Publisher’s version / Version de l'éditeur:

ACI Materials Journal, 94, Nov-Dec 6, pp. 540-545, 1997-11-01

READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE. https://nrc-publications.canada.ca/eng/copyright

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

NRC Publications Archive

Archives des publications du CNRC

This publication could be one of several versions: author’s original, accepted manuscript or the publisher’s version. / La version de cette publication peut être l’une des suivantes : la version prépublication de l’auteur, la version acceptée du manuscrit ou la version de l’éditeur.

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at

Temperature dependence of compressive strength of

conversion-inhibited high alumina cement concrete

Fu, Y.; Ding, J.; Beaudoin, J. J.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site

LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

NRC Publications Record / Notice d'Archives des publications de CNRC:

https://nrc-publications.canada.ca/eng/view/object/?id=ff7a420c-cc2e-4d48-a289-48a790ffb72a https://publications-cnrc.canada.ca/fra/voir/objet/?id=ff7a420c-cc2e-4d48-a289-48a790ffb72ahttp://www.nrc-cnrc.gc.ca/irc

T e m pe ra t ure de pe nde nc e of c om pre ssive st re ngt h of c onve

rsion-inhibit e d high a lum ina c e m e nt c onc re t e

N R C C - 3 9 8 1 1

F u , Y . ; D i n g , J . ; B e a u d o i n , J . J .

N o v e m b e r 1 9 9 7

A version of this document is published in / Une version de ce document se trouve dans:

ACI Materials Journal, 94, (6), Nov-Dec, pp. 540-545, November 01, 1997

The material in this document is covered by the provisions of the Copyright Act, by Canadian laws, policies, regulations and international agreements. Such provisions serve to identify the information source and, in specific instances, to prohibit reproduction of materials without written permission. For more information visit http://laws.justice.gc.ca/en/showtdm/cs/C-42

Les renseignements dans ce document sont protégés par la Loi sur le droit d'auteur, par les lois, les politiques et les règlements du Canada et des accords internationaux. Ces dispositions permettent d'identifier la source de l'information et, dans certains cas, d'interdire la copie de documents sans permission écrite. Pour obtenir de plus amples renseignements : http://lois.justice.gc.ca/fr/showtdm/cs/C-42

ACI MATERIALS JOURNAL

TECHNICAL PAPER

Title no. 94-M61Temperature Dependence of Compressive Strength of

Conversion-Inhibited High Alumina Cement Concrete

Q

.:

'.セ

:.

セ! セM

t. ",,*.

セ[Mセ

by Van Fu, Jian Ding, and James J. Beaudoin

The strength reduction of high alumina cement (HAC) concrete due to con-version is one of the major reasons given for limiting the use of HAC in structural members. A conversion-inhibited concrete is introduced in this paper. The effect of curing and exposure conditions (e,g., temperature) on the compressive strength of HAC or modified HAC concretes was studied. Ground granulated blastfurnace slag (ggbs) and a conversion-preventing additive (CPA) containing natural zeolite or silica fume in combination with sodium sulfate were used to inhibit the strength reduction of the HAC concretes. The results indicated that conversion-inhibited HAC concrete containing a CPA has a one-day compressive strength greater than55MPa when cured at4-5degC. The strength of the HAC/CPA concrete is much

less ajfecred by the concrete temperature than plain HAC or HAC/ggbs concrete.

Keywords: conversion; conversion preventing additive; high alumina cement; hydration exotherm; setting time; temperature.

INTRODUCTION

High early strength is one of the major advantages of high alumina cement (HAC) concrete over portland cement con-crete. The compressive strength of HAC concrete can how-ever be adversely affected by temperature. This is due to the crystalline conversion from the hexagonal CAH10or C2AHg

to cubic C3AH6 .The CAH IO and C2AHgcrystals are not

sta-ble at moist conditions with temperatures higher than about 20 deg C. They will eventually convert to C3AH6in a humid environment at elevated temperature. The effect of the con-crete temperature-time response due to hydration (referred to as hydration exotherm) on the strength of HAC grouts was reported by Jefferis and Mangabhai.! The hydration exo- セ thenn of the HAC grouts resulted in a maximum temperature higher than 100 degC.This is sufficient to cause strength re-..duction due to microcracks and conversion. High early strength is usually obtained using HAC concrete when the temperature is kept sufficiently low, e.g., construction in the winter. This high early strength may mislead designers into ignoring the conversion effect during its service life. The lack of knowledge about the characteristics of HAC concrete was responsible for the damage of three HAC concrete struc-tures in the early 1970s.

