickness

1

0.030 (0.76 mrn)Insulation

Type

/

Polyiso(t'runtivz

)Dimension

1

2 boards of 4' x 8' (121 8 mm x 2436 rnm) xDepth

Flute Spacing

Fastener Pullout as per ANSIISPRI FX-1-1996' Source

1

2" thick (50.8 mm)Compressive Strength as per ASTM D1621-94'

1

18.8 psi (1 30 kPa)Source

I

Johns Manville1.5" (38 mm) 6 (1 52 rnm) 685 lbf (3050 N) Canarn Steel AirNapor BarrierIRetarders None used Insulation Attachment Membrane Type

/

TPOWidth

/

74 718" (1910mrn) full sheet & 37 7/16" (951 rnm)Type Fastener Plate

Fastening Pattern Source

Mechanical fasteners with plates

Assembled 5" (128 mm) screws & plates 3 (77 mrn) plastic lock plate

4 fasteners per board Olympic

Membrane

Type

,

.

-..

,

. .

.- .

I-..-.

.

-..

.

-

Fastener*

1

5" (128 mm) GBatten Strip

I

1"

wide, 0.057 (1.43Thickness

Tensile property as per ASTM D 751-98 (Grab) *

half sheet 45 mil (1.1 rnm)

MD XD

Breaking strength, kN (Ibf) 1.3(293) 1.1 (248)

Elongation at Max. load, % 29 29

Welding Condition

Temperature: 950 'F (51 0 % )

Speed: 6.5'lrnin (2 rnlrnin) Weight: 1 weight (10 lbs.) * NRC test results Seam Type

p

Page 12 of 71 Seaming Overlap: 4 318" (1 1 1 rnrn)Table 5: System 5

-

Nominalphysical and mechanical properties of the components (System 1 with Foll and Half Sheets)Deck Type Thickness Depth

Flute Spacing

Fastener Pullout as per ANSllSPRl FX-1-1996- Source

Insulation

(

Source(

Olympic-

Profiled metal sheeting 22-gauge 0.030 (0.76 mm) 1.5 (38 mm) 6" (1 52 mm) 685 lbf (3050 N) Canam Steel Type Dimension

Compressive Strength as per ASTM D1621-94* Source Insulation Attachment AirNapor BarrierlRetarders

I

None used Polyiso (E'NRG'Y2IM) 2 boards of 4' x 8' (1218 mm x 2436 mm) x 2 thick (50.8 mm) 18.8 psi (1 30 kPa) Johns Manville Type Fastener Plate Fastening Pattem Membrane Type1

TPOWidth

1

74 718" (1 910 mm) full sheet & 37 7/16" (951 mm)Mechanical fasteners with plates

Assembled 5 (128 mm) screws & plates 3 (77 mm) plastic lock plate

4 fasteners per board

Thickness

Tensile property as per ASTM D 751-98 (Grab)"

half sheet 45 mil (1 .l mm)

MD XD

Breaking strength, kN (Ibf) 1.3(293) 1.1 (248)

Elongation at Max. load, % 29 29

Membrane Attachment Type

Fastener* Plate

Fastener Row Spacing Fastener Spacing Slippage Control

Seam

Metal plates and fasteners 5" (128 mm) Genfast #15 (XHD)

2 318" (61 mm) dia. Metal plate 70 112" (1790 mm), 32 718'' (835 mm) 12" (305 mm)

Yes

Type Seaming

Hot air welding

Overlap: 4 318" (1 11 mm) Type: Single Side Weld Welding Condition

Temperature: 950 'F (51 0

'

C

)Speed: 7.9'1min (2.4 mlmin) Weight: 1 weight ( 6 lbs.) NRC test results

L

SIGDERS Table 236" x 79"SIGDERS

Table 236"

x 79"Note: Two tests were done with System 2

-

Test 0802 employed one pressure sensor (PI) while Test 0806 employed two pressure sensors (PI.,, PI.d.Figure 7: System 2

-

Instrumentation Layouti

SW=

4-318''L

SIGDERS Table 236" x 79"L

SlGDERS Table 236" x 79"Figure 9: System 4

-

Instrumentation LayoutL

SlGDERS Table 236" x 79'Figure 10: System 5 -Instrumentation Layout

Table 6: Wind uplift resistance data using SIGDERS protocol

-

Imperial Units System System 1I

and tear Test Number 08991201 System 2 I I I I I System Zc I I I I I Pressure* Psf W60 08991202 System lc System 1, System 2~ 08991203 I I I I I Load* I bf W254 9011 05 08991204 08991205 0800061 5 System 3 I I I I I W60 System 4 System 5 I I I I I I*

