Publisher’s version / Version de l'éditeur:

Construction Technology Update, 1999-12-01

READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE.

https://nrc-publications.canada.ca/eng/copyright

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

NRC Publications Archive

Archives des publications du CNRC

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at

Effective installation of membranes on parking garage decks

Mailvaganam, N. P.; Collins, P.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

NRC Publications Record / Notice d'Archives des publications de CNRC:

https://nrc-publications.canada.ca/eng/view/object/?id=520ffe0c-5ed6-4403-99d5-9f87bacbf3c7 https://publications-cnrc.canada.ca/fra/voir/objet/?id=520ffe0c-5ed6-4403-99d5-9f87bacbf3c7

C o n s t r u c t i o n T e c h n o l o g y U p d a t e N o . 2 9

Th e con crete d eck in p arkin g garages m u st be p rotected again st th e in gress of w ater an d ch lorid e ion s. In gress can lead to corrosion of rein forcem en t an d even tu ally to seriou s d egrad ation of th e d eck, even stru ctu ral im p airm en t. Th e stan d ard p ro-tective m easu re is to in stall an elastom eric w aterp roofin g m em bran e system (Figu re 1).

Th e effectiven ess of th e m em bran e system in restrictin g th e in gress of w ater in to th e concrete deck depends not only on its material

p rop erties bu t also on h ow w ell it is in stalled . Poor on -site p ractice an d an in d ifferen ce to qu ality con trol d u rin g in stallation often p rod u ce a fin al p rod u ct of d u biou s p erform an ce an d d u rability.

Ap p lication p roblem s u su ally lead to p ron ou n ced d efects th at w ill act as w eak areas d u rin g th e m em bran e’s service life.1,2 Defects

can be p resen t in n u m erou s form s: blisters, u n even colou rin g, craters, su rface p in h oles, d elam i-n atioi-n s, ai-n d u i-n cu red (w et) areas. Th ese d efects u su ally lead to d eterioration of th e d eck.

A typ ical w ater-p roofin g m em bran e system con sists of a series of coats or layers. First, th e p rim er or sealer, w h ich p rom otes ad h esion of th e

m em bran e to th e con crete; n ext, th e w ater-p roof m em bran e itself, w h ich brid ges cracks an d p reven ts th e in gress of ch lorid e ion s an d w ater; th en com es th e w ear coat, w h ich con tain s em bed d ed aggregate to p rovid e abrasion resistan ce an d p reven t w ear of th e m em bran e; an d fin ally, th e tie coat, w h ich bon d s th e aggregate firm ly to th e w ear coat.

Th e typ es of coatin gs u sed in m em bran e system s in clu d e th e follow in g: one-compo-nent polyurethane; two-compoone-compo-nent

polyurethane; two-component epoxy-urethane an d on e-com p on en t w ater-based n eop ren e.

Variation s in ch em ical com p osition an d m ix ratios in th e d ifferen t m em bran e system s govern th e ap p lication ch aracteris-tics an d th e d egree of sen sitivity to site factors.

Effective Installation of

Membranes on Parking

Garage Decks

An IRC/ in d u stry con sor-tiu m p roject con d u cted in th e 1980’s fou n d exten sive d eterioration of con crete d ecks in p arkin g garages across Can ad a. Th e stu d y led to recom m en d ation s for th e im p roved d esign of th ese garages to p rovid e better p rotection again st m oistu re an d ch lorid e ion s.

For an overview of elastom eric m em bran es, read ers can con su lt th e article, “An Elastom eric Mem bran e System for Parkin g Decks,” Con stru ction Practice (available on th e IRC Web site).

Figure 1.Application of an elastomeric water-proofing membrane system by spraying and back rolling

b y N.P. Ma ilv a ga na m a nd P.G. Collins

This Update discusses how the preparation of the substrate, prevailing

ambient conditions and application practices affect the performance of

membrane systems installed on concrete decks in parking garages.