540

A conversion inhibited HAC concrete with temperature-independent characteristics is a requirement for. structural applications. A blended HAC/ground granulated blast-fur-nace slag (ggbs) was first introduced by MaJumdar and Singh in an attempt to meet these specifications. The binder contained approximately equal amounts of HAC and ggbs. No strength reduction was observed in the blended HAC concrete when water-cured at 40 deg C. However, its early strength was significantly reduced due to the dilution of HAC in the concrete by ggbs. Addition of relatively less sil-okeous material in combination with a small amount of a so-dium salt (i.e., CPA) in HAC was recently reported to he effective in inhibiting the conversion reaction.3,4A

conver-sion-preventing additive (CPA) was developed. The CPA is able to totally prevent the crystalline conversion that conven-tionally occurs in HAC products. However, the content of CPA used in real HAC concrete should be optimized in terms of early strength. Complete prevention of conversion is not practically necessary, since slight formation of hydro-garnet (C3AH6) is usually allowed and will not lead to strength reduction. Therefore, a term "conversion-inhibit-ing" is more suitable in discussion of the concrete properties rather than the tenn "conversion-preventing." The conver-sion inhibited HAC concrete had a similar early strength as that for plain HAC concrete when cured at low temperature and showed no subsequent strength reduction behavior when water-cured at 38 deg C. The conversion-inhibiting mecha-nisms have been extensively reported.4

The objective of this study was to investigate the effects of curing temperature and exposure ::onditions on the

compres-ACI Materials Journal, V. 94, No, 6, November·December 1997.

Received December 22, 1995, and reviewed under Institute pUblication policies. Copyright© 1997, American Concrete Institute. All rights reserved. including the making of copies unless pennission is obtained from the copyright proprietors. Perti-nent discussion will be published in thes・ーエ・ュ「・イセo」エッ「・イ 1998ACT Materials Jour.

nalif received by June I. 1998.

ACI memberfallFu isaresearch scientisr at the Instirute for Research in Construc-lion. Nar/ollal Research Council Canadn. He received his MASc degree from the

Uni-versity of Torontoin1992 and his PhD degree from the University of Ottawa in 1996.

He is the author of three US palents and about 50 research papers on concrete dura-bility and expansive concrete.

lion Dillg is a research engineer ar Ihe Instirule for Research in cッョウイイオセエゥッョL

National Research Council Canada, She received her BSc in chemistry from Fudan University, Shanghai. in 1983 and MASc degree in civil engineering from the

Univer-sity of Ottawa in 1995, She is the author of two

us

patellts and several researchpapers. Her research illtere.,r.. include admixtures and addirives for portland cemenr (/lid high alumina cemellt CO/Icreres.

James]. Beaudoin is a Principal Research Officer and Head. Materials Laboratory, IlIsliture for Research in Consrruction. Narional Research Council Canada. He is rhe author of more than 250 research papers and two books on concrete materials. His currenl research focuses on micro-fiber reinforced cement systems and the application

ofll.C.impedance specrroscopy in cement mId concrere science.

sive strength of conversion-inhibited HAC concrete. The ini-tial curing conditions include moist-curing at 5 or 23 deg C, and curing in a thermally insulated box to simulate the actual large volume concrete members. The effect of the hydration exotherm on early strength development and longer term strength stability due to temperature change was studied. .

RESEARCH SIGNIFICANCE

The research is intended to. advance understanding of the strength development characteristics of high alumina cement concrete. The test results should be useful for assessing the viability of conversion-inhibited HAC as a suitable cement for structural concrete use.