Value before the forward slash: the maximum (pressure, load or deflection) the system sustained; value after the forward slash: at which the system failed. Example: 90/105 in the Pressure column means the system sustained a pressure of 90 psf but failed at 90 psf.Xmeans not applicable; C denotes cold weld; R denotes repeated test; D denotes tests on a deck with pullout resistance of 690 lbf.

Deflection* In W10.1 3881446 W60 60175 75190

I

0800061 6 I I I I,

Table 7: Wind uplift resistance data using SIGDERS protocol

-

SI Units Failure Mode Membrane delamination W269 08000617 0800071 9 System 5, 8.519.5 W1 4 4 2781255 3581396 10511 20 Fastener pullout Xn.0 120KI

08000720 Seam delamination W5.8 7.718.4 7.818.4 5061555 Membrane tear at C4 75/90 Seam delamination Membrane delamination and tear at 84 Membrane tear 500K 9.219.4 3 1 51246 Membrane tear At EM 60175 Fastener pullout 9.7K 8.218.7 Passed 120 psf 273121 3 6.917.4System

I

Test1

P r e ~ ~ u r e *1

Load' Deflection* FailureNumber Mode

I t I I I

System

2

,

1

0819991203

1

XI2873

1

XI1195

I

W178

I

Seam delamination System 1 System2

0819991201

081

9991

202

I

I

I

I

I

System 1 R System2~

I I I I ISystem

5

1

08000719

1

359114309

1

140011093

1

2081221

1

Membrane tear atC4

XI2873

430915027

Systeml c

System3

System4

I

I

I

I

I

System

5R

1

08000720

1

287313591

1

121 31947

1

1751188

1

Membrane tear at 84W640

081

9991205

08000615

1

I

I

Value before the forward slash: the maximum (pressure, load or deflection) the system sustained; value after the forward slash: at which the system failed. Example: 90/105 in the Pressure column means the system sustained a pressure of 90 psf but failed at 90 psf.

Xmeans not applicable; C denotes cold weld; R denotes repeated test; D denotes on

a deck with ~ u l l o u t resistance of 690 lbf.

W1127

172411982

0819991204

08000616

0800061

7

Page 22 of 71XI2873

W1

47

287313591

359114309

W255

21 61241

Seam delamination502715746

5746K

Membrane delamination and tear Fastener pullout123611 133

I59111760

224912466

2222K

196121 3

1981213

Membrane delamination and tear at84

Membrane tear2341239

246lX

Fastener pullout Passed120

psfWeld Type

(1 W = One Side Weld or 2W = Double Side Weld or CW = Cold Weld or GW = Good Weld) System Response (Pressure or Load or Deflection) Fastener Pullout

I

I

ResistanceI

(470 lbf or 680 IbD Sensor Location

A

(as shown in Fig 6 to 10)

Response Fastener Spacing

(72")

Figure 11. Generalized Format for the Time History Plots Grouped in Appendix 1.

-

System Details

S1

System Detail

(as

shown in Fig 1 to 5)-

Fastener Row Spacing

(70

in"

or 32 7/8'1Appendix 1

Time History Plots Using

SIGDERS

Test Protocol

400 cycles

<a

500 cycles<q

800 cycles<a

11 OO cycles<q

Grgup 1

/ %A

en25 25

2200 cycles<-I

"

12

3

4

5

67 8

Loading sequence

-

I S1; Fr=70 112"; Fs=12"; Fp=470 Ibf; IW-GW; Pressure O Pref: Fig 61

120

10000 20000 30000 40000

Time, sec

OBDIWS1; Fr=70 112"; Fs=12"; Fp=470 Ibf; 1W-GW; Pressure O -- PI: Fig 6

120 1 I I

I

10000 20000 30000 40000

S1; Fr=70 . . l/Z ; Fs=12 ; Fp=470 Ibf; 1W-GW; Load @ L4Z: Flg 6

10000 20000 30000 40000

Time, sec

~ I U ZS1; Fr=70 1R"; Fs=12"; Fp=470 Ibf; 1W-GW; Load @ 152: Fig 6

10000 20000 30000

Time, sec

S1; Fr=70 112"; Fs=12"; Fp=470 Ibf; 1W-GW; Load O L5X: ~ i g 7 I I I I I

I

0 10000 20000 30000 40000Time, sec

O B D t ~ l 100 80-

60-

-

s

a

A 40/

~ 1 ; ~ ~in9,;