2

Fa c t ors Affe c t ing M e m bra ne Syst e m s

Th e m ain gu id e for th e p rop er ap p lication of a m em bran e system is th e m an u factu rer’s in stru ction s. Problem s arise w h en th ese in stru ction s are ign ored for th e sake of exp ed ien cy.

Th e p roblem s th at affect th e p erform an ce of w aterp roofin g m em bran e system s can be summarized under three categories. These are: 1) ap p lication factors: m ixin g of com p on en ts

at cold tem p eratu res, p oor m ixin g of th e com p on en ts, in correct p rop ortion in g of th e com p on en ts, an d d elayed ap p lication of th e m ixed com p on en ts;

2) su bstrate con d ition s: m oistu re in th e su bstrate an d p oor su rface p rep aration ; 3) am bien t w eath er con d ition s: variation s

in h u m id ity an d tem p eratu re.

IRC research , con sistin g of both field in vestigation s an d laboratory stu d ies, h as led to a n ew u n d erstan d in g of th e effect of th e above factors. Som e p ractical gu id elin es are p resen ted below.

Application Factors

Mixing a t cold te m p e ra ture s. Man y ap p

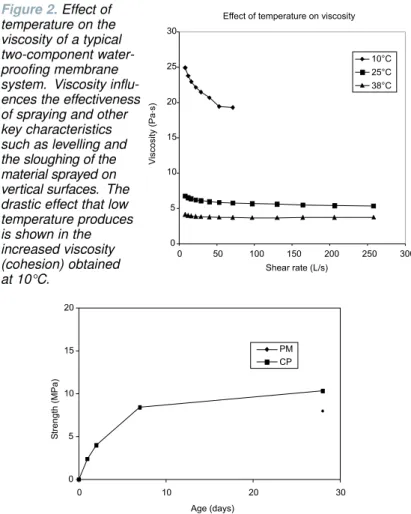

li-cators store the coating components overnight in tru cks an d m ixin g at cold tem p eratu res is n ot in frequ en t. Cold tem p eratu res affect m em bran e in stallation m ore than high tem-peratures. At cold temperatures th e in crease in viscosity cau ses im p rop er m ixin g, m akin g it m ore d ifficu lt to ap p ly th e m em bran e system an d to ach ieve th e d esired coatin g th ickn ess for each of th e layers; both p rop er mixing and application are critical to achieving good w aterp roofin g ch aracteristics. Th e resp on se of coatin g com p on en ts to tem p era-ture variation is shown by the extent to which th e viscosity of th e m em bran e system ch an ges (Figu re 2).

Poor m ixing. In th e field , p oor m ixin g of

th e com p on en ts is com m on . Th is is often th e resu lt of u sin g m ixers w ith p oor m ixin g action . Th e m an u factu rer’s m ixin g in stru c-tion s stip u late th at th e ad d ic-tion of th e resin (p olym er) an d h ard en er (th e ch em ical th at in itiates th e p olym erization ) com p on en ts sh ou ld occu r at th e com m en cem en t of th e m ixin g cycle. In p ractice, h ow ever, th e h ard en er com p on en t is som etim es ad d ed h alfw ay th rou gh th e m ixin g cycle. Fu rth er-m ore, in er-m an y in stan ces th e er-m an u factu rer’s stip u lated m ixin g tim e is n ot ad h ered to. Su ch m istakes in crease th e p erm ean ce of th e m em bran e coat, allow in g greater in gress of w ater an d ch lorid e ion s.

Th e effect of p oor m ixin g on th e d evelop -m en t of early -m ech an ical p rop erties (ten sile stren gth an d elon gation cap ability) of som e membranes can be drastic: some may not reach th e d esired ten sile stren gth for 28 d ays (Figu re 3). Th e m em bran e system is often su bjected to con sid erable stress from p ost-in stallation con stru ction activity of oth er trad es, an d if it h as n ot been able to d evelop an y stren gth becau se th e com p on en ts are reactin g very slow ly, seriou s d am age to th e m em bran e system can occu r. Foot traffic an d th e d raggin g of item s across th e p oorly cu red coatin g, for exam p le, can d am age th e m em bran e system , p rom otin g d eterioration .3 Incorre ct p rop ortioning of the com p one nts.