EXPERIMENTAL Materials

Materials used in this study included:

I.High alumina cement, Ciment Fondu, produced by La-farge Calcium Aluminates, Virginia, USA;

2.ASTM Type I Portland cement (OPC), produced by La-farge Cement Canada Inc., Canada;

3. Ground granulated blast-furnace slag (ggbs);

4. Natural zeolite, containing mainly c1inoptilolite, levyne and offretite, supplied by Zeotech Corporation, New Mexi-co, USA;

5. Silica fume, supplied by the SKW Co., Montreal, Canada;

6. Sodium sulfate, reagent grade.

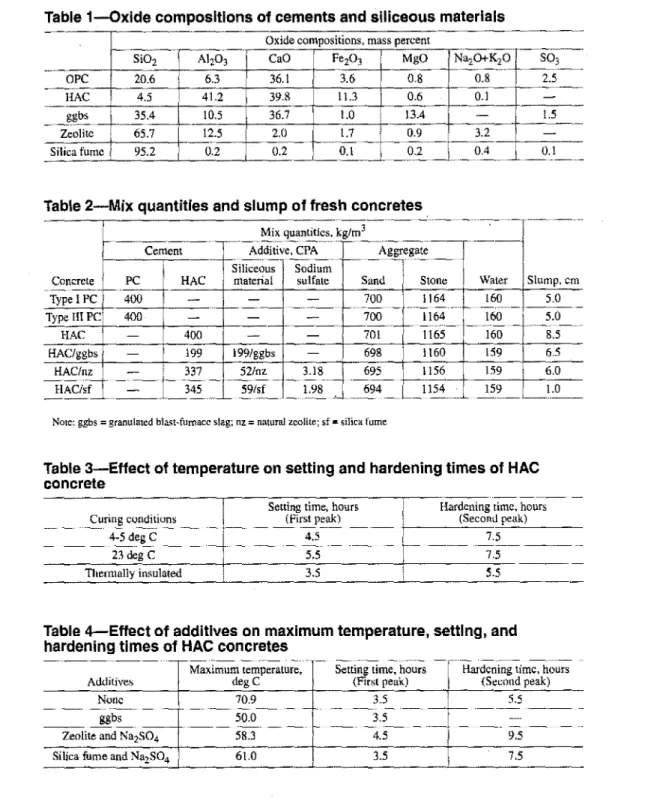

The oxide composition of the cements and siliceous mate-rials are given in Table 1.

Concrete preparation and testing

Mix quantities for the concretes used in this study are list-ed in Table 2. One concrete containing ASTM Type I port-land cement, one HAC concrete and three modified HAC concretes containing granulated blast-furnace slag (for com-parison to the BRE solution) or conversion-preventing addi-tives, containing natural zeolite (nz) or silica fume (sf) in combination with sodium sulfate were prepared. Minus 25 mm crushed limestone was used as the coarse aggregate, and the fine aggregate was natural river sand. The specific grav-ity of the」ッ。イウセ and fine aggregate was 2.56 and 2.65,

re-ACI Materials Journal/November-December 1997

セ tセ| BBBセLMセセL⦅セ

,

spectively. The aggregate was in the saturated-surface-dry state. The water/solid (cement and siliceous material) ratio was 0.4 and the cement content was 400 kg/m3.Dry cement, aggregate and additive (if used) were mixed for about 1 minute and then mixed with water for3minutes. Slump was detennined and the temperature of the fresh concrete after casting was measured (Table 2). The ambient temperature during concrete placing was 25 degC. The concrete speci-mens (200 mm long and 100 mm in diameter) cast in plastic molds were cured under different conditions: (1) moist-cured at 23 deg C; (2) moist-cured at 4-5 deg C and relative humid-ity 100 percent; (3) cured in a thermally-insulated-curing-box with relative humidity 100 percent. The objective of us-ing thermally-insulated-curus-ing is to simulate the actual con-dition for large volume concrete members in which the hydration exothenn may lead to high temperatures and cause low strength. The temperature of the concretes cured in the thermally-insulated-curing-box was recorded in the first48 hours at one-hour intervals using a Printing Thermocouple Thermometer. The temperatures of the plain HAC concretes in the plastic molds cured at 4-5 deg C or 23 deg C were also measured for the first 24 hours. The concretes were demold-ed at2days and the compressive strength values were deter-mined. The companion concretes, made with HAC or modified-HAC and initially cured at 23 deg C or in the ther-mally-insulated-curing-box, were then SUbjected to water-curing at 38 deg C allowing conversion to take place. Com-pressive strength of the concretes was measured at 14, 28, and 56 days. Low temperature (4-5 deg C) curing for the oth-er companion concretes was maintained for 28 days. Com-pressive strength of the concretes cured at 4-5 deg C was determined at 28 days. The remaining low temperature con-crete specimens were water-cured at 38 degC.Strength was also determined for these concrete cylinders at 56 days.