~ Fsz12"; ~ p = 4 7 0 7 0 ~ b f ; IW-GW, Deflection @ D l : Fig 6116

I

I 20

0

0 10000 20000 30000 40000

Time, sec

OBO-LSXi

- .. .. .

i -

/

S1; Fr=70 1 W ; Fs=12"; Fp=470 Ibf; 1WGW; Deflection @ DZ: Fig 610 10000 20000 30000 40000

Time, sec

080102-- - - -- - -.-

1

S2; Fr-70 I R " ; Fs=12"; Fp=470 Ibt; 2W-GW; PressureB

~ref-10000 20000 30000 40000

Time, sec

w p e r10000 20000 30000

Time, sec

/

~ 2 ; Fr.70 112"; Fs=12"; Fp=470 IM; 2 W d W ; Pressure 8 PI: Fig 71120 90

-

I

I 90 90 1 5I

75I

1

79LSZ

Fr.70 112"; Fs=12"; F p 4 7 0 Ibf; 2W-GW; Load @ ~ 4 2 ~ E g g 0 10000 20000 30000 40000Time, sec

-Lb2 0 10000 20000 30000 40000Time, sec

-

Page 32 of 71 500 52; Fr=70 112"; Fs=12"; F p 4 7 0 lbt; 2 W d W ; Load @ LSZ: Fig 71

I

k r = 7 0 I n " ; ~ ~ 1 2 " ; Fp1470 IM; 2W-GW; Load 8 L5X: Fig 7

100

10000 20000 30000 40000

Time, sec

-XI

52; Fr=70 I @ " ; Fs=12"; Fp.470 Ibf; 2W-GW; Deflection 8 Dl: Fig 710 , I I

I I I

0 10000 20000 30000 40000

& - d s l M

Time, sec

O B ~ D ~

. . . . - . . . . . - . . . .

52: Fr-70 In4'; Fs=12'; Fp=470 Ibf; 2W-GW: Deflection Q D2: Fig 7

.. . . . . . .

10000 20000 30000 40000

Time.

sec DBDIDZ;.

52; Fr=70 112 , Fs=12"; Fp=470 Ibt; 2W-CW; Pressure 8 Pref. Fig 7

120

10000 20000 30000 40000

Time, sec

~ n t152; Fr=70 112"; Fs=12"; Fp=470 lbf; 2W-CW; Pressure 8 PI: Fig

7/

120

I

,

I

10000 20000 30000 40000

5 2 ; Fr=70 In"; Fs=12"; Fp=470 Ibf; 2W-CW; Load 8 L4Z: Fig 7

/

0 10000 20000 30000 40000

Time, sec

-I.u1

52; Fr=70 1R"; Fs.12"; Fp=470 Ibf; 2W-CW; Load 8 L5Z: Fig 71

500

0 10000 20000 30000 40000

Time, sec

O $ ~ E!

52; Fr.70 112"; Fs=12"; Fp.470 Ibf; 2W-CW; Load Q L5X: Fig 71,

. 10000 20000 30000 40000Time, sec

~ m a 5 ~ 10000 20000 30000 40000Time, sec

080301 -52; Fr.70

In";

Fsn12"; Fp.470 IM; 2W-CW; Deflection 8 Dl: Fig 716

I

I

Page 38 of 71

1

S2; Fr=70 112 8%.,

Fs.12"; Fp=470 Ibf; 2W-CW; Deflection @ D2: Fig 740000 16 12

-

C-

.-

m C 0.-

t;

8 -Time,

sec em^7.0 ! ! - 0

-

I i 0 10000 20000 300001 ST; Fr=70 1R"; Fs=12"; Fp=470 Ibf; IW-CW; Pressure @ Pref: Fig 61

-

120

10000 20000 30000 40000

Time. sec

O~OIPR~I0000 20000 30000 40000

Time, sec

W P ~1

S1; Fr=70 In"; Fs=12"; Fp=470 lbf; 1W-CW; Pressure 8 P I : Fig 6i 120 90

-

m P 60 m2

P 30-

-

-Pt=6Op~f ;-

-

-I 30I

~

I

0.