Tw o-com p on en t m em bran e p rod u cts are form u lated w ith con trolled p rop ortion s (CP) Figure 3.Effect of poor mixing on the tensile strength development

of a typical waterproofing membrane system. The effect is illus-trated by comparing an extreme case of poor mixing (PM) to that of a correct proportioning (CP) procedure. The cure of the poorly mixed sample was so retarded that the strength value could not be recorded until 28 days had elapsed.

Figure 2.Effect of temperature on the viscosity of a typical two-component water-proofing membrane system. Viscosity influ-ences the effectiveness of spraying and other key characteristics such as levelling and the sloughing of the material sprayed on vertical surfaces. The drastic effect that low temperature produces is shown in the increased viscosity (cohesion) obtained at 10°C.

3 th at govern th e d evelop m en t of th e d esign ed

p rop erties. In com p lete d ecan tin g in th e field , h ow ever, alters th ese p rop ortion s an d eith er an excess of resin or h ard en er can be p resen t. Th e p resen ce of excess resin (ER) in th e m ix h as m ore d rastic effects (a greater in crease in th e p erm ean ce of th e m em bran e coat) th an th e p resen ce of excess h ard en er (EH). How ever, in creased levels of th e h ard en er com p on en t can resu lt in severe retard ation of the rate of tensile strength development for som e coatin gs (Figu re 4). Post-con stru ction activity on th e d eck in creases th e p oten tial for d eterioration .

De la y e d a p p lica tion. Most m em bran es are

form u lated to p rovid e for an ap p lication tim e of u p to 60 m in u tes after m ixin g. An undue delay between mixing the components an d ap p lyin g th e m em bran e system to th e con crete is a con cern p articu larly in su m m er an d w h en large batch es are u sed . Th ese con d ition s m ay sh orten th e “p ot life” of th e m ix, cau sin g p oor sp rayability an d p ossibly red u ced ad h esion to th e con crete.4

Substrate Condition

Pre se nce of m oisture in the surfa ce of the concre te . Excess (>3% by w eigh t)

m oistu re in th e con crete w ill red u ce th e ad h esion of th e w aterp roofin g system . Tw o-com p on en t u reth an e an d n eop ren e em u lsion system s ap p ear to be less sen sitive to su rface m oistu re th an on e-com p on en t u reth an e system s. Alth ou gh in m ost cases on ly sm all d ecreases in ad h esion h ave been n oted , oth er p oor p ractices m ay com bin e w ith th e excess m oistu re to m agn ify its d eleteriou s effects.5

Ty p e of surfa ce p re p a ra tion. Differen t

m eth od s of su rface p rep aration p rod u ce d ifferen t su rface p rofiles th at affect th e ad h esion of w aterp roofin g system s to th e con crete su bstrate. Su rface p rofiles sh ou ld m atch th e recom m en d ed th ickn ess for th e m em bran e coatin g. A m ism atch betw een th e su rface p rofile an d th e requ ired m em bran e coat th ickn ess affects th e coverage rate of th e w aterp roofin g system an d resu lts in p arts of th e system bein g eith er too th ick or too th in . The installed product then has altered waterp roofin g an d d u rability ch aracteristics.