Determination of setting time of the concretes

The Vicat needle test cannot be used to precisely measure the setting time of concrete. The embedded thermocouple method5 was therefore adopted in this study. An excellent correlation between the results obtained by the Vicat and the embedded thermocouple method on HAC concretes was re-ported by George,5 Bushnel-Watson and Sharp,6 and Baker and Banfin? The time to the appearance of the first peak on the differential temperature curve of the concretes. (due to hydration exotherm) was defined as the setting time. The time for the occurrence of the second peak is referred to as the hardening time of HAC concrete. A strength jump can be observed at this time.

RESULTS Hydration exotherm characteristics

Plain HAC concrete at different curing

temperatures-The temperature and differential temperature curves of the plain HAC concrete cylinders cured at 4-5 deg C, 23 deg C, and in a thermally insulated box are shown in Figs. 1 and 2. The initial temperature of the fresh HAC concrete mixed at room temperature was 24 deg C. At the ambient temperature of 4-5 deg C, the concrete temperature decreased in the first 541

Table 1-0xide compositions of cements and siliceous materials

Oxide compositions, mass percent

Si02 AI203 CaO Fe203 MgO Na20+K20 S03

OPC 20.6 6.3 36.1 3.6 0.8 0.8 2.5

HAC 4.5 41.2 39.8 11.3 0.6 0.1

-ggbs 35.4 10.5 36.7 1.0 13.4

-

1.5Zeolite 65.7 12.5 2.0 1.7 0.9 3.2

-Silica fume 95.2 0.2 0.2 0.1 0.2 0.4 0.1

Table 2-Mix quantities and slump of fresh concretes

Note: ggbs .. granulated blast-furnace slag; nz .. natural zeolite; sf .. silica furne

Table 3-Effect of temperature on setting and hardening times of HAC concrete

Table 4-Effect of additives on maximum temperature, setting, and hardening times of HAC concretes

hours respectively. The temperature in the box reached a maximum value of 70 deg C at 7 hours due to the hydration exotherm.

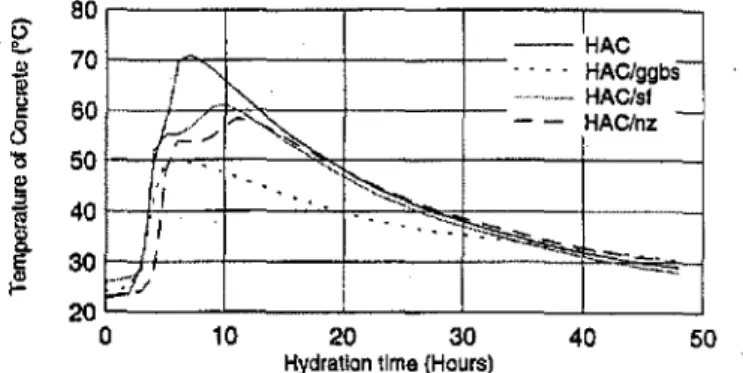

HAC concrete containing siliceous additives in combina-tion with sodium sulfate-The effect of additives, i.e. ggbs

and, CPA (zeolite or silica fume with sodium sulfate), on the exothermic characteristics of HAC concretes cured in a ther-mally-insulated curing box is shown in Figs. 3 and 4. The corresponding maximum temperature of the concretes and setting and hardening times obtained from the differential temperature curves are listed in Table 4. The temperatures of the concretes increased after about 2-3 hours. The maximum temperature was reduced by about 10 deg C in the HAC/nz and HAC/sf concretes and by 20 deg C in the HAC/ggbs concrete. The setting time of the concrete containing zeolite and sodium sulfate was delayed by about 1 hour. Other addi-ACI Materials Journal/November-December 1997