--

S1; Fr-70 112''; Fs=12"; Fpd70 lbf; 1 W C W ; Load @ L52: F8g 6

/

ST; ?r=70 112"; Fs=1Zn; Fp.470 Ibf; 1 W-CW; Load 8 L4Z: Fiw.10000 20000 30000 40000

Time, sec

0BaU_5L500 400

-

300s

d

m 0 -I 200 Page 40 of 71 83 0 10000 20000 30000 40000Time, sec

camcAzI

I

I - ~. .- ...1.

144100 80

"-

60 Q-

$

0 -1 40 20 10000 20000 30000 40000Time, sec

m ~ c . 11

S1; Fr=70 1R"; Fs=12"; Fp=470 Ibf; 1W-CW; Deflection @ Dl: Fig 6S1; Fr=70 ~~ 112"; . Fs=12"; Fp=470 Ibf; 1W-CW; Load @ L5X: Fig 6

j I I I 16 12 C

.-

-

E

'S 8 0 ac

8

0-

I 0 10000 20000 30000 10 40000i

1I

Time, sec

DBD~LSX 5.5 I -- 4.4 4-

0I

Page 42 of 71 m = 7 0 112"; Fs=12"; Fp=470 Ibf; 1W-CW; Deflection 4202: ~ i g c 16 12 (I:

-

-

" s 0-

i i 8

al=

al 0-

- 5.8 I I ! (i

I I I 0 10000 20000 30000 40000Time. sec

cm4m ! 1/

S1; Fr=70 I n " ; Fs=12"; F p = 4 T O ~ f ~ i W ~ W ~ P ~ s s ~ ~ B Pref: Fig 61120

0

0 10000 20000 30000 40000

A m p a t O f s l t e r t

Time, sec

WRdSI; Fr=70 i n a a ; Fs=12"; Fp=470 IM; IW-GW; Pressure PI: ~ i g 6

. . . . - . . . . - . . . . - - -. . . .. . . - . . . .

0 10000 20000 30000 40000

r\-Ofnm

I

S

;

'

-500 400-

300e

d

8

-I 200 100 00

0 10000 20000 30000 40000 A - ~ s z mTime, sec

m 5 ~1

S l ; Fr=70 112"; Fs=12"; F p 4 7 0 Ibf; IW-GW; Load 63 L5Z: Fig 61

500 400 .+ 300e

d

8

-I 200 100 0 ,I

1

1

4

I I I 0 10000 20000 30000 40000a-tdSj-

Time,

sec DM-)

S1; Fr=70 112"; Fs=12"; Fp=470 Ibf; 1W-GW; Load @ L~X- 100I

I

I I, II

0 10000 20000 30000 40000 A ~ ~ ~ $ -Time, sec

m L 5 xS1; Fr=70 l a " ; Fs=12"; Fp.470 Ibf; IW-GW; Deflection @ D l : Fig 6

16 12 I c

.-

"-

i j 8 a, Gp " .

4-

0 0 10000 20000 30000 40000 ~ - m ~ t e e tTime, sec

-t -- ! ij

8.1I S1; Fm70

In";

Fs=12"; Fp=470 Ibf; I W-GW; DeflectionB

D2: Fig6(

0 0 10000 20000 30000 40000 A r n p s t d d t u tTime. sec

0805D2 Page 46 of 711

52; Fr=70 ID"; Fs=12"; Fp=690 Ibf; 2W-GW; Pressure - O Pref: Fig 71 -.120

10000 20000 30000 40000

Time,

sec

-

1

52; Fr=70 1R"; Fs=12"; Fp690 Ibf; 2W-GW; Pressure 8 P1-1: Fig 7120 I

10000 20000 30000 40000

1

52; Fr=70 112"; Fs=12"; Fp=690 IM; 2W-GW; Pressure @ PI-2: Fig 7110000 20000 30000 40000