Th e best textu re for ach ievin g stip u lated coatin g th ickn ess an d ad h esion to th e con -crete su bstrate is p rod u ced by san d blastin g an d w aterblastin g; th e form er is restricted to ou td oor u se, h ow ever, becau se of th e d u st gen erated . Sh otblastin g can leave a fractu red su rface, w h ich m ay cau se th e coatin g to d ebon d .5,6

Ambient Weather Conditions

Va ria tion in a m b ie nt hum id ity a t consta nt te m p e ra ture . Moistu re p lays a sign ifican t

role in th e cu rin g of on e-com p on en t u reth an es an d n eop ren e em u lsion s. Sin ce th is typ e of u reth an e u ses m oistu re as a catalyst in th e cu rin g reaction s, retard ed cu re can occu r w h en th e relative h u m id ity is below 30% .7,8 Th e cu rin g of th e n eop ren e

coatin g (w h ich d ep en d s on evap oration of th e w ater from th e em u lsion for film form a-tion ) is accelerated in itially by low er rela-tive h u m id ity levels, bu t can later p rod u ce low er elon gation cap ability.

Th e effects of varyin g h u m id ity on th e early d evelop m en t of p h ysical an d m ech an -ical p rop erties are varied . Th ose system s th at exh ibit in creases in p rop erties early on rarely see th e in creases con tin u e over th e lon g term . In th e lon g term , cu rin g at low h u m id ity d oes n ot sign ifican tly affect th e p rop erties of m ost m em bran e system s, excep t for m oistu re-cu red u reth an e. Cu rin g at high humidity generally leads to a decrease in m ech an ical p rop erties an d ad h esion , an d an in crease in p erm ean ce.

Va ria tion in a m b ie nt te m p e ra ture a t consta nt hum id ity. Th e tem p eratu re at

w h ich th e m em bran e system is p laced an d cu red h as a great effect on th e d evelop m en t of w aterp roofin g ch aracteristics an d m ech an -ical p rop erties, becau se th e rate of reaction (for m u lti-com p on en t system s) or th e rate of evap oration of w ater (for th e em u lsion s) is tem p eratu re d ep en d en t.

Figure 4.Effect of incorrect proportioning of the resin and hardener components on the tensile strength development of a typical water-proofing membrane. Both excess resin (ER) and excess hardener (EH) retard the development of tensile strength in comparison to that of the sample made with correct proportions (CP).

Gen erally, cu rin g th ese system s at low tem p eratu res su ch as 5°C h as a greater effect on properties than curing at high temperatures su ch as 38°C. Th e retard ation of cu re at 5°C is so d rastic for som e system s th at th ey are still liqu id after 24 h ou rs. Th e very slow rate of m ech an ical p rop erty d evelop m en t at early stages therefore leaves membrane systems very susceptible to damage from ongoing construc-tion p rocesses. In th e lon g term , th e overall ch aracteristics of th e system are n ot as d evel-op ed as w h en cu red u n d er stan d ard con d i-tion s (22-30°C); p erm ean ce is in creased , an d adhesion to the concrete substrate will be poor. Pra c t ic a l Re c om m e nda t ions • Follow th e m an u factu rer’s sp ecification s

on m ixin g an d ap p lication

• Avoid m ixin g m em bran e com p on en ts at low tem p eratu res

• Pay carefu l atten tion to th e p rop ortion in g of com p on en ts w h en m ixin g

• Ap p ly th e m em bran e coat w ith in 30 m in u tes after m ixin g

• Avoid excess su rface m oistu re in th e con crete before in stallin g th e m em bran e • San d blastin g an d w aterblastin g p rod u ce sim ilar resu lts for su bstrate p rep aration • Sh otblastin g can leave a fractu red su rface,

w h ich sh ou ld be rem oved to p reven t d ebon d in g of th e m em bran e system • Con sid er altern ative m eth od s to sh

otblast-in g w h en a very th otblast-in m em bran e is to be in stalled

• Avoid ap p lication s in eith er h igh or low tem p eratu res an d in h igh h u m id ity con d ition s

• Mem bran e system s sh ou ld n ot be ap p lied u n d er low tem p eratu re/ low h u m id ity con d ition s, as th ey create m ore seroiu s p roblem s th an d o h igh tem p era-tu re/ h igh h u m id ity con d ition s