Setting time. hours Hardening time, hours Curing conditions (First peak) (Second peak)

4-5 deg C 4.5 7.5

-23 deg C 5.5 7.5

Thermally insulated 3.5 5.5

Maximum temperature, Setting time, hours Hardening time. hours

Additives degC (First peak) (Second peak)

None 70.9 3.5 5.5

ggbs 50.0 3.5

-Zeolite and Na2S04 58.3 4.5 9.5

Silica fume and Na2S04 61.0 3.5 7.5

Mix quantities, kgJm3

Cement Additive. CPA Aggregate Siliceous Sodium

Concrete PC HAC material sulfate Sand Stone Water Slump, cm

Type I PC 400

-

-

-

700 1164 160 5.0 Type III PC 400 - --

700 1164 160 5.0 HAC - 400-

- 701 1165 160 8.5 HAC/ggbs - 199 199/ggbs - 698 1160 159 6.5 HAC/nz-

337 52/nz 3.18 695 1156 159 6.0 HAC/sf-

345 59/sf 1.98 694 1154 159 1.03 hours to 11.1 degC.Itsubseq\lently increased with hydra-tion time until 6 hours reaching a peak value of 23.9 deg C. At the ambient temperature of 23 deg C, the temperature re-mained relatively constant for about 4 hours. It then in-creased to 39.5 deg C at 7 hours. The initial conc'rete temperature was maintained only for about 2 hours when curing took place in a thermally insulated box. It then in-creased to about 70 deg C at 7 hours. Two peaks were found in the differential temperature curves of the HAC concretes. The effect of temperature on setting and hardening times of HAC concrete is shown in Table 3. The setting time of the concrete cured at 23 deg C was delayed 1 hour compared to that at 4-5 deg C. No difference in hardening time was found when the ambient temperature was between 4 and 23 deg C. The setting and hardening times of the concrete cured in a thermally-insulated-curing-box were reduced to 3.5 and 5.5

Fig. 3-Temperatures of HAC and modified HAC concretes due to hydration exotherm

50

40

10 20 30

Hydration time (Hours) _ _ I HAC

I

"

- - --HAC/ggbs-l'....

_.,..LセNBNLセ⦅ ... HAC/51iセO

LNNNセセ--

HAClnz -I"...

"'"

:r

'..

セ

BGセN fI .. -...:

....:..

セ

-pi..-

---

...-.

20a

25 5 Insulated 6' 80 セセ 5°C g,.. 70 Bセ 23°Ci

'---.

/ .,..,.... ...セ..."

C 60 .. >... - - , ...8

"5 50 セt

40 E 30 セ 80, - - - - r - - - , - - - - , - - - : - - - - : - - - , - - ,e

70iMMMMMKMMイ]GセBNLLMMエ⦅MM⦅エ⦅ᆳ セ 60f---j.l----j-..;:,.,.-=::-_t_-3

501----f--II---+----f--":;;;OO"'.-O::±----1 '0 40f----+_t_----,...,---t---_j_----t----j セ - 30ヲMMMヲMMKBMMMMMBセMMMKMMM⦅ェ⦅MM⦅⦅⦅ゥi

20エ]ZZ]セOMZNNZNM]MMMMMMMNNェlZ]]ZZZZZZQ]]]ャZ]ZNNNNMMj

セ

.--- 10 1---'--"--+----1'--..,....,..--+----+---1... -..

OL----'---'----'---.J..---'o

10 15 20Hydration time (Hours)

Fig. i-Temperatures of HAC concretes

16 14 12 4 2

/J

,---.!.

HACI

r

II \ _. -. HAC/ggbs -J ._... HAC/sf-

HAC/nz-i:' ,

' .Y\

r : I\( \

V I\",

\ ....1 ..Iセ|MN⦅N

ONセ セNBBL..

;>w-.':-"7'- ... -4 ft セ •.