Time, sec

WSPI*52; Fr=70 112"; Fs=12"; Fp=690 Ibf; 2W-GW; Load @ L4Z: Fig 71

500

10000 20000 30000 40000

Time, sec

~10000 20000 30000 40000

Time,

sec

-UX1

52; Fr=70 1R"; ~ & 1 2 " ; Fp.690 Ibf; 2W-GW; Load Q L4X: Fig 71100

S2; Fr=70 1R"; Fs=12"; Fp.690 Ibt; 2W-GW; Load @? L5Z: Fig 71

5

m

1

I

10000 20000 30000 40000

Time, sec maELsz

1

S2; Fr=70 112"; Fs=12"; Fp=690 Ibf; ZW-GW; Load @ L5X: - Fig 7/

100

1

I

I

I

10000 20000 30000 40000

Time, sec

1

52; Fr-70 112"; Fs.12"; Fp=690 IM, ZW-OW; Deflection @ D l : Fig 71l6

6

II

I

I I I 0 10000 20000 30000 40000Time, sec

-1 Page 50 of 7110000 20000 30000 40000

. . .. . . . ... . .

S3; Fr=70 I n " ; Fs-12"; Fp.690 Ibf; . . . . - . . . . . . . . . . . . . . - . . . 2W-GW; - . . . Pressure . . . . . - -. . 8 Pref: Fig 8 . . .

1

10000 20000 30000 40000

Time,

sec

w p r e t/

S3; Fr=70 1R"; Fss12"; Fp=690 Ibf; ZW-GW; Pressure 8 PI-I: Fig 810000 20000 30000 40000

Time, sec

~ ~ t - ,10000 20000 30000 40000

Time, sec

0 ~ 1 . 21

S3: Fr=70 112": Fs=12": Fo=690 Ibf: 2W-GW: Load 8 L3Z: Fia 8110000 20000 30000 40000

I

S3; Fr=70 1R"; Fs=12"; Fp=690 Ibf; ~ w - G W R" I I I I I

0 10000 20000 30000 40000

Time,

sec -a1

53; Fr.70 IR"; Fs=12"; Fp~690 Ibf; 2W-GW; Load O L3X: Fig 81100

I

10000 20000 30000 40000

Time, sec

oemwi

53; Fr=70 112"; Fs=12"; Fp=690 IM; 2W-GW; Load Q L4X: Fig81 100i

10000 20000 30000 40000Time, sec

~X Page 55 of 71E 7 0I D " ; Fs=12"; Fp=690 Ibf; $-GW; Deflection Q Dl: Fig 81 16 12 s

-

"s

0.-

'ii

8 al=

4 I 0---

10000 20000 I 30000 I 40000 0Time, sec

~ m m/

53; Fr=70 IR"; Fs=12"; Fp=690 Ibf; 2W-GW; Deflection 63 02: Fig 81 . 16 12 C.-

rn C 0.-

Z i 8 a,=

8

4 0 0 I0000 20000 30000 40000Time, sec

D B ~ M Page 56 of 7154; Fr=70 IW, 32 718"; Fs=12"; ~ & 9 0

IG;

2 ~ - G W ; Pressure @ Pref: Fig 91

10000 20000 30000 40000Time, sec

O B O B ~ ~.~ 54; Fr=70 I n " , 32 718"; Fs=12"; Fp=690 Ibf; zW-GW; Pressure 8 P I - 1 : m I I I I 10000 20000 30000 40000S4; Fr=70 l a " , 32 7B"; ~ s = 1 2 " ' ~ ~ = 6 9 0 IM; 2W-GW; Pressure 8 PI-2: Fig

10000 20000 30000 40000

Time, sec

m P ~ a1

S4; Fr=70 I/2", 32 7m"; Fs=12"; Fp=690 IM; 2W-GW; Load @ L3Z: Fig 910000 20000 30000 40000

Time, sec

-L9/

54; Fr=70 1/2", 32 718"; Fs=12"; Fp=690 - Ibf; 2W-GW; Load @ L4Z: ~ i g F10000 20000 30000 40000

Time,

sec mZ. . - . .- . .- - -

S4; Fr.70 112', 32 7 W ; Fs=12"; Fp-690 Ibf; 2W-GW; Load @ L3X: Fig 9

. . . . .. . . . - - - . . - . . . . - -. . . . .. . . -. . . . - -. . .