• Avoid am bien t tem p eratu res ou tsid e th e 10-28°C ran ge an d relative h u m id ities ou tsid e th e 30-70% ran ge

• Avoid con crete d eck tem p eratu res an d m oistu re con ten ts exceed in g 30°C an d 3% (w eigh t m eth od ), resp ectively • Avoid a con crete su rface p rofile th at

sign ifican tly exceed s th e stip u lated m em bran e coatin g th ickn ess

• Avoid u sin g low -viscosity m aterials on vertical su rfaces an d ram p s

• Do n ot ap p ly a m em bran e system if th ere is a p rosp ect of rain occu rrin g w ith in fou r h ou rs

• Avoid construction traffic on the membrane system , u n til p rop er cu re is ach ieved

Sum m a ry

Th ree key elem en ts affect th e p erform an ce of elastom eric m em bran es for p arkin g garage d ecks: ap p lication factors, su bstrate con d i-tion s an d w eath er. Carefu l con sid erai-tion of th ese elem en ts is n ecessary to avoid jeop ard izin g p erform an ce. Ad h eren ce to th e m an u factu rer’s in stru ction s is p aram ou n t. Re fe re nc e s

1. Feld m an , D. Du rability of p olym ers u sed in th e bu ild in g in d u stry. 5thCan ad ian

Bu ild in g an d Con stru ction Con gress, Mon treal, Nov. 1988, p p . 167-174. 2. Davis, A. an d Sim s, D. Weath erin g of

p olym ers, Ap p lied Scien ce, Lon d on an d New York. 1983, p p . 34-39.

3. Moller, L. an d Han sen , J.H. Practical asp ects on p rotectin g of exterior con crete stru ctu res by su rface coatin g, First In tern ation al Con feren ce on Deterioration an d Rep air of Rein forced Con crete in th e Arabian Gu lf, CIRIA/ BSE, Bah rain , Oct. 1985, p p . 46-52.

4. Soebbin g, J.B. Tip s on im p rovin g ap p li-cation of p lu ral com p on en t p olyu reth an e lin in gs to p ip elin es, Jou rn al of Protective Coatin gs an d Lin in gs. May 1994,

p p . 148-155.

5. Silw erbran d , J. Im p rovin g con crete bon d in rep air of brid ge d ecks, Con crete In tern ation al, Sep t. 1990, p p . 61-66. 6. Tsch egg, E.K. an d Tsch egg S.E.

Ad h esive p ow er m easu rem en ts of bon d s betw een old an d n ew con crete, Materials an d Stru ctu res, Au g. 1991, p p .189-192. 7. Regan , F. Perform an ce ch aracteristics

of traffic d eck m em bran es, Con crete In tern ation al, Vol. 6, No. 4, Ju n e 1992, p p . 48-51.

8. Ng, Y.L. an d Pash in a, K.A. Selectin g an d ap p lyin g traffic-bearin g m em bran es, Con crete Con stru ction s, Ju n e 1990, p p . 545-548.

Mr. N.P. Ma ilv a ga na mis a Prin cip al Research Officer in th e Bu ild in g En velop e an d S tru ctu re Program of th e N ation al Research Cou n cil’s In stitu te for Research in Con stru ction .

Mr. P.G. Collinsis a sen ior tech n ical officer in IRC’s Urban Infrastructure Rehabilitation Program .

“Construction Te chnology Up d a te s” is a se rie s of te chnica l a rticle s conta ining p ra ctica l inform a tion d istille d from re ce nt construction re se a rch.

For more information, contact Institute for Research in Construction, National Research Council of Canada, Ottaw a K1A 0R6

Telephone: (613) 993-2607; Facsimile: (613) 952-7673; Internet: http://irc.nrc-cnrc.gc.ca © 1999

Nation al Research Cou n cil of Can ad a Decem ber 1999