6 8 10Hydration lime (Hours)

Fig. 4-Differential temperature curves of HAC and modi-fied HAC concretes duetothe hydration exotherm

16 Insulated 5°C 23°C

[

25 20 IIIi

15j

10 ]Ij

5 ./.. ,...

i5 /a

0 2 4 6 B 10 12 14Hydration time (Hours)

Fig. 2-Differential temperature curves of HAC concretes

tives showed no effect on the setting time. The second peak disappeared in the differential temperature curve of the HAC/ggbs concrete. A slight increase in temperature from the minimum point on the curve occurs until about 5.5 hours. The differential curve then becomes relatively constant. It is therefore believed that the hardening time ofHAC/ggbs con-crete was still about 5.5 hours. The disappearance of the sec-ond peak may be due to the large dilution of HAC by ggbs. The hardening time of HAC concretes containing zeolite or silica fume in combination with sodium sulfate was delayed by about 2-4 hours depending on siliceous material and so-dium sulfate contents. This is attributed to the retardation ef-fect of dissolved silicate on hydration of HAC8Dissolved silicate may form more readily from zeolite than from silica fume in the presence of sodium ions.

Compressive strength

Curing at 4·5 deg C-Compressive strength values of the

concretes are shown in Table 5. The 2-day strength of OPC concrete was lower than that of the HAC concretes. The strength of the OPC concrete at 14 days was the similar val-ues to that of the HAC or modified HAC concretes. HAC concrete had a high early strength of about 57 MPa at 2 days. The modified·HAC concretes containing natural zeolite or silica fume in combination with sodium sulfate showed sim-ilar early strength to that of the plain HAC concrete when cured at low temperature. HAC/ggbs concrete had a relative-ly low 2-day strength of about 39 MPa. The 28-day strength of the concretes, except the HAC/ggbs concrete, were all ACI Materials Journal/November-December 1997

about 60 MPa. The HAC/ggbs concrete had compressive strength of about 53 MPa at 28 days.

The effect of a curing temperature change (i.e. initial cur· ing at 4-5 deg C for 28 days followed by water-curing at 38 deg C until 56 days) on compressive strength of the con-cretes was studied. The 56-day compressive strength of plain HAC concrete was significantly reduced from 60.4 MPa at 28 days (cured at4-5 degC)to 42.1 MPa at 56 days (cured at 38 deg C)due to the conversion. The m04ified HAC con· cretes all showed a strength increase after the temperature change. The HAC/ggbs and HAC/NZ concretes had about 20 percent strength gain at 56 days after curing at 38 deg C.

Curing at 23 degC-The compressive strength values of the concretes are shown in Table 6. The compressive strength of HAC concrete was about 36 percent higher than that of

ope

concrete at 2 days. However, its strength dropped by 14 percent at 14 days after water-curing at 38 deg C. The 2-day strength of the modified HAC concrete Con-taining a CPA (natural zeolite or silica fume in combination with a small amount of sodium sulfate) was slightly lower than that of the plain HAC concrete. Their strength increased greatly at 14 days after water-curing at 38 deg C. The strength of the HAC/ggbs concrete was only about 40 per-cent of that of the plain HAC concrete at 2 days. It increased continuously to about 113 percent of that of plain HAC con-crete and 77 percent of that of modified HAC concon-crete at 28 days after water-curing at 38 degC.Curing in a thermally-insulated curing box-The

com-pressive strength values of the concretes initially cured in a thermal-insulated curing box are shown in Table 7. The 2-543

Table 5-Compressive strength (MPa) of concrete initially cured at 5 deg C

Hydration time, days

Cements 2* 14* 28* 56** OPC 21.7 56.4 56.6

-HAC 57.3 57.6 60.4 42.1 HAC/ggbs 39.6 44.0 53.0 64.5 HAC/nz 56.6 59.4 62.3 74.0 HAC/sf 60.2 61.8 63.2 64.7 *Curedat4-5 deg C-- C;:ured at 4-5 deg C for 28 days followed by water-curing at 38 deg C for 28 days