10000 20000 30000 4&00

1

54; Fr-70 I n u u , 32 718"; ~s=12";~p=690 IM; 2W-GW; Load @ L4X: ~ i g 4 ~100

10000 20000 30000 40000

Time, sec

-UX1

54; Fr=70In",

32 718"; Fs=12"; Fp=690 Ibf; 2W-GW; Deflection 8 Dl: Fig 9116

10000 20000 30000 40000

Time, sec

010811154; Fr=70 IR", 32 - 718"; Fs=12"; Fp=690 IM; 2WGW; kflection @ D Fig 9 1 16 12 E

.-

mc

0.-

z 8

a3 E8

4 0 0 10000 20000 30000 40000Time,

sec -02. . . . S5; ~ r = 7 0 ID", 32 7m"; Fs=12'; Fp=6901bf; IW-GW; Pressure @ Pref: Fig10

.- . . . ...

0 10000 20000 30000 40000

Time, sec

~

/

S5; Fr=70In",

32 718"; Fs=12"; Fp.6901bf; IW-GW; Pressure B Pl-1: Fig10110000 20000 30000 40000

Time, sec

0 ~ o ~ p l - t155; Fr.70 l R " , . 32 718"; Fs=12"; Fp=6901bf; 1W-GW; Pressure @ P1-2: ~ i ~ l 0 ' 120 10000 20000 30000 40000

Time, sec

B B W ~ ~ . Z 10000 20000 30000 40000Time, sec

0800w1

~ 5 ; Fr=70 l a " , 32 718"; Fs=12"; Fp=6901M; 1W-OW; Load @ L3Z:6%

500 400-

I

I 3151

55; Fr=70 I W , 32 718"; Fs112"; Fp=6901M; 1W-GW; Load 8 L4Z: - Fig - 10j ..500

o

10000 20000 30000 40000

Time, sec

wuz/

S5; Fr=70In",

32 7B"; Fs=12"; Fp=690iW 1W-GW; Load @ L3X: Fig 1 0100 80

-

60 Ga-

8

A 40 20 0 10000 20000 30000 40000Time, sec

owux0

0 10000 20000 30000 40000

Time, sec

DBWUU; S5FFi=70-ili1r327/8"; F X 2 ' ; Fp=6901bt; 1 W G W ; D e f l e c t b n ~ @ ~ D E F g i O ~

I

I I

0 10000 20000 30000 40000

10000 20000 30000 40000

Time, sec

0 8 0 9 ~ ~1

S-r=70 IR". 32 718"; Fs.12"; Fp=6901bt; IW-GW; Pressure @ Pret Fig i t i120

10000 20000 30000 40000

Time, sec

rnl0pnfI

S5; Fr=70 I R " , 327/8"; Fs=12"; Fp~6901bt; 1W-GW; Pressure B PI-1: Fig 101120

10000 20000 30000 40000

! ~ 5 ; Fr=70 ID", ~~ .. 32 7 ~ " ; Fs=12"; Fp=6901bt; IW-GW; pressure 8 PI-2-

120

!I0000

20000

30000

40000

Time, sec

0B101.2/

S5; Frs70 112", 32 7B"; Fs=12"; Fp=6901bf; I W G W ; Load 8 L3Z: Fig 101

500

1

W O O

20000

30000

40000

Time, see

OBIOLtl1

S5; Fr=70 1/2", 32 718; FS=12"; Fp=6901bf; - IW-GW; Load 8 L4Z: Fig 10110000 20000 30000 40000

Time, sec

-1OLUI

S5; R=70 112", 32 718"; Fs=12"; Fp=6901bf; 1W-GW; Load 8L3~rFia

100

I

0 0

0 10000 20000 30000 40000

. - . . . .. . .

S5; Fr=70 I n " , 32 718"; Fs=12"; Fp~6901bf: 1W-GW; Load 8 L4X: Fig 10

. -. .. . 100

10000 20000 30000 40000

Time, sec

OQIDUX-p--p ~ p~~~ ~~~~~.~ . .. .. .. ~~ ~ ~~- -~-~ ~p S5; Fr=70 l R " , 32 718; ~ s G 2 " ; Fp.6901M; 1W-GW; Deflection @ Dl: Fig 101 16 10000 20000 30000 40000

Time, sec

W I D 1 Page 70 of 71. . . .

S5; . .. Fr=70 112". 32 718"; ~ c i E ~ p = 6 9 0 1 b f ; .. . IW-GW; Deflection B D2: Fig 10

3 .

-10000 20000 30000 40000

Time, sec 081002