Table 6-Compresslve strength (MPa) of concretes initially cured at23deg C

Hydration time. days

Cements 2* 14** 28** OPC 37.6 58.9 63.3 HAC 57.0 45.1 42.S HACJggbs 29.9 45.3 50.7 HAC/nz 53.9 61.1 62.8 HAC/sf 53.5 62.1 65.9 - Cured at 23 deg C

-*

Cured at 23 deg C for 2 days followed by water-curing at 38 deg CTable 7-Compressive strength (MPa) of concretes initially cured in an insulated box

Hydration time, days

Cements 2* 14** 28** 56** Type 1 PC 41.1 52.8 59.1

-HAC 42.6 43.7 44.8 44.5 HAC/ggbs 29.6 32.5 42.0 42.2 HACJnz 51.3 53.6 56.6 57.3 HAC/sf 51.3 53.6 62.0 62.3*Cured in thennally-insulated box

**Cured in thermally-insulated box for2days followed by water·curing at 38 degC

day compressive strength values of OPC and plain HAC concretes were similar. No strength reduction was found in the plain HAC concrete after curing in water at 38 deg C when it was initially cured in the thermally-insulated curing box. The 28-day strength of the HAC concrete cured in an in-sulated box was still much lower (about 45 MPa) than that cured at low temperature (60 MPa) due to conversion, Le. hydrogarnet formation. The HAC/ggbs concrete had low strength (about 30 MPa) at 2 days. The strength increased with time of water-curing at 38 deg C. Its 28-day strength however was still lower than the converted plain HAC con-crete. The modified HAC concretes containing zeolite or sil-ica fume in combination with sodium sulfate had a 2-day strength above 50 MPa. Their strength continuously in-creased after curing in water at 38 deg C. The 28-day strength of HAC/sf concrete was 62 MPa, similar to that of plain HAC concrete cured at 4-5 deg C (Le. no conversion). The 56-day strength of all the HAC concretes was similar to the 28-day strength.

544

DISCUSSION

Utilization of HAC in structural concrete members

High early strength may be obtained in thin concrete mem-bers at low ambient temperature, since CAB10and C2AH

s

are the dominate hydration products. However, the strength of HAC concrete initially under this condition may drop sig-nificantly due to conversion ofCAHIQ and C2AHgto C3AH6when the ambient temperature increases. Strength reduction of the HAC concrete can result in the collapse of the concrete structure. This may be the case if a strength value is used without consideration of the conversion effect in the design of a concrete structure built in the winter. A large volume HAC concrete member or HAC concrete initially cured at high ambient temperature, (as may occur when concreting in the summer) usually have relatively low early strength, be-cause C3AH6directly forms as the dominant phase. The

de-gree of strength reduction of HAC concrete (initially cured at high temperature) due to further conversion at later ages may be relatively less than that of the concrete initially cured at low temperature. The strength data measured on converted concretes are more reliable for structural design since the ACI Materials Journal/November-December 1997

\

-.conversion effect has, at least partially, been taken into ac-count. Extensive investigations9have reported that most of the HAC concrete structures remain in good condition, even those exposed to aggressive environments over 60 years of service. HAC concrete behavior has been reasonably well understood. However, use of HAC is still influenced by three building failures in the early 1970s. The use of HAC con-crete in structure members may require a fresh look at exist-ing regulations. Elimination of conversion-induced strength reduction appears to be the only solution to recover the mar-ket for HAC in the structural area.

The compressive strength of conversion inhibited HAC concretes appears to be insensitive to the curing tempera-tures in this study. The concretes have similar early strength as that of plain HAC concrete even at low temperature. Their strength is much less affected by the hydration exotherm than that of plain HAC concrete and HAC/ggbs concrete. No strength reduction is found in these modified HAC concretes when cured in water at 38 deg C at 56 days. The authors' long-term tests (up to about two years) showed that the strength values of the conversion-inhibited HAC mortar specimens were always higher than their 56-day strength values, This indicates that a conversion inhibited HAC mor-tar that can overcome any strength reduction before 56 days may be considered as a stable materiaL The conversion in-hibited HAC concrete retains the original advantages of HAC concrete which are desirable for many special applica-tions.

Mechanisms of early strength reduction of HAC! ggbs concrete

The hydration exotherm greatly affects the strength of HAC/ggbs concrete at early ages. The 56-day strength was still lower than the converted plain HAC concrete even though its strength increased with hydration time. In addition to the ggbs-diIution effect the high waterlHAC ratio is also a key factor affecting the early strength of HAC/ggbs con-crete. The ggbs reacts slowly in the concrete in the absence of additional sodium ions. Therefore ggbs can be considered as a relatively inert micro-filler in HAC concrete particularly at early ages, Only a small amount of water will be con-sumed by ggbs to form hydrates at early ages (e.g, in 24 hours). The water/solid (HAC and ggbs) ratio of 0.4 yields an actual waterlHAC ratio of 0.8. This is high enough to fa-cilitate formation of C3AH6when the concrete temperature exceeds the critical point due to the hydration exotherm. Stratlingite (C2ASHs) formation requires a sufficient supply of dissolved silicate. Non-activated ggbs does not provide sufficient dissolved silicate to form stratIingite at very early ages. Once hydrogarnet (C3AH6)forms as a dominate phase, stratIingite formation is minimized. Therefore the HAC/ggbs concrete will have low early strength and slow strength

re-ACI Materials Journal/November-December 1997

covery at later ages as a consequence of the initially elevated temperature curing due to the hydration exotherm.

CONCLUSIONS

I. Modified HAC concrete containing a conversion-pre-venting additive (CPA) has a I-day compressive strength greater than 55 MPa when cured at 4-5 deg C.

2. Compressive strength of the modified HAC concretes continuously increases after a curing temperature change (e.g. 28-day curing at 4-5 deg C followed by another 28 days water-curing at 38 degC).

3. Compressive strength of modified HAC concretes is much less affected by the concrete temperature due to the hy-dration exotherm than that of the plain HAC concrete and the HAC/ggbs concrete.

4. Heat developed due to the hydration exotherm of HAC concrete is reduced by using conversion-preventing addi-tives.

ACKNOWLEDGEMENTS

The financial support from NSERC and the Network of Centres of Excel-lence on High Performance Concrete is gratefUlly acknowledged.

CONVERSION FACTORS

1 MPa=145 psi 25.4 mm=1in.

te ", (tr32)/1.S

REFERENCES

1. Jefferis, S. A" and Mangabhai,R,J., "Effect of Temperature Rise on Properties of High Alumina Cement Grout," Calcium Aluminate Cement, Chapman and Hall, London, 1990, pp. 363-371.

2. Majumdar, A. J" and Singh, B., Cement Compositions, European

Patent, No.0/312/323,1989.

3.Fu,Y.;Ding, J,; and Beaudoin,J.1.,Conversion-Preventing Additives for High Alumina Cement ProduCts, US Patent Application, No. OSI

377,109,1995.

4. Ding,J.,"Conversion Prevention in High Alumina Cement Products," MASc Thesis, Department of Civil Engineering, University of Ottawa, Oct., 1995.

5, George, C. M" "The Hydration Kinetics of RefractoryAluminas Cements and Their Influence on Concrete Properties," Trans,JBrit Ceram Soc, 79, 1980, pp. 82-90.

6.Bushnell-Watson, S. M., and Sharp, J. H., "The Effect of Temperature upon the Setting Behaviour of Refractory Calcium Aluminate Cements,"

Cem Concr Res,16, 1986,pp.875-884.

7.Baker, N,c.,and"Bantill, P,F.G" "Properties of Fresh Mortars Made with High Alumina Cement and Admixtures for the Marine Environment,"

Calcium Aluminate Cements, ProeIntiSym, London, Chapman and Hall,

1990. pp, 142-515.

8. Ding, J,; Fu. Y; and Beaudoin, J. J., "Study of Hydration Mechanisms in the High Alumina Cement-Sodium Silicate System," Accepted, Cem

Coner Res, 1995,

9, Capmas, A., and George, C. M., "Durability of Calcium Aluminate Cement Concretes," Adv in Cem Con" Proc of Eng Foundation Conf, Durham, New Hampshire, 1994, pp. 377-405.